方案详情

文

麦奇克在测量打印机的颜料悬浮液微粒粒径方面已经建立了一套成熟的标准方法。在高浓度进行测量以免稀释对分散产生影响。

打印和书写从石器时代开始就热衷于使用隐藏在各种载体中的彩色或者黑色物质。最早使用黑炭作为颜料相信可以追溯到长达4000-5000年前。现代的打印油墨包含很多组分,每种组分都有各自特定的作用,包括:颜色、强度、分散、粘度,以及充当铣削助手。下面的表格显示了常用类型的化学名称和对应的用途。这些材料所赋予油墨的具体特性必须考虑到打印机的设计和最终用途。

方案详情

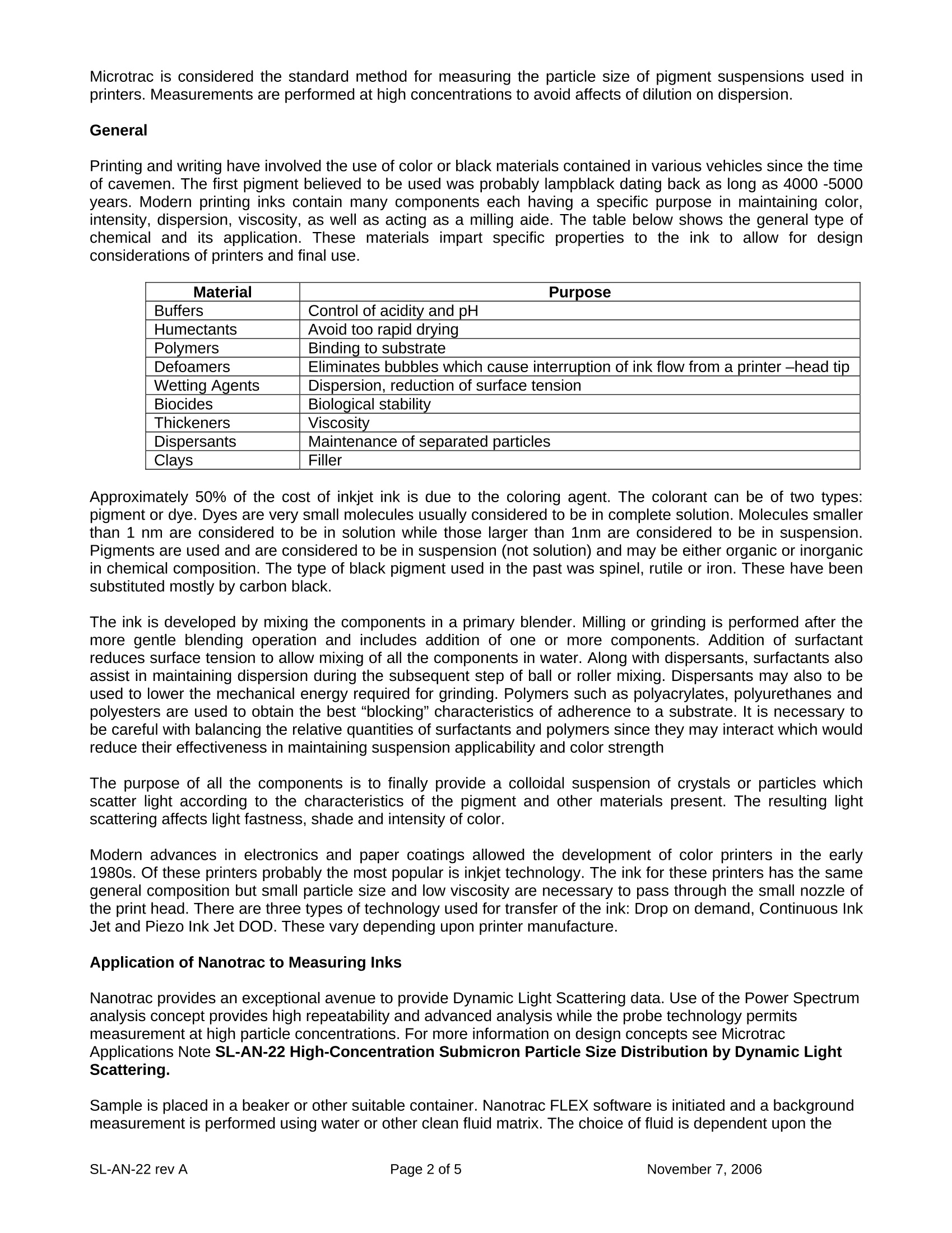

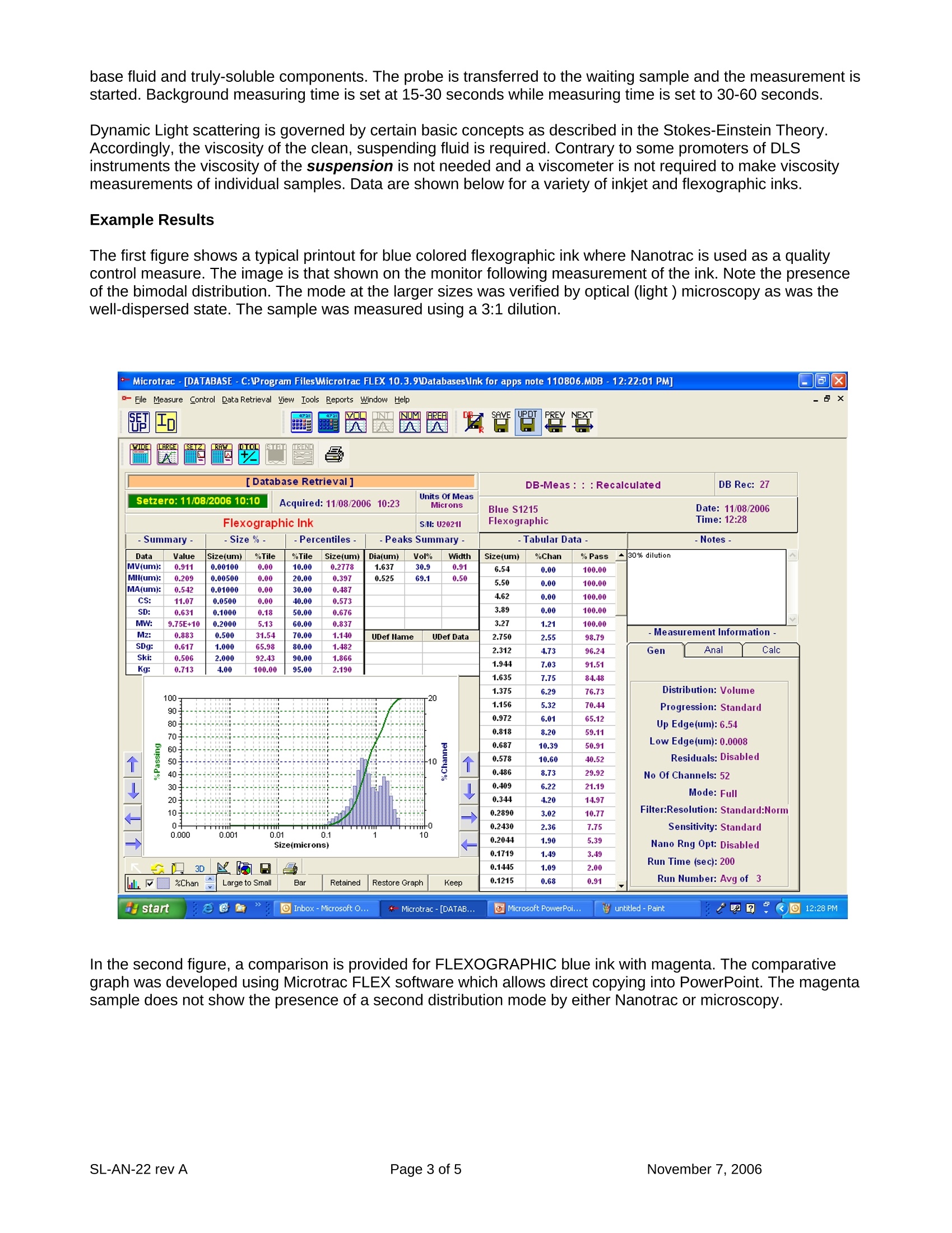

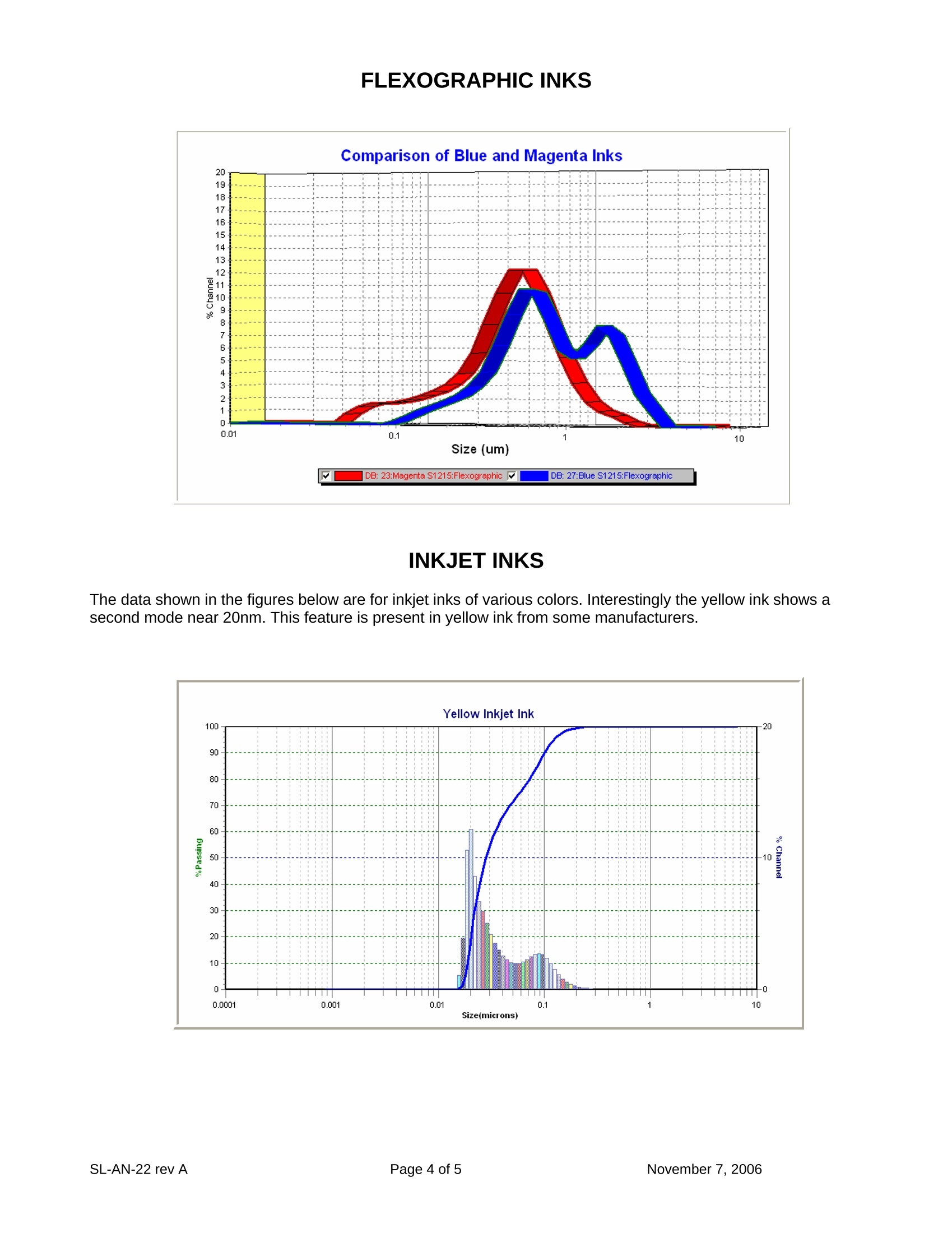

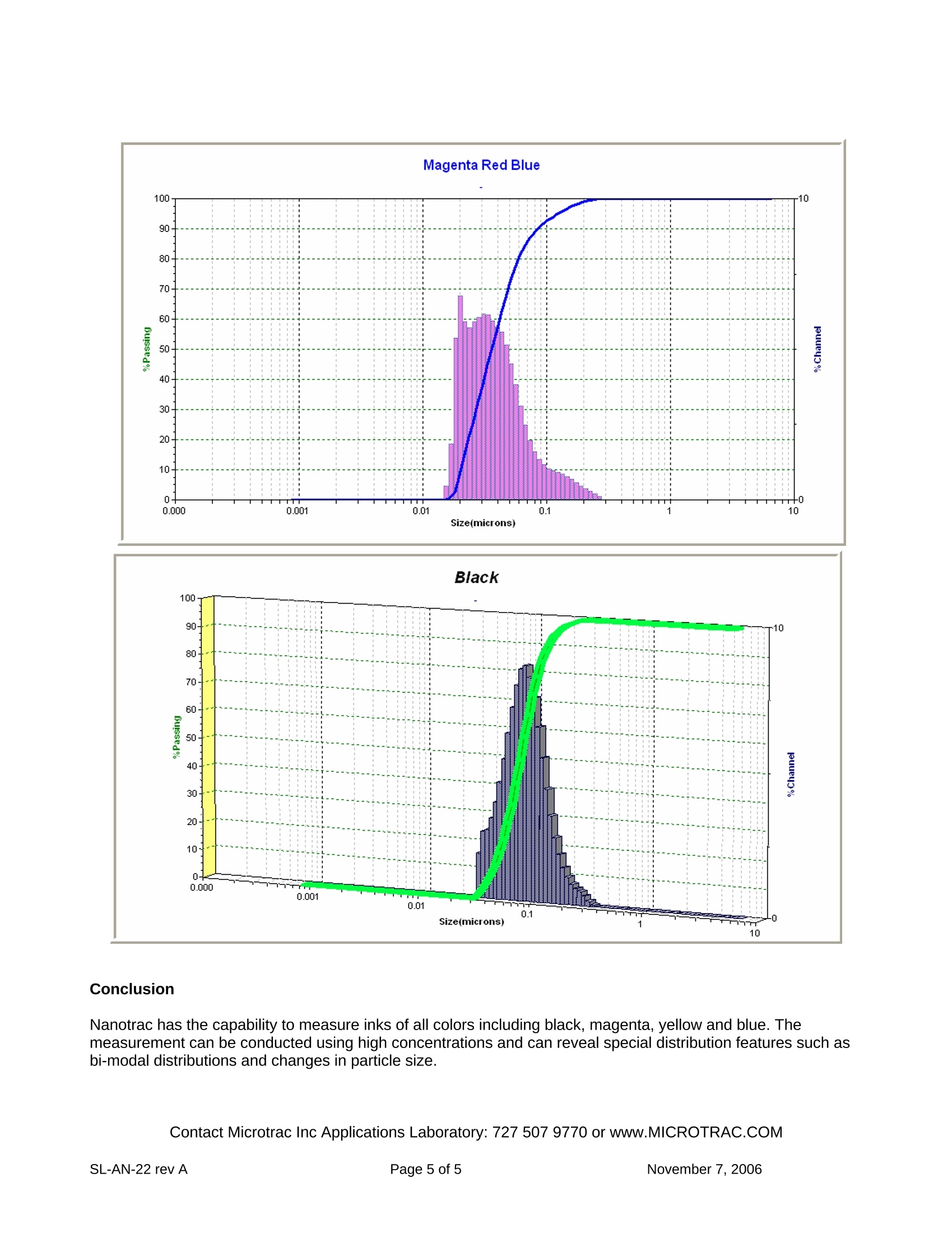

Printer Ink Nanosize Measurement Using NanotracParticle Size Analyzers Philip E. Plantz, PhD Application Note SL-AN-22 Revision A Provided By:Microtrac, Inc.Particle Size Measuring Instrumentation Microtrac is considered the standard method for measuring the particle size of pigment suspensions used inprinters.Measurements are performed at high concentrations to avoid affects of dilution on dispersion. General Printing and writing have involved the use of color or black materials contained in various vehicles since the timeof cavemen. The first pigment believed to be used was probably lampblack dating back as long as 4000 -5000years. Modern printing inks contain many components each having a specific purpose in maintaining color,intensity, dispersion, viscosity, as well as acting as a milling aide. The table below shows the general type ofchemical and its application. These materials impart specific properties to the ink to allow for designconsiderations of printers and final use. Material Purpose Buffers Control of acidity and pH Humectants Avoid too rapid drying Polymers Binding to substrate Defoamers Eliminates bubbles which cause interruption of ink flow from a printer-head tip Wetting Agents Dispersion, reduction of surface tension Biocides Biological stability Thickeners Viscosity Dispersants Maintenance of separated particles Clays Filler Approximately 50% of the cost of inkjet ink is due to the coloring agent. The colorant can be of two types:pigment or dye. Dyes are very small molecules usually considered to be in complete solution. Molecules smallerthan 1 nm are considered to be in solution while those larger than 1nm are considered to be in suspension.Pigments are used and are considered to be in suspension (not solution) and may be either organic or inorganicin chemical composition. The type of black pigment used in the past was spinel, rutile or iron. These have beensubstituted mostly by carbon black. The ink is developed by mixing the components in a primary blender. Milling or grinding is performed after themore gentle blending operation and includes addition of one or more components. Addition of surfactantreduces surface tension to allow mixing of all the components in water. Along with dispersants, surfactants alsoassist in maintaining dispersion during the subsequent step of ball or roller mixing. Dispersants may also to beused to lower the mechanical energy required for grinding. Polymers such as polyacrylates, polyurethanes andpolyesters are used to obtain the best “blocking”characteristics of adherence to a substrate. It is necessary tobe careful with balancing the relative quantities of surfactants and polymers since they may interact which wouldreduce their effectiveness in maintaining suspension applicability and color strength The purpose of all the components is to finally provide a colloidal suspension of crystals or particles whichscatter light according to the characteristics of the pigment and other materials present. The resulting lightscattering affects light fastness, shade and intensity of color. Modern advances in electronics and paper coatings allowed the development of color printers in the early1980s. Of these printers probably the most popular is inkjet technology. The ink for these printers has the samegeneral composition but small particle size and low viscosity are necessary to pass through the small nozzle ofthe print head. There are three types of technology used for transfer of the ink: Drop on demand, Continuous InkJet and Piezo Ink Jet DOD. These vary depending upon printer manufacture. Application of Nanotrac to Measuring Inks Nanotrac provides an exceptional avenue to provide Dynamic Light Scattering data. Use of the Power Spectrumanalysis concept provides high repeatability and advanced analysis while the probe technology permitsmeasurement at high particle concentrations. For more information on design concepts see MicrotracApplications Note SL-AN-22 High-Concentration Submicron Particle Size Distribution by Dynamic LightScattering. Sample is placed in a beaker or other suitable container. Nanotrac FLEX software is initiated and a backgroundmeasurement is performed using water or other clean fluid matrix. The choice of fluid is dependent upon the base fluid and truly-soluble components. The probe is transferred to the waiting sample and the measurement isstarted. Background measuring time is set at 15-30 seconds while measuring time is set to 30-60 seconds. Dynamic Light scattering is governed by certain basic concepts as described in the Stokes-Einstein Theory.Accordingly, the viscosity of the clean, suspending fluid is required. Contrary to some promoters of DLSinstruments the viscosity of the suspension is not needed and a viscometer is not required to make viscositymeasurements of individual samples. Data are shown below for a variety of inkjet and flexographic inks. Example Results The first figure shows a typical printout for blue colored flexographic ink where Nanotrac is used as a qualitycontrol measure. The image is that shown on the monitor following measurement of the ink. Note the presenceof the bimodal distribution. The mode at the larger sizes was verified by optical (light ) microscopy as was thewell-dispersed state. The sample was measured using a 3:1 dilution. In the second figure, a comparison is provided for FLEXOGRAPHIC blue ink with magenta. The comparativegraph was developed using Microtrac FLEX software which allows direct copying into PowerPoint. The magentasample does not show the presence of a second distribution mode by either Nanotrac or microscopy. FLEXOGRAPHIC INKS INKJET INKS The data shown in the figures below are for inkjet inks of various colors. Interestingly the yellow ink shows asecond mode near 20nm. This feature is present in yellow ink from some manufacturers. Conclusion Nanotrac has the capability to measure inks of all colors including black, magenta, yellow and blue. Themeasurement can be conducted using high concentrations and can reveal special distribution features such asbi-modal distributions and changes in particle size. Contact Microtrac Inc Applications Laboratory: 727 507 9770 or www.MICROTRAC.COM SL-AN-rev APage of November , SL-AN-rev ANovember , age of 麦奇克在测量打印机的颜料悬浮液微粒粒径方面已经建立了一套成熟的标准方法。在高浓度进行测量以免稀释对分散产生影响。 打印和书写从石器时代开始就热衷于使用隐藏在各种载体中的彩色或者黑色物质。最早使用黑炭作为颜料相信可以追溯到长达4000-5000年前。现代的打印油墨包含很多组分,每种组分都有各自特定的作用,包括:颜色、强度、分散、粘度,以及充当铣削助手。下面的表格显示了常用类型的化学名称和对应的用途。这些材料所赋予油墨的具体特性必须考虑到打印机的设计和最终用途。

确定

还剩3页未读,是否继续阅读?

大昌华嘉科学仪器为您提供《印刷油墨中粒径检测方案(激光粒度仪)》,该方案主要用于油墨中粒径检测,参考标准--,《印刷油墨中粒径检测方案(激光粒度仪)》用到的仪器有麦奇克激光粒度仪 S3500系列、麦奇克激光粒度分析仪(粒形分析)

推荐专场

相关方案

更多

该厂商其他方案

更多