方案详情

文

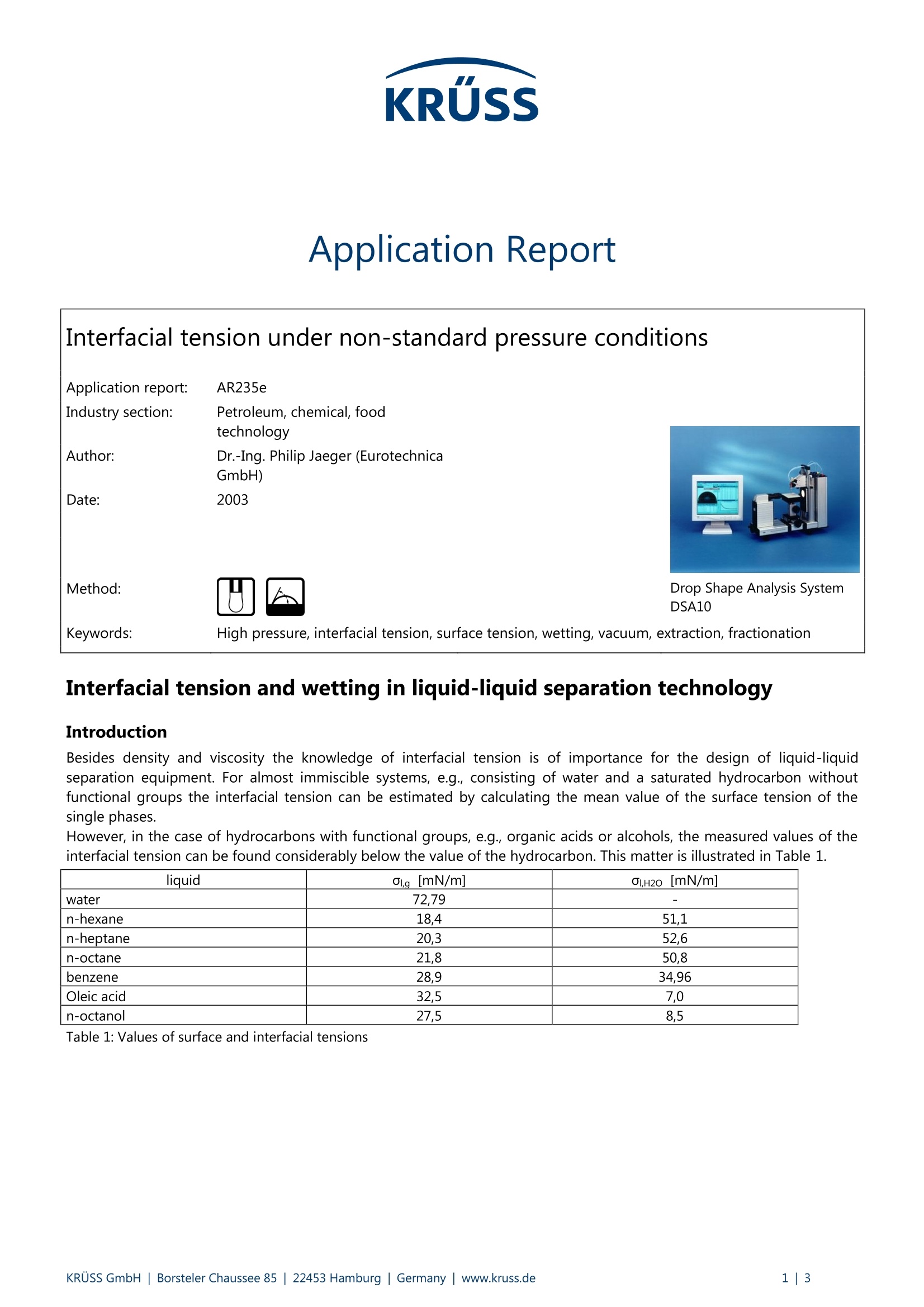

标准压力和室温下,液体间表面张力测量可以使用板法或环法。对于高度不稳定的液体则需要封装在高压环境中。KRUSS基于悬滴和座滴法开发出了接近实际过程的可测量设备。

方案详情

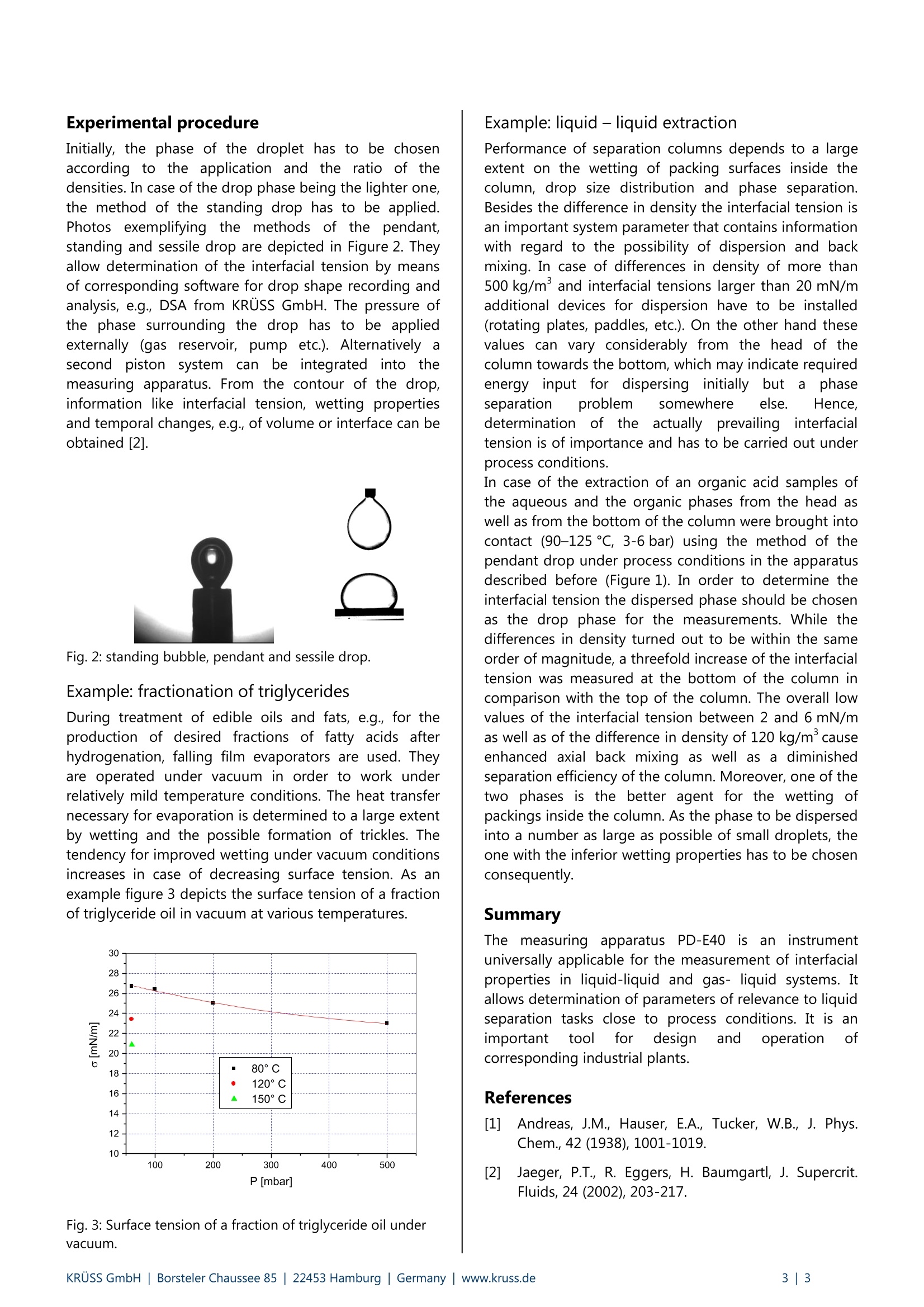

KRUSS Application Report Interfacial tension under non-standard pressure conditions Application report: AR235e Industry section: Petroleum, chemical, food technology Author: Dr.-Ing. Philip Jaeger (Eurotechnica GmbH) Date: 2003 Method: UA D rop Shap e Analys is System DSA10 Keywords: High pressure, interfacial tension, surface tension, wetting, vacuum, extraction, fractionation Interfacial tension and wetting in liquid-liquid separation technology Introduction Besides density and viscosity the knowledge of interfacial tension is of importance for the design of liquid-liquidseparation equipment. For almost immiscible systems, e.g., consisting of water and a saturated hydrocarbon withoutfunctional groups the interfacial tension can be estimated by calculating the mean value of the surface tension of thesingle phases. However, in the case of hydrocarbons with functional groups, e.g., organic acids or alcohols, the measured values of theinterfacial tension can be found considerably below thevalue of the hydrocarbon. This matter is illustrated in Table 1. liquid alg [mN/m] O,H2o [mN/m] water 72,79 一 n-hexane 18,4 51,1 n-heptane 20,3 52,6 n-octane 21,8 50,8 benzene 28,9 34,96 Oleic acid 32,5 7,0 n-octanol 27,5 8,5 Table 1: Values of surface and interfacial tensions At ambient conditions, i.e., standard pressure and roomtemperature, the interfacial tension between two liquidscan be determined with the help of the Wilhelmy-Plateor the Du Nouy-Ring method. In case of highly volatileliquids the complete system has to be encapsulated insome sort of pressure chamber. This autoclave needs tobe evacuated before the respective liquids enter and themeasuring conditionsareestablished. Then, deter-mination of the wetting force becomes technicallydemanding since the sample liquids and the system fordetecting the force are separated from each other. Itbecomess d transmit the force for itsdetermination e.g. gravimetrically. In addition, thematerial transport that occurs in extractive processes canonly be defined and documented in an unsatisfactorymanner. In cooperation with the company KRUSS GmbH theEurotechnica GmbH has developed an apparatus basedon the measuring method of the pendant, standing orsessile droplet [1], that allows measurements close to theoperating conditions of liquid-liquid separation columnsworking in the droplet- and falling film mode. Whenjoining two fluid phases within a pressure tight view cell,defined conditions regarding pressure, temperature andcomposition of the adjoining phases can be adjusted.The interfacial tension of the adjoining phases can thusbe determined close to conditions of the actual processespecially in dependence on their compositions. Fig. 1: PD-E40 for measuring interfacial tension and contactangle. Figure 1 depicts the PD-E40 apparatus for investigationof liquid-liquid and gas-liquid systems, respectively,under pressures up to 40 bar. Besides determination ofinterfacial tension the volume of the view cell of the PD-E40 containing a relatively large high pressure window(optical view diameter 32 mm) is ready for investigationof wetting on solid surfaces like packing materials, e.g. inthe case of mixtures of volatile hydrocarbons at elevatedpressures. A number of examples for application arelisted in Table 2. typical range of technical drop phase surrounding temperature and application phase pressure fine chemicals aqueous organic phase 5 -20 bar, phase + 十 40° bis 120°℃ transfer transfer component component petro- bitumen, Aliphatic and 30 bar, 180°C chemistry asphaltenes aromatic compounds (Xylenel) lubricants water organic phase 3-5 bar, 180°C (emulsions) absorption, water + cO2, H2s 1-10 bar, 20°C washing additives towers food edible oil solvent vacuum (to 5 mbar) technology fraction up to 80°C refrigeration transmission tetrafluoroetha 1-40 bar technology oil ne (R134a), -30°bis 40°C propane distillation, alcohol vapour phase 50 mbar-1 bar rectification volatile 60° bis 80°C organic solvents coating glue solvent (water, 1 bar, 20°C technology hexane, benzene) Table 2: Technical applications for measurement ofinterfacial tensions. Experimental procedure Initially, the phase of the droplet has to be chosenaccording to the application and the ratio of thedensities. In case of the drop phase being the lighter one,the method of the standing drop has to be applied.Photos exemplifying the methods of the pendant,standing and sessile drop are depicted in Figure 2. Theyallow determination of the interfacial tension by meansof corresponding software for drop shape recording andanalysis, e.g., DSA from KRUSS GmbH. The pressure ofthe phase surrounding the drop has to be appliedexternally (gas reservoir, pump etc.). Alternatively asecondppistonsystem can be integratedinto themeasuring apparatus. From the contour of the drop,information like interfacial tension, wetting propertiesand temporal changes,e.g., of volume or interface can beobtained [21. Fig. 2: standing bubble, pendant and sessile drop. Example: fractionation of triglycerides During treatment of edible oils and fats, e.g., for theproduction of desired fractions of fatty acids afterhydrogenation, falling film evaporators are used. Theyare operated under vacuum in order to work underrelatively mild temperature conditions. The heat transfernecessary for evaporation is determined to a large extentby wetting and the possible formation of trickles. Thetendency for improved wetting under vacuum conditionsincreases in case of decreasing surface tension. As anexample figure 3 depicts the surface tension of a fractionof triglyceride oil in vacuum at various temperatures. Fig. 3: Surface tension of a fraction of triglyceride oil undervacuum. Example: liquid - liquid extraction Performance of separation columns depends to a largeextent on the wetting of packing surfaces inside thecolumn, drop size distribution and phase separation.Besides the difference in density the interfacial tension isan important system parameter that contains informationwith regard to the possibility of dispersion and backmixing. In case of differences in density of more than500 kg/m’ and interfacial tensions larger than 20 mN/madditional devices for dispersion have to be installed(rotating plates, paddles, etc.). On the other hand thesevalues can vary considerably from the head of thecolumn towards the bottom, which may indicate requiredenergy input for dispersing initiallyjybut phaseseparationpproblem somewhere else. FHence,determinationnofthe actuallyprevailingiirnterfacialtension is of importance and has to be carried out underprocess conditions. In case of the extraction of an organic acid samples ofthe aqueous and the organic phases from the head aswell as from the bottom of the column were brought intocontact (90-125℃, 3-6 bar) using the method of thependant drop under process conditions in the apparatusdescribed before (Figure 1). In order to determine theinterfacial tension the dispersed phase should be chosenas the drop phase for the measurements. While thedifferences in density turned out to be within the sameorder of magnitude, a threefold increase of the interfacialtension was measured at the bottom of the column incomparison with the top of the column. The overall lowvalues of the interfacial tension between 2 and 6 mN/mas well as of the difference in density of 120 kg/mcauseenhanced axial back mixing as well as a diminishedseparation efficiency of the column. Moreover, one of thetwo phases is the better agent for the wetting ofpackings inside the column. As the phase to be dispersedinto a number as large as possible of small droplets, theone with the inferior wetting properties has to be chosenconsequently. Summary The measuring apparatusPD-E40is an1Iinstrumentuniversally applicable for the measurement of interfacialproperties in liquid-liquid and gas- liquid systems. Itallows determination of parameters of relevance to liquidseparation tasks close to process conditions. It is animportant: tool forrdesign and operation ofcorresponding industrial plants. ( References ) [1]Andreas, J.M., Hauser, E.A., Tucker, W.B., J. Phys.Chem., 42 (1938),1001-1019. [2] Jaeger, P.T., R. Eggers, H. Baumgartl, J. Supercrit.Fluids, 24 (2002),203-217. KRUSS GmbH|Borsteler Chaussee Hamburg| Germany| www.kruss.de|

确定

还剩1页未读,是否继续阅读?

克吕士科学仪器(上海)有限公司为您提供《表面活性剂溶液中高压液液分离检测方案(接触角测量仪)》,该方案主要用于其他中高压液液分离检测,参考标准--,《表面活性剂溶液中高压液液分离检测方案(接触角测量仪)》用到的仪器有KRUSS DSA100接触角测量仪

推荐专场

相关方案

更多

该厂商其他方案

更多