方案详情

文

采用LaVision公司由增强型CCD相机构成的平面激光诱导荧光(PLIF)测试系统对直喷汽油发动机内混合物形成的不同的激发态复合物和模型燃料的应用有效性进行了分析研究。

方案详情

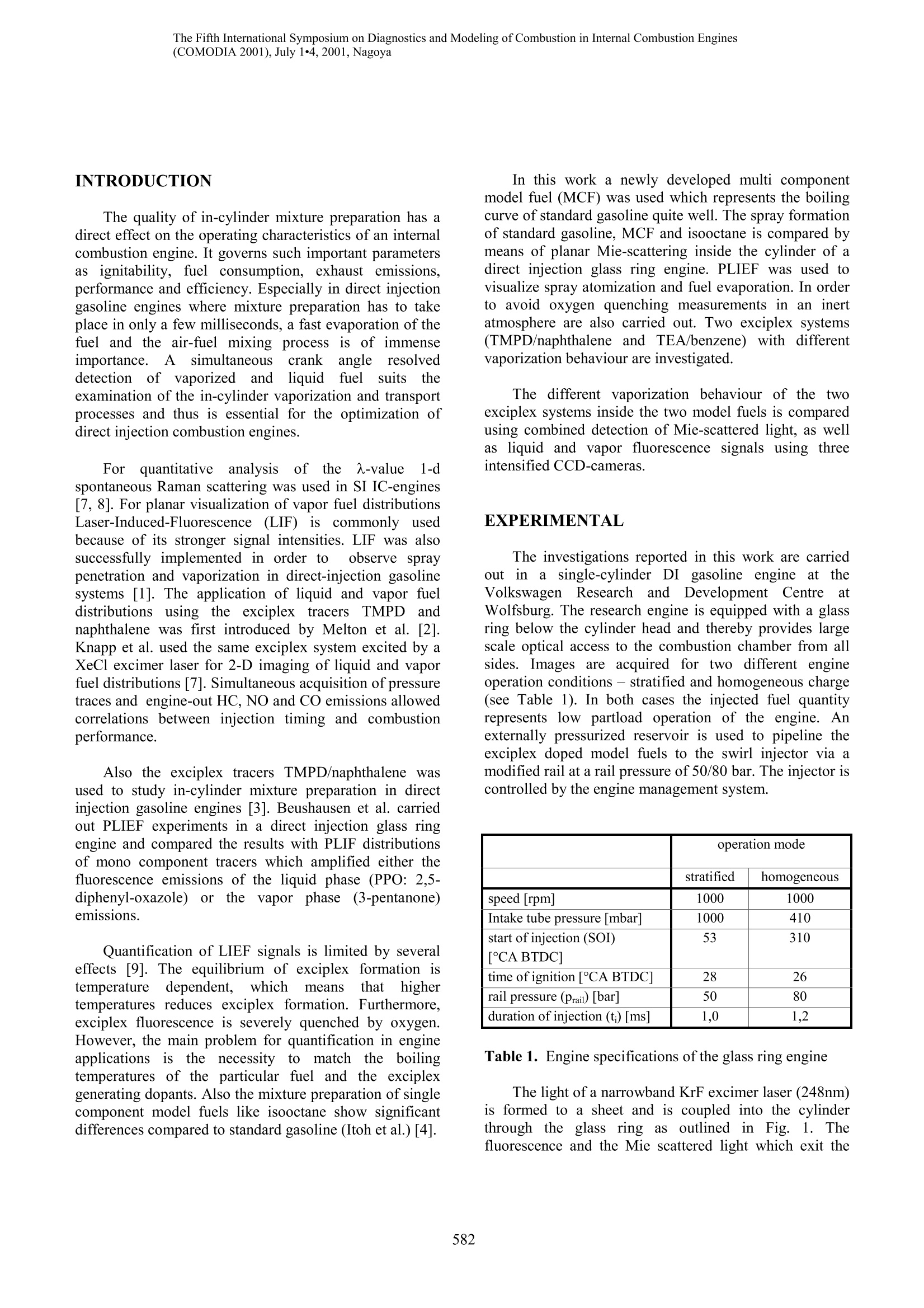

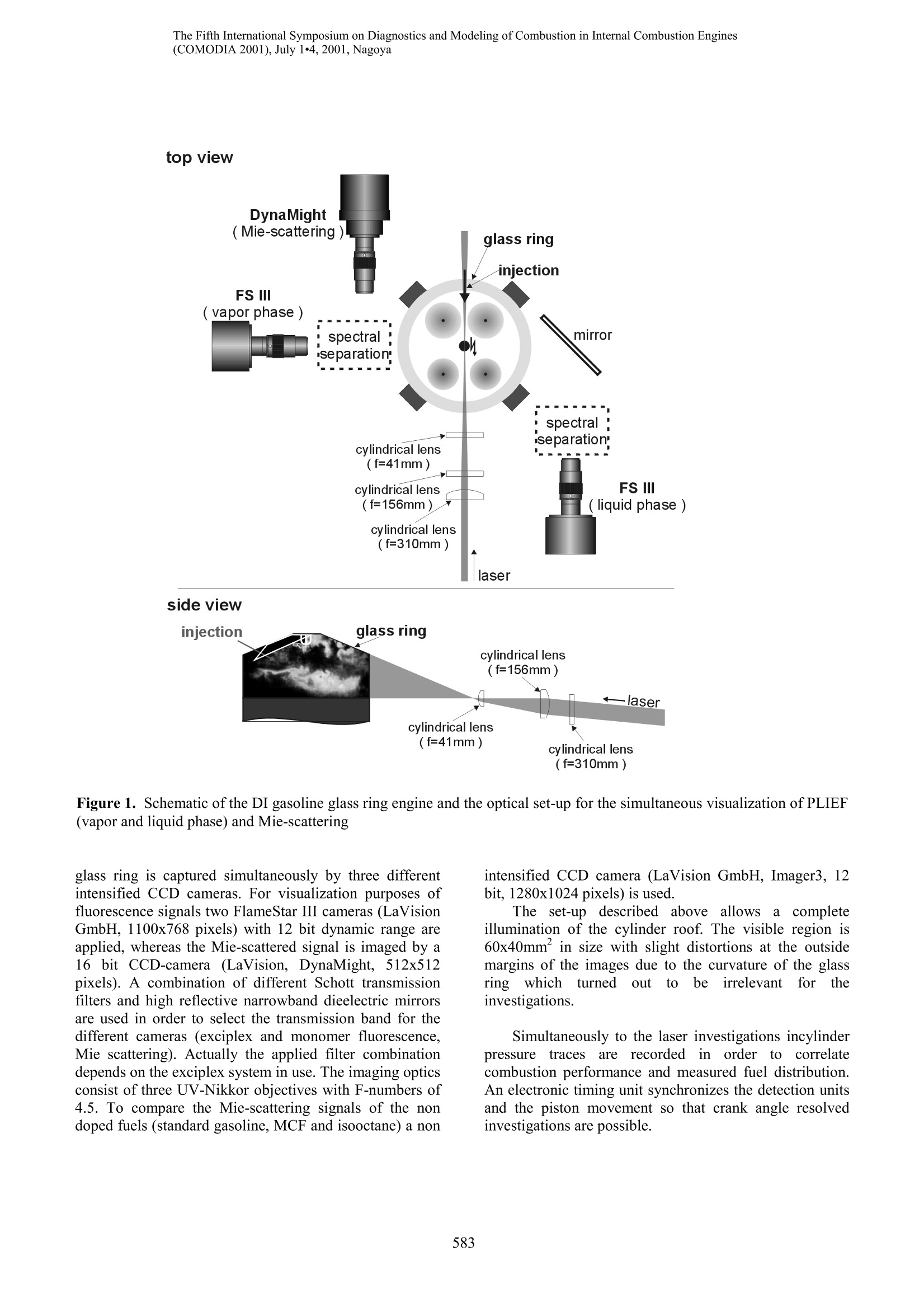

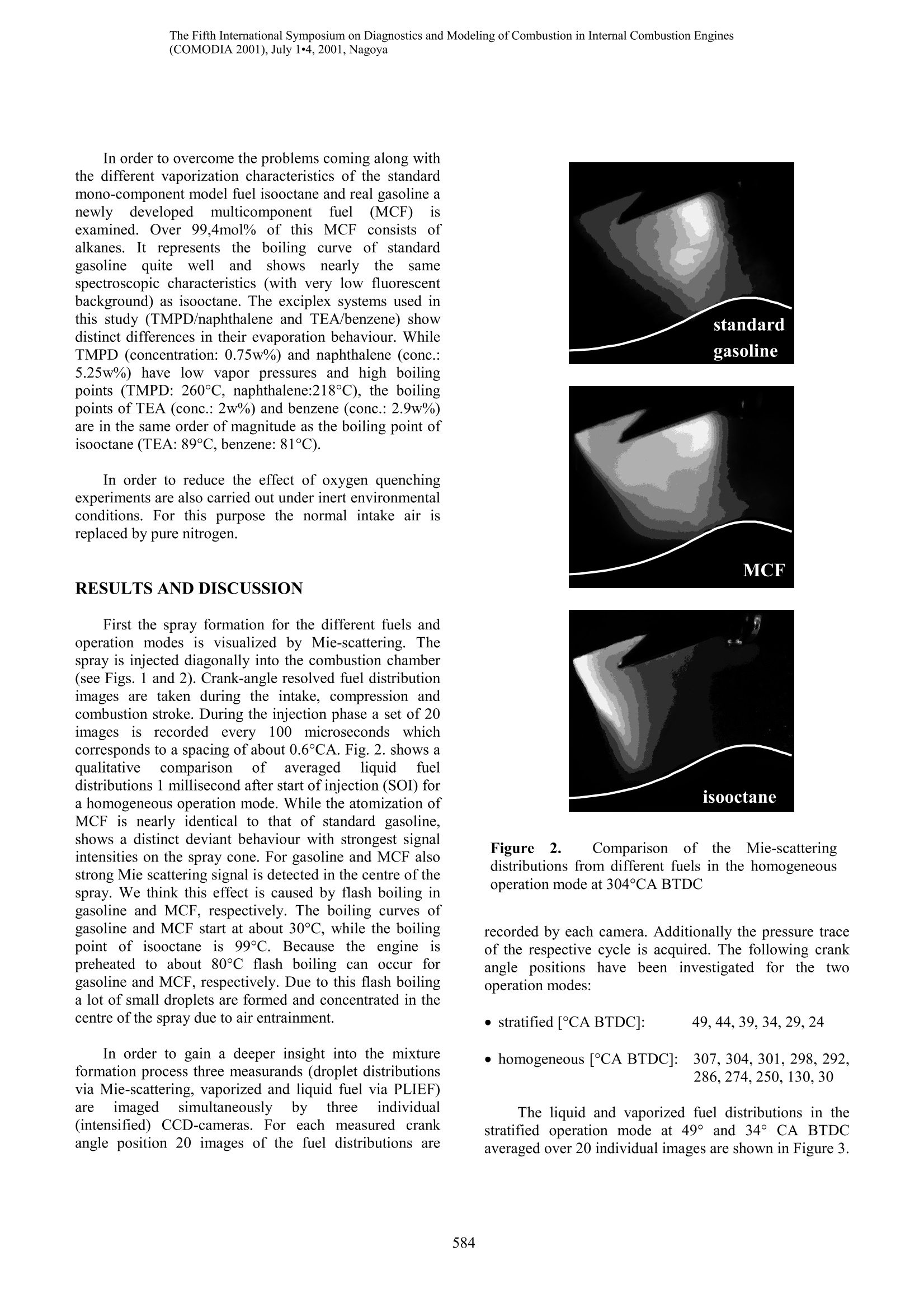

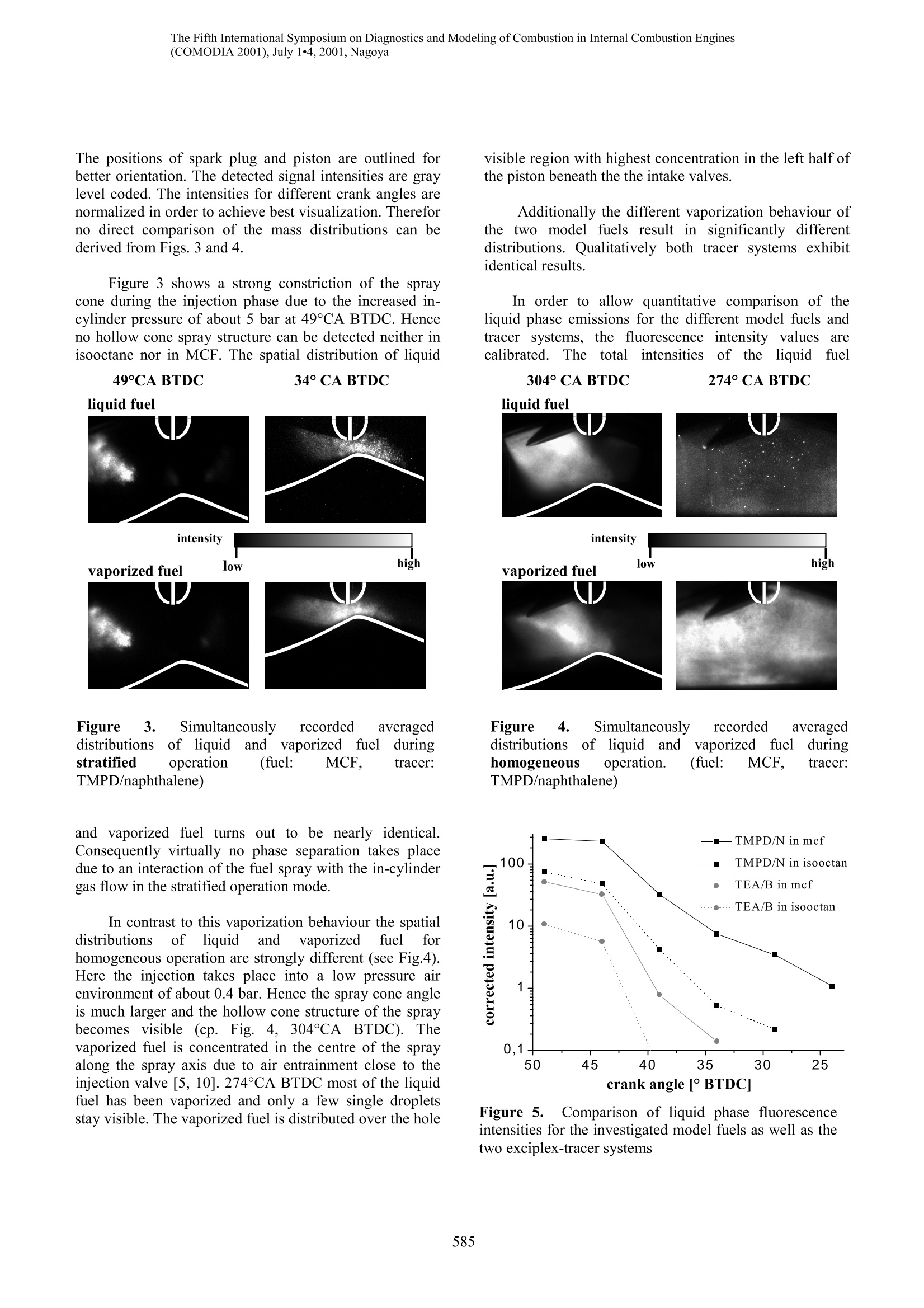

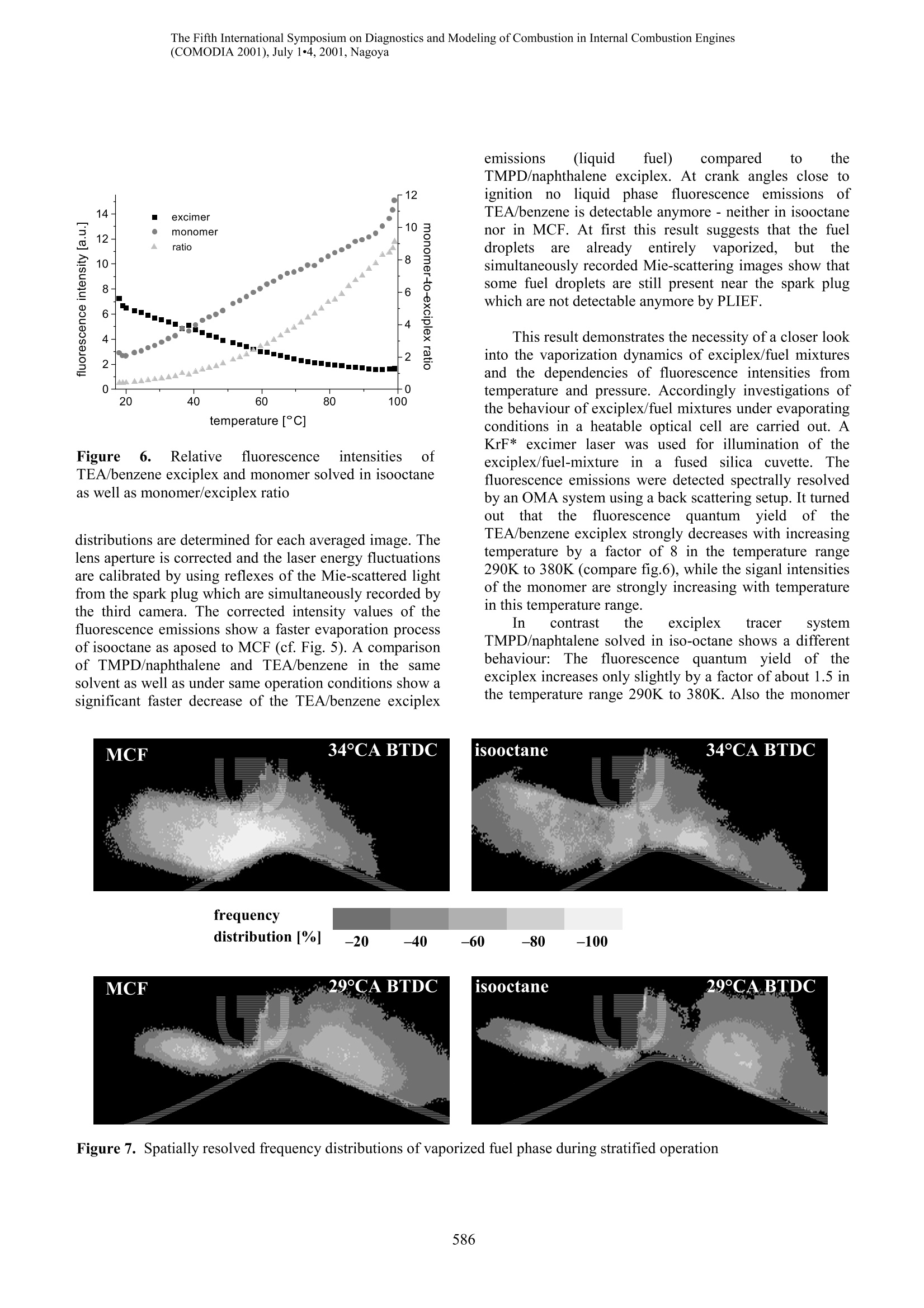

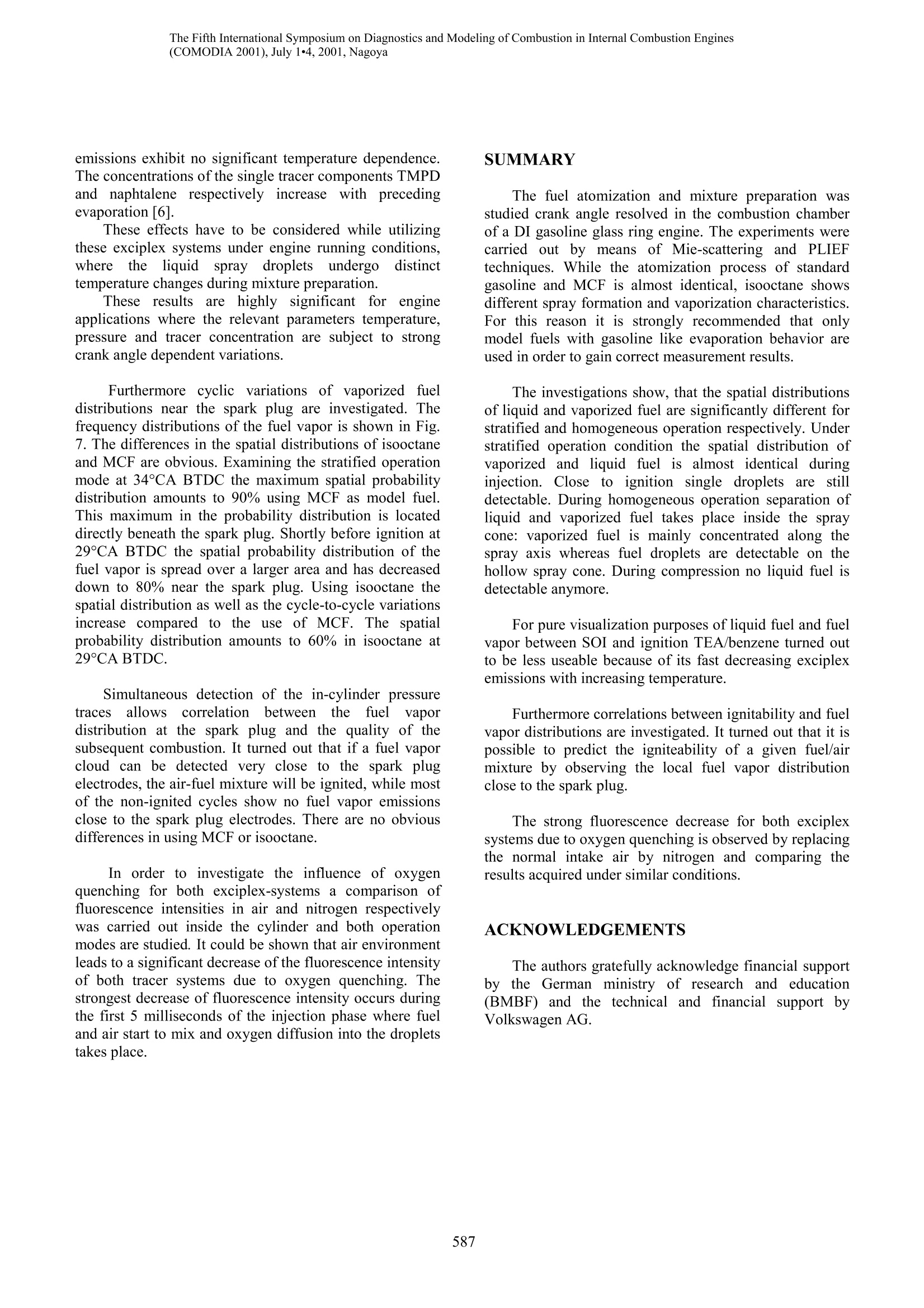

The Fifth International Symposium on Diagnostics and Modeling of Combustion in Internal Combustion Engines(COMODIA2001), July 1·4, 2001, Nagoya (3-16) Applicability of different exciplex tracers and model fuels forinvestigation of mixture formation in direct injection gasolineengines *C. Kornmesser, T. Miller,V. Beushausen Laser-Laboratorium Gottingen e.V., Hans-Adolf-Krebs-Weg 1, D-37077 Goettingen, Germany W. Hentschel Volkswagen AG, Forschung & Entwicklung, EZMM 1785, D-38436 Wolfsburg, Germany P. Andresen University Of Bielefeld, Fakultat fiir Physik D3,D-33 501 Bielefeld, Germany Key Words: PLIEF, Exciplex, Fluorescence, Internal Combustion, Spray, Model Fuels Abstract In this work we study mixture preparation inside the cylinder of an optically accessible DI gasoline-engine. Crank angleresolved investigation of the atomization process of different model-fuels is carried out by means of planar Mie-scattering.The vaporization of the liquid fuel and the transport processes inside the cylinder are studied by Planar Laser-Induced-Exciplex-Fluorescence (PLIEF) using two different exciplex-systems and two different model-fuels. Besides the standardmono-component model fuel isooctane a newly developed multi component fuel (MCF) was examined. It represents theboiling behaviour of standard gasoline quite well and shows almost the same spectroscopic characteristics as isooctane. Thesimultaneously recorded crank angle resolved distributions of liquid and vaporized fuel for a stratified and homogeneousoperation are visualized for both model fuels and both exciplex-tracers. The corrected intensity values of the fluorescenceemissions of the two exciplex-systems TMPD/naphthalene and TEA/benzene were compared under same operationconditions. Furthermore cyclic variations of vaporized fuel distributions near the spark plug are investigated. Simultaneous detection ofthe in-cylinder pressure allowed the correlation between the fuel vapor distribution near the spark plug and the combustionquality of this air-fuel-mixture. The quality of in-cylinder mixture preparation has adirect effect on the operating characteristics of an internalcombustion engine. It governs such important parametersasignitability, fuel consumption, exhaust emissions,performance and efficiency. Especially in direct injectiongasoline engines where mixture preparation has to takeplace in only a few milliseconds, a fast evaporation of thefuel and the air-fuel mixing process is of immense..importance.Asimultaneouscrankangle resolveddetection of vaporized andliquid fuel suitstheexamination of the in-cylinder vaporization and transportprocesses and thus is essential for the optimization ofdirect injection combustion engines. or quantitative analysisof the A-value 1-dspontaneous Raman scattering was used in SI IC-engines[7, 8]. For planar visualization of vapor fuel distributionsLaser-Induced-Fluorescence (LIF) is commonly usedbecause of its stronger signal intensities. LIF was alsosuccessfully implemented in order toobserve spraypenetration and vaporization in direct-injection gasolinesystems [1]. The application of liquid and vapor fueldistributions using the exciplex tracers TMPD andnaphthalene was first introduced by Melton et al. [2].Knapp et al. used the same exciplex system excited by aXeCl excimer laser for 2-D imaging of liquid and vaporfuel distributions [7]. Simultaneous acquisition of pressuretraces and engine-out HC, NO and CO emissions allowedcorrelations between injection timing and combustionperformance. Also the exciplex tracers TMPD/naphthalene wasused to study in-cylinder mixture preparation in directinjection gasoline engines [3]. Beushausen et al. carriedout PLIEF experiments in a direct injection glass ringengine and compared the results with PLIF distributionsof mono component tracers which amplified either thefluorescence emissions of the liquid phase (PPO:2,5-diphenyl-oxazole) or thevapor phase (3-pentanone)emissions. Quantification of LIEF signals is limited by severaleffects[9]. The equilibrium of exciplex formation istemperaturedependent,whichnmeans that highertemperatures reduces exciplex formation. Furthermore,exciplex fluorescence is severely quenched by oxygen.However, the main problem for quantification in engineapplicationsistheenecessity toiomatchhthe boilingtemperatures of the particular fuel and the exciplexgenerating dopants. Also the mixture preparation of singlecomponent model fuels like isooctane show significantdifferences compared to standard gasoline (Itoh et al.) [4]. In this work a newly developed multi componentmodel fuel (MCF) was used which represents the boilingcurve of standard gasoline quite well. The spray formationof standard gasoline, MCF and isooctane is compared bymeans of planar Mie-scattering inside the cylinder of adirect injection glass ring engine. PLIEF was used tovisualize spray atomization and fuel evaporation. In orderto avoid oxygen quenching measurements in an inertatmosphere are also carried out. Two exciplex systems(TMPD/naphthalene and TEA/benzene)with differentvaporization behaviour are investigated. The different vaporization behaviour of the twoexciplex systems inside the two model fuels is comparedusing combined detection of Mie-scattered light, as wellas liquid and vapor fluorescence signals using threeintensified CCD-cameras. EXPERIMENTAL The investigations reported in this work are carriedoutin a single-cylinder DI gasoline engine atlttheVolkswagenResearchand Development Centre18atWolfsburg. The research engine is equipped with a glassring below the cylinder head and thereby provides largescale optical access to the combustion chamber from allsides. Images are acquired for two different engineoperation conditions - stratified and homogeneous charge(see Table 1). In both cases the injected fuel quantityrepresents low partload operation of the engine. Anexternally pressurized reservoir is used to pipeline theexciplex doped model fuels to the swirl injector via amodified rail at a rail pressure of 50/80 bar. The injector iscontrolled by the engine management system. operation mode stratified homogeneous speed [rpm] 1000 1000 Intake tube pressure [mbar] 1000 410 start of injection (SOI) 53 310 [CA BTDC] time of ignition [℃A BTDC] 28 26 rail pressure (prai) [bar] 50 80 duration of injection (t;) [ms] 1,0 1,2 Table 1. Engine specifications of the glass ring engine The light of a narrowband KrF excimer laser (248nm)is formed to a sheet and is coupled into the cylinderthrough theeglass ring as outlined in Fig. 1. Thefluorescence and the Mie scattered light which exit the glass ring is captured simultaneously by three differentintensified CCD cameras. For visualization purposes offluorescence signals two FlameStar III cameras (LaVisionGmbH, 1100x768 pixels) with 12 bit dynamic range areapplied, whereas the Mie-scattered signal is imaged by a16 bit CCD-camera (LaVision, DynaMight, 512x512pixels). A combination of different Schott transmissionfilters and high reflective narrowband dieelectric mirrorsare used in order to select the transmission band for thedifferent cameras (exciplex and monomer fluorescence,Mie scattering). Actually the applied filter combinationdepends on the exciplex system in use. The imaging opticsconsist of three UV-Nikkor objectives with F-numbers of4.5. To compare the Mie-scattering signals of the nondoped fuels (standard gasoline, MCF and isooctane) a non intensified CCD camera (LaVision GmbH, Imager3, 12bit, 1280x1024 pixels) is used. The set-up described above allows a completeillumination of the cylinder roof. The visible region is60x40mm’ in size with slight distortions at the outsidemargins of the images due to the curvature of the glassringwhichturned out tobbee irrelevantfortheinvestigations. Simultaneously to the laser investigations incylinderpressure traces are recordedin order to correlatecombustion performance and measured fuel distribution.An electronic timing unit synchronizes the detection unitsand the piston movement so that crank angle resolvedinvestigations are possible. In order to overcome the problems coming along withthe different vaporization characteristics of the standardmono-component model fuel isooctane and real gasoline anewlydeveloped mmuulticomponentfuel(MCF) isexamined. Over 99,4mol% of this MCF consists ofalkanes. It represents the boiling curve of standardgasoline quite well and sshowsnearly the samespectroscopic characteristics (with very low fluorescentbackground) as isooctane. The exciplex systems used inthis study (TMPD/naphthalene and TEA/benzene) showdistinct differences in their evaporation behaviour. WhileTMPD (concentration: 0.75w%) and naphthalene (conc.:5.25w%) have low vapor pressures and high boilingpoints (TMPD: 260℃, naphthalene:218°℃), the boilingpoints of TEA (conc.: 2w%) and benzene (conc.: 2.9w%)are in the same order of magnitude as the boiling point ofisooctane (TEA:89°℃, benzene: 81°℃). In order to reduce the effect of oxygen quenchingexperiments are also carried out under inert environmentalconditions. For this purpose the normal intake air isreplaced by pure nitrogen. RESULTS AND DISCUSSION First the spray formation for the different fuels andoperation modes is visualized by Mie-scattering. Thespray is injected diagonally into the combustion chamber(see Figs. 1 and 2). Crank-angle resolved fuel distributionimages are taken during the intake, compression andcombustion stroke. During the injection phase a set of 20images is recorded every 100 microsecondsswhichcorresponds to a spacing of about 0.6°CA. Fig. 2. shows aqualitative: comparisonof averagedliquidfueldistributions 1 millisecond after start of injection (SOI) fora homogeneous operation mode. While the atomization ofMCF is nearly identical to that of standard gasoline,shows a distinct deviant behaviour with strongest signalintensities on the spray cone. For gasoline and MCF alsostrong Mie scattering signal is detected in the centre of thespray. We think this effect is caused by flash boiling ingasoline and MCF, respectively. The boiling curves ofgasoline and MCF start at about 30°C, while the boilingpoint of isooctane is 99°℃. Because the engine ispreheated to about 80C flash boiling can occur forgasoline and MCF, respectively. Due to this flash boilinga lot of small droplets are formed and concentrated in thecentre of the spray due to air entrainment. In order to gain a deeper insight into the mixtureformation process three measurands (droplet distributionsvia Mie-scattering,vaporized and liquid fuel via PLIEF)are imaged simultaneouslyby three individual(intensified) CCD-cameras. For each measured crankangle position 20 images of the fuel distributions are Figure 22. Comparisonn of the Mie-scatteringdistributions from different fuels in the homogeneousoperation mode at 304°CA BTDC recorded by each camera. Additionally the pressure traceof the respective cycle is acquired. The following crankangle positions have been investigated for thetwooperation modes: · stratified [°CA BTDC]: 49,44,39,34,29,24 homogeneous [°CA BTDC]::307,304,301,298,292,286,274,250,130,30 The liquid and vaporized fuel distributions in thestratified operation mode at 49° and 34°CA BTDCaveraged over 20 individual images are shown in Figure 3. The positions of spark plug and piston are outlined forbetter orientation. The detected signal intensities are graylevel coded. The intensities for different crank angles arenormalized in order to achieve best visualization. Thereforno direct comparison of the mass distributions can bederived from Figs. 3 and 4. Figure 3 shows a strong constriction of the spraycone during the injection phase due to the increased in-cylinder pressure of about 5 bar at 49°CA BTDC. Henceno hollow cone spray structure can be detected neither inisooctane nor in MCF. The spatial distribution of liquid 49°CA BTDC 34°CA BTDC Figure 3. Simultaneously recorded averageddistributionsSof liquidaand vaporized fuelduringstratified operation (fuel: MCF. tracer:TMPD/naphthalene) and vaporized fuel turns out to be nearly identical.Consequently virtually no phase separation takes placedue to an interaction of the fuel spray with the in-cylindergas flow in the stratified operation mode. In contrast to this vaporization behaviour the spatialdistributions of liquid andvaporized fuelforhomogeneous operation are strongly different (see Fig.4).Here the injection takes place into a low pressure airenvironment of about 0.4 bar. Hence the spray cone angleis much larger and the hollow cone structure of the spraybecomes vvisible (cp. Fig. 4, 304°CABTDC). Thevaporized fuel is concentrated in the centre of the sprayalong the spray axis due to air entrainment close to theinjection valve [5, 10]. 274°CA BTDC most ofthe liquidfuel has been vaporized and only a few single dropletsstay visible. The vaporized fuel is distributed over the hole visible region with highest concentration in the left half ofthe piston beneath the the intake valves. Additionally the different vaporization behaviour ofthe two model fuels result in ssignificantly differentdistributions. Qualitatively both tracer systems exhibitidentical results. In order to allow quantitative comparison of theliquid phase emissions for the different model fuels andtracer systems, the fluorescence intensity values arecalibrated. The total intensities of theielliquiddffuel 304°CA BTDC 274°CABTDC Figure 4 Simultaneouslyrecorded averageddistributions Boofliquid andvaporizel dfuelduringhomogeneous operation. (fuel: MCF. tracer:TMPD/naphthalene) Figure 5.). CComparison of liquid phase fluorescenceintensities for the investigated model fuels as well as thetwo exciplex-tracer systems Figure 6. Relative fluorescence intensities ofTEA/benzene exciplex and monomer solved in isooctaneas well as monomer/exciplex ratio distributions are determined for each averaged image. Thelens aperture is corrected and the laser energy fluctuationsare calibrated by using reflexes of the Mie-scattered lightfrom the spark plug which are simultaneously recorded bythe third camera. The corrected intensity values of thefluorescence emissions show a faster evaporation processof isooctane as aposed to MCF (cf. Fig.5). A comparisonof TMPD/naphthalene and TEA/benzene in the samesolvent as well as under same operation conditions show asignificant faster decrease of the TEA/benzene exciplex emissions (liquid fuel) compared ·to theTMPD/naphthalene exciplex. At crank angles close toignition no liquid phase fluorescence emissionsofTEA/benzene is detectable anymore - neither in isooctanenor in MCF. At first this result suggests that the fueldropletsarealready entirelyy vaporized, but thesimultaneously recorded Mie-scattering images show thatsome fuel droplets are still present near the spark plugwhich are not detectable anymore by PLIEF. This result demonstrates the necessity of a closer lookinto the vaporization dynamics of exciplex/fuel mixturesand the dependencies of fluorescence intensities fromtemperature and pressure. Accordingly investigations ofthe behaviour of exciplex/fuel mixtures under evaporatingconditions in a heatable optical cell are carried out. AKrF* excimer laser was used for illumination of theexciplex/fuel-mixture inafused silica cuvette. Thefluorescence emissions were detected spectrally resolvedby an OMA system using a back scattering setup. It turnedout that theleffluorescence(quantum yieldoftheTEA/benzene exciplex strongly decreases with increasingtemperature by a factor of 8 in the temperature range290K to 380K (compare fig.6), while the siganl intensitiesof the monomer are strongly increasing with temperaturein this temperature range. In contrast the exciplex tracer systemTMPD/naphtalene solved in iso-octane shows a differentbehaviour::The fluorescencequantumyielddof theexciplex increases only slightly by a factor of about 1.5 inthe temperature range 290K to 380K. Also the monomer Figure 7. Spatially resolved frequency distributions of vaporized fuel phase during stratified operation emissions exhibit no significant temperature dependence.The concentrations of the single tracer components TMPDand naphtalene respectively increasewith1 precedingevaporation [6]. These effects have to be considered while utilizingthese exciplex systems under engine running conditions,where the liquidspray droplets undergoodistincttemperature changes during mixture preparation. These results are highly significant: for engineapplications where the relevant parameters temperature,pressure and tracer concentration are subject to strongcrank angle dependent variations. Furthermore cyclic> variations of vaporized fueldistributions near the spark plug are investigated. Thefrequency distributions of the fuel vapor is shown in Fig.7. The differences in the spatial distributions ofisooctaneand MCF are obvious. Examining the stratified operationmode at 34°CA BTDC the maximum spatial probabilitydistribution amounts to 90% using MCF as model fuel.This maximum in the probability distribution is locateddirectly beneath the spark plug. Shortly before ignition at29°CA BTDC the spatial probability distribution of thefuel vapor is spread over a larger area and has decreaseddown to 80% near the spark plug. Using isooctane thespatial distribution as well as the cycle-to-cycle variationsincrease compared to the use of MCF. The spatialprobability distribution amounts to 60% in isooctane at29°CA BTDC. Simultaneous detection of the in-cylinder pressuretracesallowsccorrelationnbbetweentheeffuelvapordistribution at the spark plug and the quality of thesubsequent combustion. It turned out that if a fuel vaporcloud can be detected very close to the spark plugelectrodes, the air-fuel mixture will be ignited, while mostof the non-ignited cycles show no fuel vapor emissionsclose to the spark plug electrodes. There are no obviousdifferences in using MCF or isooctane. In order to investigate the influence of oxygenquenching for both exciplex-systems a comparison offluorescence intensities in air and nitrogen respectivelywas carried out inside the cylinder and both operationmodes are studied. It could be shown that air environmentleads to a significant decrease of the fluorescence intensityof both tracer systems due to oxygen quenching. Thestrongest decrease of fluorescence intensity occurs duringthe first 5 milliseconds of the injection phase where fueland air start to mix and oxygen diffusion into the dropletstakes place. SUMMARY The fuel atomization and mixture preparation wasstudied crank angle resolved in the combustion chamberof a DI gasoline glass ring engine. The experiments werecarried out: by means of Mie-scattering andPLIEFtechniques. While the atomization process of standardgasoline and MCF is almost identical, isooctane showsdifferent spray formation and vaporization characteristics.For this reason it is strongly recommended that onlymodel fuels with gasoline like evaporation behavior areused in order to gain correct measurement results. The investigations show, that the spatial distributionsof liquid and vaporized fuel are significantly different forstratified and homogeneous operation respectively. Understratified operation condition the spatial distribution ofvaporized and liquid fuel is almost identical duringinjection. Close to ignition single droplets are stilldetectable. During homogeneous operation separation ofliquid and vaporized fuel takes place inside the spraycone: vaporized fuel is mainly concentrated along thespray axis whereas fuel droplets are detectable on thehollow spray cone. During compression no liquid fuel isdetectable anymore. For pure visualization purposes of liquid fuel and fuelvapor between SOI and ignition TEA/benzene turned outto be less useable because ofits fast decreasing exciplexemissions with increasing temperature. Furthermore correlations between ignitability and fuelvapor distributions are investigated. It turned out that it ispossible to predict the igniteability of a given fuel/airmixture by observing the local fuel vapor distributionclose to the spark plug. The strong fluorescence decrease for both exciplexsystems due to oxygen quenching is observed by replacingthe normal intake air by nitrogen and comparing theresults acquired under similar conditions. ACKNOWLEDGEMENTS The authors gratefully acknowledge financial supportby the German ministry of research and education(BMBF) and the technical and financial support byVolkswagen AG. REFERENCES ( PROCEEDINGS: ) ( [1] Hentschel W., Homburg A., Ohmstede G., Mu l ler T.,Grunefeld G., SAE 1999-01-3660 ) ( [21 Melton L . A.. Verdieck J.F.: Vapor/Liquid Visualizatio n i n Fuel Sprays, 20 Symposium on Combustion, 1984 ) ( [3] ] Kornmesser C.. Muller T.. Beushausen V.,Andresen P.. H entschel W. , H omburg A., 7. Fachtagung G ala'99, I S L S a int-Louis, September 1999 ) ( 4] Itoh T., Kakuho A., Hishinuma H., Urushiahara T., Takagi Y., Horie K.. Asano M.. Ogata E.,Yamasita T.,SAE 952465 (1995) ) ( [51 Ferrand V . , Bazile R., BoreeJ., C harnay G.: The Effect of Droplets on Turbulence Modulation and Air Entrainment i n an A xisymmetric S p ray Jet, 8 " International Conference on Liquid Atomization and Spray System, Pasadena 2000 ) ( [6] Felton P. G., Bracco F. V., Bardsley M. E. A.: On the Quantitative Application of Exciplex Fluorescence to Engine Sprays, SAE 9 30870, 1 993 ) ( PHD THESIS: ) ( [7] Knapp M., U V La s er Sp e ctroscopy Applied to In - Cylinder P henomena of Sp a rk Ig n ition En g ines,Dissertation U niversitat Bielefeld, C uvillier Ve rlagGottingen, 1997 ) REPORTS: ( [8] 1 Hentschel W., B lock B ., Hovestadt T., Meyer H., Ohmstede G .. B eushausen V.. M i ller T.. Kornmesser C., A ndresen P . , Grinefeld G . , S c h iitte M., KoB H . -J., Linnemann U., ThiemannJ.: Mehrdimensiomale Laserdiagnostik zur Untersuchung der Gemischbildung und Gemischschichtung im DI-Verbrennungsmotor,VDITechnologiezentrum (Hrg.), R e ichel K. , Sellhorst M ( editor), pp. 51-65, September 2000 ) [9]Melton L. A.: Quantitative Use of Exciplex-BasedVapor-Liquid Visualization Systems Appropriate forAutomotive Gasoline (aUsers Manual), FinalReport (1993) JOURNALS: ( [10] Kriger S, Grunefeld G.: Gas-Phase Velocity FieldMeasurements in Dense Sprays by L aser-BasedF l ow Tagging, Applied Physics B Lasers and O p ticsVolume 70, Issue 3, pp 463-466,2000 ) In this work we study mixture preparation inside the cylinder of an optically accessible DI gasoline-engine. Crank angleresolved investigation of the atomization process of different model-fuels is carried out by means of planar Mie-scattering.The vaporization of the liquid fuel and the transport processes inside the cylinder are studied by Planar Laser-Induced-Exciplex-Fluorescence (PLIEF) using two different exciplex-systems and two different model-fuels. Besides the standardmono-component model fuel isooctane a newly developed multi component fuel (MCF) was examined. It represents theboiling behaviour of standard gasoline quite well and shows almost the same spectroscopic characteristics as isooctane. Thesimultaneously recorded crank angle resolved distributions of liquid and vaporized fuel for a stratified and homogeneousoperation are visualized for both model fuels and both exciplex-tracers. The corrected intensity values of the fluorescenceemissions of the two exciplex-systems TMPD/naphthalene and TEA/benzene were compared under same operationconditions.Furthermore cyclic variations of vaporized fuel distributions near the spark plug are investigated. Simultaneous detection ofthe in-cylinder pressure allowed the correlation between the fuel vapor distribution near the spark plug and the combustionquality of this air-fuel-mixture.

确定

还剩6页未读,是否继续阅读?

北京欧兰科技发展有限公司为您提供《直喷汽油发动机内混合物中激发态复合物和模型燃料的应用有效性检测方案(尾气检测)》,该方案主要用于汽车电子电器中热性能检测,参考标准--,《直喷汽油发动机内混合物中激发态复合物和模型燃料的应用有效性检测方案(尾气检测)》用到的仪器有汽车发动机多参量测试系统、德国LaVision PIV/PLIF粒子成像测速场仪、PLIF平面激光诱导荧光火焰燃烧检测系统、LaVision SprayMaster 喷雾成像测量系统、激光诱导白炽光烟雾粒子成像分析仪(LII)

推荐专场

相关方案

更多

该厂商其他方案

更多