方案详情

文

A biomimetic approach has been investigated and developed for the total synthesis of azonazine, an unusual marine natural cyclopeptide containing a rigid transannular 10-membered ring. A hypervalent iodine-mediated direct oxidative cyclization was successfully developed and applied to construct the highly strained core, which was the key step in the first total synthesis of ent-()-azonazine. Based on the physical evidences of synthesized diastereomer and enantiomer of azonazine, both the relative and absolute configurations of the natural product were revised. Two fluorinated azonazine derivatives were also synthesized in short convenient steps utilizing the same intermediate in this work. The established total synthesis opens a potential opportunity to study the structureeactivity relationship of natural azonazine.

方案详情

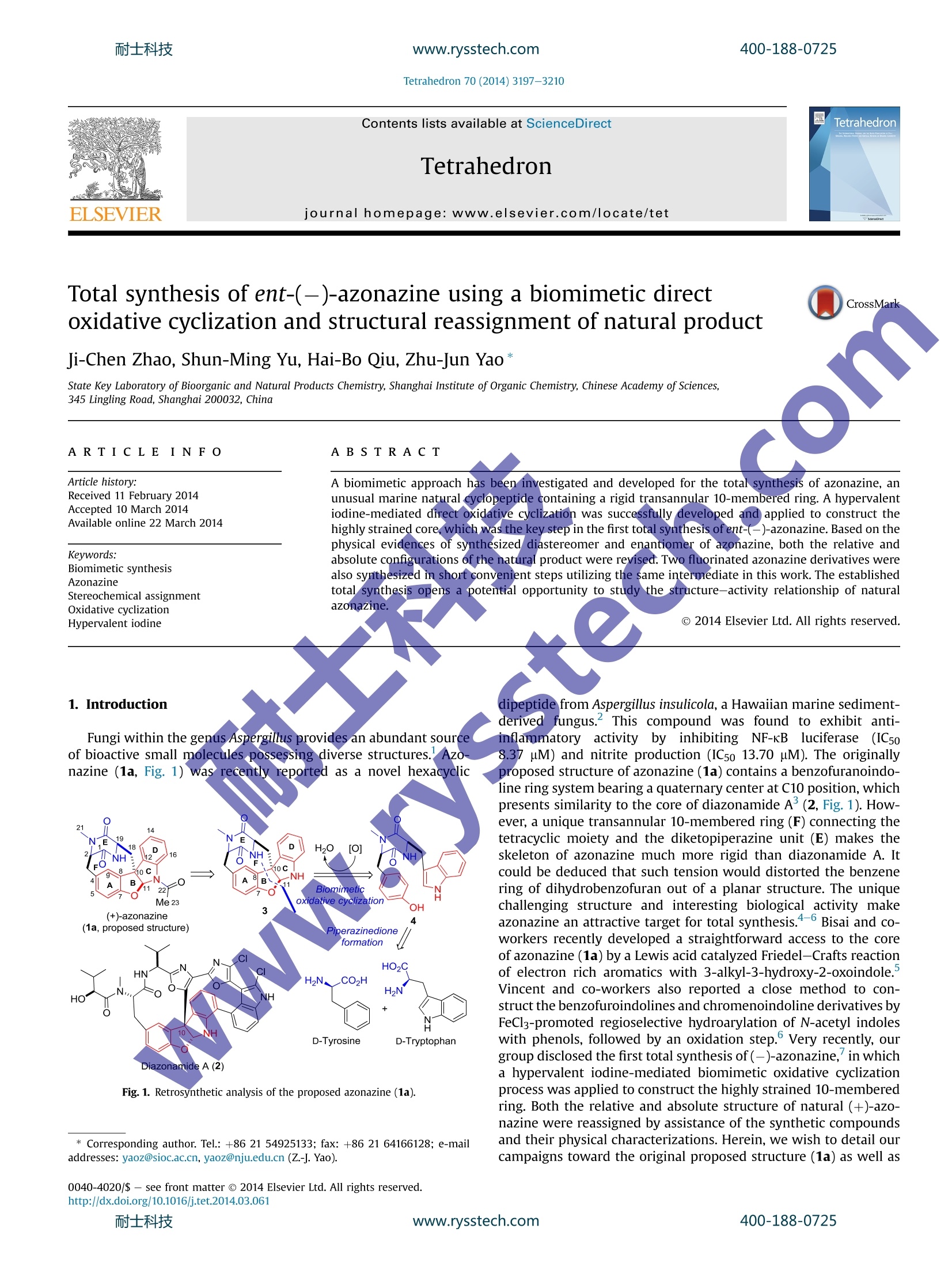

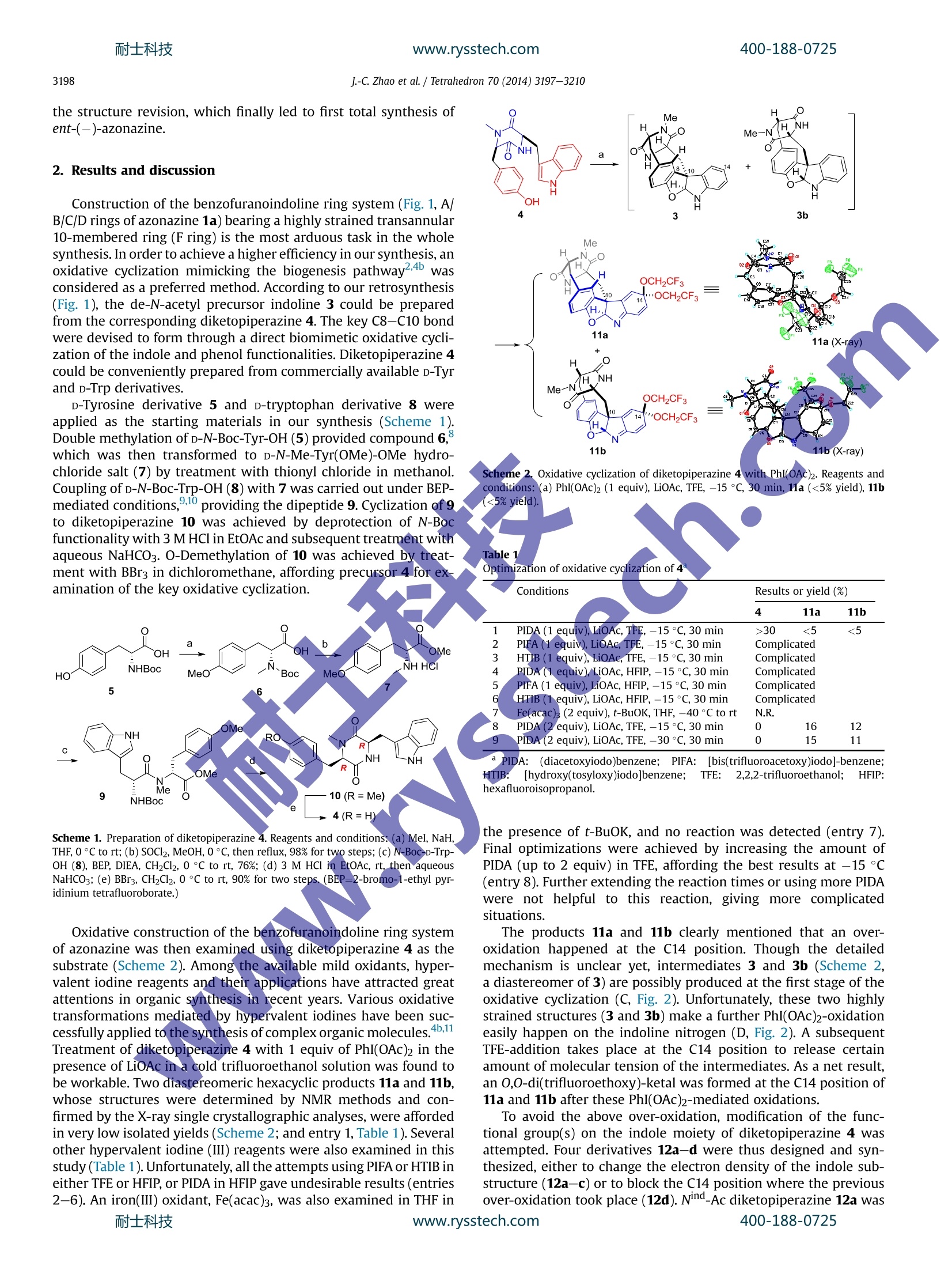

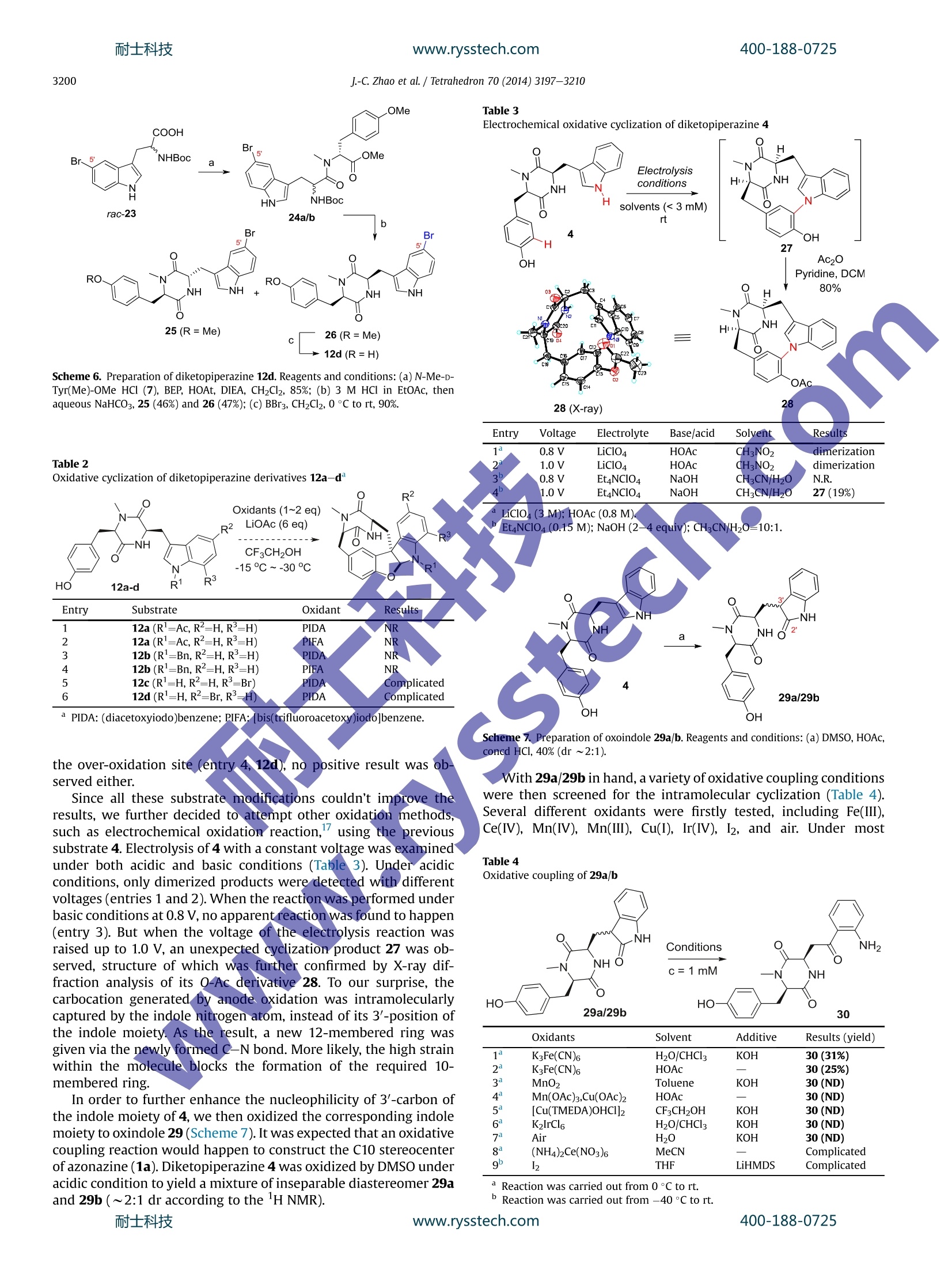

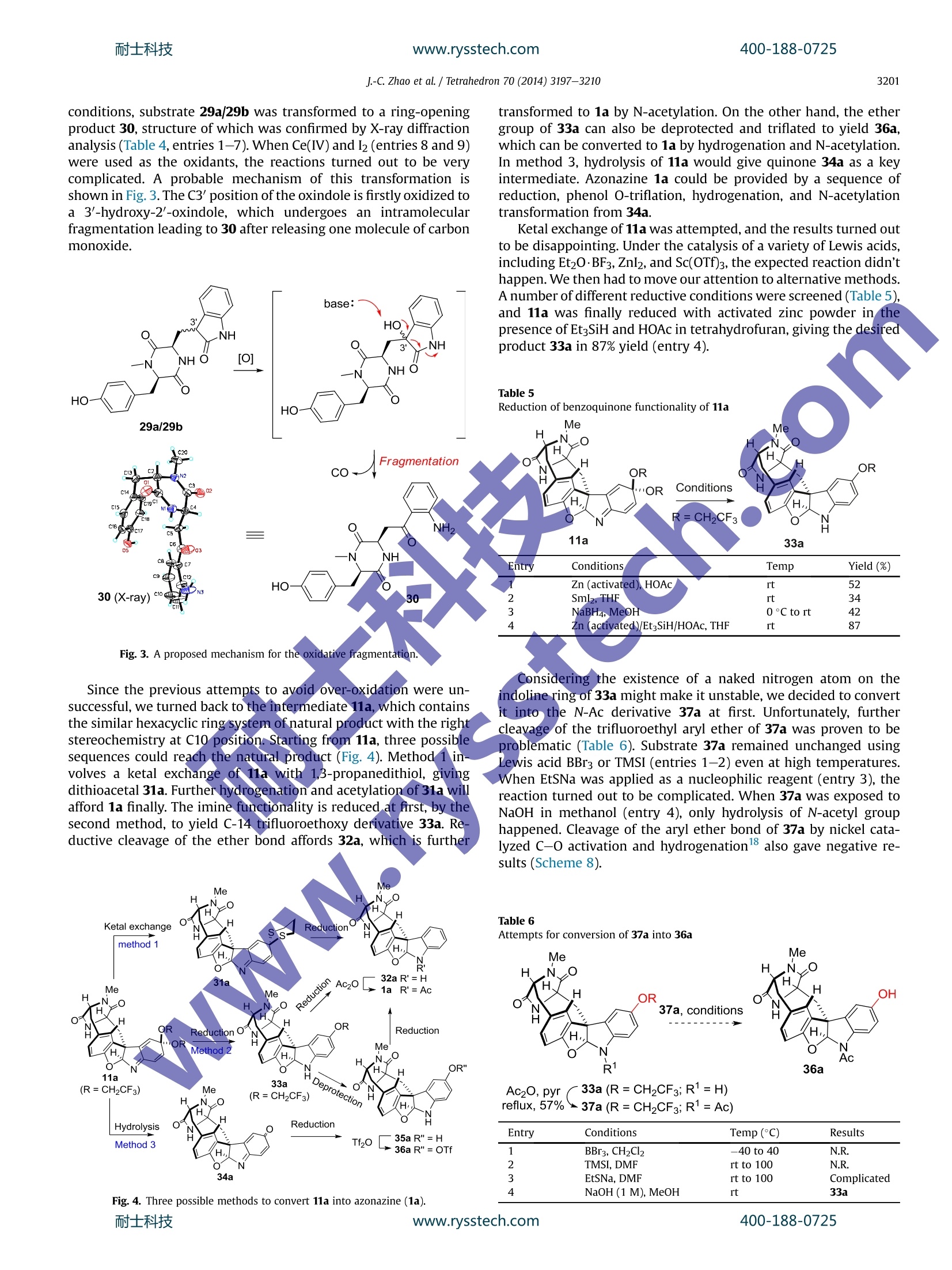

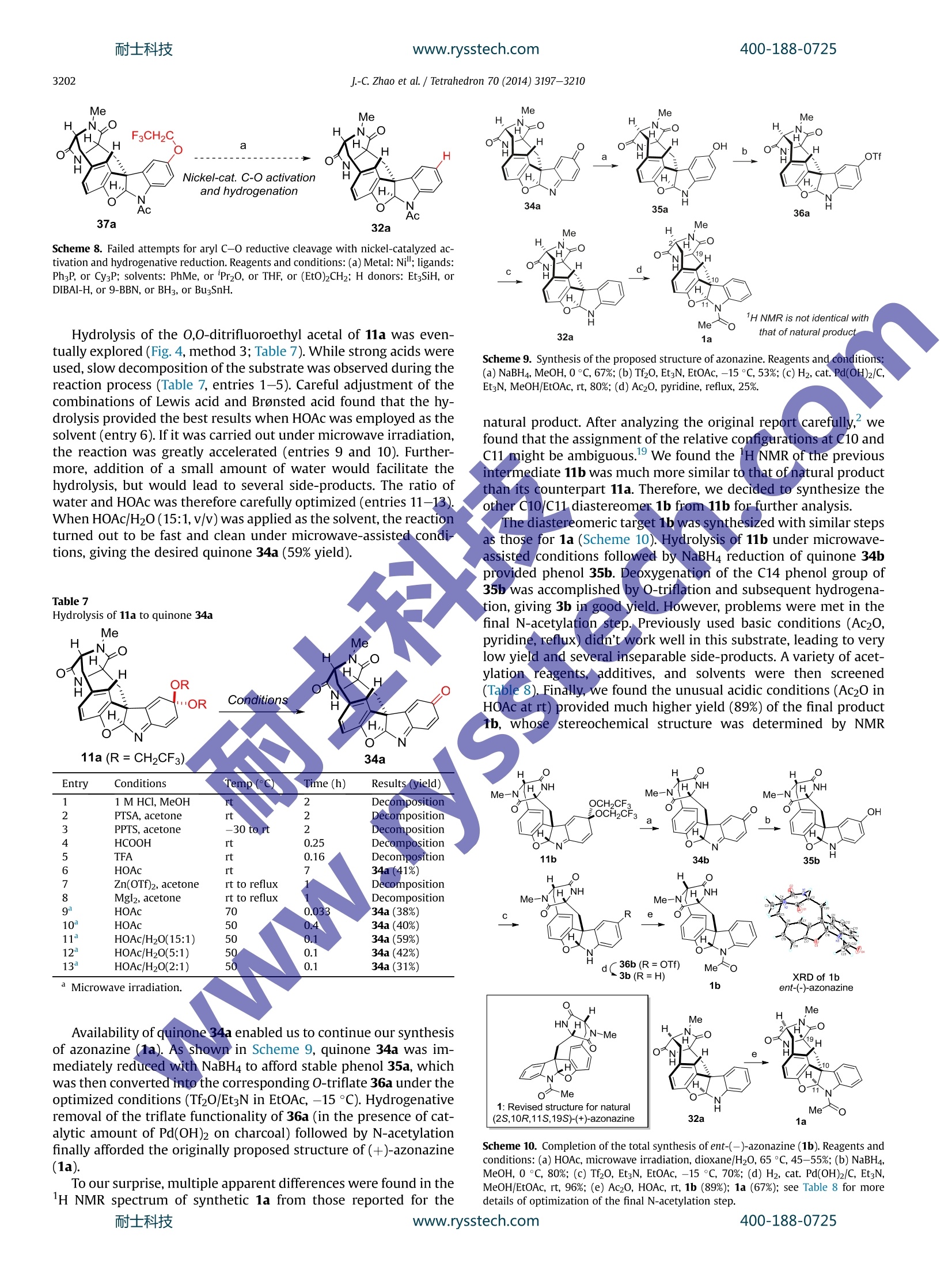

耐士科技400-188-0725www.rysstech.comTetrahedron 70 (2014)3197-3210 耐士科技400-188-0725www.rysstech.comJ.-C. Zhao et al./ Tetrahedron 70 (2014) 3197-32103198 Contents lists available at ScienceDirect Tetrahedron Tetrahedron ELSEVIER journalhomepage: www.elsevier.com/locate/tet Total synthesis of ent-(-)-azonazine using a biomimetic directoxidative cyclization and structural reassignment of natural product Ji-Chen Zhao, Shun-Ming Yu, Hai-Bo Qiu, Zhu-Jun Yao* State Key Laboratory of Bioorganic and Natural Products Chemistry, Shanghai Institute ofOrganic Chemistry, Chinese Academy of Sciences,345 Lingling Road, Shanghai 200032, China ARTICLEINF O ABSTRACT Article history:Received 11 February 2014Accepted 10 March 2014Available online 22 March 2014 Keywords: Biomimetic synthesisAzonazineStereochemical assignmentOxidative cyclizationHypervalent iodine A biomimetic approach has been investigated and developed for the total synthesis of azonazine, anunusual marine natural cyclopeptide containing a rigid transannular 10-membered ring. A hypervalentiodine-mediated direct oxidative cyclization was successfully developed and applied to construct thehighly strained core, which was the key step in the first total synthesis ofent-(-)-azonazine. Based on thephysical evidences of synthesized diastereomer and enantiomer of azonazine, both the relative andabsolute configurations of the natural product were revised. Two fluorinated azonazine derivatives werealso synthesized in short convenient steps utilizing the same intermediate in this work. The establishedtotal synthesis opens a potential opportunity to study the structure-activity relationship of naturalazonazine. 2014Elsevier Ltd. All rights reserved. Fungi within the genus Aspergillus provides an abundant sourceof bioactive small molecules possessing diverse structures.Azo-nazine (1a, Fig.1) was recently reported as a novel hexacyclic Fig. 1. Retrosynthetic analysis of the proposed azonazine (1a). ( * C orresponding a u thor. T el.: +86 215 4 925133; fax: + 8 6 21 64 1 66128; e-mail addresses: ya o z @ si oc.a c .cn, yao z@nju.edu.cn ( Z . -J. Yao). ) dipeptide from Aspergillus insulicola, a Hawaiian marine sediment-deriveld fungus. This compound was found to exhibit anti-inflammatory activity by inhibiting NF-KB luciferase (IC508.37 uM) and nitrite production (IC50 13.70 pM). The originallyproposed structure of azonazine (1a) contains a benzofuranoindo-line ring system bearing a quaternary center at C10 position, whichpresents similarity to the core of diazonamide A(2, Fig.1).How-ever, a unique transannular 10-membered ring (F) connecting thetetracyclic moiety and the diketopiperazine unit (E) makes theskeleton of azonazine much more rigid than diazonamide A. Itcould be deduced that such tension would distorted the benzenering of dihydrobenzofuran out of a planar structure. The uniquechallenging structure and interesting biological activity makeazonazine an attractive target for total synthesis.4-6 Bisai and co-workers recently developed a straightforward access to the coreof azonazine (1a) by a Lewis acid catalyzed Friedel-Crafts reactionof electron rich aromatics with 3-alkyl-3-hydroxy-2-oxoindole.Vincent and co-workers also reported a close method to con-struct the benzofuroindolines and chromenoindoline derivatives bvFeCl3-promoted regioselective hydroarylation of N-acetyl indoleswith phenols, followed by an oxidation step.Very recently, ourgroup disclosed the first total synthesis of(-)-azonazine, in whicha hypervalent iodine-mediated biomimetic oxidative cyclizationprocess was applied to construct the highly strained 10-memberedring. Both the relative and absolute structure of natural (+)-azo-nazine were reassigned by assistance of the synthetic compoundsand their physical characterizations. Herein, we wish to detail ourcampaigns toward the original proposed structure (1a) as well as 2. Results and discussion Construction of the benzofuranoindoline ring system (Fig. 1, A/B/C/D rings of azonazine 1a) bearing a highly strained transannular10-membered ring (F ring) is the most arduous task in the wholesynthesis. In order to achieve a higher efficiency in our synthesis, anoxidative cyclization mimicking the biogenesis pathway2.4b wasconsidered as a preferred method.According to our retrosynthesis(Fig. 1), the de-N-acetyl precursor indoline 3 could be preparedfrom the corresponding diketopiperazine 4. The key C8-C10 bondwere devised to form through a direct biomimetic oxidative cycli-zation of the indole and phenol functionalities. Diketopiperazine 4could be conveniently prepared from commercially available D-Tyrand D-Trp derivatives. D-Tyrosine derivative 5 and p-tryptophan derivative 8 wereapplied as the starting materials in our synthesis (Scheme 1).Double methylation of D-N-Boc-Tyr-OH(5) provided compound 6,i.which was then transformed to D-N-Me-Tyr(OMe)-OMe hydro-chloride salt (7) by treatment with thionyl chloride in methanol.Coupling of D-N-Boc-Trp-OH (8) with 7 was carried out under BEP-mediated conditions,910 providing the dipeptide 9. Cyclization of9to diketopiperazine 10 was achieved by deprotection of N-Bocfunctionality with 3 M HCl in EtOAc and subsequent treatment withaqueous NaHCO3.O-Demethylation of 10 was achieved by treat-ment with BBr3 in dichloromethane, affording precursor 4 for ex-amination of the key oxidative cyclization. Scheme 1. Preparation of diketopiperazine 4. Reagents and conditions: (a) MeI, NaH,THF,0 °C to rt;(b) SOCl2,MeOH,0°C, then reflux, 98% for two steps; (c) N-Boc-D-Trp-OH (8), BEP, DIEA, CH2Cl2, 0 °C to rt, 76%; (d) 3 M HCl in EtOAc, rt, then aqueousNaHCO3; (e) BBr3, CH2Cl2, 0 °C to rt, 90% for two steps. (BEP=2-bromo-1-ethyl pyr-idinium tetrafluoroborate.) Oxidative construction of the benzofuranoindoline ring systemof azonazine was then examined using diketopiperazine 4 as thesubstrate (Scheme 2). Among the available mild oxidants, hyper-valent iodine reagents and their applications have attracted greatattentions in organic synthesis in recent years. Various oxidativetransformations mediated by hypervalent iodines have been suc-cessfully applied to the synthesis of complex organic molecules.4b.11Treatment of diketopiperazine 4 with 1 equiv of PhI(OAc)2 in thepresence of LiOAc in a cold trifluoroethanol solution was found tobe workable. Two diastereomeric hexacyclic products 11a and 11b,whose structures were determined by NMR methods and con-firmed by the X-ray single crystallographic analyses, were affordedin very low isolated yields (Scheme 2; and entry 1, Table 1). Severalother hypervalent iodine (III) reagents were also examined in thisstudy (Table1). Unfortunately, all the attempts using PIFA or HTIB ineither TFE or HFIP, or PIDA in HFIP gave undesirable results (entries2-6). An iron(III) oxidant, Fe(acac)3, was also examined in THF in Scheme 2. Oxidative cyclization of diketopiperazine 4 with PhI(OAc)2. Reagents andconditions: (a) PhI(OAc)2 (1 equiv), LiOAc, TFE, -15 °C, 30 min, 11a (<5% yield), 11b(<5%yield). Table1Optimization of oxidative cyclization of 4 Conditions Results or yield(%) 4 11a 11b 1 PIDA (1 equiv), LiOAc, TFE, -15 °C, 30 min >30 <5 <5 2 PIFA (1 equiv), LioAc, TFE, -15 °C, 30 min Complicated 3 HTIB (1 equiv),LiOAc, TFE,-15 °C, 30 min Complicated 4 PIDA (1 equiv), LiOAc, HFIP, -15 °C, 30 min Complicated PIFA (1 equiv), LiOAc, HFIP,-15°C, 30 min Complicated HTIB (1 equiv), LiOAc, HFIP,-15C, 30 min Complicated Fe(acac)3 (2 equiv), t-BuOK, THF, -40 °C to rt N.R. PIDA (2 equiv),LiOAc, TFE, -15°C, 30 min 19 PIDA (2 equiv),LiOAc, TFE, -30 °C, 30 min PIDA: (diacetoxyiodo)benzene;PIFA:A:[bis(trifluoroacetoxy)iodo]-benzene;B [hydroxy(tosyloxy)iodo]benzene;;TFE:2,2,2-trifluoroethanol;HFIP:hexafluoroisopropanol. the presence of t-BuOK, and no reaction was detected (entry 7).Final optimizations were achieved by increasing the amount ofPIDA (up to 2 equiv) in TFE, affording the best results at -15 C(entry 8). Further extending the reaction times or using more PIDAwere not helpful to this reaction, giving more complicatedsituations. The products 11a and 11b clearly mentioned that an over-oxidation happened at the C14 position. Though the detailedmechanism is unclear yet, intermediates 3 and 3b (Scheme 2,a diastereomer of 3) are possibly produced at the first stage of theoxidative cyclization (C, Fig. 2). Unfortunately, these two highlystrained structures (3 and 3b) make a further PhI(OAc)2-oxidationeasily happen on the indoline nitrogen (D, Fig.2). A subsequentTFE-addition takes place at the C14 position to release certainamount of molecular tension of the intermediates. As a net result,an O,0-di(trifluoroethoxy)-ketal was formed at the C14 position of11a and 11b after these PhI(OAc)2-mediated oxidations. To avoid the above over-oxidation, modification of the func-tional group(s) on the indole moiety of diketopiperazine 4 wasattempted. Four derivatives 12a-d were thus designed and syn-thesized, either to change the electron density of the indole sub-structure (12a-c) or to block the C14 position where the previousover-oxidation took place (12d). Nind-Ac diketopiperazine 12a was synthesized using Nind_Ac-D-Trp derivative 1312 and N-Me-Boc-p-Try("Bu)-OH (14) as the starting materials. Compound 13 wasdeprotected and coupled with 14 to yield dipeptide 15. Depro-tection of the N-Boc functionality followed by ring-closing undermicrowave-assisted conditionsafforded 12a in satisfactory yields(Scheme 3). Scheme 3. Synthesis of diketopiperazine 12a. Reagents and conditions: (a) 3 M HCl inEtOAc; (b) N-Me-Boc-D-Tyr(Bu)-OH (14), EDCI, HOBt, DIEA, CH2Cl2, 0 °C to rt, 76% fortwo steps; (c)3 M HCl in EtOAc;(d)"BuOH/NMM/HOAc, MW, 100 °C, 83% for two steps. Accordingly, Nind Bn diketopiperazine 12b was obtained usingD-Nind-Bn Trp derivative 1614 and D-Tyr derivative 7 as the startingmaterials. Hydrolysis of 16 followed by coupling with 7 gave di-peptide 17, which was further transformed to 12b by a sequence ofdeprotection, cyclization, and O-demethylation (Scheme 4). A racemic material of N-Ac-(7'-Br-Trp)-0H (18)15 was used asthe starting material to synthesize 7'-Br substituted diketopiper-azine 12c. After amino-protecting group exchange, compound 18 Scheme 4. Preparation of diketopiperazine 12b. Reagents and conditions: (a) NaOH,H2O/MeOH;(b)N-Me-D-Tyr(Me)-OMe HCl (7), BEP, DIEA, CH2Cl2,0°C to rt, 71% for twosteps; (c) 3 M HCl in EtOAc; (d) NaHCO3 (aqueous);(e) BBr3, DCM, 0 °C to rt, 79% forthree steps. was transformed to rac-N-Boc-Trp derivative 19, which was reactedwith D-Tyr derivative 7 to yield a mixture of two dipeptide di-astereomers 20a and 20b. Both of them were further converted intotwo separable diketopiperazine 21 and 22 by a sequence of acidicdeprotection and alkalic cyclization. Diketopiperazine substrate 12cwas finally obtained by O-demethylation of 22 (Scheme 5). Scheme 5. Preparation of diketopiperazine 12c. Reagents and conditions:(a)6 M HCI,reflux; (b) Boc20, NaOH, THF/H20, 70% for two steps;(c) N-Me-D-Tyr(OMe)-OMe HCl(7), BEP, HOBt, CH2Cl2, 65%;(d) 3 M HCl in EtOAc, then aqueous NaHCO3,21(41%), and22(43%);(e) BBr3, CH2Cl2,0 °C to rt, 85%. 5'-Bromo-diketopiperazine 12d was designed to block the C14position where the over-oxidation happened. Starting with rac-N-Boc-(5'-Br-Trp)-OH (23)16 and 7, a mixture of two dipeptide di-astereomers 24a and 24b were synthesized. After similar depro-tection and cyclization, diketopiperazine 25 and 26 were obtained.O-Demethylation of 26led1 to the desired substrate 1:(Scheme 6). Al four cyclopeptide derivatives 12a-d were examined underoxidative cyclization conditions, but the results turned out to bedisappointing (Table2). When the indole nitrogen was protectedeither by an electron-withdrawing group (Ac, entry 1, 12a) or anelectron-donating group (Bn, entry 2, 12b), the correspondingsubstrates displayed no reactivity under the oxidation conditions.This indicated that the free indole nitrogen (NH) was an essentialgroup for the oxidative cyclization process initiated by PIDA. Whena bromine atom was introduced into 7' position of the indolemoiety to decrease the electron density (entry 3, 12c), the reactionturned out to be very complicated. Furthermore, when 5' positionof the indole moiety was substituted by a bromine atom to block Scheme 6. Preparation of diketopiperazine 12d. Reagents and conditions:(a) N-Me-D-Tyr(Me)-0Me HCl (7), BEP, HOAt, DIEA, CH2Cl2, 85%; (b) 3 M HCl in EtOAc, thenaqueous NaHCO3,25 (46%) and 26 (47%);(c) BBr3, CH2Cl2,0°C to rt, 90%. Table 2Oxidative cyclization of diketopiperazine derivatives 12a-d Entry Substrate Oxidant Results 1 12a (R=Ac, R²=H,R=H) PIDA NR 2 12a(R=Ac,R²=H,R=H) PIFA NR 3 12b (R=Bn,R²=H,R=H) PIDA NR 4 12b (R=Bn, R²=H,R=H) PIFA NR 5 12c (R=H, R²=H,R=Br) PIDA Complicated 6 12d(R'=H,R=Br, R=H) PIDA Complicated a PIDA: (diacetoxyiodo)benzene; PIFA: [bis(trifluoroacetoxy)iodo]benzene. the over-oxidation site (entry 4,12d), no positive result was ob-served either. Since all these substrate modifications couldn't improve theresults, we further decided to attempt other oxidation methods,such as electrochemical oxidation reaction,using the previoussubstrate 4. Electrolysis of 4 with a constant voltage was examinedunder both acidic and basic conditions (Table3). Under acidicconditions, only dimerized products were detected with differentvoltages (entries 1and 2). When the reaction was performed underbasic conditions at 0.8V, no apparent reaction was found to happen(entry 3). But when the voltage of the electrolysis reaction wasraised up to 1.0 V, an unexpected cyclization product 27 was ob-served, structure of which was further confirmed by X-ray dif-fraction analysis of its O-Ac derivative28. To our surprise, thecarbocation generated by anode oxidation was intramolecularlycaptured by the indole nitrogen atom, instead of its 3'-position ofthe indole moiety.As the result, a new 12-membered ring wasgiven via the newly formed C-N bond. More likely, the high strainwithin the molecule blocks the formation of the required 10-membered ring. In order to further enhance the nucleophilicity of 3'-carbon ofthe indole moiety of 4, we then oxidized the corresponding indolemoiety to oxindole 29 (Scheme7). It was expected that an oxidativecoupling reaction would happen to construct the C10 stereocenterof azonazine (1a). Diketopiperazine 4 was oxidized by DMSO underacidic condition to yield a mixture of inseparable diastereomer 29aand 29b (~2:1 dr according to the HNMR). Table 3 Electrochemical oxidative cyclization of diketopiperazine 4 Entry Voltage1.0 V LiClO4 HOAc CH3NO2 dimerization0.8 V Et4NClO4 NaOH CH3CN/H2O N.R.1.0 V Et4NClO4 NaOH CH3CN/H2O 27(19%) LiCl04 (3 M); HOAc (0.8 M) Et4NCl04(0.15M); NaOH (2-4 equiv); CH;CN/H20=10:1. Scheme 7. Preparation of oxoindole 29a/b. Reagents and conditions: (a) DMSO, HOAc,concd HCl, 40%(dr ~2:1). With 29a/29b in hand, a variety of oxidative coupling conditionswere then screened for the intramolecular cyclization (Table 4).Several different oxidants were firstly tested, including Fe(ⅢI),Ce(IV), Mn(IV), Mn(Il), Cu(I), Ir(IV), I2, and air. Under most Table 4Oxidative coupling of 29a/b o NH Conditions NH2 NH 0 0 C=1mM NH 0 HO- HO- 29a/29b 30 Oxidants Solvent Additive Results (yield) 1 K3Fe(CN)6 H2O/CHC3 KOH 30 (31%) 2 K3Fe(CN)6 HOAc 30 (25%) 3 Mn02 Toluene KOH 30 (ND) 4 Mn(OAc)3,Cu(OAc)2 HOAc _ 30 (ND) 5 [Cu(TMEDA)OHCl]2 CF3CH2OH KOH 30 (ND) 6 K2IrCl6 H2O/CHCl3 KOH 30 (ND) 7 Air H20 KOH 30 (ND) 8 (NH4)2Ce(NO3)6 MeCN Complicated 9 12 THF LiHMDS Complicated Reaction was carried out from 0°C to rt. Reaction was carried out from -40 °C to rt. conditions, substrate 29a/29b was transformed to a ring-openingproduct 30, structure of which was confirmed by X-ray diffractionanalysis (Table 4,entries 1-7). When Ce(IV) and I2 (entries 8 and 9)were used as the oxidants, the reactions turned out to be verycomplicated. A probable mechanism of this transformation isshown in Fig. 3. The C3' position of the oxindole is firstly oxidized toa 3'-hydroxy-2'-oxindole, which undergoes an intramolecularfragmentation leading to 30 after releasing one molecule of carbonmonoxide. Fig. 3. A proposed mechanism for the oxidative fragmentation. Since the previous attempts to avoid over-oxidation were un-successful, we turned back to the intermediate 11a,which containsthe similar hexacyclic ring system of natural product with the rightstereochemistry at C10 position. Starting from 11a, three possiblesequences could reach the natural product (Fig. 4). Method 1 involves a ketal exchange of 11a with 1,3-propanedithiol, givingdithioacetal 31a. Further hydrogenation and acetylation of 31a willafford 1a finally. The imine functionality is reduced at first, by thesecond method, to yield C-14 trifluoroethoxy derivative 33a. Re-ductive cleavage of the ether bond affords 32a, which is further Fig. 4. Three possible methods to convert 11a into azonazine (1a). transformed to 1a by N-acetylation. On the other hand, the ethergroup of 33a can also be deprotected and triflated to yield 36a,which can be converted to 1a by hydrogenation and N-acetylation.In method 3, hydrolysis of 11a would give quinone 34a as a keyintermediate. Azonazine 1a could be provided by a sequence ofreduction, phenol O-triflation, hydrogenation, and N-acetylationtransformation from 34a. Ketal exchange of 11a was attempted,and the results turned outto be disappointing. Under the catalysis of a variety of Lewis acids,including Et2O·BF3, ZnI2, and Sc(OTf)3, the expected reaction didn'thappen. We then had to move our attention to alternative methods.A number of different reductive conditions were screened (Table 5),and 11a was finally reduced with activated zinc powder in thepresence of Et3SiH and HOAc in tetrahydrofuran, giving the desiredproduct 33a in 87% yield (entry 4). Considering tthe existence of a naked nitrogen atom on theindoline ring of 33a might make it unstable, we decided to convertitinto the N-Ac derivative 37a at first. Unfortunately, furthercleavage of the trifluoroethyl aryl ether of 37a was proven to beproblematic (Table 6). Substrate 37a remained unchanged usingLewis acid BBr3 or TMSI (entries 1-2) even at high temperatures.When EtSNa was applied as a nucleophilic reagent (entry 3), thereaction turned out to be complicated. When 37a was exposed toNaOH in methanol (entry 4), only hydrolysis of N-acetyl grouphappened. Cleavage of the aryl ether bond of 37a by nickel cata-lyzed C-O activation and hydrogenation also gave negative re-sults (Scheme 8). Table 6Attempts for conversion of 37a into 36a Me Me H .0 H H OH o' OR 37a, conditions H, H. O Ac R1 36a Ac2O, pyr-33a (R=CH2CF3;R1=H) reflux, 57% -37a (R=CH2CF3;R1=Ac) Entry Conditions Temp (C) Results 1 BBr3, CH2Cl2 -40 to 40 N.R. 2 TMSI, DMF rt to 100 N.R. 3 EtSNa, DMF rt to 100 Complicated 4 NaOH(1 M), MeOH rt 33a Scheme 8. Failed attempts for aryl C-O reductive cleavage with nickel-catalyzed ac-tivation and hydrogenative reduction. Reagents and conditions: (a) Metal: Ni'; ligands:Ph3P, or Cy3P; solvents: PhMe, or 'Pr20, or THF, or (EtO)2CH2; H donors: Et SiH, orDIBAl-H, or 9-BBN, or BH3, or BuzSnH. Hydrolysis of the O,0-ditrifluoroethyl acetal of 11a was even-tually explored (Fig. 4, method 3; Table 7). While strong acids wereused, slow decomposition of the substrate was observed during thereaction process (Table 7, entries 1-5). Careful adjustment of thecombinations of Lewis acid and Bronsted acid found that the hy-drolysis provided the best results when HOAc was employed as thesolvent (entry 6). If it was carried out under microwave irradiation,the reaction was greatly accelerated (entries 9 and 10). Further-more, addition of a small amount of water would facilitate thehydrolysis, but would lead to several side-products. The ratio ofwater and HOAc was therefore carefully optimized (entries 11-13).When HOAc/H20(15:1,v/v) was applied as the solvent, the reactionturned out to be fast and clean under microwave-assistedcondi-tions, giving the desired quinone 34a (59% yield). Entry Conditions Temp(C叭 Time (h) Results (yield) 1M HCl, MeOH Decomposition PTSA,acetone Decomposition PPTS,acetone -30 to rt Decomposition HCOOH rt 0.25 Decomposition TFA rt 0.16 Decomposition HOAc rt 7 34a(41%) Zn(OTf)2, acetone rt to reflux Decomposition 11 Mgl2, acetone rt to reflux Decomposition HOAc 0.033 34a (38%) HOAc 0.44 34a (40%) HOAc/H20(15:1) 0.1 34a (59%) HOAc/H20(5:1) 0.1 34a (42%) HOAc/H2O(2:1) 0.1 34a (31%) Microwave irradiation. Availability of quinone 34a enabled us to continue our synthesisof azonazine (1a). As shown in Scheme 9, quinone 34a was im-mediately reduced with NaBH4 to afford stable phenol 35a, whichwas then converted into the corresponding O-triflate 36a under theoptimized conditions (Tf2O/Et3N in EtOAc, -15 °C). Hydrogenativeremoval of the triflate functionality of 36a (in the presence of cat-alytic amount of Pd(OH)2 on charcoal) followed by N-acetylationfinally afforded the originally proposed structure of (+)-azonazine(1a). To our surprise, multiple apparent differences were found in theH NMR spectrum of synthetic 1a from those reported for the Scheme 9. Synthesis of the proposed structure of azonazine. Reagents and conditions:(a) NaBH4,MeOH,0°C, 67%; (b) Tf2O, Et3N, EtOAc, -15 °C, 53%; (c) H2, cat. Pd(OH)2/C,Et3N, MeOH/EtOAc, rt, 80%; (d) Ac20, pyridine, reflux, 25%. natural product. After analyzing the original report carefully, wefound that the assignment of the relative configurations at C10 andC11might be ambiguous.1 we found the H NMR of the previousintermediate 11bwas much more similar to that of natural productthan its counterpart 11a. Therefore, we decided to synthesize theother C10/C11 diastereomer 1b from 11b for further analysis. The diastereomeric target 1b was synthesized with similar stepsas those for 1a (Scheme 10). Hydrolysis of 11b under microwave-assisted conditions followed by NaBH4 reduction of quinone 34bprovided phenol 35b. Deoxygenation of the C14 phenol group of35b was accomplished by O-triflation and subsequent hydrogena-tion, giving 3b in good yield. However, problems were met in thefinal N-acetylation step. Previously used basic conditions (Ac20,pyridine, reflux) didn’t work well in this substrate, leading to verylow yield and several inseparable side-products. A variety of acet-ylation reagents, additives, and solvents were then screened(Table 8). Finally, we found the unusual acidic conditions (Ac2O inHOAc at rt) provided much higher yield (89%) of the final product1b, whose stereochemical structure was determined by NMR Scheme 10. Completion of the total synthesis of ent-(-)-azonazine (1b). Reagents andconditions: (a) HOAc, microwave irradiation, dioxane/H20, 65 °C, 45-55%; (b) NaBH4,MeOH,0 °C, 80%; (c) Tf20, Et3N, EtOAc,-15 °C, 70%; (d) H2, cat. Pd(OH)2/C, Et3N,MeOH/EtOAc, rt, 96%; (e) Ac20, HOAc, rt, 1b (89%); 1a (67%); see Table 8 for moredetails of optimization of the final N-acetylation step. Table 8Conditions for selective N-acetylation of 3b Entry Conditions Temp(°C) 1b(%) Ac20,DCM/Py (5:1), 48 h Ac2O, Py,4 h Ac2O, Py, 30 min Ac2O, TEA, DCM,11 h Reflux 8 AcCl, TEA, DMF rt Complicated Ac2O, TEA, DMF, DMAP (0.05 equiv) -30°C to rt _b HOAc, HATU, DIEA, DMF 0 °C to rt N.R. HOAc, BEP, DIEA, DMF o°C to rt N.R. 1-Acetylimidazole, TEA, DMF o°C to rt N.R. Ac2O, AcOH rt 89 Microwave irradiation. No desired product were found. methods and further confirmed by an X-ray single crystal diffrac-tion experiment. The optimized acidic N-acetylation conditionswere also workable to convert 32a into 1a (previously in Scheme 9,25% yield) in an improved yield (67%, Scheme 10). Scheme 11. Convenient synthesis of fluorinated azonazine analogues 33a and 33b.Reagents and conditions:(a) EtsSiH, Zn, HOAc, THF, rt;(b) Ac20, AcOH, rt. Compound33a (70% for two steps); 33b (67% for two steps). 3. Conclusions In summary, we have successfully accomplished the first totalsynthesis of ent-(-)-azonazine. A biomimetic direct oxidative cy-clization has been successfully developed and applied as the key step to construct the highly strained hexacyclic core of azonazine.An unusual product 28 contains a 12-membered ring via new spC-N bond formation in the electrochemical oxidation furtherconfirmed that high strain exists within the natural skeleton. Byanalysis of spectroscopic evidences and X-ray single crystal studiesof the synthesized enantiopure diastereomers, the absolute ste-reochemistry of natural (+)-azonazine was unambiguously revisedas (2S,10R,11S,19S)-1. In addition, two intermediates produced inthis work were utilized to the synthesis of corresponding fluori-nated azonazine derivatives in short convenient steps. Biologicalproperties of these unnatural products including the two-fluori-nated derivatives are currently under investigation in our labora-tory and will be reported in due course. 4. Experimental section 4.1. General All reactions were carried out in flame-dried glassware withmagnetic stirring and monitored by thin-layer chromatography(TLC). THF was distilled from sodium; dichloromethane was dis-tilled from CaH2; and ethyl acetate was dried over K2CO3 and dis-tilled. All melting points were uncorrected.H NMR was recordedon a Varian instrument(300 or 500 MHz) and a Bruker instrument(400 or 600 MHz);13CNMR were recorded on a Varian instrument(75 or 125 MHz) and a Bruker instrument (100 or 150 MHz). IRspectra were recorded on Nicolet 380 FT-IR instrument. Opticalrotations were measured on a Jasco P-1030 digital polarimeter.High resolution mass spectra (HRMS) were measured on an Ion-Spec 4.7 Tesla FTMS spectrometer. Flash column chromatographieswere performed on silica gel H (10-40 um). MPLC purification wasperformed using a Biotage Isolera system and KP-SIL SNAP flashcartridge column packed with silica gel (particle size 50-60 mi-cron,50-52 A pore size). Microwave reactions were run on a CEMDiscover S Microwave Synthesizer. X-ray intensity data were col-lected on a Bruker APEX-II CCD area detector employing graphite-monochromated Cu-Ka radiation (l=1.54178 A) at a temperatureof 296(2)K. 4.2. D-N-Me-Tyr(Me)-OMe·HCl (7) To a solution of D-Boc-Tyr-OH(5)(50.0g, 178 mmol) in 500 ml ofdry THF under N2 atmosphere at 0 °C was added sodium hydride(60% oil dispersion, 35.6 g, 890 mmol, 5 equiv) in portions. Theresulting reaction mixture was stirred at 0 °C for 15 min, andmethyl iodide (44.3 ml, 712 mmol, 4 equiv) was then added. Thereaction was stirred overnight at rt. The excess sodium hydride wasquenched by the careful addition of water, and the solvents wereremoved in vacuo. The residue was diluted with 300 ml of waterand washed with Et20. The aqueous phase was then acidified withKHSO4 (to pH 3) and was extracted with EtOAc. The combinedextracts were successively washed with aqueous Na2S203 andbrine, dried over Na2SO4, and concentrated in vacuo. The resultingcrude compound 6 was used directly for the next step. The above crude product was dissolved in methanol (400 ml)and cooled down to 0 °C under N2 atmosphere. Thionyl chloride(14.3 ml, 196 mmol, 1.1 equiv) was slowly added to the reactionsystem. The resulting mixture was stirred at 0 °C for 0.5 h, and thenrefluxed for 2 h. The solvents were removed in vacuo to give 7 aswhite solid (45.3 g, 174 mmol, 98% for two steps).Mp: 152-155°C.a]25.2-31.3 (c1.0, MeOH); IR (KBr): 3417, 2954, 2834, 2691, 2433,1745, 1612,1514,1249,1029,835 cm-1;1H NMR(500 MHz, DMSO-d6); 9.88 (br s, 2H), 7.22 and 7.16 (two d,J=8.5 Hz, 2H), 6.87 (d,J=8.5 Hz, 2H), 4.22 and 4.08 (two dd,J=7.5, 4.8 Hz, 1H), 3.71 (s,3H),3.63 (s,3H), 3.27 (m,1H), 3.14(m,1H), 2.54 and 2.52 (twos, 3H);13cNMR (125 MHz, DMSO-d6)8 169.45 and 168.62 (1C),158.48 and 400-188-0725 158.44(1C),130.61 and 130.47 (2C),126.55 and 126.18 (1C),114.00and 113.91 (2C), 61.39 and 61.20(1C), 55.07,52.59, 33.91 and 33.84(1C), 31.79 and 31.52 (1C); ESI-MS (m/z): 224(M-HCl+H+); HRMS(ESI) calcd for C12H18NO3(M-HCl+H+)224.1287, found 224.1281. 4.3. Dipeptide 9 4.4. Diketopiperazine 4 To a solution of 3 M HC in EtOAc (100 ml) was added 9 (17.9 g,35.1 mmol) at rt. The mixture was stirred at rt for 2 h. The solventwas removed in vacuo. The resulting residue was diluted withEtOAc, and the organic layer was successively washed with aqueousNaHCO3,water and brine, dried over Na2SO4,and concentrated. Thecrude product 10 was used directly for the next step without fur-ther purification. To a solution of crude 10 (13.0 g, 34.4 mmol, 1 equiv) in dryCH2Cl2 (400 ml) was added BBr3 (1.9 M in CH2Cl2, 90 ml, 171 mmol,5 equiv) at 0 °C. The resulting mixture was stirred at rt overnight.Water was slowly added at 0 °C to quench the reaction. Theresulting solution was filtered, and the solid was washed withCH2Cl2. The organic phases were concentrated (to remove CH2Cl2),and then diluted with EtOAc. The organic layer was washed withaqueous NaHCO3, water, and brine, dried over Na2SO4, and con-centrated. The residue combined with the previously filtered solidwas purified by MPLC on silica gel (MeOH in CH2Cl2:0-5%) to give 4(11.3 g, 90% fortwo steps) as a white solid. Mp: 128-132C.[+157.1 (c 0.65, CH3CN); IR (KBr):3291,2926,2685,2600,2261,1664,1632,1516, 1458,1233,1100, 746 cm-1; 1H NMR (400 MHz,CD3CN) ; 9.15 (s, 1H), 7.44(d,J=8.1 Hz, 1H), 7.38 (d,J=8.1 Hz,1H),7.13 (t,J=7.2 Hz,1H), 7.05 (t,J=7.5 Hz,1H), 6.96-6.84 (m,4H), 6.78(d, J=8.5 Hz, 2H), 6.19 (s, 1H), 4.02 (t,J=4.5 Hz, 1H), 3.92 (d,J=9.6 Hz, 1H), 2.95-2.81(m,5H), 2.73 (dd,J=14.3,4.3 Hz,1H),1.56(dd, J=14.3, 9.7 Hz, 1H); C NMR (100 MHz, CD3CN) 6 167.00,166.96,157.28,137.63,132.25(2C),128.14, 128.05, 125.12, 122.51,119.89,119.50,116.41(2C),112.35,110.48, 64.09,56.45,36.91, 33.41, 31.75; ESI-MS (m|z): 364(M+H*); HRMS (ESI) calcd for C21H22N302(M+H+) 364.1648, found 364.1656. 4.5. Ketals 11a and 11b To a solution of PhI(OAc)2 (3.86 g, 12.0 mmol, 2 equiv)and LiOAc(2.38 g, 6 equiv) in CF3CH2OH (550 ml) was added 4 (2.18 g,6.0 mmol) in 50 ml CF3CH2OH slowly at -15 C. The reactionmixture was stirred for 30 min and quenched with aqueousNa2S203(10 ml). The solvents were removed, and MeOH/CH2Cl2(1:20) was added. The sediment was filtered and washed threetimes with MeOH/CH2Cl2(1:20). The filtrates were concentrated invacuo. The resulting residue was purified by MPLC on silica gel(MeOH in CH2Cl2: 0-5%) to give a mixture of 11a/b, which wasfurther purified by preparative TLC (EtOAc) to give 11a (535 mg,16%) and 11b (401 mg, 12%) as slightly yellow solids. Compound 11a: Single crystal for X-ray analysis was prepared byslow evaporation from DMSO. Mp:>270°C(decomposition);[5.0-56.0 (c 1.0, THF). IR (KBr): 3445, 3218,2945,1678,1621, 1580,1483,1282,1170,1107,992 cm-1; 1H NMR(500MHz,CD:CN)8 7.05(s, 1H), 6.93 (d,J=8.2 Hz, 1H), 6.89 (s, 1H), 6.85 (d,J=10.2 Hz,1H),6.78 (d,J=8.1 Hz,1H),6.58(dd,J=10.2,2.4Hz,1H), 6.11 (s,1H), 5.47(s,1H), 4.19-4.00(m,6H), 3.30(d,J=14.0 Hz, 1H), 3.06 (s, 3H), 2.89(dd, J=14.1, 4.3 Hz, 1H), 2.81 (dd,J=16.1, 3.2 Hz, 1H), 2.00 (dd,16.2, 3.8 HZ,1H); 13C NMR (125 MHz, CD3CN)6 168.76, 165.87,164.86,158.89,148.41,139.26,133.55,133.25,128.13,127.52,126.05,125.33 (q,J=275 Hz, 1C),125.28(q,J=275 Hz, 1C), 122.28, 116.86,111.37,98.84,66.32, 62.08 q,J=34.6 Hz, 2C), 57.42, 56.12, 38.38,37.60, 33.86; ESI-MS (m|z): 558(M+H); HRMS (ESI) calcd forC25H22N305F6(M+H+)558.1469, found 558.1458. Compound 11b: Single crystals for X-ray analysis was preparedby vapor diffusion (THF/hexanes). Mp:>250 °C (decomposition);25.1[ 20.4 (c 1.02, THF). IR (KBr): 3260, 2933,1682,1655,1579,1484,1287,1155,1112,988,752 cm-1;1H NMR (500 MHz, CD3CN); 7.32 (s, 1H), 6.97 (dd,J=8.1, 1.7 Hz, 1H), 6.94 (s, 1H), 6.87 (d,J=10.2 Hz,1H), 6.66(d,J=8.1 Hz,1H), 6.58 (dd,J=10.2, 2.4 Hz, 1H),6.46(d,J=2.4 Hz, 1H), 6.25 (s, 1H), 4.17-3.99(m, 6H), 3.48 (d,J=14.0Hz,1H), 3.05(dd,J=14.1, 6.4 Hz,1H), 2.71(dd,J=16.4, 3.9 Hz,1H), 2.44 (s,3H), 2.28 (dd,J=16.4, 3.6 Hz,1H); 13C NMR (125 MHz,CD3CN) 169.87, 165.19,164.78,159.56, 149.67,139.18,132.92,132.31,129.16,127.40,126.46,125.37 (q,J=275 Hz, 1C), 125.23 (q,J=275 Hz, 1C), 121.23,110.86,118.18,98.71,66.84,62.25(q,J=35 Hz,1C), 62.10 (q,J=35 Hz, 1C), 57.17, 55.62, 39.29, 38.66,32.93; ESI-MS(m(z): 558 (M+H+). HRMS (ESI) calcd for C25H22N305F6(M+H+)558.1472, found 558.1458. 4.6. Dipeptide 15 To a solution of 3 M HCl in dioxane (30 ml) was added com-pound 13 (1.62 g,4.5 mmol) at rt. The mixture was stirred at rt for3 h. The solvent was removed in vacuo.The resulting residue wasdiluted with EtOAc, and the organic layer was successively washedwith aqueous NaHCO3, water, and brine, dried over Na2SO4, andconcentrated. The crude product was used directly for the next stepwithout further purification. To a solution of the above crude product in dry CH2Cl2 (40 ml)under N2 atmosphere at 0 °C was added EDCI (0.920 g, 4.8 mmol),HOBt (0.648 g, 4.8 mmol). The reaction mixture was stirred at 0 °Cfor 0.5 h, and then 14 (1.405 g, 4.0 mmol) was added. N-ethyl-diisopropylamine (1.31 ml, 8.0 mmol)was slowly added. Theresulting mixture was stirred at 0°C for 0.5 h and then stirred at rtovernight. The organic solvent was removed in vacuo, and theresulting mixture was diluted with EtOAc. The organic layer waswashed with H2O, brine, dried over Na2SO4, and concentrated. Thecrude residue was purified by flash chromatograph on silica gel(EtOAc/PE: 0-1/2), to give 15 as a white foam (1.80 g, 76% for two steps).[]6+31.75(c1.20,CHCl3); IR (KBr): 3334,2976,2932,1743,1685, 1507,1452,1388,1366,1327,1162,1015,750 cm-1;1H NMR(500 MHz, CDCl3)8 8.41 (d,J=7.7 Hz, 1H), 7.48 (d,J=7.7Hz,1H), 7.28(m, 3H),7.05 (m,2H), 6.88 (d,J=8.2 Hz, 2H), 6.70 (m,1H), 4.83 (m,2H), 3.66(m, 3H), 3.23(m, 3H), 2.88 (m, 1H), 2.64 (s, 3H), 2.56 (s,3H), 1.28 (m 18H). 13C NMR (125 MHz, CDCl3) 6 171.77, 170.88,170.41,168.66,156.41,155.14,154.03,135.83,132.22,129.49, 129.42(2C), 125.51,124.30 (2C),123.79, 118.65, 116.80,80.52,78.39, 60.81,52.60,52.08,33.64,31.77,28.90(3C), 28.23 (3C),27.61, 24.10. HRMS(MALDI): calcd for C33H43N307Na (M+Na*) 616.3003; found616.2993. 4.7. Diketopiperazine 12a To a solution of 3 M HCl in dioxane (5 ml) was added compound15 (0.10 g, 0.17 mmol) at rt. The mixture was stirred at rt for 3 h. Thesolvent was removed in vacuo. The resulting residue was dilutedwith EtOAc, and the organic layer was successively washed withaqueous NaHCO3, water, and brine, dried over Na2SO4, and con-centrated. The crude product was used directly for the next stepwithout further purification. To a solution of the above crude product in n-butyl alcohol(1 ml) was added HOAc(0.15 ml) and N-methylmorpholine (0.1 ml).The resulting mixture was irradiated by microwave (150 W) at100 °C for 15 min. The organic solvent was removed in vacuo, thecrude residue was purified by MPLC on silica gel (MeOH in CH2Cl2:0-6%) to give 12a (57 mg, 83% for two steps) as a white solid.Mp179-185C. [a23+153.82 (c 0.50, MeOH); IR (KBr): 3250, 3016,2938,2814,1676,1637,1612,1452,1329,1245,1227,1017,748 cmHNMR(400 MHz, CD3CN)8.20(m,1H), 7.99 (s,1H), 7.45(m,1H),7.26(m,2H), 7.00(m,2H), 6.88(dd,J=6.5, 2.0 Hz, 3H), 6.21 (s,1H),4.12 (t,J=4.0 Hz, 1H), 3.88 (dt,J=10.9,2.8 Hz,1H), 3.06(S,5H), 2.73(ddd,J=14.1, 3.0, 1.1 Hz, 1H), 2.47 (s, 3H), 0.95 (dd,J=14.1,11.0 Hz,1H). 13cNMR (100 MHz, CD3CN) 6 169.76, 166.92, 166.52, 157.62,136.84, 132.62 (2C), 130.69, 127.59,125.83,125.79, 124.04, 119.84,117.25, 117.15, 116.44 (2C), 63.93,55.28,36.35,33.34, 31.50, 24.37.HRMS (MALDI): calcd for C233H243N304(M+H*) 406.1770; found406.1761. 4.8. Dipeptide 17 To a solution of 16 (300 mg, 0.62 mmol) in methanol (6 ml) wasadded 2 M NaOH solution (1ml) at 0°C. The resulting mixture wasslowly warmed to rt and stirred until the consumption of thestarting material (monitored by TLC). The resulting residue wasdiluted with EtOAc, and the water layer was acidified by 1 M HCl (topH~3). The organic layer was successively washed with water andbrine, dried over Na2SO4, and concentrated. The crude product wasused directly for the next step without further purification. To a solution of the above crude product, 7(169 mg, 0.65 mmol)and BEP (221.7 mg, 0.81 mmol) in dry CH2Cl2 (40 ml) under N2atmosphere at 0 C was slowly added N-ethyldiisopropylamine(0.30 ml, 1.86 mmol), the reaction mixture was stirred at 0C for0.5 h and then stirred at rt overnight. The organic solvent was re-moved in vacuo, and the resulting mixture was diluted with EtOAc.The organic layer was washed with H2O, brine, dried over Na2SO4,and concentrated. The crude residue was purified by flash chro-matograph on silica gel (EtOAc/PE: 0-1/2), to give 17 as a whitefoam (227 mg, 71%). [c]+38.37(c 1.75, CHCl3). IR (KBr): 3430,3302,2999,2976,2932,2831,1740,1707,1647,1513,1364,1247,1227,1175, 741 cm-1;1HNMR(400MHz, CDCl3) 6 7.66 (d,J=7.7 Hz,1H), 7.14 (m,9H), 6.94(d,J=8.6 Hz,2H), 6.70 (d,J=8.6 Hz, 2H), 5.24(t,J=10.4 Hz, 2H), 5.15 (d,J=9.1 Hz,1H), 5.05 (dd,J=9.9,5.7 Hz,1H),4.88 (m, 1H), 3.69 (d,J=32.1Hz, 3H), 3.57 (d,J=14.7 Hz, 3H), 3.21(m, 2H),3.05 (dd,J=14.4, 6.0 Hz,1H), 2.86(m,1H),2.72(s,3H), 1.48(d,J=77.5 Hz, 9H); 13c NMR (100 MHz, CDCl3) 6 172.66, 171.06, 158.45, 155.22,137.71, 136.56,129.93 (2C), 128.93, 128.80 (2C),128.63, 127.63,127.43,126.88 (2C), 121.86, 119.42, 119.18, 113.98(2C),109.85,109.74, 79.59,59.39, 55.25,52.23,50.98, 50.07, 33.90,33.28,28.95,28.42 (3C); HRMS (MALDI): calcd for C35H41N306Na(M-Na+) 622.2903; found 622.2888. 4.9. Diketopiperazine 12b To a solution of 3 M HCl in dioxane (3 ml) was added compound17(163 mg, 0.27 mmol) at rt. The mixture was stirred at rt for 2 h.The solvent was removed in vacuo. The resulting residue was di-luted with EtOAc, and the organic layer was successively washedwith aqueous NaHCO3, water, and brine, dried over Na2SO4, andconcentrated. To a solution of the crude product in CH2Cl2 (3 ml)under N2 atmosphere at 0C was slowly added BBr3 (1.9 M inCH2Cl2, 0.6 ml, 1.14 mmol). The resulting mixture stirred at rtovernight. The reaction was quenched by slow addition of waterand extracted by DCM/MeOH(20:1). The organic layer was washedwith H20 and brine, dried over Na2SO4, and concentrated. Thecrude residue was purified by flash chromatograph on silica gel(DCM-DCM/MeOH=20:1) to give 12b (97 mg, 79% for three steps)as a white solid. Mp: 122-125°C;[a]26'+118.44(c 1.60, MeOH); IR(KBr):3340,3245,3062,3028,2926,1669,1637,1515,1466,1331,1234,1026,742 cm-1,1HNMR(400MHz,CD3CN)67.46(d,J=7.8Hz,1H),7.28 (tt,J=6.9, 6.1 Hz, 4H), 7.19 (m, 2H), 7.12(m,1H), 7.05 (m,1H), 6.97 (s, 1H), 6.94 (s, 1H), 6.84 (m,2H), 6.77 (m, 2H), 6.19 (s,1H),5.31 (s,2H), 4.02 (t,J=4.5 Hz, 1H), 3.93 (dt,J=9.5, 3.1 Hz, 1H), 2.89(m,4H), 2.77(ddd,J=34.0,14.2, 4.6 Hz,2H), 1.58(dd,J=14.3,9.6 Hz,1H). 13c NMR (100 MHz, CD3CN) ; 167.08, 167.02, 157.47,139.25,137.62,132.32 (2C),129.63(2C),129.04,129.01, 128.48,128.09 (2C),127.93,122.62,120.08,120.06, 116.54 (2C), 110.99,110.25, 64.13,56.51,50.52,2,37.07,,33.52,31.73. HRMSS (MALDI): calcd forC28H28N303(M+H*)454.2135; found 454.2125. 4.10. CCompound rac-19 To a solution of rac-18 in dioxane (60 ml) was added HCl (6 M,60 ml). The reaction mixture was heated to reflux for 6 h before thesolvent was removed in vacuo.The crude residue was dissolved inNaOH (aqueous, 3 M, 50 ml). Then water (100 ml), THF (150 ml),Boc2O(9.2 g, 42.2 mmol) was added and the reaction mixture wasstirred at rt overnight. The solvent was removed in vacuo and theresulting mixture was diluted with EtOAc. The organic layer waswashed with H20 and brine, dried over Na2SO4, and concentratedto give rac-19 (9.90 g,70%) was brown solid. The crude residue useddirectly for the next step without further purification. Mp:116-120°C; IR (KBr): 3418,3334,2976,2926,1698,1506, 1435,1161,1073,1023,823 cm-,1HNMR(400MHz, DMSO-d6)612.62(s,1H), 11.08 (s,1H), 7.55(d,J=7.8Hz,1H), 7.29 (d,J=7.5Hz,1H), 7.23 (s,1H), 7.04(d,J=7.9Hz, 1H), 6.95 (t,J=7.7 Hz, 1H), 4.15(m, 1H), 3.14(dd, J=14.4, 4.2 Hz, 1H), 2.98 (dd,J=14.3, 9.7 Hz, 1H), 1.26 (d,J=51.2 Hz, 8H). 13c NMR (100 MHz, DMSO-d6) 6 173.83, 155.41,134.33, 129.00, 125.07, 123.48, 119.88, 117.84, 111.78,104.21,78.05,54.43, 28.17, 26.78. HRMS (MALDI): calcd for C16H19N204BrNa(M+Na*) 405.0431; found 405.0420. 4.11. Diketopiperazines 21 and 22 To a solution of rac-19 (3.1 g, 8.10 mmol) in dry CH2Cl2 (80 ml)under N2 atmosphere at 0°C was slowly added BEP (2.41 g,8.8 mmol), HOAt (1.43 g, 8.8 mmol). The reaction mixture wasstirred at 0 °C for 0.5 h, then N-Me-D-Tyr(Me)-0Me HCl (2.18 g,8.4 mmol) was added followed by slowly addition of N-ethyl-diisopropylamine (4.42 ml, 26.8 mmol). The reaction mixture wasstirred at rt overnight. The solvent was removed in vacuo. Theresulting residue was diluted with EtOAc, and the organic layer was successively washed with water and brine, dried over Na2SO4, andconcentrated. The crude residue was purified by flash chromato-graph on silica gel (PE-PE/EA=2:1) to give 20a/20b (3.11 g, 65%) asa mixture of two diastereomers, which was used directly for thenext step without further purification. To a solution of 3 M HCl in EtOAc (30 ml) was added compounds20a/20b (2.3 g, 3.91 mmol) at rt. The mixture was stirred at rt for2 h. The solvent was removed in vacuo. The above residue wasdissolved in methanol (100 ml) and ammonium hydroxide (6 ml)was added. The reaction mixture was stirred at rt for 0.5 h beforethe solvent was removed in vacuo. The crude residue was purifiedby flash chromatograph on silica gel (DCM-MeOH/DCM=20:1) togive 21 (0.77 g, 43%) and 22 (0.73 g, 41%) as white foams. Compound 21:[a]7-35.61(c0.95,MeOH); IR (KBr): 3256, 2928,2830, 1676, 1653, 1511,1437,1325,1248,1111,1030, 780 cm-,1HNMR (400 MHz, CD3CN);9.33(s,1H), 7.36(d,J=7.9Hz,1H),7.32(d,J=7.6 Hz, 1H), 7.07 (d,J=2.4 Hz, 1H), 6.96 (t,J=7.5 Hz, 3H), 6.77 (d,J=8.0 Hz, 2H), 6.07 (s, 1H), 3.93 (t,J=4.1 Hz, 1H), 3.74 (s, 3H), 3.13(dd,J=11.0, 0.8 Hz, 1H), 3.03(dd,J=5.9, 4.2 Hz, 2H), 2.89(m, 5H).13cNMR(100 MHz, CD3CN); 168.65,167.35,159.91,135.70,131.80 (2C),129.82,127.75,126.20,124.94, 121.12, 119.16,114.59 (2C), 111.54,105.21, 64.15,55.74, 54.11,36.26,33.02,29.05. HRMS (ESI): calcd forC22H23N303Br(M+H+) 456.0928; found 456.0917. Compound 22: [x]+129.54 (c 1.15, MeOH); IR (KBr): 3250,2929,2834,1676,1652,1512,1460,1330,1249,1032,832,743 cm'H NMR (400 MHz, CD3CN);9.38(s,1H), 7.41 (d,J=7.9 Hz,1H), 7.32(d,J=7.6 Hz,1H), 6.99 (dd,J=5.0, 2.7 Hz, 2H), 6.95 (m,2H), 6.89 (d,J=8.7 Hz, 2H), 6.36(s,1H), 4.03 (t,J=4.5 Hz,1H), 3.92(m,1H),3.70(s, 3H), 2.86 (m, 5H), 2.76 (dd,J=14.2, 4.3 Hz, 1H), 1.54 (dd,J=14.3,9.6 Hz, 1H). 13c NMR (100 MHz, CD3CN) 6 165.53,165.25,158.67130.88(2C),128.55,127.91,124.61,123.81,120.03,117.85,113.72 (2C), 111.14, 103.88, 62.76,55.16, 54.62,35.71,32.03, 30.67.HRMS (ESI): calcd for C22H23N303Br (M+H+) 456.0904; found456.0917. 4.12. Diketopiperazine 12c To a solution of 22 in CH2Cl2 (60 ml) under N2 atmosphere at0 °C was slowly added BBr3(1.9 M in CH2Cl2, 10 ml). The resultingmixture stirred at rt for 12 h. The reaction was quenched by slowaddition of water and extracted by DCM.The crude residue waspurified by flash chromatograph (onsilica gel (DCM-DCM/MeOH=20:1) to give 12c (4.20 g, 885%) as a white solid. Mp:152-155C; [α]23+136.95(c1.25, MeOH); IR (KBr): 3256,3016,2938,2362,1667,1643,1515,1471,1334,1237,1046,1026,835,737 cm-1; 1H NMR (400 MHz, CD3CN) 8 9.27 (s, 1H), 7.42 (d,J=7.9 Hz, 1H), 7.32 (d,J=7.6 Hz, 1H), 7.06(s,1H), 6.97(dd,J=10.5,5.1 Hz,2H), 6.89(d,J=8.6Hz,2H), 6.80(d,J=8.6Hz, 2H), 6.21 (s,1H),4.04 (t,J=4.3 Hz, 1H), 3.89 (dt,J=9.8, 3.1 Hz,1H), 2.92 (s, 3H), 2.83(m,3H), 1.47 (dd,J=14.3, 9.9Hz, 1H).C NMR (100 MHz, CD3CN)i 166.79, 166.68,157.26,135,98,132.29,129.74,128.16, 125.93,125.08,121.29, 119.14,116.40,112.33, 105.14,64.08, 56.43,36.90,33.34, 31.89. HRMS (MALDI): calcd for C21H21N303Br (M+H+)442.0769; found 442.0761. 4.13. Diketopiperazines 25 and 26 To a solution of rac-23 (3.1 g,8.10 mmol) in dry CH2Cl2 (40 ml)under N2 atmosphere at 0 C was slowly added BEP (2.41 g,8.8 mmol), HOAt (1.43 g, 8.8 mmol). The reaction mixture wasstirred at 0 °C for 0.5 h, then N-Me-D-Tyr(Me)-OMe HCl (2.18 g,8.4 mmol) was added followed by slowly addition of N-ethyl-diisopropylamine (4.42 ml, 26.8 mmol). The reaction mixture wasstirred at rt overnight. The solvent was removed in vacuo. Theresulting residue was diluted with EtOAc, and the organic layer wassuccessively washed with water and brine, dried over NazSO4, and concentrated. The crude residue was purified by flash chromato-graph on silica gel (PE-PE/EA=2:1) to give 24a/24b (4.05 g, 85%) asa mixture of two diastereomers, which was used directly for thenext step without further purification. To a solution of 3 M HCl in EtOAc (30 ml) was added compound24a/24b (2.3 g, 3.91 mmol) at rt. The mixture was stirred at rt for2 h. The solvent was removed in vacuo. The above residue wasdissolved in methanol (100 ml) and ammonium hydroxide (6 ml)was added. The reaction mixture was stirred at rt for 0.5 h beforethe solvent was removed in vacuo. The crude residue was purifiedby flash chromatograph on silica gel (DCM-MeOH/DCM=20:1) togive 25 (0.84 g, 47%) and 26 (0.80 g, 45%) as white foams. compound25:[]-21.05(c0.68,MeOH); IR(KBr): 3266,2932,2829, 1674,1644,1511,1455,1397,1248,1180,1107,1030,881,793 cm-, H NMR (400 MHz, CD3CN) 6 9.39 (s, 1H), 7.62 (d,J=1.4Hz, 1H), 7.29(d,J=8.6 Hz, 1H), 7.19 (dd,J=8.6,1.9 Hz,1H), 7.01(d,J=2.3 Hz,1H), 6.97 (d,J=8.6 Hz,2H), 6.78 (d,J=8.6 Hz,2H), 6.40(s, 1H), 3.87 (t,J=4.0 Hz, 1H), 3.71 (s, 3H), 3.01(m, 4H), 2.96 (s,1H),2.88(s,3H).C NMR (100 MHz, CD3CN) ; 168.30,167.38,160.12,135.98, 131.94,130.39,128.05,126.71,125.05,122.17,114.66, 114.10,112.75, 110.06, 64.18,55.89,54.44,36.40,32.99,28.80. HRMS(MALDI): calcd for C22H23N303Brr((M+H))456.0915;found456.09173. Compound 26:[]6+80.20(c1.80, MeOH); IR(KBr): 3261,2934,2827, 1673,1644,1512,1456,1335,1248,1030,882,798 cm-, 1HNMR (400 MHz, CD3CN)9.31 (s,1H), 7.58(d,J=1.8 Hz, 1H), 7.32 (d,=8.6Hz,1H), 7.23 (dd,J=8.6,1.8Hz,1H), 6.97 (d,J=2.4Hz,1H), 6.92(q,J=8.8 Hz, 4H), 6.24(s,1H), 4.03 (t,J=4.6Hz,1H), 3.91 (dt,J==9.1,3.2 Hz,1H), 3.71 (s, 3H), 2.89 (S, 3H), 2.81 (dt,J=14.3, 3.5 Hz, 2H),2.71 (dd,J=14.2,4.4 Hz,1H), 1.59 (dd,J=14.4, 9.2 Hz, 1H).1cNMR(100 MHz, CD3CN) 0 166.80,166.56,159.93,136.28,132.13,130.20,129.28,126.70,125.14,122.05,115.02, 114.22, 112.77,110.66, 64.08,56.57,55.93,37.12,33.37,31.68. HRMS (MALDI): calcd forC22H23N303Br(M+H) 456.0919; found 456.09173. 4.14. Diketopiperazine 12d To a solution of 26 (5.84 g, 12.8 mmol) in CH2Cl2 (60 ml) underN22 atmosphere at 0 °C was slowly added BBr3 (1.9 M in CH2Cl2,10 ml). The resulting mixture stirred at rt for 12 h. The reaction wasquenched by slow addition of water and extracted by DCM. Thecrude residue was purified by flash chromatograph on silica gel(DCM-DCM/MeOH=20:1) to give 12d (5.38 g, 95%) as a white solid.Mp:161-165°C; [α]?7+112.40(c0.65,MeOH). IR(KBr): 3272,2935,2825,1670,1639,1515,1460,1341,1233,1046,878 cm-1; 1H NMR(400 MHz, CD3CN) ; 9.08 (s, 1H), 7.91 (s,1H), 7.58 (s,1H), 7.17 (m,2H), 6.89 (d,J=8.4 Hz,2H), 6.83(d,J=8.6 Hz,2H), 6.75 (d,J=1.8 Hz,1H),6.24(s,1H), 4.04(t,J=4.3 Hz,1H),3.80(d,J=9.8Hz,1H), 2.95 (s,3H), 2.90 (dd,J=14.3, 4.7 Hz,1H), 2.79 (dd,J=14.3, 3.9 Hz,1H), 2.71(dd,J=14.2, 2.9 Hz, 1H), 1.23 (m, 1H); 1’c NMR (100 MHz, CD3CN)o 167.21,166.81,157.44,136.09,132.29(2C), 129.78,127.79, 126.56,124.90, 121.97,116.49 (2C), 113.99, 112.59, 110.10, 64.02, 56.36,36.73,33.47, 31.36; HRMS(MALDI): calcd for C21H21N303Br(M+H*)442.0775; found 442.0761. 4.15. Cyclopeptide 28 A solution of 4 (200 mg, 0.55 mmol), NEt4ClO4 (3 g, 13.1 mmol)in CH3CN(70 ml) and aqueous NaOH(0.6M, 10 ml) was transferredinto an undivided electrolysis cell equipped with a graphite feltanode and a platinum cathode. Electrolysis with a constant voltageof 1.0 V was performed at rt, using a standard calomel electrode asa reference electrode. After the consumption of the starting mate-rial, the electrolysis was stopped and the reaction mixture wasneutralized by KHSO4 (aqueous) and the solvent was removed invacuo. The resulting residue was diluted with EtOAc, and the 耐士科技 www.rysstech.com 400-188-0725 organic layer was successively washed with water and brine, driedover NazSO4, and concentrated. The crude residue was purified bypreparative TLC (CH2Cl2/MeOH=20:1) to give 27 (38 mg,19%). To a solution of 27 (19 mg, 0.053 mmol) in CH2Cl2 (2 ml) wasadded pyridinium (0.2 ml) and acetic anhydride (20 mg,0.20 mmol), the reaction mixture was heated to reflux until theconsumption of the starting material. The solvent was removed invacuo. The resulting residue was diluted with EtOAc, and the or-ganic layer was successively washed with 1 M HCl, water, aqueousNaHCO3 and brine, dried over Na2SO4,and concentrated. The cruderesidue was purified by preparative TLC (CH2Cl2/MeOH=20:1) togive 28 (17 mg, 80%) as a white solid. Single crystals for X-rayanalysis were prepared by vapor diffusion (THF/hexanes). Mp>270C(decomposition).[]3-93.54 (c0.40, MeOH); IR (KBr):3451,3248,2932,1761,1673,1651,1504,1449,1324,1198,1101,1016,910,755 cm-1, 1H NMR (400 MHz, CD3CN) 6 7.68 (d,J=7.7 Hz,1H), 7.40 (d,J=7.8 Hz, 1H), 7.31 (td,J=7.5,1.1 Hz, 1H), 7.25(m,1H),7.05 (dd,J=8.3, 1.6 Hz, 1H), 7.01 (d,J=8.3 Hz,1H), 6.48 (s, 1H), 6.45(s, 1H), 5.54 (s,1H), 4.41 (dd,J=4.5, 1.9 Hz,1H), 4.17 (dd,J=5.9,1.7 Hz, 1H), 3.50 (ddd,J=17.3,15.7, 0.9 Hz, 2H), 3.05 (dd,J=14.8,4.7 Hz, 1H), 2.93 (dd,J=16.5, 7.1Hz, 1H), 2.41 (s, 3H), 2.34(s,3H).13cNMR (100 MHz, CD3CN) ; 170.79,168.12,166.47,153.49, 148.25,144.33,138.31,138.26,135.57,130.42,130.28,126.01,124.66,124.06,122.64,120.93,117.77,61.26,58.99,34.22,31.55,26.69,21.04.HRMS(MALDI): calcd for C23H22N304(M+H+) 404.1611; found 404.1605. 4.16. Compound 30 To a solution of 4 (100 mg, 0.27 mmol) in HCl (concd, 0.3 ml) andHOAc (2.7 ml) was slowly added DMSO (48.8 ul), the reactionmixture was stirred at rt until the consumption of the startingmaterial. The solvent was removed in vacuo. The resulting residuewas diluted with EtOAc, and the organic layer was successivelywashed with aqueous NaHCO3, water and brine, dried over Na2SO4,and concentrated. The crude residue was purified by flash chro-matograph on silica gel (DCM/MeOH-100:1-DCM/MeOH=20:1)to give a mixture of 29a/29b (40 mg,39%) as a yellow solid, whichwas used directly for the next step without further purification. A solution of 29a/29b in aqueous KOH (1M, 0.15 ml) was dilutedwith water (6 ml). The above solution was added to aqueous so-lution of K3Fe(CN)6(52 mg,0.158 mmol) at 0°C, then CHCl:(10ml)was added and the reaction mixture was stirred at it until theconsumption of the starting material. The reaction mixture wasneutralized by KHSO4 (aqueous)and extracted with CH2Cl2 for twotimes. The organic layer was washed with brine and dried overNa2SO4, and concentrated. The crude residue was purified by pre-parative TLC (CH2Cl2/MeOH=20:1) to give 30 (3 mg, 31%) asa slightly yellow solid. Single crystals for X-ray analysis was pre-pared by vapor diffusion (THF/hexanes). +70.37(c 0.20,MeOH); IR (KBr): 3444,3345,2923,1675,1638,1617,1590, 1515,1450, 1338, 1253, 1026,980,832,754 cm-1; 1H NMR (400 MHz,DMSO-d6) ǒ 9.48 (s,1H), 7.83 (d,J=2.1Hz,1H), 7.24(t,J=7.2Hz,1H),7.16 (d,J=9.1 Hz, 3H), 6.88 (d,J=8.4 Hz,2H), 6.73 (t,J=8.1 Hz, 3H),6.58 (t,J=7.5 Hz, 1H), 4.34-4.26(m, 1H), 4.21 (s,1H), 3.09-2.99 (m,2H), 2.98 (s,3H), 2.54 (d,J=3.4Hz,1H), 1.62 (dd,J=17.4,8.2Hz, 1H).13c NMR (100 MHz, DMSO-d6) 197.35, 165.84, 165.54, 156.89,151.10, 134.32, 131.35 (2C), 131.06, 125.36, 116.78,115.95, 115.26(2C), 114.65,62.21,50.18,43.95, 34.80, 32.19. HRMS (MALDI): calcdfor C20H22N304(M+H+) 368.1614; found 368.1605. 4.17. Quinone 34a Ketal 11a (60 mg, 0.108 mmol), HOAc (4.5 ml), and water(0.03 ml) were introduced into an oven-dried 20 ml CEMvial. Thevial was then sealed with a Teflon-lined septum. The resultingmixture was irradiated by microwave (50 W) at 50 °C for 15 min. Solvents were removed in vacuo, and the residue was diluted withEtOAc. The organic layer was washed by aqueous NaHCO3, waterand brine, dried over Na2SO4, and concentrated. The crude residuewas purified by MPLC on silica gel (MeOH in CH2Cl2:0-5%) to give34a (24 mg, 59%) as a yellow solid. Mp: 135-137°C; [c]24.8-197.3 (c0.50,THF); IR (KBr): 3244,3062,2922,2851,1679,1638,1481,1235,1030,733 cm-1;1HNMR(400 MHz, CDCl3) 6 7.42 (d,J=10.0Hz,1H),7.32 (s,1H), 7.03 (d,J=8.0 Hz, 1H), 6.91 (d,J=8.2Hz, 1H), 6.88 (s,1H),6.67 (d,J=9.9 Hz, 1H), 6.17(s, 1H), 5.39 (s, 1H), 4.24 (s,1H), 4.20 (d,J=3.7 Hz, 1H), 3.29 (d,J=13.9 Hz, 1H), 3.13 (s, 3H), 3.10-3.01 (m,2H), 1.99 (d,J=15.6 Hz,1H); 13C NMR (100 MHz, CDCl3)6 187.94,166.97, 166.32,165.74, 157.75,154.02,137.33,133.39,133.15,131.76,125.79,125.17,123.85, 115.62,111.61,65.35,57.18,54.95,37.69,36.08, 33.83; ESI-MS (m|z): 376 (M+H*); HRMS (ESI): calcd forC21H18N304(M+H+) 376.1298; found 376.1292. 4.18. Quinone 34b Ketal 11b (40 mg, 0.072 mmol),HOAc(1 ml),and dioxane (1 ml),water (0.1 ml) were introduced into an oven-dried 10 ml CEM"vial.The vial was then sealed with a Teflon-lined septum. The resultingmixture was irradiated by microwave (50 W) at 65 °C for 1.2 h.Solvent was removed in vacuo, and the residue was diluted withEtOAc. The organic layer was washed by aqueous NaHCO3, waterand brine, dried over Na2SO4, and concentrated. The crude residuewas purified by MPLC on silica gel(MeOH in CH2Cl2:0-5%) to give34b (13 mg, 48%) as a yellow solid. Mp: 160-165C;[]75.6-1.72(c0.275, CHCl3); IR (KBr): 3473,3223, 2928,1672,1637,1483,1274,1027,753 cm-1; 1H NMR (500 MHz, CDCl3)6 8.95 (s,1H), 7.46 (d,J=9.9 Hz,1H), 7.36(s,1H), 7.08(s,1H), 6.99(d,J=8.1Hz,1H), 6.83(d,J=8.1Hz,1H),6.63(d.J=9.9Hz,1H), 6.40 (s,1H),4.28(s,1H), 4.16(d,J=6.1 Hz,1H), 3.90 (d,J=14.3 Hz, 1H), 3.06 (dd,J=14.4, 6.3 Hz,1H),2.97(dd,J=16.4,3.7 Hz, 1H), 2.56 (s,3H), 2.48 (dd,J=16.3, 3.4 Hz,1H);;C NMR (125 MHz, CDCl3) 6 187.77, 170.58, 165.65, 163.93,158.51, 155.48,136.79,133.65,131.31,131.28,126.34,125.12,122.11,116.32,110.58,65.84, 56.86,54.34,38.54,36.19,32.62; ESI-MS (m/z): 376 (M+H+); HRMS (ESI): calcd for C21H18N304 (M+H+)376.1295; found 376.1292. 4.19. Phenol 35a To a solution of 34a (86 mg, 0.23 mmol) in MeOH (5 ml) wasadded NaBH4 (10 mg, 0.26 mmol, 1.14 equiv) at 0 °C. The reactionwas monitored by TLC until the starting material was consumed.Silica gel was added and the solvent was removed in vacuo. Theresidue was purified by flash column chromatography (CH2Cl2/MeOH,100:1-20:1)to give 35a (58 mg,67%) as a white solid. Mp:>240 C (decomposition); []?+193.7(c0.108,MeOH); IR (KBr):3350,2970,2937,2835,1661,1635,1481,1236,1058,925 cm-1;'H NMR (500 MHz, CD3CN) ; 7.52 (d, J=2.6 Hz, 1H), 6.93 (d,J=1.6 Hz, 1H), 6.85 (dd,J=8.0, 1.7 Hz, 1H), 6.71 (d,J=8.0 Hz,1H),6.53 (dd,J=8.3,2.5 Hz, 1H), 6.49-6.44(m,2H), 6.08 (d,J=5.3 Hz,1H), 5.50(s,1H), 5.27 (d,J=5.3 Hz, 1H), 4.10 (d,J=4.2 Hz, 2H),3.26(d,J=14.0 Hz, 1H), 3.08 (s, 3H), 2.96 (dd,J=16.1, 3.2 Hz, 1H), 2.86(dd,J=14.0, 4.6 Hz, 1H), 1.91 (d,J=4.3 Hz, 1H); 13C NMR (125 MHz,CD3CN) ; 168.18,165.84,158.50, 151.61,142.54,133.81, 132.57,132.46,130.61,125.53, 115.18,113.25,110.87,110.73,110.32,65.97,59.95, 56.18,41.15,38.15,33.86; ESI-MS (m/z): 378 (M+H+);HRMS (ESI): calcd for C21H20N304 (M+H+) 378.1459; found378.1448. 4.20. Phenol 35b To a solution of 34b (110 mg, 0.29 mmol) in MeOH (5 ml) wasadded NaBH4 (12 mg, 0.32 mmol, 1.1 equiv) at 0 °C. The reactionwas monitored by TLC until consumption of the starting material. Silica gel was added and the solvent was removed in vacuo. Theresidue was purified by flash column chromatography (CH2Cl2/MeOH, 100:1-20:1) to give 35b (88 mg, 80%) as a white solid. Mp:>220°C (decomposition); [a]24-253.6(c 0.33, MeOH); IR (KBr):3336,2935,2852,1662,1632,1482,1454,1200,1019,819 cm-1;1HNMR (500 MHz, CD3CN) 7.33 (d,J=1.5 Hz,1H), 7.00 (s, 1H), 6.96(d,J=2.3 Hz, 1H), 6.89 (dd,J=8.0, 1.7 Hz, 1H), 6.62-6.48 (m, 4H),6.17 (d,J=4.6 Hz, 1H),5.40 (d,J=4.1 Hz, 1H), 4.12(s,1H), 4.07 (d,J=6.5 Hz, 1H), 3.46 (d,J=14.0 Hz, 1H), 3.02 (dd,J=14.1,6.6 Hz,1H),2.62 (dd,J=16.3, 4.5 Hz, 1H), 2.43-2.38 (m, 4H); 13c NMR(125 MHz, CD3CN) ; 169.94, 165.32, 159.23,151.88,142.32,134.20,132.19,131.81,130.82,126.00,115.60, 111.53,111.00,110.74, 110.12,66.52,59.88,55.18, 42.19,38.92, 32.76; ESI-MS (m/z): 378(M+H+);HRMS (ESI): calcd for C21H20N304 (M+H+) 378.1455; found378.1448. 4.21. Triflate 36a To a solution of 35a (50 mg, 0.13 mmol) in dry EtOAc (8 ml)under N2 atmosphere was added triethylamine (0.3 ml). The so-lution was cooled down to -15 °C for 10 min, and Tfz0 (48pl,0.28 mmol, 2.15 equiv) was slowly added. The solution was stirredfor 3 h at -15 °C until aqueous NH4Cl solution was added. Theresulting mixture was diluted with EtOAc and washed with waterand brine, dried over Na2SO4, and concentrated. The crude residuewas purified by flash column chromatograph (CH2Cl2/MeOH,100:1-20:1) to give 36a (36 mg, 53%) as a white solid. Mp:>270 C (dec); []+217.0 (c0.16, MeOH); IR (KBr):3285,c;b 30533. 2928, 2845,1673,1654,1488,1418,1213,1060,893 cm1.1HNMR(500MHz,DMSO-d6) 8 8.03 (d,J=2.7 Hz,1H), 7.36(d,J=3.7Hz,1H)7.26 (d,J=1.6 Hz, 1H), 7.12 (dd,J=8.6, 2.7 Hz, 1H), 6.86 (dd,J=8.0,1.6 Hz,1H), 6.75 (dd,J=6.1,4.8 Hz, 2H), 6.62 (d,J-8.6 Hz,1H), 6.20(d,J=3.8 Hz, 1H), 4.18 (d, J=4.2 Hz, 1H), 4.14 (s, 1H), 3.26 (d,J=13.8 Hz, 1H), 3.03 (s, 3H), 2.79 (dd,J=14.0,4.6 Hz, 1H), 2.74 (dd,J=15.9,3.6 Hz,1H), 1.94 (dd,J=16.1,3.9Hz,1H),13CNMR(125 MHz,DMSO-d6)6 167.41,164.24, 156.49, 148.89, 141.32, 132.82, 131.60,131.50, 128.47, 123.91,121.09,118.38 (q,J=319 Hz, 1C), 117.26,109.93,108.68,107.95,64.43,58.13,54.20,39.09,36.71,32.67; ESI-MS (m|z): 510 (M+H); HRMS (ESI):calcd for C22H19N306F3S(M+H+) 510.0957; found 510.0941. 4.22. Triflate 36b To a solution of 35b (28 mg, 0.074 mmol) in dry EtOAc (2 ml) under N2 atmosphere was added triethylamine (0.05 ml). The so-lution was cooled down to -15 °C for 10 min, and Tfz0 (25 pl,0.15 mmol, 2 equiv) was slowly added. The solution was stirred for1h at-15°Cuntil aqueous NH4Cl solution was added. The resultingmixture was diluted with EtOAc and washed with water and brine,dried over Na2SO4, and concentrated. The crude residue was puri-fied by flash column chromatograph (CH2Cl2/MeOH, 100:1-20:1)to give 36b (26.5 mg, 70%) as a white solid. Mp: >250°C (de-composition); [a]-368.4(c 0.115,MeOH); IR (KBr): 3444, 2934,2848, 1673, 1636, 1490,1419, 1217, 1137, 884 cm-1; 1H NMR(500 MHz, DMSO-d6)08.83 (s,1H), 7.58 (d,J=2.6 Hz, 1H), 7.52 (d,J=3.1 Hz, 1H), 7.22(d,J=1.5Hz,1H), 7.10 (dd,J=8.6, 2.6Hz,1H), 6.93(dd,J=8.0,1.7 Hz,1H),6.63 (d,J=3.7 Hz, 1H), 6.62 (d,J=3.1 Hz, 1H),6.28(d,J=3.2Hz,1H), 4.12 (d,J=6.5 Hz, 2H), 3.35 (d,J=13.7 Hz,1H),3.02(dd,J=13.9, 6.4Hz,1H), 2.55(dd,J=16.2, 4.5 Hz,1H), 2.39-2.32(m, 4H); 13c NMR (125 MHz, DMSO-d6); 168.19, 164.00, 157.60,148.64,141.29,133.21,130.74,130.15,129.93,124.52,120.89,118.28(q,J=319 Hz, 1C), 116.78, 109.16, 108.58, 108.01, 64.83, 58.04, 53.41,39.59 (DEPT, HMQC), 37.55, 31.62; ESI-MS (m|z): 510 (M+H+);HRMS (ESI): calcd for C22H18N306F3SNa(M+Na+)532.0760; found532.0761. A mixture of 36a (35 mg, 0.069 mmol), triethylamine (30 ul,0.22 mmol), and 15 mg Pd(OH)2/C(20%Pd) in MeOH (1.5 ml) andEtOAc (1.5 ml) was stirred at rt under hydrogen atmosphere (1 atm)at rt for 2 h. The reaction mixture was filtered through a pad ofCelite. The solid was washed with 5% MeOH/CH2Cl2. The combinedorganic phases were concentrated in vacuo. The residue was puri-fied by flash column chromatography (CH2Cl2/MeOH, 100:1-20:1)to afford 32a (20 mg, 80%) as a white solid. Mp: >300°C (de-composition);[]°+154.8 (c 0.14,CHCl3); IR (KBr): 3330,2925,2848,1670,1650,1485,1316,1233,1057,944,752 cm-1; 1H NMR(500 MHz, CDCl3) 8.01 (d, J=7.5 Hz, 1H), 7.12 (t,J=7.7 Hz, 1H),6.97-6.89(m,3H), 6.83 (d,J=8.5 Hz, 1H), 6.67 (d,J=7.8 Hz, 1H), 6.14(d,J=3.6Hz,1H), 5.44 (s,1H), 4.91(d,J=3.6Hz,1H), 4.22(s,1H), 4.17(d,J=4.5 Hz, 1H), 3.29-3.24 (m, 2H), 3.16 (s, 3H), 3.02 (dd,J=14.0,4.6 Hz,1H), 1.89 (dd,J=16.2, 4.3 Hz,1H);1’cNMR(125 MHz, CDCl3);166.95,165.57,156.95,147.47,131.93,131.39,130.82,129.55,128.51,124.82, 124.75,120.59, 110.94, 109.20, 109.07, 65.35,58.93,55.48,40.58,37.61,33.84; ESI-MS (m/z): 362(M+H+); HRMS (ESI): calcdfor C21H20N303(M+H+)362.1496; found 362.1499. 4.24. Compound 3b A mixture of 36b (62.6 mg,0.123 mmol), triethylamine (34 ul,0.246 mmol), and 15 mg Pd(OH)2/C (20% Pd) in MeOH(3 ml) andEtOAc(1 ml) was stirred at rt under hydrogen atmosphere (1 bar) atrt for 2 h. The reaction mixture was filtered through a pad of Celite.The solid was rinsed with 5%%methanol/dichloromethane. Thecombined filtrates were concentrated in vacuo. The residue waspurifiedbyflashcolumnchromatography (CH2Cl2/MeOH,100:1-20:1) to afford 3b (43.0 mg, 96%) as a white solid. Mp:>300°C(dec);[a]28.7-416.2(c0.125, MeOH); IR(KBr): 3430,2979,2858, 1664, 1634,1479,1055,1012, 810, 744 cm-1; 1H NMR(400 MHz, DMSO-d6) 8.78 (s, 1H), 7.44(d,J=7.2 Hz, 1H), 7.22 (d,J=1.4Hz,1H), 7.14 (d,J=3.5 Hz,1H), 7.03 (td,J=7.7, 1.2Hz, 1H), 6.88(dd,J=8.0, 1.7 Hz, 1H), 6.73 (td,J=7.4,0.8 Hz,1H), 6.60-6.54 (m,2H), 6.19 (d,J=3.6 Hz, 1H), 4.12 (m, 2H), 3.36(m, 1H), 2.99 (dd,J=14.0, 6.4 Hz, 1H), 2.55 (m, 1H), 2.41-2.34(m, 4H); 13c NMR(100MHz, DMSO); 168.28,164.18,157.70,148.45,131.67,131.11,130.30,129.66,127.96,124.51,122.92,118.20,108.87, 108.58,108.06,64.92,58.02, 53.60, 40.47, 37.49, 31.63; ESI-MS (m/z): 362 (M+H+);HRMS (ESI): calcd for C21H20N303 (M+H+) 362.1504; found362.1499. 4.25. Azonazine diastereomer 1a (the originally proposedstructure) To a solution of 32a (14 mg, 0.039 mmol) in HOAc (2 ml) wasadded Ac20 (0.01 ml, 0.106 mmol) at rt. The resulting mixture wasstirred at rt for 6 h. The solvent was removed, and the residue wasdiluted by EtOAc. The organic layer was washed with aqueousNaHCO3,water and brine, dried over Na2SO4,and concentrated. Thecrude residue was purified by preparative TLC (EtOAc/MeOH,50:1)to afford 1a (10.5 mg, 67%) as a white solid. Mp:>300 °C (dec);[a28.2+342.7 (c 0.175, MeOH); IR (KBr): 3518, 3232, 3012,2928,2848, 1677,1649, 1485, 1391, 1241, 971,756 cm-1; 1H NMR(500 MHz, CD3CN) ò 8.10(s,1H), 8.06 (d,J=7.1 Hz, 1H), 7.26 (t,J=7.3 Hz, 1H), 7.19 (t, J=7.4 Hz, 1H), 7.01 (s, 1H), 6.91 (d,J=8.1 Hz,1H), 6.80(d,J=8.1Hz, 1H), 6.46(s,1H), 5.61 (s,1H), 4.18(s,1H), 4.14(d,J=4.5 Hz, 1H), 3.29 (d,J=14.1 Hz, 1H), 3.13 (dd,J=16.3, 2.8 Hz,1H), 3.09 (s, 3H), 2.89(dd,J=14.1, 4.7 Hz,1H), 2.41(s,3H), 2.18 (dd,J=16.3, 4.8 Hz, 1H); 13C NMR (125 MHz, CD3CN) 6 171.74, 168.24,165.77,157.67,142.95,134.78,133.77,132.82,130.35,129.28,125.35(2C),124.95,116.52,111.25,107.01, 65.97, 58.79, 56.18, 40.98, 38.20, 33.94, 24.37; ESI-MS (m/z): 404(M+H*); HRMS (ESI): calcd forC23H21N304Na (M+Na+) 426.1429; found 426.1424. 4.26. ent-(-)-Azonazine (1b) To a solution of 3b (13 mg, 0.036 mmol) in HOAc (1.5 ml) wasadded Ac2O (0.01 ml, 0.106 mmol) at rt. The resulting mixture wasstirred at rt for 4 h. The solvent was removed and the residue wasdiluted by EtOAc. The organic layer was washed with aqueousNaHCO3, water and brine, dried over Na2SO4,and concentrated. Thecrude residue was purified by preparative TLC (EtOAc/MeOH, 50:1)to afford 1b (13 mg, 89%). The single crystal for X-ray analysis wasprepared by slow evaporation from CH3CN. Mp: >350°C (dec);[x]26.5-299.3 (c 0.11, MeOH); IR (KBr): 3430,3219,2926,2849,1661,1626,1485,1394,1283,1027,740 cm-1; 1H NMR (600 MHz,CD3CN) 8 8.13 (s, 1H), 7.60 (dd,J=7.5, 0.8 Hz,1H), 7.51 (d,J=1.6 Hz,1H), 7.29 (td,J=7.8,1.3 Hz, 1H), 7.19 (td,J=7.5, 1.1 Hz, 1H), 6.96 (m,2H), 6.67 (d,J=8.1 Hz, 1H), 6.59 (s,1H), 4.27 (d,J=5.1 Hz, 1H), 4.09(d,J=6.5 Hz, 1H), 3.50 (d,J=14.2 Hz, 1H), 3.08 (dd,J=14.2, 6.9 Hz,1H), 2.84 (dd,J=16.5, 5.8 Hz,1H), 2.49 (dd,J=16.5, 2.2 Hz,1H), 2.42(s, 3H), 2.40 (s, 3H); 13C NMR (150 MHz, CD3CN) 6 171.29, 169.43,165.49,159.05,142.52,135.37,133.22,132.02,131.51,129.62,126.46,125.71,124.15,117.31,110.84,106.98,66.32,59.08,54.84, 43.41,39.24, 32.83, 24.17; ESI-MS (m/z): 404 (M+H*); HRMS (ESI): calcdfor C23H22N304(M+H*) 404.1610; found 404.1605. The above crude product was treated with HOAc (1.5ml) andAc2O (0.01 ml, 0.106 mmol), and the resulting mixture was stirredat rt for 10 h. The mixture was concentrated in vacuo, and theresidue was then diluted by EtOAc.The solution was washed withaqueous NaHCO3, water, and brine, dried over NazSO4, and con-centrated. The crude residue was purified by preparative TLC(EtOAc/MeOH, 50:1) to afford 33a (16 mg, 70% for two steps) asa white solid. [+282.10 (c 0.20, THF), IR (KBr):3224, 2924,2854,1677,1651,1619,1490,1390,1261,1162,1066,971,818 cm;HNMR(400MHz,CD3CN)88.05(s,1H), 7.83(d,J=2.7Hz,1H), 7.00(s, 1H), 6.92(d,J=8.1 Hz, 1H), 6.84(m,2H), 6.45 (s,1H), 5.63 (s,1H),4.58 (q,J=8.4 Hz, 2H), 4.19 (s,1H), 4.15 (d,J=4.3 Hz, 1H), 3.28 (d,J=14.0 Hz, 1H), 3.07 (m, 4H), 2.89 (dd,J=14.1, 4.6 Hz, 1H), 2.39 (s,3H), 2.12(s,1H).1CNMR(100 MHz, CD3CN) 6 171.37,168.37,165.76,157.59,155.33,138.00,133.81,131.38(q,J=329 Hz), 125.37, 123.71,118.38,117.26,114.37,112.57,111.29,106.99,66.7(q,J=35Hz), 65.97,65.93,58.84,56.10,40.60,38.19,34.95,33.93,30.44, 24.12. HRMS(MALDI): calcdforrC25H22N305Na (M+Na) 524.1428; found524.1404. 4.28. Azonazine analogue 33b To a solution of 11b (20 mg, 0.036 mmol) in THF (1 ml) wasadded Zn powder (5.0 mg, 0.077 mmol), Et3SiH (22.9 pl, 0.14 mmol),and AcOH (23 ul, 0.40 mmol) at rt under N2 atmosphere. The re-action mixture was stirred at rt until consumption of the startingmaterial (monitored by TLC). The reaction mixture was diluted withEtOAc and filtered through a pad of Celite. The solid was washed The above crude product was treated with HOAc (2.0 ml) andAc20 (0.01 ml, 0.106 mmol), and the resulting mixture was stirredat rt for 10 h. The mixture was concentrated in vacuo, and theresidue was then diluted by EtOAc. The solution was washed withaqueous NaHCO3, water, and brine, dried over Na2SO4, and con-centrated. The crude residue was purified by preparative TLC(EtOAc/MeOH,50:1) to afford 33b (12.6 mg, 70% for two steps) as26a white solid. Mp:>270 °C (dec); [a26 -251.4 (c 0.725, THF); IR(KBr): 3451,2964,2917,2844,1673,1656,1492,1391,1259,1154,1077, 1018, 797 cm-1;1H NMR(400 MHz, DMSO-d6)88.82 (s,1H),8.00 (d,J=8.7Hz,1H), 7.39 (s,1H), 7.35(d,J=2.5 Hz,1H), 6.99(s,1H),6.97 (d,J=1.8 Hz, 1H), 6.74-6.68 (d,J=8.5 Hz, 2H), 4.87-4.71 (m,2H), 4.25 (s,1H), 4.16(d,J=6.3 Hz, 1H), 3.40 (d,J=13.9 Hz,1H), 3.06(dd,J=14.0, 6.6 Hz, 1H), 2.80 (dd,J=16.2, 5.1 Hz, 1H), 2.50-2.43(m,1H), 2.38 (s, 3H), 2.35 (s, 3H); 13C NMR (100 MHz, DMSO-d6); 169.64,168.07,164.17,157.14,153.98,135.95,135.82,131.76,130.44,129.98, 124.92,124.02 (q,J=277 Hz, 1C), 116.20, 113.55, 110.82,109.49,105.49, 65.13 (q, J=34 Hz, 1C), 64.73,57.37,53.33, 40.64,37.73,31.67,23.36; ESI-MS (m/z): 502 (M+H+); HRMS (ESI): calcdfor C25H23N305F3(M+H*)502.1576; found 502.1584. Acknowledgements Financial support from the Ministry of Science and Technologyofthe People’s Republic of China (2010CB833200, SS2013AA090203) and National Natural Science Foundation of China grant(21032002) is greatly appreciated. The authors would like to thankMr.Lan-De Zhang at Chemistry Department of Nanjing Universityfor his assistance in the 'H NMR analysis, and Dr. Gang Chen andJian-Feng Mou at SIOC for their help in performing the electrolysischemistry. Supplementary data Supplementary data related to this article can be found at http://dx.doi.org/10.1016/j.tet.2014.03.061. References and notes ( 1 . Cole, R. J ; Jarvis, B . B.; Schweiker t , M. A. Handbook of Secondary Fungal M e- t abolites; Ac a demic : S a n D iego, USA, 20 0 3, Vol s . I-I I I. ) ( 2. W u, Q. X . ; C r ews, M . S. ; Dr a skovic, M . ; S o h n , J; J oh n son, T. A . ; Te n n e y , K.; V aleriote, F . A.; Yao, X. J; Bje l danes, L. F; Crews, P . Org. Lett. 2010, 12, 4 458. ) 3.Lindquist, N.; Fenical, W.; Van Duyne, G. D.; Clardy, J. j. Am. Chem. Soc. 1991, 113,2303. 4. For total syntheses of diazonamide A: (a) Nicolaou, K. C.; Bella, M.; Chen, D. Y.K.; Huang, X.; Ling, T.; Snyder, S. A. Angew. Chem., Int. Ed. 2002, 41,3495; (b)Burgett, A. W. G.; Li, Q; Wei, Q.; Harran, P. G. Angew. Chem., Int. Ed. 2003, 42,4961; (c) Nicolaou, K. C.; Bheema Rao, P.; Hao, J; Reddy, M. V.; Rassias, G.;Huang, X.;Chen, D. Y. K.; Snyder,S. A. Angew. Chem., Int. Ed. 2003,42,1753;(d)Cheung, C.-M.; Goldberg, F. W.;Magnus, P.; Russell, C. J.; Turnbull, R.;Lynch, V.J.Am. Chem. Soc. 2007, 129, 12320;(e) Mai, C.-K.; Sammons, M. F; Sammakia, T.Angew. Chem., Int.Ed. 2010, 49, 2397; (f) Knowles, R. R.; Carpenter, J; Blakey, S.B.; Kayano, A.; Mangion, I. K.; Sinz, C. J; MacMillan, D. W. C. Chem. Sci. 2011,2,308. 5.For a recent study on the synthesis of azonazine, see: Ghosh, S.; Kinthada, L. K.;Bhunia, S.; Bisai, A. Chem. Commun. 2012, 10132. 6.F1or a recent synthesis of benzofuroindolines: Beaud, R.; Guillot,R.; Kouklovsky,C.; Vincent, G. Angew. Chem., Int. Ed. 2012, 51,12546. ( Sil v a,L. F; Olofsson, B . Nat. Prod. Re p. 2011, 2 8,1722;(g ) Du sc hek, A.; Kirsch, S.F. Angew. C h em., Int. Ed. 2 011, 50, 1 5 24. ) ( 12. Coste, A. ; Toumi, M. ; Wright, K. ; Razafimahal e o,V.; Couty, F.; Marrot, J; Evano, G. Org. Lett.2008, 10,3841. ) ( 13. ( a) Suzuki, K .; Sasak i , Y.; E n do, N. ; Mihara, Y. C hem. P h arm. Bu l l. 1 9 81, 29, 2 3 3; (b) D u row, A . C.; L ong, G. C.; O ' C onnel, S. J; Will i s, C . L . Org . Let t . 2006, 8 , 5401. ) Leathen, M. L.; Rosen, B. R.; Wolfe, J. P. J. Org.Chem. 2009,74,5107. ( 15. Konda - Yamada , Y.; Okada, C.; Y o s hida, K.; Umeda, Y.; Ar i ma, S.; Sato, N.; K ai, T.; T a kayanagi, H .; H a rigaya, Y. Tetrahedron 2 002, 58, 7 85 1 . ) ( B laser, G .;S a nde r s o n , J. M . ; Ba t sa n ov, A. S .; Ho w ard, J . A . K . T et r a hedron Lett. 2008,49,2795 . ) ( ( a) S ainsbury, M . ; W y att, J. J. C hem. S o c., P erkin Trans. 1 1 979,1 0 8;(b ) Kee c h, P. G .; Bunce, N. J .J. Appl. Electrochem . 2003, 33, 7 9; ( c ) Kim, S.; H irose, K .; Uem a tsu, ) ( J ; Mika m i,Y.; Chiba, K . Chem.-E ur .J. 2 0 12,18,6284; (d ) En a che, T. A . ; O l iveira- B rett, A. M. E lectroanalysis 2 011, 2 3 , 1 337. ) 18.(a)Dankwardt,J.W. Angew. Chem., Int. Ed. 2004, 43,2428;(b)Guan, B. T.; Xiang,S. K.; Wu, T.; Sun, Z. P.; Wang, B. Q; Zhao, K. Q.; Shi, Z. J. Chem. Commun. 2008,1437. 19. The authors (Ref. 2) favored to assign the absolute configuration of azonazine inparallel to that of diazonamide A (R10/S11), since the chemical shifts of dihy-drobenzofuran of diazonamide A (Ref. 3) were virtually identical to those of (+)-azonazine. ( 20. A r ev iew on fl u orin e in m e d i c inal che m istry, see : Pur s er, S.; Moo r e , P. R . ; S wallow, S.; Gouverne u r, V. Chem. S oc. Rev. 2008, 37 , 320 . ) ( 21. G h a ffa r z a deh, M . ; Joghan, S. S. ; F a raji, F. T etrahedron L e tt. 2012,53, 2 0 3 . ) $ - see front matter @ Elsevier Ltd.All rights reserved.http://dx.doi.org/j.tet.ww.rysstech.com耐士科技 www.rysstech.com士科技

确定

还剩12页未读,是否继续阅读?

上海鑫欣生物科技有限公司为您提供《化学药中主要物质含量分析检测方案 》,该方案主要用于化药新药研发中其他检测,参考标准--,《化学药中主要物质含量分析检测方案 》用到的仪器有

相关方案

更多

该厂商其他方案

更多