方案详情

文

采用由LaVision公司的增强型CCD像机为核心构成的平面激光诱导荧光PLIF测试系统,用激发态复合物Exciplex作为示踪粒子,分析研究汽车发动机燃料混合物的制备过程特别是喷雾气液两相转化过程。

方案详情

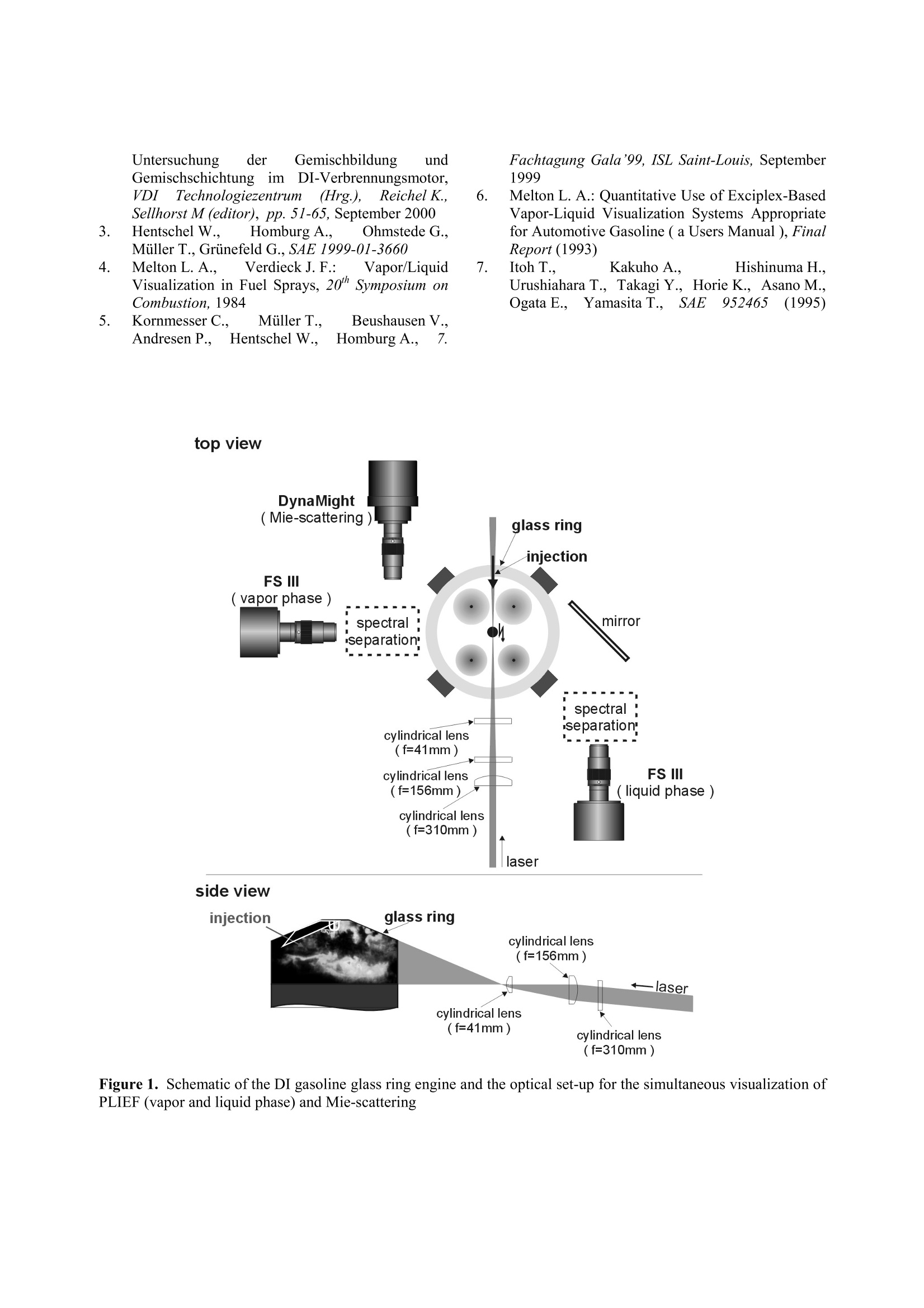

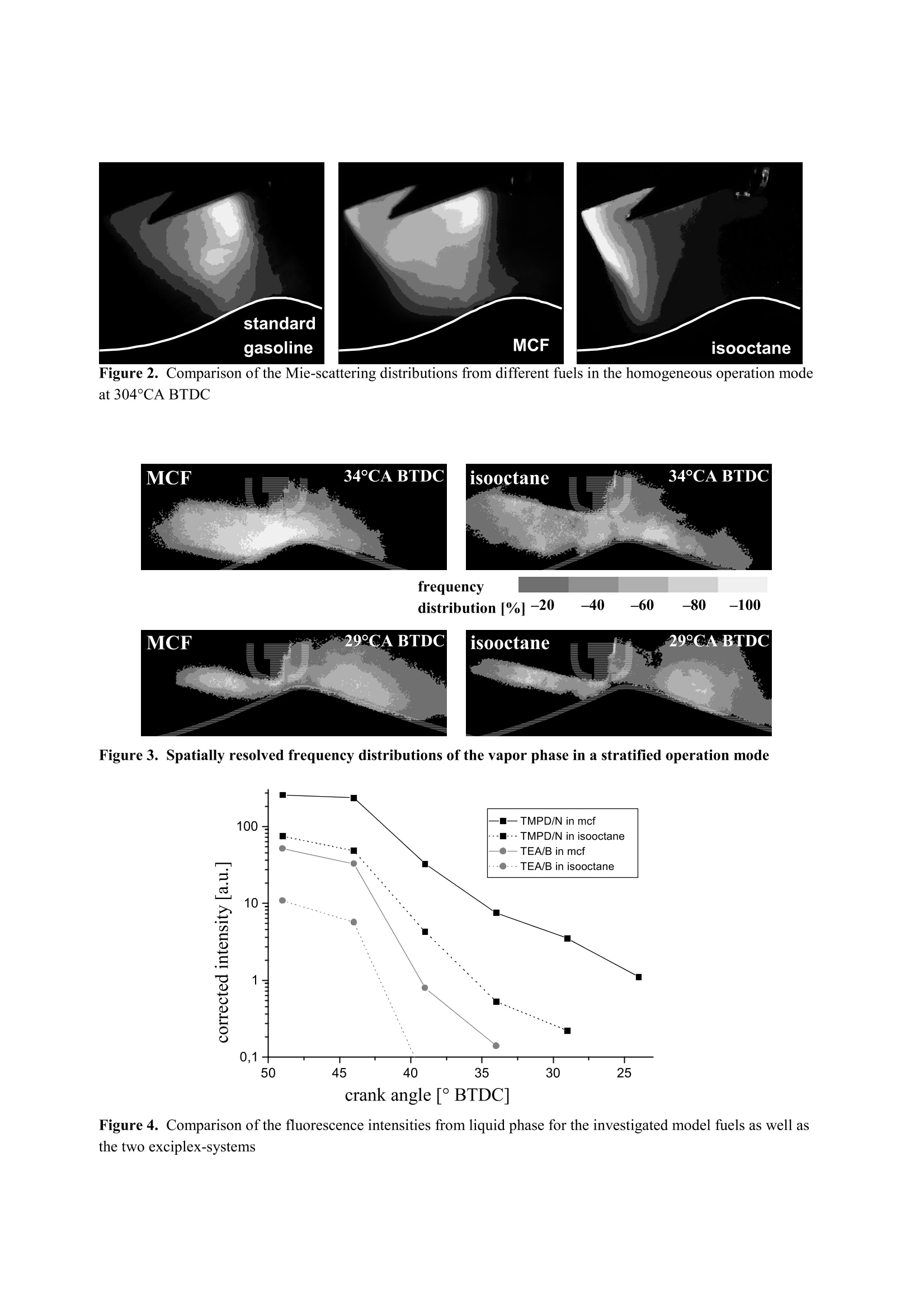

ILASS Americas, 14" Annual Conference on Liquid Atomization and Spray Systems, Dearborn, MI, May 2001 Spectroscopic investigation of mixture formation in a DI gasoline engine using twodifferent exciplex tracers and model fuels C. Kornmesser*,T. Miller, V. Beushausen Laser-Laboratorium Gottingen e.V.,Hans-Adolf-Krebs-Weg 1, D-37077 Goettingen, Germany W. Hentschel Volkswagen AG, Forschung & Entwicklung, EZMM 1785, D-38436 Wolfsburg, Germany Peter Andresen University Of Bielefeld, Fakultat fur Physik D3, D-33 501 Bielefeld, Germany Abstract In this work we study mixture preparation inside the cylinder of an optically accessible DI gasoline-engine. Crankangle resolved investigation of the atomization process of different model-fuels is carried out by means of planarMie-scattering. The vaporization of the liquid fuel and the transport processes inside the cylinder are studied byplanar Laser-Induced-Exciplex-Fluorescence (PLIEF) using two different exciplex-systems and two differentmodel-fuels. Besides the standard mono-component model fuel isooctane a newly developed multi component fuel(MCF) was examined. It represents the boiling curve of standard gasoline quite well and shows nearly the samespectroscopic characteristics as isooctane. The crank angle resolved liquid and vapor distributions for a stratified anda homogeneous operation mode are visualized for both model fuels and both exciplex-tracers. Furthermore cyclicvariations of vaporized fuel distributions near the spark plug are investigated. Simultaneous detection of the in-cylinder pressure allowed the correlation between the fuel vapor distribution near the spark plug and the combustionquality of this air-fuel-mixture. The corrected intensity values of the fluorescence emissions of the two exciplex-systems TMPD/naphthalene and TEA/benzene were compared under same operation conditions. Introduction The quality of in-cylinder mixture preparation hasa direct effect on the operating characteristics of aninternal combustion engine. It governs such importantparameters as ignitability, fuel consumption, exhaustemissions, performance and efficiency. Especially indirectt. injectiongasoline engines where mixturepreparation has to take place in only a few milliseconds,a fast evaporation of the fuel and the air-fuel mixingprocess is of immense importance. A simultaneouscrank angle resolved detection of vaporized and liquidfuelsuitstSthe examinationofthe in-cylindervaporization and. transport processes and thus isessentialfor theeoptimizationof ddireecctt injectitioncombustion engines. For quantitative analysisof the A-value1-dspontaneous Raman scattering was used in SI IC-engines [1;2]. For planar visualization of vapor fueldistributionssLaser-Induced-Fluorescence (LIF) iscommonlyused because of its strongersignalintensities. LIF was also successfully implemented inorder to observe spray penetration and vaporization in direct-injection gasoline systems [3]. The application ofliquid and vapor fuel distributions using the exciplextracers TMPD and naphthalene was first introduced byMelton et al. [4]. Knapp et al. used the same exciplexsystem excited by a XeCl excimer laser for 2-Dimaging of liquid and vapor fuel distributions[1].Simultaneousacquisitioni of pressuretraces andengine-outHC, NO and Co emissionsallowedcorrelations between injection timing and combustionperformance. Also the exciplex tracers TMPD/naphthalene wasused to study in-cylinder mixture preparation in directinjection gasoline engines [5]. Beushausen et al. carriedout PLIEF experiments in a direct injection glass ringengine and compared the results with PLIF distributionsof mono component tracers which amplified either thefluorescence emissions of the liquid phase (PPO:2,5-diphenyl-oxazole) or the vapor phase (3-pentanone)emissions Quantification of LIEF signals is limited by severaleffects [6]. The equilibrium of exciplex formation istemperature dependent,whichmeans thathhigher temperatures reduces exciplex formation. Furthermore,exciplex fluorescence is severely quenched by oxygen.However, the main problem for quantification in engineapplications is the necessity to match the boilingtemperatures of the particular fuel and the exciplexgenerating dopants. Also the mixture preparation ofsingle component model fuels like isooctane showsignificant differences compared to standard gasoline(Itohet al.) [7]. In this work a newly developed multi componentmodel fuel (MCF) was used which represents theboiling curve of standard gasoline quite well. The sprayformation of standard gasoline, MCF and isooctane iscompared by means of planar Mie-scattering inside thecylinder of a direct injection glass ring engine. PLIEFwas used to visualize spray atomization and fuelevaporation. In order to avoid oxygen quenchingmeasurements in an inert atmosphere are also carriedout. Two exciplex systems (TMPD/naphthalene andTEA/benzene) with different vaporization behaviourare investigated. The different vaporization behaviour of the twoexciplex systems inside the two model fuelsiscompared using combined detection of Mie-scatteredlight, as well as liquid and vapor fluorescence signalsusing three intensified CCD-cameras. Experimental The investigations reported in this work are carriedout in a single-cylinder DI gasoline engine at theVolkswagen Research and Development Centre atWolfsburg. The research engine is equipped with aglass ring below the cylinder head and thereby provideslarge scale optical access to the combustion chamberfrom all sides. Images are acquired for two differentengine operation conditions - stratified and homoge-neous charge. In both cases the injected fuel quantityrepresents low partload operation of the engine. Anexternal pressurized reservoir is used to pipeline theexciplex doped model fuels to the injector via amodified rail at a rail pressure of 50/80 bar. Theinjectorr isiScontrolledbytthe engine managementsystem. The light of a narrowband KrF excimer laser(248nm) is formed to a sheet and is coupled into thecylinder through the glass ring as outlined in Fig. 1. Thefluorescence and the Mie scattered light which exit theglass ring is captured simultaneously by three differentintensified CCD cameras. For visualization purposes offluorescence signals twoFlameStar IIIccameraS(LaVision GmbH, 1100x768pixels))with 12bitdynamic range are applied, whereas the Mie-scatteredsignal is imaged by a 16 bit CCD-camera (LaVision,DynaMight, 512x512pixels).A combinationofdifferent Schott transmission filters and high reflectivenarrowband dieelectric mirrors are used in order to select the transmission band for the different cameras.Actually the applied filter combination depends on theexciplex system in use. The imaging optics consist ofthree UV-Nikkor objectives with F-numbers of 4.5. Tocompare the Mie-scattering signals of the non dopedfuels (standard gasoline, MCF and isooctane) a nonintensified CCD camera (LaVision GmbH, Imager3,12bit, 1280x1024 pixels) is used. The set-up described above allows a completeillumination of the cylinder roof. The visible region is60x40mm’ in size with slight distortions at the outsidemargins ofthe images due to the curvature of the glassring which1turnedd outitto be irrelevant for theinvestigations. Simultaneously t the laser investigationsincylinder pressure traces are recorded in order tocorrelate combustion performance and measured fueldistribution. An electronic timing unit synchronizes thedetection units and the piston movement so that crankangle resolved investigations are possible. In order to overcome the problems coming alongwith the different vaporization characteristics of thestandard mono-component model fuel isooctane andreal gasoline a newly developed multicomponent fuel(MCF) is examined. Over 99,4mol% of this MCFconsists of alkanes. It represents the boiling curve ofstandard gasoline quite well and shows nearly the samespectroscopic characteristics (with very low fluorescentbackground) as isooctane. The exciplex systems used inthis study (TMPD/naphthalene and TEA/benzene) showdistinct differences in their evaporation behaviour.WhileeTMPDand naphthalene have lowvaporpressures and high boiling points (TMPD: 260℃,naphthalene:218°C), the boiling points of TEA andbenzene are in the same order of magnitude as theboiling point of isooctane (TEA: 89℃, benzene: 81°℃). In order to reduce the effect of oxygen quenchingexperiments are alsocarriedout under1inertenvironmental conditions. For this purpose the normalintake air is replaced by pure nitrogen. Results and discussion First of all the spray formation for the differentfuels and operation modes isvisualized by Mie-scattering. The spray is injected diagonally into thecombustion chamber (see Figs. 1 and 2). Crank-angleresolved fuel distribution images are taken during theintake, compression and combustion stroke. Fig. 2.shows a qualitative comparison of averaged liquid fueldistributions 1 millisecond after start of injection (SOI)forr aa homogeneousoperation mode.While theatomization of MCF is nearly identical to that ofstandard gasoline, isooctane shows a distinct deviantbehaviour with strongest signal intensities on the coneof the spray. The PLIEF experiments show very similar liquidand vapor fuel distributions for the stratified operationmode. For homogeneous operation it turned out thatliquid and vaporized fuel show strongly differentdistributions. Additionally the different vaporizationbehaviour of the two model fuels result in significantlydifferent distributions. Qualitatively both tracer systemsexhibit identical results. Furthermore cyclic variations of vaporized fueldistributions near the spark plug are investigated. Thefrequency distributions of the fuel vapor is shown inFig. 3. The differences in the spatial distributions ofisooctane andMCF are obvious. Examiningstratifiedoperation modeat 34°CABTDCmaximum spatial probability distribution amounts to90% using MCF as model fuel. This maximum in theprobability distribution is located directly beneath thespark plug. Shortly before ignition at 29°CA BTDC thespatial probability distribution of the fuel vapor isspread over a larger area and has decreased. Usingisooctane the spatial distribution as well as the cycle-to-cycle variations increase compared to the use of MCF. Simultaneous detection of the in-cylinder pressuretraces allows correlation between the fuel vapordistribution near the ignition spark and the quality ofthe subsequent combustion. It turned out that when afuel vapor cloud can be detected divery close to thespark plug, the air-fuel mixture has been ignited, whilemost of the non-ignited cycles show no fuel vaporemissions close to the spark plug. There are no obviousdifferences in using MCF or isooctane. In order to allow quantitative comparison of theliquid phase emissions for the different model fuels andtracer systems, the fluorescence intensity values arecalibrated. The total intensities of the liquid fueldistributions are determined for each averaged image.The lens aperture is corrected and the laser energyfluctuations are calibrated by using reflexes of the Mie-scatteredlight from the: spark plugwhicharesimultaneously detected by the third camera. Thecorrected intensity values of the fluorescence emissionsshow a faster evaporation process of isooctane asaposed to MCF (cf. Fig. 4). A comparison of the twoexciplex-systems TMPD/naphthalene and TEA/benzeneunder same operation conditions indicate, that theevaporation rates are different, and that both tracer-systems do not track the overall fuel concentration. Theconcentration of TMPD/naphthalene with its low vaporpressure increases. while the concentration ofTEA/benzene with boiling points slightly below theboiling point of isooctane decreases in the remainingliquid fuel during evaporation. Near the point ofionition no liquid phase fluorescence emissions ofTEA/benzene 1sdetectable anymore neitheririsooctane nor in MCF.This suggests the conclusion thatthe fuel droplets are entirely vaporized. In (order to investigate the influence of oxygenquenching for both exciplex-systems a comparison offluorescence intensities in air and nitrogen respectivelywas carried out inside the cylinder and both operationmodeses are Sstudied. It could be shownnthat airenvironment leads to a significant decrease of thefluorescence intensity of both tracer systems due tooxygen quenching. Thestrongesttdecreaseoffluorescenceintensity occurs during the firstmilliseconds of the injection phase where fuel and airstart to mix and oxygen diffusion into the droplets takesplace. Conclusion The fuel atomization and mixture preparation wasstudied crank angle resolved iinnthe combustionchamber of a DI gasoline glass ring engine. Theexperimentss were carried outby means of Mie-scattering and PLIEF techniques. While the atomizationprocess of standard gasoline and MCF is nearlyidentical, isooctane shows different spray formationcharacteristics.Fortthisrreason it is stronglyrecommended that only model fuels with gasoline likeboiling curves should be used in order to create realisticvaporization conditions. Furthermore correlations between ignitability andthe fuel vapor distributions are investigated. It turnedout that it is possible to predict the igniteability of agiven fuel/air mixture by measuring and analyzing thelocal fuel vapor distribution close to the spark plug. For pure visualization purposes of liquid fuel andfuel vapor between SOI and ignition TEA/benzeneturned out to be less useable because of its fastevaporation. The strong fluorescence decrease for both exciplexsystems due to oxygen quenching is recorded byreplacing the normaliintake air by nitrogen andcomparing the results acquired under Ss1imilarconditions. Acknowledgements Theaauthorsgratefully acknowledgeefinancialsupport by the German ministry of research andeducation (BMBF) and the technical and financialsupport by Volkswagen AG. ( References ) l. Knapp M., UV Laser Spectroscopy Applied to InCylinder Phenomena of Spark Ignition Engines,Dissertation Universitat Bielefeld, CuvillierVerlag Gottingen, 1997 2. Hentschel W., Block B., Hovestadt T., Meyer H.,Ohmstede G.. Beushausen V.. Miller T..Kornmesser C., AndresenP.,Griinefeld G..Schiitte M., KoB H.-J., Linnemann U., ThiemannJ.: Mehrdimensiomale Laserdiagnostik zur Fachtagung Gala'99, ISL Saint-Louis, September1999 6. Melton L. A.: Quantitative Use of Exciplex-BasedVapor-Liquid Visualization Systems Appropriatefor Automotive Gasoline ( a Users Manual), FinalReport (1993) 7. Itoh T.. Kakuho A.. Hishinuma H..Urushiahara T., Takagi Y., Horie K., Asano M.,Ogata E., Yamasita T., SAE 952465 (1995) 3. Hentschel W.. Homburg A., Ohmstede G..Muller T., Griinefeld G., SAE 1999-01-3660 4. Melton L. A.. Verdieck J.F.: Vapor/LiquidVisualization in Fuel Sprays, 20"h Symposium onCombustion, 1984 5. Kornmesser C.. Miller T.. Beushausen V..Andresen P., Hentschel W.,,FHomburg A., 7. cylindrical lens (f=41mm) cylindrical lens (f=310mm) Figure 2. Comparison of the Mie-scattering distributions from different fuels in the homogeneous operation modeat 304°CA BTDC Figure 3. Spatially resolved frequency distributions of the vapor phase in a stratified operation mode Figure 4. Comparison of the fluorescence intensities from liquid phase for the investigated model fuels as well asthe two exciplex-systems In this work we study mixture preparation inside the cylinder of an optically accessible DI gasoline-engine. Crankangle resolved investigation of the atomization process of different model-fuels is carried out by means of planarMie-scattering. The vaporization of the liquid fuel and the transport processes inside the cylinder are studied byplanar Laser-Induced-Exciplex-Fluorescence (PLIEF) using two different exciplex-systems and two differentmodel-fuels. Besides the standard mono-component model fuel isooctane a newly developed multi component fuel(MCF) was examined. It represents the boiling curve of standard gasoline quite well and shows nearly the samespectroscopic characteristics as isooctane. The crank angle resolved liquid and vapor distributions for a stratified anda homogeneous operation mode are visualized for both model fuels and both exciplex-tracers. Furthermore cyclicvariations of vaporized fuel distributions near the spark plug are investigated. Simultaneous detection of the incylinderpressure allowed the correlation between the fuel vapor distribution near the spark plug and the combustionquality of this air-fuel-mixture. The corrected intensity values of the fluorescence emissions of the two exciplexsystemsTMPD/naphthalene and TEA/benzene were compared under same operation conditions.

确定

还剩3页未读,是否继续阅读?

北京欧兰科技发展有限公司为您提供《直喷汽油发动机中燃料混合物的形成检测方案(粒子图像测速)》,该方案主要用于汽车电子电器中热性能检测,参考标准--,《直喷汽油发动机中燃料混合物的形成检测方案(粒子图像测速)》用到的仪器有德国LaVision PIV/PLIF粒子成像测速场仪、汽车发动机多参量测试系统、PLIF平面激光诱导荧光火焰燃烧检测系统、LaVision SprayMaster 喷雾成像测量系统、激光诱导白炽光烟雾粒子成像分析仪(LII)

推荐专场

汽车尾气分析仪

更多

相关方案

更多

该厂商其他方案

更多