方案详情

文

涂料和油墨行业有机溶剂使用降少逐渐被水取代,纸的润湿性变成质量保证的重要影响因子。使用润湿图谱和表面自由能绘图研究纸主要组成部分的表面自由能和润湿性。

方案详情

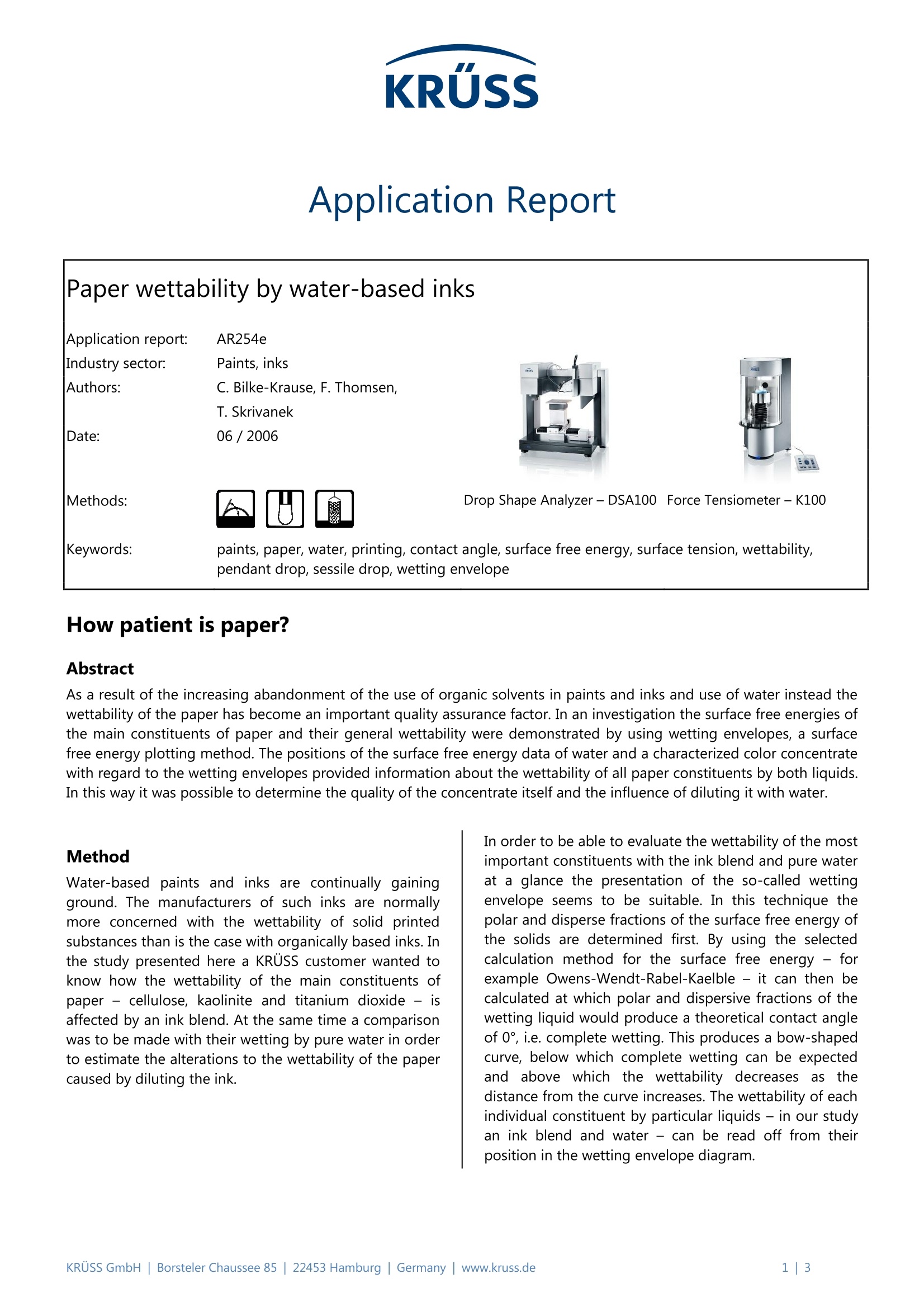

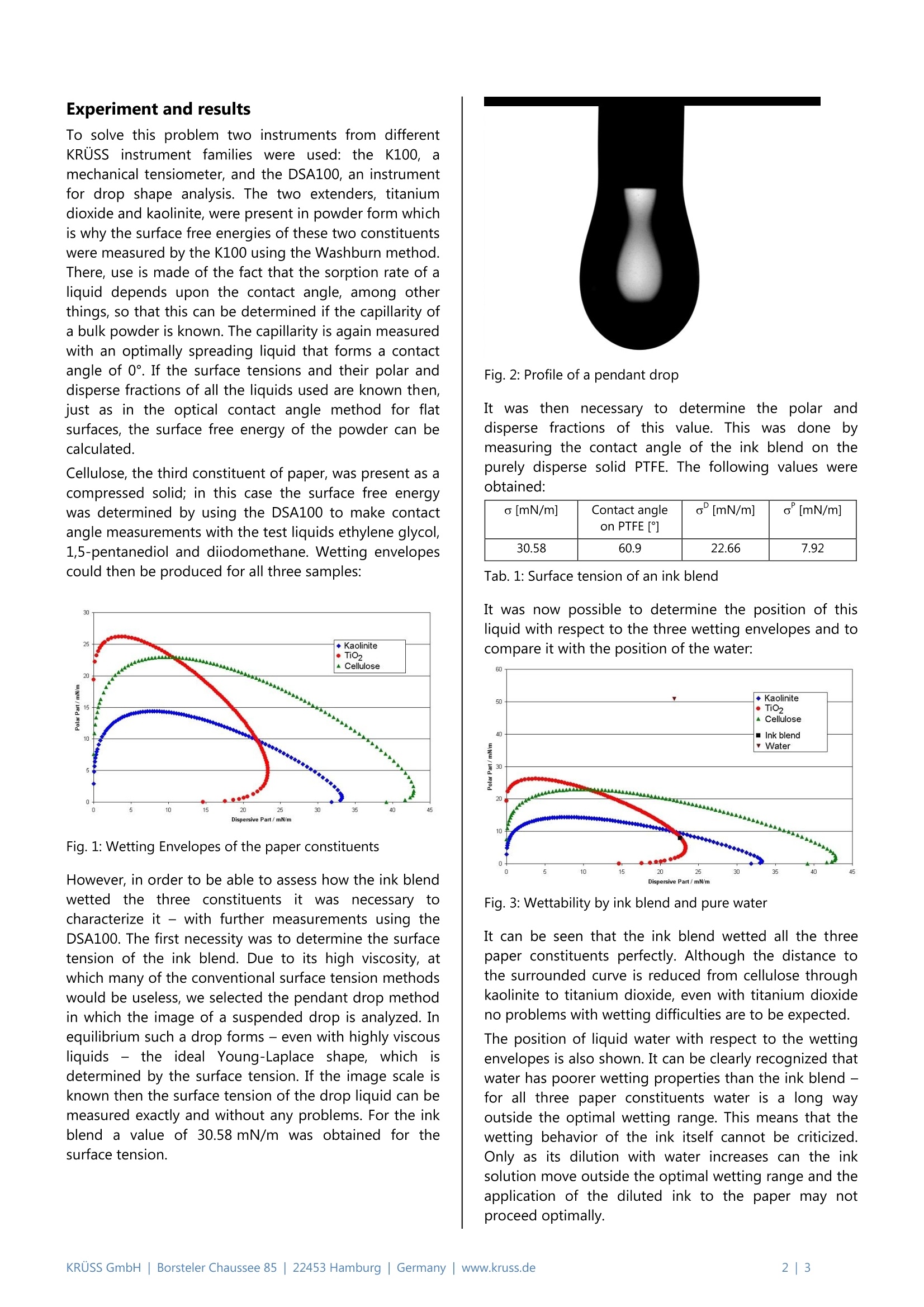

KRUSS Application Report Paper wettability by water-based inks Application report: AR254e Industry sector: Paints, inks Authors: C. Bilke-Krause, F. Thomsen, T. Skrivanek Date: 06/ 2006 Methods: Drop Shape Analyzer-DSA100 Force Tensiometer- K100 Keywords: paints, paper, water, printing, contact angle, surface free energy, surface tension, wettability,pendant drop, sessile drop, wetting envelope How patient is paper? Abstract As a result of the increasing abandonment of the use of organic solvents in paints and inks and use of water instead thewettability of the paper has become an important quality assurance factor. In an investigation the surface free energies ofthe main constituents of paper and their general wettability were demonstrated by using wetting envelopes, a surfacefree energy plotting method. The positions of the surface free energy data of water and a characterized colorconcentratewith regard to the wetting envelopes provided information about the wettability of all paper constituents by both liquids.In this way it was possible to determine the quality of the concentrate itself and the influence of diluting it with water. Method Water-based paints and inks are continually gainingground. The manufacturers of such inks are normallymore concerned with the wettability of solid printedsubstances than is the case with organically based inks. Inthe study presented here a KRUSS customer wanted toknow how the wettability of the main constituents ofpaper - cellulose, kaolinite and titanium dioxide - isaffected by an ink blend. At the same time a comparisonwas to be made with their wetting by pure water in orderto estimate the alterations to the wettability of the papercaused by diluting the ink. In order to be able to evaluate the wettability of the mostimportant constituents with the ink blend and pure waterat a glance the presentation of the so-called wettingenvelope seems to be suitable. In this technique thepolar and disperse fractions of the surface free energy ofthe solids are determined first. By using the selectedcalculation method for the surface free energy - forexample Owens-Wendt-Rabel-Kaelble - it can then becalculated at which polar and dispersive fractions of thewetting liquid would produce a theoretical contact angleof 0°, i.e. complete wetting. This produces a bow-shapedcurve, below which complete wetting can be expectedand above which the wettability decreases as thedistance from the curve increases. The wettability of eachindividual constituent by particular liquids - in our studyan ink blend and water - can be read off from theirposition in the wetting envelope diagram. Experiment and results To solve this problem two instruments from differentKRUSS instrument families were used: the K100, amechanical tensiometer, and the DSA100, an instrumentfor drop shape analysis. The two extenders, titaniumdioxide and kaolinite, were present in powder form whichis why the surface free energies of these two constituentswere measured by the K100 using the Washburn method.There, use is made of the fact that the sorption rate of aliquid depends upon the contact angle, among otherthings, so that this can be determined if the capillarity ofa bulk powder is known. The capillarity is again measuredwith an optimally spreading liquid that forms a contactangle of 0°. If the surface tensions and their polar anddisperse fractions of all the liquids used are known then,just as in the optical contact angle method for flatsurfaces, the surface free energy of the powder can becalculated. Cellulose, the third constituent of paper, was present as acompressed solid; in this case the surface free energywas determined by using the DSA100 to make contactangle measurements with the test liquids ethylene glycol,1,5-pentanediol and diiodomethane. Wetting envelopescould then be produced for all three samples: Fig. 1:Wetting Envelopes of the paper constituents However, in order to be able to assess how the ink blendwetted the three constituents it was necessary tocharacterize it - with further measurements using theDSA100. The first necessity was to determine the surfacetension of the ink blend. Due to its high viscosity, atwhich many of the conventional surface tension methodswould be useless, we selected the pendant drop methodin which the image of a suspended drop is analyzed. Inequilibrium such a drop forms- even with highly viscousliquids - the ideal Young-Laplace shape, which isdetermined by the surface tension. If the image scale isknown then the surface tension of the drop liquid can bemeasured exactly and without any problems. For the inkblend a value of 30.58 mN/m was obtained for thesurface tension. Fig. 2: Profile of a pendant drop It was then necessary to determine the polar anddisperse fractions of this value. This was done bymeasuring the contact angle of the ink blend on thepurely disperse solid PTFE. The following values wereobtained: o [mN/m] Contact angleon PTFE [°] o”[mN/m] o[mN/m] 30.58 60.9 22.66 7.92 Tab.1: Surface tension of an ink blend It was now possible to determine the position of thisliquid with respect to the three wetting envelopes and tocompare it with the position of the water: Fig. 3: Wettability by ink blend and pure water It can be seen that the ink blend wetted all the threepaper constituents perfectly. Although the distance tothe surrounded curve is reduced from cellulose throughkaolinite to titanium dioxide, even with titanium dioxideno problems with wetting difficulties are to be expected. The position of liquid water with respect to the wettingenvelopes is also shown. It can be clearly recognized thatwater has poorer wetting properties than the ink blend -for all three paper constituents water is a long wayoutside the optimal wetting range. This means that thewetting behavior of the ink itself cannot be criticized.Only as its dilution with water increases can the inksolution move outside the optimal wetting range and theapplication of the diluted ink to the paper may notproceed optimally. Summary By using powder contact angle measurements with theForce Tensiometer-K100 and optical contact anglemeasurements with the DSA100 the surface free energiesof the main constituents of paper - cellulose, kaoliniteand titanium dioxide - could be characterized and shownas an arrangement of three wetting envelopes. The polarand dispersive fractions of the surface tension of thewater-based ink concentrate were also measured by thependant drop method and contact angle measurements.The position of the result within the assembled wettingenvelopes proved the good wettability of all the paperconstituents by the ink blend. By a comparison of the inkwith pure water it could be shown that water wets papermuch worse and that possible loss of quality whenapplying the diluted ink is not caused by the quality ofthe ink blend, but could be caused by the wettingproperties of the water. KRUSS GmbH|Borsteler Chaussee Hamburg|Germany |www.kruss.de|

确定

还剩1页未读,是否继续阅读?

克吕士科学仪器(上海)有限公司为您提供《油墨中表面能检测方案(表面张力仪)》,该方案主要用于油墨中表面能检测,参考标准--,《油墨中表面能检测方案(表面张力仪)》用到的仪器有KRUSS DSA100接触角测量仪

推荐专场

相关方案

更多

该厂商其他方案

更多