A microwave-assisted, sequential, one-pot protocol has been developed for the synthesis of a variety of benzothiadiazin-3-one-1,1-dioxides. This protocol utilizes a copper catalyzed N-arylation of a-bromobenzenesulfonamides with a number of amines to generate the corresponding 2 aminobenzenesulfonamides,which undergo cyclization to the desired sultams using carbonyl diimidazole (CDI). A range ofconditions was evaluated for the key C–N bond formation step with tolerance toward functionalized amines.

方案详情

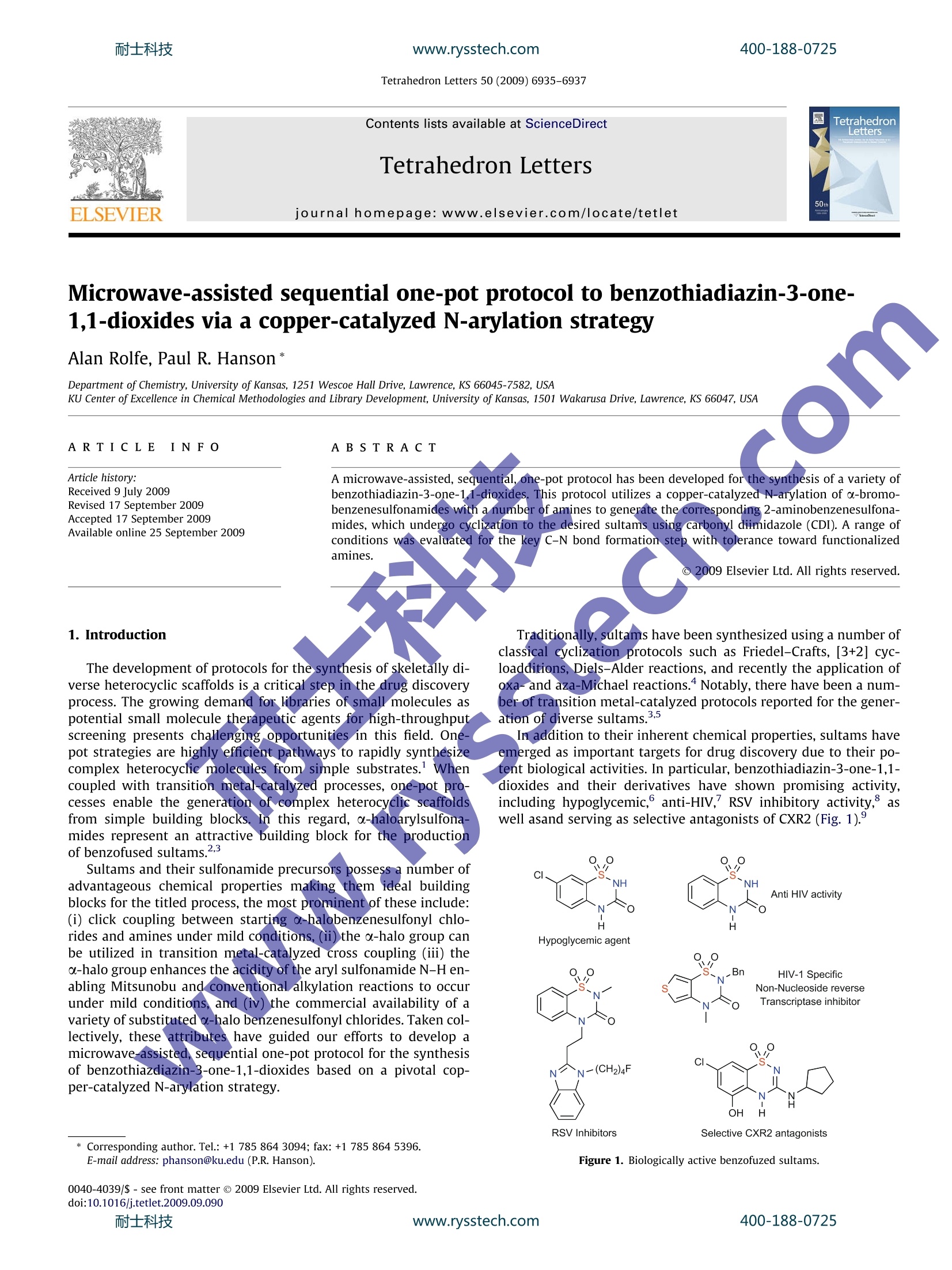

www.rysstech.comTetrahedron Letters 50 (2009) 6935-6937耐士科技400-188-0725 耐士科技400-188-0725www.rysstech.com6936A. Rolfe, P. R. Hanson/Tetrahedron Letters 50 (2009) 6935-6937 Contents lists available at ScienceDirect Tetrahedron Letters ELSEVIER journalhomepage: www.elsevier.com/locate/tetlet Microwave-assisted sequential one-pot protocol to benzothiadiazin-3-one-1,1-dioxides via a copper-catalyzed N-arylation strategy Alan Rolfe, Paul R. Hanson* Department of Chemistry, University of Kansas, 1251 Wescoe Hall Drive, Lawrence, KS 66045-7582, USAKU Center of Excellence in Chemical Methodologies and Library Development, University of Kansas, 1501 Wakarusa Drive, Lawrence, KS 66047, USA ABSTRAC T Article history: Received 9 July 2009 Revised 17 September 2009 Accepted17 September 2009 Available online 25 September 2009 1. Introduction The development of protocols for the synthesis of skeletally di-verse heterocyclic scaffolds is a critical step in the drug discoveryprocess. The growing demand for libraries of small molecules aspotential small molecule therapeutic agents for high-throughputscreening presents challenging opportunities in this field. One-pot strategies are highly efficient pathways to rapidly synthesizecomplex heterocyclic molecules from simple substrates. Whencoupled with transition metal-catalyzed processes,one-pot pro-cesses enable the generation of complex heterocyclic scaffoldsfrom simple building blocks. In this regard, o-haloarylsulfona-mides represent an attractive building block for the productionof benzofused sultams.2.3 Sultams and their sulfonamide precursors possess a number ofadvantageous chemical properties making them ideal buildingblocks for the titled process, the most prominent of these include:(i) click coupling between starting a-halobenzenesulfo(1)nyl chlo-rides and amines under mild conditions, (ii) the o-halo group canbe utilized in transition metal-catalyzed cross coupling (iii) theo-halo group enhances the acidity of the aryl sulfonamide N-H en-abling Mitsunobu and conventional alkylation reactions to occurunder mild conditions, and (iv) the commercial availability of avariety of substitutedo-halo benzenesulfonyl chlorides. Taken col-lectively, these attributes have guided our efforts to develop amicrowave-assisted, sequential one-pot protocol for the synthesisof benzothiazdiazin-3-one-1,1-dioxides based on a pivotal cop-per-catalyzed N-arylation strategy. ( * Corresponding author. Tel.: +1 785 864 30 9 4; fax: +1 78 5 864 5396. E-mail address: p h anson@ku . edu (P . R. H a nson). ) o 2009 Elsevier Ltd. All rights reserved. Traditionally, sultams have been synthesized using a number ofclassical cyclization protocols such as Friedel-Crafts,[3+2] cyc-loadditions, Diels-Alder reactions, and recently the application ofoxa-and aza-Michael reactions.Notably, there have been a num-ber of transition metal-catalyzed protocols reported for the gener-.35ation of diverse sultams.3.5 In addition to their inherent chemical properties, sultams haveemerged as important targets for drug discovery due to their po-tent biological activities. In particular, benzothiadiazin-3-one-1,1-dioxides and their derivatives have shown promising activity,including hypoglycemic,anti-HIV,’ RSV inhibitory activity, aswell asand serving as selective antagonists of CXR2 (Fig. 1). Figure 1. Biologically active benzofuzed sultams. 2. Results and discussion Since the observation of copper-catalyzed coupling of a arylbr-omide with an acetanilide by Goldberg in 1907,1copper-catalyzedN-arylation represents an effective reaction for the formation of C-N and C-O bonds.11 FEarly reports classically required harsh reac-tion conditions and stoichiometric quantities of copper. Seminalwork by Buchwald, Hartwig and Ley reported notable advancesin both ligands and reduced reaction temperatures for copper-cat-alyzed couplings. Traditionally, benzothiadiazin-3-one-1,1-dioxides have beennthesized in a number of linear protocols.6-9,13Envisioning acopper-catalyzed approach to benzothiadiazin-3-one-1,1-dioxides,a variety of conditions were evaluated to probe and subsequentlyoptimize the N-arylation of allyl amine with N-allyl-2-bromo-4-fluorobenzenesulfonamide 1 to yield N-allyl-2-(allylamino)-4-flu-orobenzenesulfonamide 2 (Scheme 1, Table 1).14 An array of cop-per sources (Table 1, entries 1-3) and ligands (Table 1, entries 4-7) were initially evaluated followed by a survey of reaction solvent.Under conventional heating, the desired sulfonamide 2, could beisolated in 92% yield after 6 h. Further optimization was achieved using microwave irradia-tion, which reduced reaction times to 11 min at 150 ℃ with com-parable yields (Table 1, entry 8 vs 11).With these results in hand,a number of 2-aminobenzenesulfonamide derivatives were syn-thesized to demonstrate the versatility of the protocol with a variety of amines, amides,and sulfonamide starting materials (Scheme2, Table 2). Table 1 Screening conditions for reaction optimization Entryad [Cu]cat. Ligand Solvent Y 1 CuI L-Proline DMSO 65 2 CuBr L-Proline DMSO 55 3 Cu2O L-Proline DMSO 10 4 CuI (CH2OH)2 DMSO 78 5 CuI 1,10-Phenanthroline DMSO 94 6 CuI DBU DMSO 50 7 CuI (CH2NHMe)2 DMSO 72 8 CuI 1,10-Phenanthroline DMF 92 9 Cul 1,10-Phenanthroline Dioxane 84 10 CuI 1,10-Phenanthroline DMF 96 11 CuI 1,10-Phenanthroline DMF 94 ° Reaction conditions: 1 (0.17 mmol), allylamine (0.2 mmol), CuX (0.017 mmol),ligand (0.034 mmol), Cs2CO3 (0.34 mmol) in solvent (0.5M) at 100 ℃ for 6 h. Microwave irradiation for 22 min at 140℃. Microwave irradiation for 11 min at 150°C. Entry° R R² R3 R4-NH, Yield (%) 1 H H Bn 4-MeOBnNH, 90 2 H H Bn 4-ClBnNH, 89 3 H H Bn Octylamine 94 4 H H Bn Phenethylamine 91 5 H H Bn Allylamine 96 6 H H 4-MeOBn Cyclopentylamine 90 7 H H Cp 4-MeOBnNH, 96 8 H F Allyl Allyl NH2 94 9 H F n-Butyl BnNH2 92 10 CF3 H Allyl n-Butyl amine 95 11 CF3 H (CH2)2Bn Propargyl amine 69 12 H F Allyl EtC(O)NH2 80 Reaction conditions: sulfonamide (0.17 mmol), amine (0.2 mmol),Cul(0.017 mmol),1,10-phenanthroline (0.034 mmol),Cs2CO3(0.34 mmol) in dry DMSO(0.5 M) in microwave for 11 min at 150C. With an array of2-aminobenzenesulonfamides in hand, cycliza-tion to the corresponding benzothiadiazin-3-one-1,1-dioxideswith carbonyl diimidazole (CDI) was achieved in excellent yieldsunder thermal conditions (Scheme 3, Table 3).13b,17 Finally with both protocols in hand, a sequential, two-step,one-pot approach was achieved whereby microwave irradiation affor-ded the desired benzothiadiazin-3-one-1,1-dioxides in good yield(Scheme 4).8 To achieve this, the CDI cyclization was conductedunder microwave irradiation following the initial copper-catalyzedstep in the same microwave vial.l. This required a change of solventto DMF which was the optimum compatible solvent for both the N-arylation and CDI cyclization steps while maintaining good yields. Table 3 Entry" R1 R2 R R4-NH, Yield(%) 1 H H Bn 4-MeOBnNH, 96 2 H H Bn Octylamine 96 3 H F Allyl Allylamine 98 4 H H Bn Phenethylamine 94 5 CF3 H Allyl n-Butylamine 97 6 H H 4-MeOBn Cyclopentylamine 92 7 H H Cp 4-MeOBnNH, 93 8 H F n-Butyl BnNH2 97 Reaction conditions: sulfonamide (0.17 mmol), CDI(0.69 mmol), Et3N(0.34 mmol) in dry DMF (0.2 M) at 100 C for 6 h. R1=H,R2=Allyl, R3=Allyl,72% R1=F,R2=4-MeOBn, R3=Octyl, 68% R1=H,R2= Allyl,R3=OBn, 73% In conclusion, we have developed a microwave-assisted, cop-per-catalyzed, sequential, one-pot synthesis of benzothiadiazin-3-one-1,1-dioxides. A variety of derivatives of benzothiadiazin-3-one-1,1-dioxides can be rapidly accessed by combining a copper-mediated N-arylation followed by cyclization with CDI.Further ef-forts toward employment of this method in library production willbe published in due course. Acknowledgments This publication was made possible by the Pilot-Scale LibrariesProgram (P41 GM076302), the National Institutes of General Med-ical Sciences (KU Chemical Methodologies and Library Develop-ment Center of Excellence P50 GM069663) and by Grant NumberP20 RRO15563 from the National Center for Research Resources,a component of the National Institutes of Health, and the State ofKansas. Its contents are solely the responsibility of the authorsand do not necessarily represent the official view of the NCRR orNIH. Supplementary data Supplementary data associated with this article Letter can befound, in the online version, at doi:10.1016/j.tetlet.2009.09.090. References and notes ( 1. ( a) Fustero, S.; Jimeez, D.; Sánchez-Rosell6, M.; del P ozo, C . J. Am. Chem. S oc. 2007,129,6700-6701;(b) Bi, H.-P.; Liu, X.-Y.; G o u, F.-R.; G u o, L . - N .; D u an, X .- H .; Shu,X.-Z.; Liang, Y.-M. Angew. Chem., Int. Ed. 2007,46,70 6 8- 70 71;( c ) Z en g Y .; Reddy,D.S. ; Hirt,E.; Aube, J. Org. Lett. 2004, 6, 4993- 4 -49995;(d) K irsch b au m , S .; Waldmann, H. T e trahedron Lett. 1997, 38,2829-2832 ) ( 2. F 1 or the use of a-halo arylsulfonamides in sy n thesis of sulta m s see : (a) G rig g , R.; York, M . T etrahedron L ett. 2000, 41, 7 255-7 2 5 8; (b ) E v ans, P . ; Mc Ca b e, T. ; De M organ, B. S.; Reau, S. Org. Lett. 2005, 7,44-46; (c) Vas udevan, A.; T s e n g , P .-S.; D juric, S. W. Tetrahedron Lett. 2006, 47,8591-8593;(d) Paquette, L. A.; Du r a,R.;Fosnaugh, N .; Stephanian, M. J . Org. Chem . 2006 , 71 , 8445-8483; For radical c yclization:(f) B ressy, C.; Menant,C . ; Piva,O . Syn l ett 2005,57 7 -582; For alkyne 6-endo cyclizations:(g) B arange, D . K .; N i sh a d, T. C.; Swamy, K .; Bandameedi, (8 V .; Kumar, D.; Bukkapattanam, R. S . ; V y a s , K . ; Pal, M . J . Org. Chem. 2007, 7 2,8547-8550. ) 3.(a) Zhou, A.; Hanson, P. R. Org. Lett.2008, 10,2951-2954;(b) Jeon, K.O.;Rayabarapu, D.; Rolfe, A.; Volp, K.;Omar, I; Hanson, P. R. Tetrahedron 2009,4992-5000. ( 4.( hou, A.; Rayabarapu, K. D . : Hanso n , P . R . O r g. Lett. 200 9 ,531-53 4; ( b) Rolfe, A.; Young, K .; Hanson, P. R . Eur . J . Or g . Chem. 2008,5254-5262;( c ) Ro l feYoung, K.; V olp, K . A .; S choenen, F . ; N e u enswander, B.; Lu s hingt o n, G . H.; H anson, P. R. J . Comb. Chem.2009,1 1, 732-738;(d)Rayabarapu, D. K.; Zhou,A . ; J eon, K . O.; Samarakoon, T . ; R olfe, A .; Siddiqui, H.; Hanson, P. R . Tetrahedro n 2009,6 5 ,3180-3188. and references cited therein.5. (a) McReynolds, M. D.; D ougherty, J. M.; Hanson, P . R. Chem. Re v . 2004,104, ) ( 2239-2258;(b ) Jimenez-Hopkins,M.; Hanson, P. R. Org. Lett. 2 008, 1 0, 2951- 2 954.a n d references cited therein. ) ( 6. W ales, J . K.; Krees, S. V .; G rant, A. M.; V i kroa, J.K . ; W o l ff, F. W. J. Pharm. Exp. Ther. 1968 , 164,421-432. ) ( 7. ( ( a) B uckheit, W. R. ; Fliaka-Boltz, V.; De c k e r, D. W; Robe r son, L. J; Pyle, C. A.; W hite, L . E.; Bowden, B. J . ;M c Mahon,J. B. , B o y d ,M. R. ; Bader , J. P.; Nickell, D. G .; Barth, H.; Antonucci, T . K . Antiviral Res. 1994, 2 5,43-56; (b)Arranz, E. M.; D iaz, J. A.; Ingate, S. T.; Witvrouw, M.; P a nnecouque, C.; Bal z arini,J.; C lercq, E.D.; Vega,S. Bioorg. Med. Che m .1999 , 7 ,2811-2822. ) ( 8. C ombrink, K. D. ; Gulgeze, H. B.; T hu r ing,J. W . ; Yu, K.-L.; Civiello, R. L.; Zhang, Y.; P earce, B. C.; Yin, Z .; La ngley, D. R. ; K a d ow, K. F . ; C ia n ci, C. W.; Li, Z .; Cla r ke,J.;Genovesi, E.V.; M edina, I.; Lamb, L .;;Yang,Z.; Zadjura, L.; Krystal, M. ; Meanwell, N . A. Bioorg. Med . Ch e m. L ett. 2007, 17, 4784-4790. ) ( 9. W ang, Y.; B u sch-Petersen, J; Wa n g, F.; Ma, L.; F u, W.; Kern s , J. K . ; Jin , J.; P alovich, M. R . ; Shen, J.-K.; B urman, M.; Fo l ey,J.J.; Schmidt, D. B.; Hunsberger,G. E.; Sara u , H. M.; Widdowson, K . L. Bioorg. Med. Chem. L ett. 2007, 1 7,3864-3867. ) ( 10.G(olberg, I. Ber. Dtsch. Chem. Ge s .1907,40,4541. ) ( 1 1 . ( ( a ) G eorge, T.G.; Endeshaw, M . M . ; Morgan, R. E.; M ahasenan, K.V.; D e lfin, D .A.; Mukherjee, M. S . ; Y akovich, A. J.; Fotie, J; Li , C.;Werbovetz, K . A. Bioorg.Med. Chem. Lett 2007,15,6071-6079; (b) Zhu, L.; Li, G.; Luo, L.; Guo, P.; Lan,J; Y ou0,UJ.J. Org. Chem. 2009, 74,2200-2202;(c) F eng,E.; Huang, H.; Z hou, Y.; Ye,D.; Jiang, H.; Liu , H. J. Org. Chem . 2009,7 4 ,2846-2849; (d) Stieter, E. R.;Bhayana, B.; B uchwald, S. L . J . Am. Chem. Soc. 2009,31, 78-88. ) 12.(a) Klapars, A.; Abtilla, J. C.; Huang, X.; Buchwald, S. L. J. Am. Chem. Soc. 2001,123, 7727; (b) Hartwig, J. F. Synlett 2006, 1283;(c) Ley, S. V.; Thomas, A. W.Angew. Chem. Int. Ed. 2003, 42,5400. ( 13. (a)B o verie, S.; A ntoine, M.-H.; S o mers, F. ; Becker, B.; S e bille, S .; Ouedraogo,R. ; Counerotte, S . ; P irotte, B.; Lebrun, P.; Tullio , P. J. Med. Chem . 2005, 48, 3492 - 3 503; ( b ) Khazi, I . A.; Jung, Y. - S. Lett . Org . Chem. 2007,4,4 2 3-428. ) ( 14. ( a) Lai, G.; Gum, R . J.; Daly,M.; Fry, E. H. ; Hutchins, C.; Abad - Zapatero, C ; v o nGeldern, T. W. Bioorg. Med. Chem. Lett. 20 0 6, 1 6,1807-1810 ; (b) Fr e eman,H.S.; B utler, J . R.; Freedman, L. D . J. Org. Chem. 1978,43, 4975-4978; (c) Ba co n , R. G . R .; Rennison, S. G. J . Chem. Soc . 1969, 312; (d) Wu, Y.J.; He, H. ; L'Heureux, A. T etrahedron Lett. 2004, 4 4, 4 217-4218; (e) Ki m , J. K . ; L e e, Y.; L e e,J;D o , Y., Chang, S. J. Org. Chem.2008,73,9454-9457. ) 15. W\hile final yields obtained with DMSO,using DMF gave results within 5%experimental error. However it was found that under microwave conditions at150℃, a small amount of by-product was formed from the addition ofdimethylamine into the 4-F position of the benzene ring in a SnAr mechanism.It is proposed that a small amount of dimethylamine is produced from thedecomposition of DMF under these conditions and hence DMSO is a bettersolvent for such substrates. 16.0. Dstidte General procedure for the N-arylation of a-bromobenzenesulfonamides: Into a microwave reaction vial was added sulfonamide (0.17 mmol,1 equiv), Cul(0.017 mmol. 0.1 equiv), 1,10-phenanthroline (0.034 mmol, 0.2 equiv), Cs2CO3(0.34 mmol, 2 equiv), dry DMSO or DMF (0.5M), and amine (0.2 mmol,1.22( equiv). The reaction was heated in the microwave (Biotage initiator,0Ldwww.biotage.com) at 150C for 11 min. After such time, the crude reactionwas purified by flash chromatography [hexane/EtOAc, 8:2] to afford thedesired product as a solid. Table 2,, entry 8. FTIR (neat): 3400,1579,1301,1149,547 cm-;mp178-181℃:HNMR(400MHz, CDCl;)8 7.73(dd,J=8.5,6.6 Hz,1H), 6.42 (ddd,J=13.5,9.7, 2.0 Hz, 2H), 6.19 (s, 1H), 5.98-5.83 (m, 1H), 5.67(qt, J=15.0, 7.5 Hz, 1H), 5.25 (dd,J=19.5, 13.8 Hz, 2H), 5.12 (dd,J=25.7,13.7Hz, 2H), 4.67(t,J=5.6 Hz, 1H), 3.88-3.74 (m, 2H), 3.52 (t,J=5.8 Hz,2H);CNMR(126 MHz,CDCl3)8 167.8,165.8,147.9(d,Jc-F=13.1 Hz), 133.2,132.7,117.8, 116.9,103.5,103.3,99.6,99.4,46.1; HRMS calcd for C12H16FN202S(M+H)271.0917; found 271.0923. ( 7 . G eneral procedure for the synthesis ofbenzothiadiazin-3-one-1,1-dioxides via CDI cyc lization: T o a round-bottomed flask was added sulfonamide (0.17 mmol, 1 e quiv), dry DMF (0.2M ) , EtgN ( 0 .34 m m ol, 2 e quiv) an d CDI (0. 6 9 mmol, 4 e q uiv ) . The reaction mixture was heated at 1 00 C for 6 h, c ooled t o rt and concentrated under reduced p r essure. T h e crude oil w a s di l uted in C H 2Cl2, w ashed with 1 M HC l (a q ,5 mL), water (5 mL), an d dried (M g SO4). Subsequent ' filtration an d concentration yielded a crude oi l which was p urified by flash c hromatography [hexane/EtOAc, 7:3] to afford the desired product as c lear oil. (Tabl e 3, entry 3) . FTIR (neat) : 3400,1575, 1 310, 1 149 cm- 1 ; H N M R (500 MHz, CDCl3) 8 7 . 92-7.83 (m, 1H), 7.03-6. 9 4 (m , 2H ) , 6. 0 4-5.88 (m, 2H), 5.39-5.30(m, 2H), 5.29-5.19 (m, 2H), 4.69-4.59 (m,2H), 4.52-4.46 (m, 2H); ’C NMR ( 1 26MHz, CDCl)81 6 6.7, 16 4 .6,15 0 .2,13 8 .8 (dd, Jc-F=10.8 Hz), 1 31.6,130.7,125.3,1 1 9.2,118.0,11 1 .1,104.7,104.4,48.5,44.8; HRMS calcd for C13H13FN202S(M+H)*297.0709; f o und 297.0712. ) ( 18 G eneral one-pot procedure f o r t h e s y nthesis o f benzothiadiazin-3-one-1,1-dioxides: Into a microwave reaction vial (0.5-2.0 ml) w a s added sul f onamide (0.17 mmol, 1 equiv), CuI (0 .017 mmol. 0.1 equiv), 1 , 10-phenanthroline ( 0.034 mmol, 0.2 equiv), Cs2CO3 ( 0.34 m mol, 2 equiv), d ry solvent (0.5M ) , and amine (0.2 mmol, 1.2 equiv). The reaction was heated in the microwave ( Biotage i nitiator, www.biotage.com) at 150℃ for 1 1 min. After such time Et3N (0.34 mmol, 2 equiv) and CDI (0.69 m mol, 4 equiv) was a d ded directly to the microwave vial. The r eaction mixture was heated at 150 ℃ f o r 11 m in, cooled to rt and concentrated u nder reduced p r essure. The crude oil was d i luted inCH2Cl2, washed with 1 M HCl (aq, 5 mL), water (5 mL) a n d dried (MgSO4). S ubsequent filtration and concentration yielded a cr u de oil, which was purified b y flash chromatography [hexane/EtOAc, 7:3] to a f ford the desired p roduct. ) ww.rysstech.com耐士科技 www.rysstech.com

确定

还剩1页未读,是否继续阅读?

上海鑫欣生物科技有限公司为您提供《化学药中特殊物质和基团检测方案 》,该方案主要用于化药新药研发中其他检测,参考标准--,《化学药中特殊物质和基团检测方案 》用到的仪器有

相关方案

更多

该厂商其他方案

更多