方案详情

文

A microwave-promoted three-step tandem process for the synthesis of bicyclic c-lactams is developed. In all cases examined this led to significantly faster tandem processes producing the bicyclic c-lactams more cleanly and reproducibly compared to standard thermal conditions.

方案详情

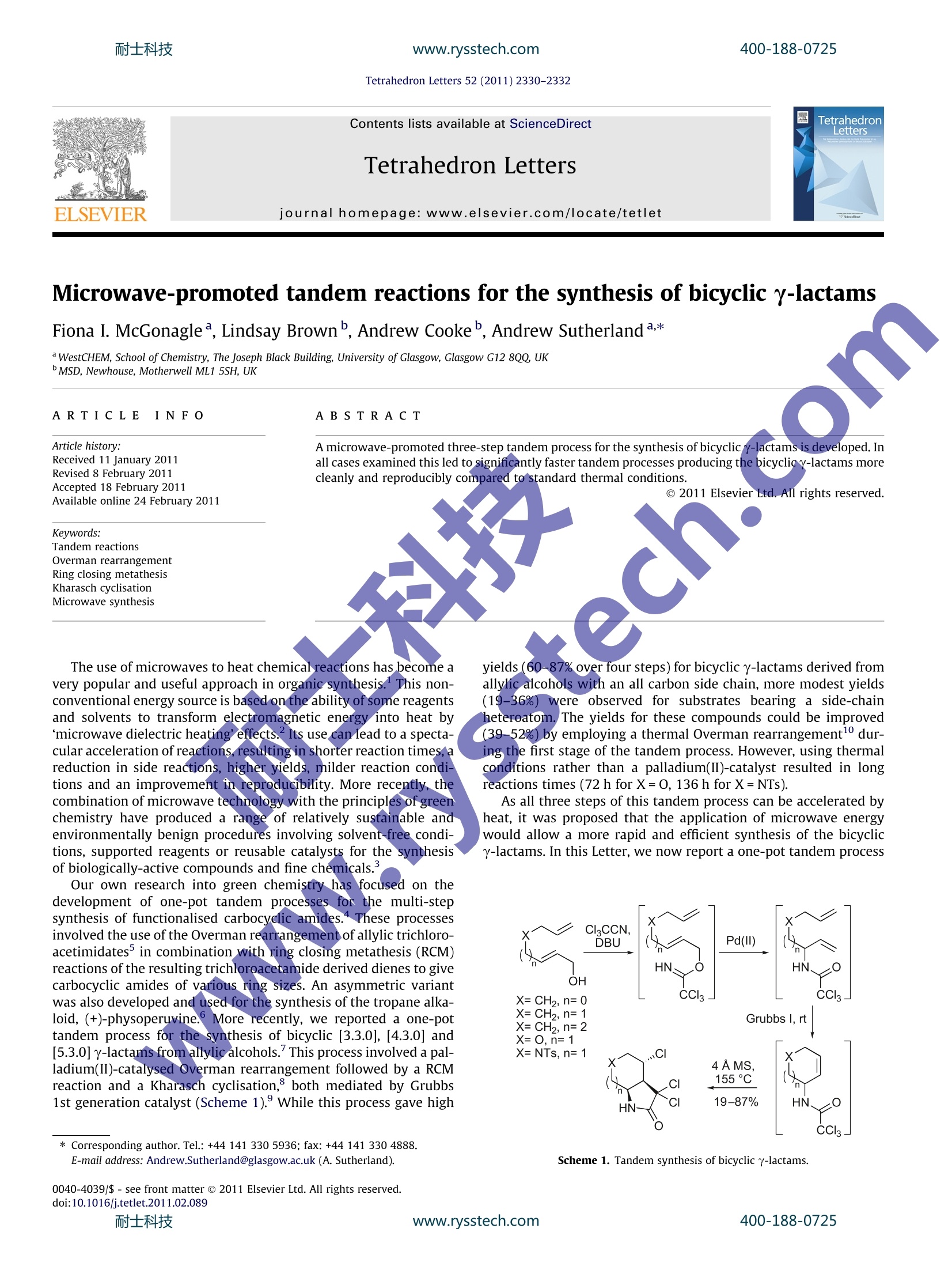

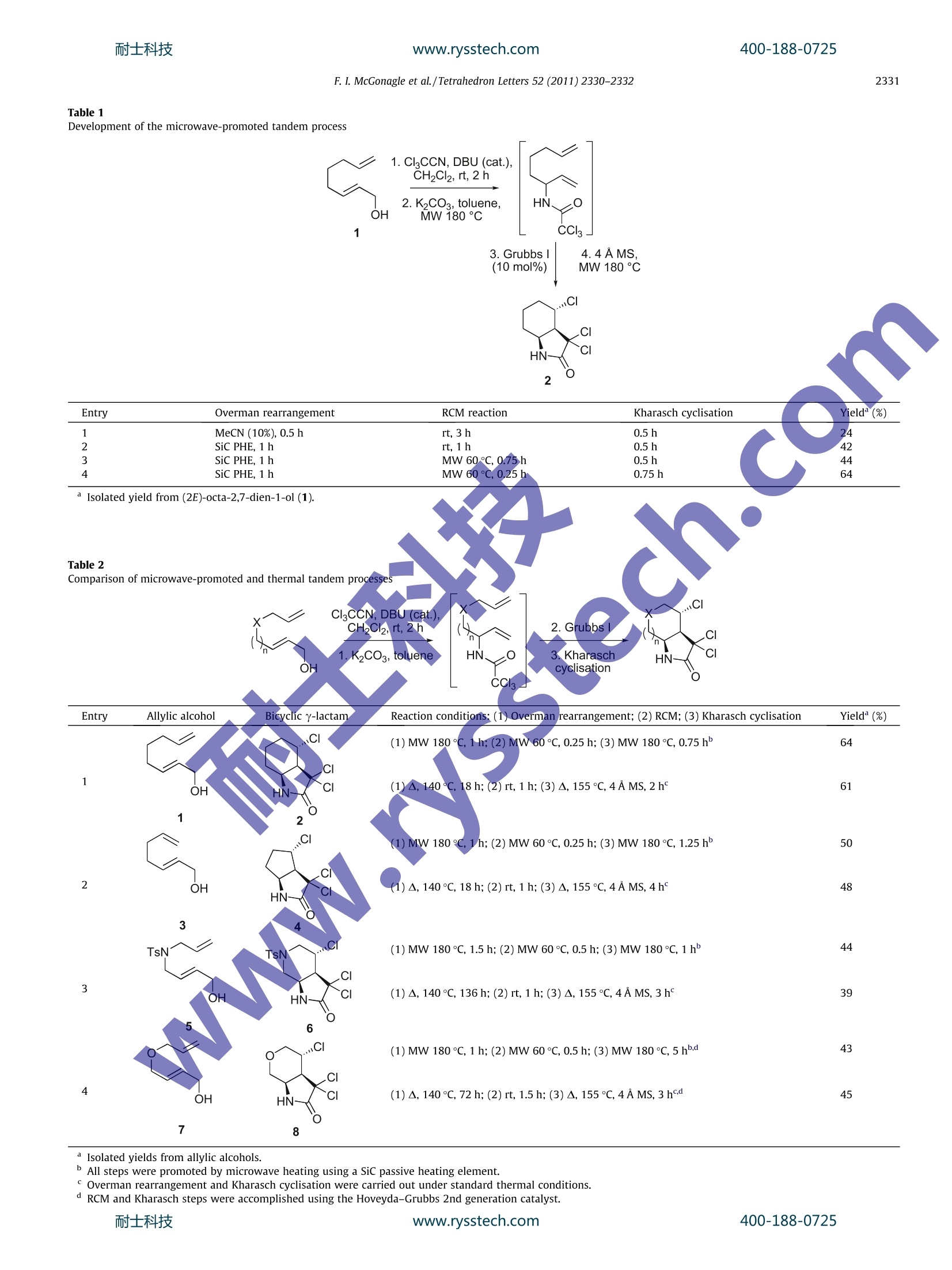

耐士科技400-188-0725www.rysstech.comTetrahedron Letters 52 (2011)2330-2332 Contents lists available at ScienceDirect Tetrahedron Letters ELSEVIER journal homepage: www.elsevier.com/locate/tetlet Microwave-promoted tandem reactions for the synthesis of bicyclic y-lactams Fiona I. McGonagle, Lindsay Brown, Andrew Cooke , Andrew Sutherland a.* WestCHEM, School of Chemistry, The Joseph Black Building, University of Glasgow, Glasgow G12 8QQ, UKPMSD, Newhouse, Motherwell ML1 5SH, UK ARTICL E I N F O ABSTRA C T Article history:Received 11 January 2011Revised 8 February 2011Accepted 18 February 2011Available online 24 February 2011 A microwave-promoted three-step tandem process for the synthesis of bicyclic y-lactams is developed. Inall cases examined this led to significantly faster tandem processes producing the bicyclic y-lactams morecleanly and reproducibly compared to standard thermal conditions. @ 2011 Elsevier Ltd. All rights reserved. Keywords: Tandem reactionsOverman rearrangementRing closing metathesisKharasch cyclisationMicrowave synthesis The use of microwaves to heat chemical reactions has become avery popular and useful approach in organic synthesis. This non-conventional energy source is based on the ability of some reagentsand solvents to transform electromagnetic energy into heat by‘microwave dielectric heating'effects. Its use can lead to a specta-cular acceleration of reactions, resulting in shorter reaction times, areduction in side reactions, higher yields, milder reaction condi-tions and an improvement in reproducibility. More recently, thecombination of microwave technologywith the principles of greenchemistry have produced a range of relatively sustainable andenvironmentally benign procedures involving solvent-free condi-tions, supported reagents or reusable catalysts for the synthesisof biologically-active compounds and fine chemicals. Our own research into green chemistry has focused on thedevelopment of one-pot tandem processess for the multi-stepsynthesis of functionalised carbocyclic amides. These processesinvolved the use of the Overman rearrangement of allylic trichloro-acetimidates in combination with ring closing metathesis (RCM)reactions of the resulting trichloroacetamide derived dienes to givecarbocyclic amides of various ring sizes. An asymmetric variantwas also developed and used for the synthesis of the tropane alka-loid,(+)-physoperuvine.More recently, we reported a one-pottandem process for the synthesis of bicyclic [3.3.0],[4.3.0] and[5.3.0]y-lactams from allylic alcohols. This process involved a pal-ladium(II)-catalysed Overman rearrangement followed by a RCM8reaction and a Kharasch cyclisation, both mediated by Grubbs1st generation catalyst (Scheme 1). While this process gave high ( * C orresponding author. T el.: +44 141 330 5936; fax: +44 141 330 4888. ) yields (60-87% over four steps) for bicyclic y-lactams derived fromallylic alcohols with an all carbon side chain, more modest yields(19-36%) were observed for substrates bearing a side-chainheteroatom. The yields for these compounds could be improved(39-52%) by employing a thermal Overman rearrangement ° dur-ing the first stage of the tandem process.However, using thermalconditions rather than a palladium(II)-catalyst resulted in longreactions times (72 h for X=0, 136h for X=NTs). As all three steps of this tandem process can be accelerated byheat, it was proposed that the application of microwave energywould allow a more rapid and efficient synthesis of the bicyclicy-lactams. In this Letter, we now report a one-pot tandem process Scheme 1. Tandem synthesis of bicyclic y-lactams. ( E-mail address: And r ew.Sutherland@gl a sgow.ac.u k (A. Sutherland). ) Table 1Development of the microwave-promoted tandem process Entry Overman rearrangement Kharasch cyclisation Yield(%) 1 MeCN (10%),0.5 h rt, 3 h 0.5 h 24 2 SiC PHE, 1 h rt, 1 h 0.5h 42 3 SiC PHE, 1 h MW 60 ℃, 0.75 h 0.5 h 44 4 SiC PHE, 1 h MW 60C, 0.25 h 0.75 h 64 Isolated yield from (2E)-octa-2,7-dien-1-ol (1). Table 2Comparison of microwave-promoted and thermal tandem processes .CI Cl,CCN, DBU (cat.), CH2Cl2, rt, 2 h .CI 1.K2CO3, toluen e HN CI OH 0 Reaction conditions: (1) Overman rearrangement; (2) RCM; (3) Kharasch cyclisation Yield (%) (1)MW 180°C,1h; (2) MW 60C, 0.25h; (3) MW 180°C,0.75 h 64 (1) MW 180℃, 1.5 h; (2) MW 60°C, 0.5 h; (3) MW 180℃,1h" 44 (1)A, 140℃, 136 h; (2) rt, 1 h; (3)A, 155℃,4A MS,3h 39 (1) MW 180℃, 1 h; (2) MW 60℃, 0.5 h; (3) MW 180℃, 5 hhd 43 (1)A, 140C, 72 h; (2) rt, 1.5 h; (3)A, 155℃,4A MS, 3 hd 45 Isolated yields from allylic alcohols. " All steps were promoted by microwave heating using a SiC passive heating element. ( · O verman re a rrangement and Kha r asch cyclisation we r e carried out under standard thermal conditions. ) RCM and Kharasch steps were accomplished using the Hoveyda-Grubbs 2nd generation catalyst. for the synthesis of bicyclic y-lactams in which all three-steps areaccelerated using microwave heating. For comparison, the synthe-sis of these compounds under standard thermal conditions is alsodescribed.1. The development of a microwave-assisted tandem process wasinitially studied using (2E)-octa-2,7-dien-1-ol (1) (Table 1). Thiswas converted into the allylic trichloroacetimidate using trichloro-acetonitrile and DBU under standard conditions.2 Our previoustandem process for the synthesis of bicyclic y-lactams used tolu-ene as the solvent. However, toluene is an example of a microwavetransparent solvent due to its inability to absorb effectively themicrowave energy (low tan ǒ value). Thus, our initial attempt in-volved using more polar acetonitrile as a co-solvent (entry 1). TheOverman rearrangement was carried out at 180C in a microwavereactor and was complete in 0.5 h. The reaction vessel was cooledto room temperature and Grubbs 1stgeneration catalyst(10 mol%) was added. After 3 h, molecular sieves were addedand the microwave reactor was again heated to 180°C. Althoughthe three steps were complete in only 4 h, (1S*,5S*,6S*)-5,7,7-tri-chloro-8-oxo-9-azabicyclo[4.3.0]nonane (2) was isolated in only24% overall yield from allylic alcohol 1. 4 With these optimised conditions in hand, a number of otherallylic alcohols were subjected to the microwave-assisted tandemprocess (Table 2).1 For comparison, the three-step tandem processfor each substrate was also performed under standard thermalconditions. In all cases, the bicyclic y-lactams were isolated muchmore cleanly using the microwave-promoted process than underthe standard thermal conditions. However, the most dramatic dif-ference between the two types of reaction conditions is the timerequired for completion of the tandem process. Bicyclic y-lactams2 and 4 could be prepared in 2 and 2.5 h, respectively, under micro-wave conditions, while requiring nearly one day under standardthermal conditions. The heterocyclic analogues 6 and 8 could beprepared in 3 and 6.5 h, respectively, using the microwave-pro-moted process while requiring several days under standard ther-mal conditions. Although the microwave heating of the RCM andKharasch steps does, in most cases, lead to significant shorteningof reaction times,it is the acceleration of the Overman rearrange-ment that leads to the dramatic differences observed between themicrowave and thermal tandem processes.18 Furthermore, while developing the microwave-promoted tandem processes shown inTable 2, it was found that the short reaction times for the Kharaschcyclisation meant that the addition of molecular sieves was notrequired. In summary, a one-pot tandem process where all three-stepsare promoted by microwave heating has been developed for theeffective synthesis of a series of bicyclic y-lactams. These new con-ditions allow the synthesis of the bicyclic y-lactams more cleanly,more reproducibly and in significantly shorter reaction times com-pared to standard thermal conditions. In particular, this new ap-proach circumvents the problems and limitations of usingpalladium(II)-catalysed or thermal Overman rearrangements dur-ing the three-step tandem process for the synthesis of heteroatomderived bicyclic y-lactams. Acknowledgements Financial support from the Scottish Funding Council,i,theUniversity of Glasgow and MSD is gratefullyacknowledged. References and notes For reviews, see: (a) Perreux, L.; Loupy, A. Tetrahedron 2001,57,9199-9223; (b)Hayes, B. L. Aldrichim. Acta 2004, 37, 66-77; (c) de la Hoz, A.; Diaz-Ortiz, A.; Moreno, A. Chem. Soc. Rev. 2005, 34, 164-178. Kaarpppee,, C. O. Angew. Chem., Int. Ed. 2004,43, 6250-6284. For reviews, see: (a) Roberts, B. A., Strauss, C. R. Acc. Chem. Res.2005,38,653- 661;: (b) Polshettiwar, V.; Varma, R. S. Acc. Chem. Res. 2008, 41,629-639;(c)P.tWolshettiwar, V.; Varma, R. S. Chem.. Soc. Rev. 2008,37,1546-1557; (d) Polshettiwar, V.; Nadagouda,M.N.; Varma, R. S. Aust. J. Chem. 2009,62,16-26.4.(a) Swift, M. D.; Sutherland, A. Org. Lett. 2007,9,5239-5242; (b) Swift, M. D.; Donaldson, A.; Sutherland, A. Tetrahedron Lett.2009, 50,3241-3244. 5..Overman,L. E.; Carpenter, N. E. In Organic Reactions; Overman, L. E., Ed.; Wiley:Hoboken, NJ, 2005;66, pp 1-107. and references cited therein. 6.Zaed, A. M.: Swift, M. D.; Sutherland, A. Org. Biomol. Chem. 2009, 7,2678-2680.7 . McMGonagle, F. I.; Brown, L.; Cooke, A.; Sutherland, A. Org. Biomol. Chem. 2010, 8,3418-3425 8..(a) Kharasch, M. S.; Jensen, E. V.; Urry, W. H. Science 1945, 102, 128; (b)Nagashima, H.; Wakamatsu, H.; Ozaki, N.; Ishii, T.; Watanabe, M.; Tajima, T.;Itetoh, K. J. Org. Chem. 1992, 57,1682-1689. 9.(a) Schwab, P.; France, M. B.; Ziller, J. W.; Grubbs, R. H.Angew. Chem., Int. Ed.Engl. 1995, 34, 2039-2041; (b) Schwab, P.; Grubbs, R. H.; Ziller, J. W. J. Am.Chem. Soc. 1996, 118,100-110. 10.(a) Overman, L. E. J. Am. Chem. Soc. 1974,96,597-599;(b)Overman, L. E. J. Am.Chem. Soc. 1976, 98,2901-2910. All allylic alcohols used in this study were prepared as previously reported. SeeRef. 7 for full details. 12. Anderson, C. E.; Overman, L. E.; Watson, M. P. Org. Synth. 2005, 82, 134-139.13. During previous studies on the Kharasch cyclisation of cyclic allylictrichloroacetamides, we found that 4 A molecular sieves act as an effectiveacid scavenger resulting in high yields of products. See Refs. 4b,7 for fulldetails. ( 14. A / lthough racemic, the b i cyclic y-lactams formed from this tandem pro c ess are i solated as single diastereomers. ) ( 15.K r emsner, J. M . ; Kappe, C. O. J. O rg. Chem. 2006, 71, 4651-4658. ) ( 16. G eneral p rocedure: The allylic alcohol (0.4 mmol) w as dissolved i n CH2Cl2 (10 mL) and c ooled t o 0 ℃. To the solution was added DBU (0.5 equiv) and t richloroacetonitrile (1. 5 equiv).The reaction mixture was allowed to warm toroom temperature be f ore st i rring f o r 2 h. The reaction mixture w a s fi l tered through a s h ort pad of s i lica gel a nd the f i ltrate concentrated i n vacuo to give t he a llylic trichloroacetimidate which was used w i thout further purification. The a llylic trichloroacetimidat e was dissolved in t oluene (5mL) a n d transferred to a microwave v ial containing K2CO3 (0.02g) and a s ilicon carbide (SiC) bar. The vial was then sealed under Ar and t he r eaction mixture h eated in a m icrowave reactor (Biotage initiator, 300 W) for the required time at 180℃. Grubbs f i rst-generation catalys t (10 mol%) was added a nd t he mixture was h e ated at 6 0 ℃ un t il c o mplete. The temperature was then raised t o 1 80℃ and he a ting continued unt i l the reaction wa s complete. Purification was c arried out by flash column chromatography eluting with p etroleum ether/EtOAc t o a f ford t h e desired bicyclic y - lactam. ) 17. The use of Hoveyda-Grubbs 2nd generation catalyst for the RCM and Kharaschsteps gave more consistent yields of bicyclic y-lactam 8 than using Grubbs 1stgeneration catalyst. 18..Gonda,J; Martinková, M.; Zadrosova, A.; Soteková, M.; Raschmanova,J.; Conka,P.; Gajdosikova, E.; Kappe, C. O. Tetrahedron Lett. 2007, 48, 6912-6915. $ - see front matter @ Elsevier Ltd. All rights reserved.doi:j.tetlet.ww.rysstech.com耐士科技 士科技www.rysstech.com

确定

还剩1页未读,是否继续阅读?

上海鑫欣生物科技有限公司为您提供《化学药中特殊物质和基团检测方案 》,该方案主要用于化药新药研发中其他检测,参考标准--,《化学药中特殊物质和基团检测方案 》用到的仪器有

相关方案

更多

该厂商其他方案

更多