尼龙纤维中油剂含量检测方案

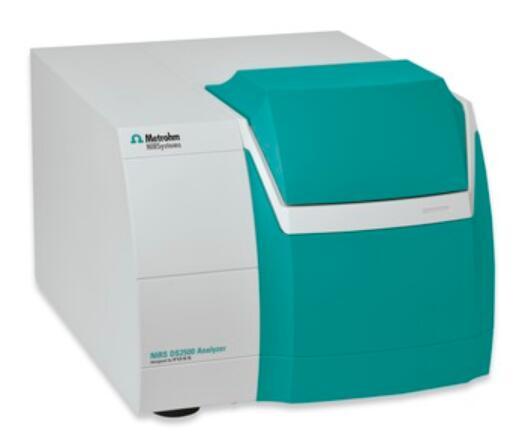

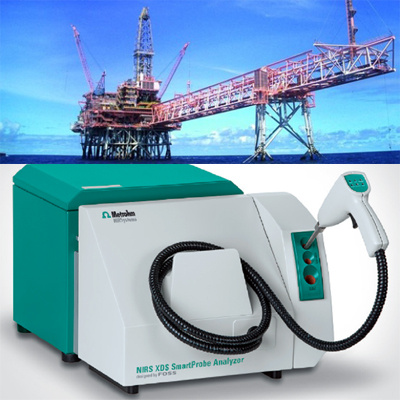

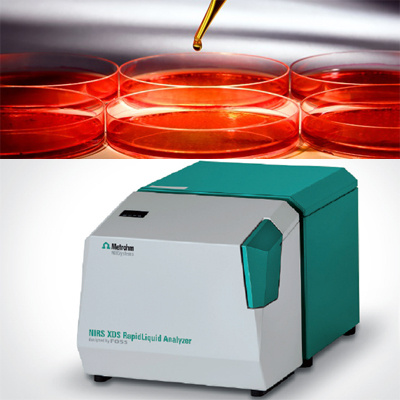

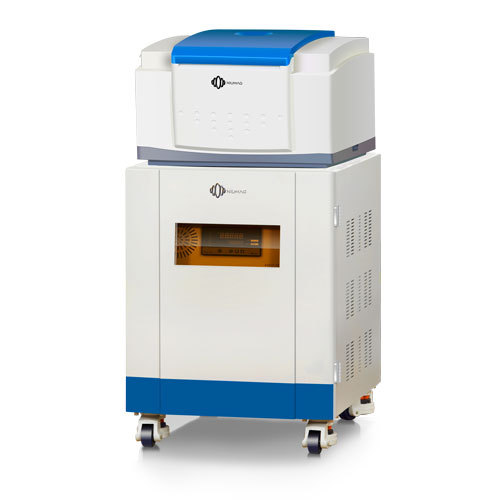

2013年,Metrohm收购Foss NIRSystems Inc.公司,以Metrohm-NIRSystems作为近红外产品品牌开始进军光谱领域,在工业领域开始与Foss公司进行全球战略合作。Metrohm-NIRSystems为客户提供实验室型、旁线以及在线近红外解决方案。 XDS系列近红外产品是新一代的光栅型扫描近红外分析仪,采用基于偏移技术数字全息光栅系统,其对应的NIIST可追溯的标准和方法保证了每台仪器的光度计,波长和带宽等重要技术参数的高度一致,保证了仪器之间定标模型无缝转移并且可实现网络控制操作。基于XDS近红外分析技术,Metrohm-NIRSystems开发了一系列新一代的过程分析仪,用于制药和化工领域的实时分析。样品无需破损、测试精确等优点都在加工过程、搅拌器、干燥器、反应器等不同阶段的检测中得到了体现。XDS近红外在线分析仪典型的应用案例包括炼油厂、石化企业、聚合过程、原料药的溶媒保护等的反应监测和终点判断,以及压缩聚合物薄膜或包衣的分析。

检测样品:

合成纤维

检测项:

油剂含量

瑞士万通中国有限公司

查看联系电话

前往展位

纤维中表面形态检测方案

Fiber ClassifFicCation with the Phenom

Fibers play an important part in everyday materials and cutting edge research. The Phenom has been used to investigate several different cutting edge applications in industries covering filtration, medical equipment, insulation, aerospace, and nanotechnology. It provides accurate information about fibers like general construction, diameter, and surface morphology.

检测样品:

合成纤维

检测项:

表面形态

复纳科学仪器(上海)有限公司

查看联系电话

前往展位

尼龙纤维中油剂含量检测方案

2013年,Metrohm收购Foss NIRSystems Inc.公司,以Metrohm-NIRSystems作为近红外产品品牌开始进军光谱领域,在工业领域开始与Foss公司进行全球战略合作。Metrohm-NIRSystems为客户提供实验室型、旁线以及在线近红外解决方案。 XDS系列近红外产品是新一代的光栅型扫描近红外分析仪,采用基于偏移技术数字全息光栅系统,其对应的NIIST可追溯的标准和方法保证了每台仪器的光度计,波长和带宽等重要技术参数的高度一致,保证了仪器之间定标模型无缝转移并且可实现网络控制操作。基于XDS近红外分析技术,Metrohm-NIRSystems开发了一系列新一代的过程分析仪,用于制药和化工领域的实时分析。样品无需破损、测试精确等优点都在加工过程、搅拌器、干燥器、反应器等不同阶段的检测中得到了体现。XDS近红外在线分析仪典型的应用案例包括炼油厂、石化企业、聚合过程、原料药的溶媒保护等的反应监测和终点判断,以及压缩聚合物薄膜或包衣的分析。

检测样品:

合成纤维

检测项:

油剂含量

上海纳锘实业有限公司

查看联系电话

前往展位

碳纤维增强塑料中剪切弹性模量 剪切强度检测方案(万能试验机)

本文使用岛津公司AG-X plus电子万能试验机,复合材料剪切夹具,根据ASTM D5379 ISO14129和ASTM D7078三种测试标准要求,采用位移速度对复合材料进行剪切试验。用本次试验系统可顺利进行 V-Notched RailShear(ASTM D7078)的剪切试验。在系统中安装非接触式引伸计后,不仅能够评价剪切弹性模量和剪切强度等基本数据,还可做为分析CFRP破坏原理的参考数据,实时跟踪样片的破坏状况,以及通过DIC技术进行应变分析

检测样品:

合成纤维

检测项:

理化分析

岛津企业管理(中国)有限公司

查看联系电话

前往展位

碳纤维增强聚合物中脱模剂检测方案(红外光谱仪)

Release agents are applied as a liquid that forms a thin film coating to aid removal of carbon-fiber-reinforced polymer (CFRP) parts from a mold or peel ply. This process, however, leads to inevitable contact transfer, causing release agent to remain on the part or repair. Before painting or bonding of the CFRP component to other structures, proper post-treatment to remove vaporizable components of the release agent is required. Improper or inadequate post-treatment leads directly to reduction of bond strength of joined parts or topcoat paint adhesion. The complexity of CFRP systems requires the use of new nondestructive analysis technologies such as FTIR spectroscopy, for the analysis of the surface matrix of the material. The primary objective of this application note is to demonstrate that FTIR spectroscopy can nondestructively measure the level of release agent on a carbon fiber epoxy system before bonding. The analysis uses an Agilent 4100 ExoScan FTIR. This handheld spectrometer enables in-situ inspection during manufacturing, in-service, or repair environments, or ex-situ in a laboratory. The analysis is accomplished in less than 1 minute and does not require any sample pretreatment. This work was part of a joint project commissioned by the European Union entitled ENCOMB (extended nondestructive testing of composite bonds) [1].

检测样品:

合成纤维

检测项:

脱模剂

安捷伦科技(中国)有限公司

查看联系电话

前往展位

涤纶纤维中温度对力学性能的影响检测方案(热机械分析仪)

this study investigates the mechanical behaviour of polyester fibres over a range of temperatures by the use of a number of experimental techniques including tensile, creep and fatigue tests.the influences of temperature on the different mechanical properties is investigated with particular emphasise on the loss of rigidity and reduction of creep and fatigue lifetimes.A precise description of the stress /strain curves of the fibres highlights the effects with respect to the glass transition temperature. The fatigue failure process is precisely detailed and changes, at high temperatures, to the classical fracture morphology observations made of single fibres and yarns provides valuable information about the interpretation of result obtained with single fibre test to fibre assemblies

检测样品:

合成纤维

检测项:

力学性能

仪尊科技有限公司

查看联系电话

前往展位

纤维中流变性能研究检测方案(流变仪)

In this work the unsteady-state contact angle at the interface between polymer melt and carbon black (CB) was measured. The transition of contact angle from an unsteady to a steady state can be divided into three stages, the unsteady thermo-stage, the wetting stage, and the reach of equilibrium contact angle. Subsequently, three critical indices, the unsteady heat-transfer period t0, the retardation time τ, and the contact angle at equilibrium state A∞ are defined herein. The decrease in contact angle against time can be simulated by an exponential decay that involves these three critical indices. Molten polypropylene (PP) and polystyrene (PS) have the smallest equilibrium angle A∞, followed by polybutylene terephthalate (PBT), and polymethyl methacrylate (PMMA) has the greatest angle. Interestingly, this order is strongly related to the solubility parameter of each polymer. The CB coated with sulfonated polyester slightly changes the equilibrium angle A∞, but drastically reduces the retardation

time τ for PP and PBT. This finding indicates that the CB, whose surface is modified by sulfonated polyester, can effectively reduce the compounding time of PP and polyester. Experimental results also reveal that reduce compact density slightly increases A∞ but barely affects τ. Furthermore, modifying PS with polybutadiene particles yields a high contact angle A∞ and a low τ value.

检测样品:

合成纤维

检测项:

流变性能研究

仪尊科技有限公司

查看联系电话

前往展位

仪器信息网行业应用栏目为您提供28篇合成纤维检测方案,可分别用于含量分析检测、力学性能检测,参考标准主要有等