方案详情

文

油墨或涂料生产中的一些不利影响如泡沫或气泡涉及到额外表面活性剂的表面粘附行为。KRüSS提供科学仪器帮助解决快速变化和发泡趋势问题:基于DSA100用于表面流变性测量的EDM/ODM模块。

方案详情

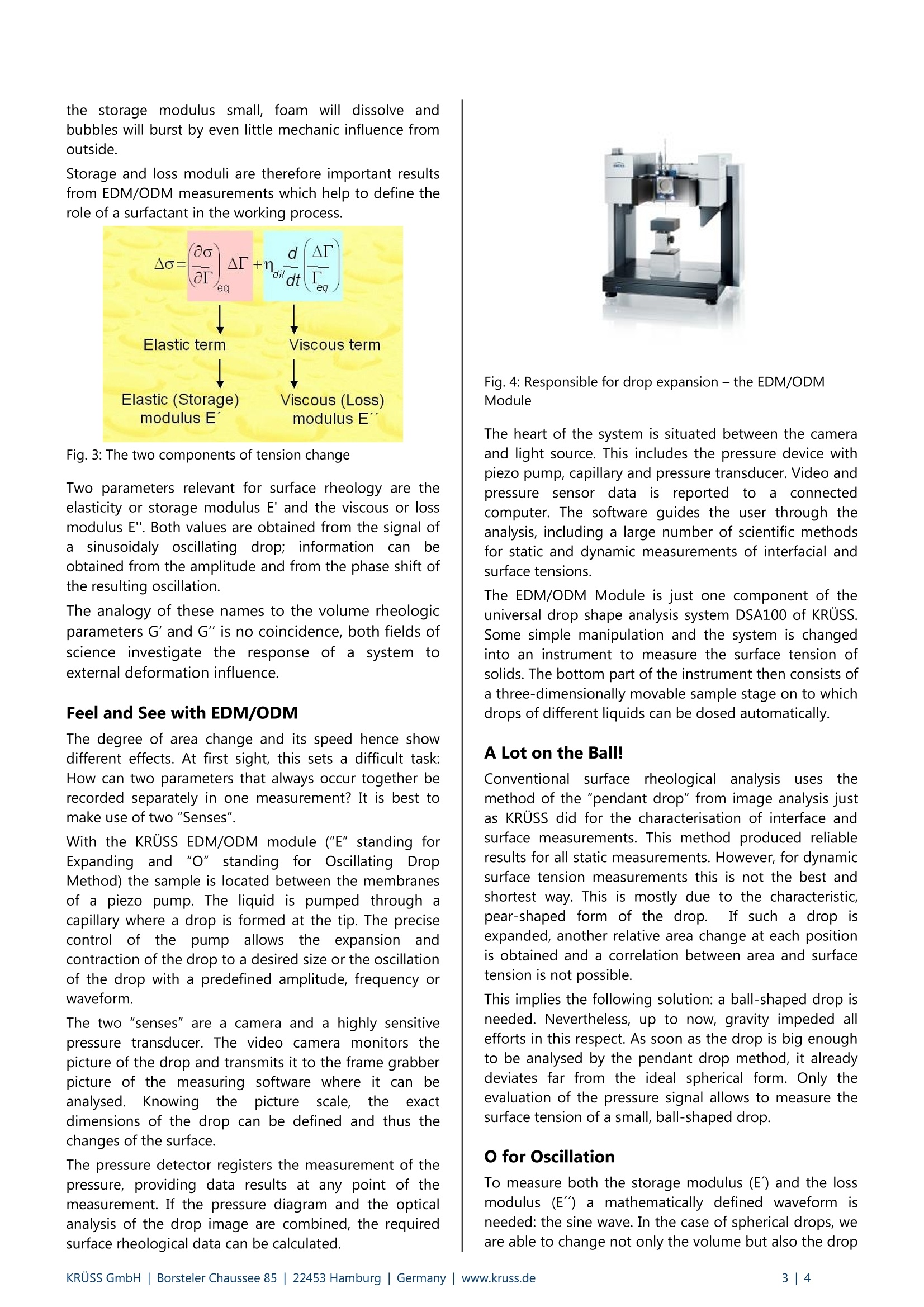

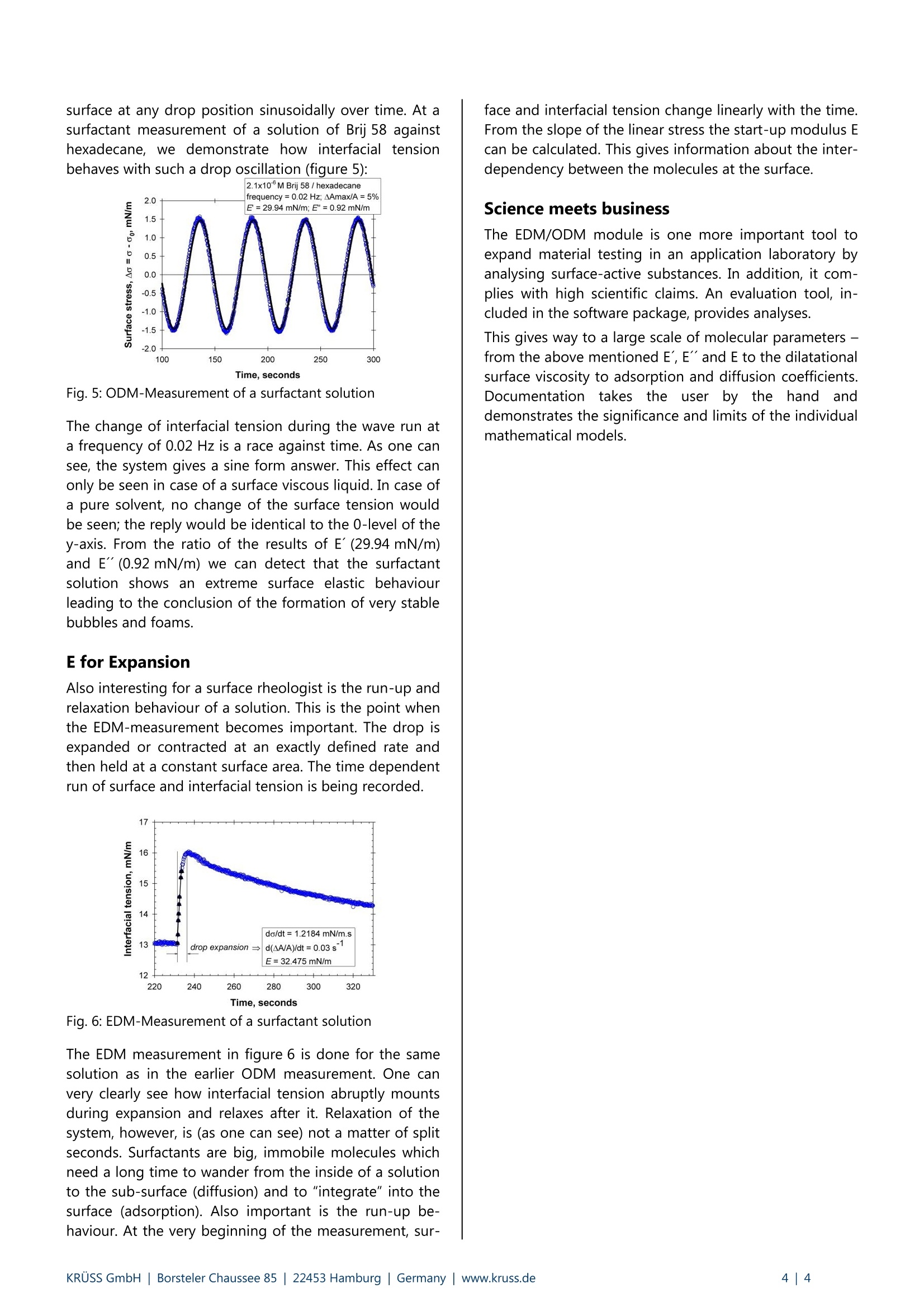

KRUSS Stretching Exercises for Drops Application note: 246e Industry section: Printing, chemicals, food, petroleum technology Author: FT Date: 2005 Method: Drop Shape Analyzer- DSA100R Keywords: Surface rheology, viscoelasticity, foaming, surfactant, elastic modulus, loss modulus Stretching Exercises for Drops Abstract Some unwelcome effects in the production of inks or paints such as foams or bubbles relate to the surface viscousbehaviour of added surfactants. KRUSS offers a scientific instrument that helps to master problems in fast processes andthe tendency of foaming: the EDM/ODM module for surface rheologic measurements with the measuring systemDSA100. Introduction Panta rhei - everything flows. This saying - attributed tothe Greek philosopher Heraclites - defines water to bethe symbol of all changes. The science of rheology, in itsnamee still showing this: Greek root, analyses thebehaviour of liquid substances - their viscosity andelasticity. The area of surface rheology investigates theeffects that a size change of a surface has on its surfacetension. Everything flows, but what does it mean when we speakof the flowing of a surface? For so-called Newtonianliquids such as water, the flowing behaviour on thesurface is not interesting. If the surface expands, watermolecules from inside the liquidtaketheir placeimmediately and the surface tension does not depend ontime and speed. This changes as soon as surface activeagents are included in the liquid: a time dependentbehaviour is initiated and the work of the surfacerheologist begins. Surfactants and other surface-active substances have ahydrophobic part in their molecular structure andtherefore, they accumulate at the water surface. By doingso, they reduce the surface tension and increase theaffinity of the liquid solution to hydrophobic solids andfluids. This property makes surfactants very useful. Forexample surfactant addition can improve the wetting of asolid material. The formula of water-based inks, paintsandlIlacquerstherefore alwaysincludessurfactants.However, surfactants also show unwanted secondaryeffects such as foaming. Fig. 1: Foaming-not always as desired as here A lot of motions on the surface The quantity of these molecules at each surface area isthe surface concentration and is specified by the symbol"T". Gibb's Elasticity (EG) defines the dependence of thesurface tension (a) on the surface concentration: With an insoluble surface-active substance, the surfaceconcentration will decrease when the surface area isincreased. Imagine a spotted balloon: the number of dotsper area unit decreases as the balloon is blown up. For afluid, this means that the surface tension depends on thesize (A) of the surface. The thermodynamic technical termfor this effect is "surface elasticity"EA: In case of the chosen example of insoluble material, changes of area and concentration go hand in hand, and both elasticities, EG and EA, are in accordance with eachother. However, if the fluid includes soluble particles,which applies to soluble surfactants, the molecules frominside the bulk material take the available place at thesurface (see figure 2) or vice versa: if it gets crowded on acontracted surface, particles will move in the otherdirection until the old, equilibrium surface concentrationhas been achieved again. Suddenly, surface tension is nota constant value anymore but depends on the degreeand the speed of the area change and on the mobility ofthe dissolved molecules. Fig. 2: Available area for new molecules after expansion Surfactants: Agents with risks and side effects In the manufacturingg process of inks and paints,surfactants are used, among other additives, to decreasethe surface tension and to mediate between ink and solidmaterial - as for example between printer ink and paper.In high-speed processes, however, they lose some oftheir efficiency because molecules do not reach theplace, i.e. the surface, fast enough where they becomeactive. A second property of surfactants is also highlyunwanted in the manufacturing of inks: their dispositionto foaming. The cosmetic industry tries to achievemechanically stable foams by using suitable surfactantswhereas in colour manufacturing foams and bubblesshould vanish into thin air as fast as possible. Often so-called "defoamers" are used to suppress foaming. Ofcourse, each additional component increases the cost ofproduction and each substance added leads to moreunwanted synergy effects. It is, therefore, important tocarefully choose surfactants with a minor disposition totoaming. Both effects, dependency on speed and the dispositionto stable foaming need to be investigated. Classictensiometry, such as the plate method of the KRUSSK100 Tensiometer, is important to analyse the auxiliarymaterial but cannot help to know more about the surfacebehaviour of fast changes.In order to investigate moreclose into this, the KRUSS BP2 Tensiometer (bubblepressure) is used. The surface tension is measured by the maximumpressure of a bubble formed in a test fluid. The speed ofbubble formation is varied and the surface tension independent of the age of the bubbles that are formed.However, bubble pressure measurements do not allowdirect statements about foam stability. These are onlypossible with a surface rheologic approach. When Loss means Gain Surface rheology differentiates between two effectswhich appear in changing the surface and which havedifferent influence on the processing behaviour: Thedependency on the degree of area change and thedependency on the speed of expanding or reducing thesurface. The former is called surface elasticity and thelatter surface viscosity. Put into a formula, the change insurface tension called surface stress (T) is divided into thecomponents Tyis and Tel. The following applies: Important figures for the characterisation of surfactantsare the storage modulus E' (elastic component) and theloss modulus E" (viscous component; see figure 3). Thesefigures and the stability of a foam bubble are coherent.At a high surface elasticity, the produced foam reacts justlike a spring. This phenomenon can be seen for examplewhen pressing the foam crown in a bubble bath and thefoam getting back to more or less the same shapeimmediately. If, however, the loss modulus is high and the storage modulus small, foam will dissolve andbubbles will burst by even little mechanic influence fromoutside. Storage and loss moduli are therefore important resultsfrom EDM/ODM measurements which help to define therole of a surfactant in the working process. Fig. 3: The two components of tension change Two parameters relevant for surface rheology are theelasticity or storage modulus E' and the viscous or lossmodulus E". Both values are obtained from the signal ofa sinusoidaly oscillating drop; information can beobtained from the amplitude and from the phase shift ofthe resulting oscillation. The analogy of these names to the volume rheologicparameters G'and G" is no coincidence, both fields ofscience investigate the response of a system toexternal deformation influence. Feel and See with EDM/ODM The degree of area change and its speed hence showdifferent effects. At first sight, this sets a difficult task:How can two parameters that always occur together berecorded separately in one measurement? It is best tomake use of two "Senses". With the KRUSS EDM/ODM module ("E” standing forExpandingi and"O" standingfor OscillatingDropMethod) the sample is located between the membranesof a piezo pump. The liquid is pumped through acapillary where a drop is formed at the tip. The precisecontrol of the pump allows the expansion andcontraction of the drop to a desired size or the oscillationof the drop with a predefined amplitude, frequency orwaveform. The two "senses" are a camera and a highly sensitivepressure transducer. The video camera monitors thepicture of the drop and transmits it to the frame grabberpicture of the measuring software where it can beanalysed. Knowingtthe已ppicture scale, the exactdimensions of the drop can be defined and thus thechanges of the surface. The pressure detector registers the measurement of thepressure, providing data results at any point of themeasurement. If the pressure diagram and the opticalanalysis of the drop image are combined, the requiredsurface rheological data can be calculated. Fig. 4: Responsible for drop expansion- the EDM/ODMModule The heart of the system is situated between the cameraand light source. This includes the pressure device withpiezo pump, capillary and pressure transducer. Video andpressure sensor data isreporteddto)a connectedcomputer. The software guides the user through theanalysis, including a large number of scientific methodsfor static and dynamic measurements of interfacial andsurface tensions. The EDM/ODM Module is just one component of theuniversal drop shape analysis system DSA100 of KRUSS.Some simple manipulation and the system is changedinto an instrument to measure the surface tension ofsolids. The bottom part of the instrument then consists ofa three-dimensionally movable sample stage on to whichdrops of different liquids can be dosed automatically. A Lot on the Ball! Conventional surface rheological analysisISuuses themethod of the "pendant drop" from image analysis justas KRUSS did for the characterisation of interface andsurface measurements. This method produced reliableresults for all static measurements. However, for dynamicsurface tension measurements this is not the best andshortest way. This is mostly due to the characteristic,pear-shaped form of the drop.).If such a drop isexpanded, another relative area change at each positionis obtained and a correlation between area and surfacetension is not possible. This implies the following solution: a ball-shaped drop isneeded. Nevertheless, up to now, gravity impeded allefforts in this respect. As soon as the drop is big enoughto be analysed by the pendant drop method, it alreadydeviates far from the ideal spherical form. Only theevaluation of the pressure signal allows to measure thesurface tension of a small, ball-shaped drop. O for Oscillation To measure both the storage modulus (E') and the lossmodulus (E") a mathematically defined waveform isneeded: the sine wave. In the case of spherical drops, weare able to change not only the volume but also the drop surface at any drop position sinusoidally over time. At asurfactant measurement of a solution of Brij 58 againsthexadecane, we demonstrate how interfacial tensionbehaves with such a drop oscillation (figure 5): Fig.5:ODM-Measurement of a surfactant solution The change of interfacial tension during the wave run ata frequency of 0.02 Hz is a race against time. As one cansee, the system gives a sine form answer. This effect canonly be seen in case of a surface viscous liquid. In case ofa pure solvent, no change of the surface tension wouldbe seen; the reply would be identical to the 0-level of they-axis. From the ratio of the results of E' (29.94 mN/m)and E"(0.92mN/m) we can detect that the surfactantsolution shows an extreme surface elastic behaviourleading to the conclusion of the formation of very stablebubbles and foams. E for Expansion Also interesting for a surface rheologist is the run-up andrelaxation behaviour of a solution. This is the point whenthe EDM-measurement becomes important. The drop isexpanded or contracted at an exactly defined rate andthen held at a constant surface area. The time dependentrun of surface and interfacial tension is being recorded. Fig. 6: EDM-Measurement of a surfactant solution The EDM measurement in figure 6 is done for the samesolution as in the earlier ODM measurement. One canvery clearly see how interfacial tension abruptly mountsduring expansion and relaxes after it. Relaxation of thesystem, however, is (as one can see) not a matter of splitseconds. Surfactants are big, immobile molecules whichneed a long time to wander from the inside of a solutionto the sub-surface (diffusion) and to "integrate" into thesurface (adsorption). Also important is the run-up be-haviour. At the very beginning of the measurement, sur- face and interfacial tension change linearly with the time.From the slope of the linear stress the start-up modulus Ecan be calculated. This gives information about the inter-dependency between the molecules at the surface. Science meets business The EDM/ODM module is one more important tool toexpand material testing in an application laboratory byanalysing surface-active substances. In addition, it com-plies with high scientific claims. An evaluation tool, in-cluded in the software package, provides analyses. This gives way to a large scale of molecular parameters -from the above mentioned E, E"and E to the dilatationalsurface viscosity to adsorption and diffusion coefficients.Documentation takes thee user by the hand anddemonstrates the significance and limits of the individualmathematical models. KRUSS GmbH|Borsteler Chaussee Hamburg| Germany |www.kruss.de|

确定

还剩2页未读,是否继续阅读?

克吕士科学仪器(上海)有限公司为您提供《油墨中粘弹性检测方案(接触角测量仪)》,该方案主要用于油墨中粘弹性检测,参考标准--,《油墨中粘弹性检测方案(接触角测量仪)》用到的仪器有KRUSS DSA100接触角测量仪

推荐专场

相关方案

更多

该厂商其他方案

更多