方案详情

文

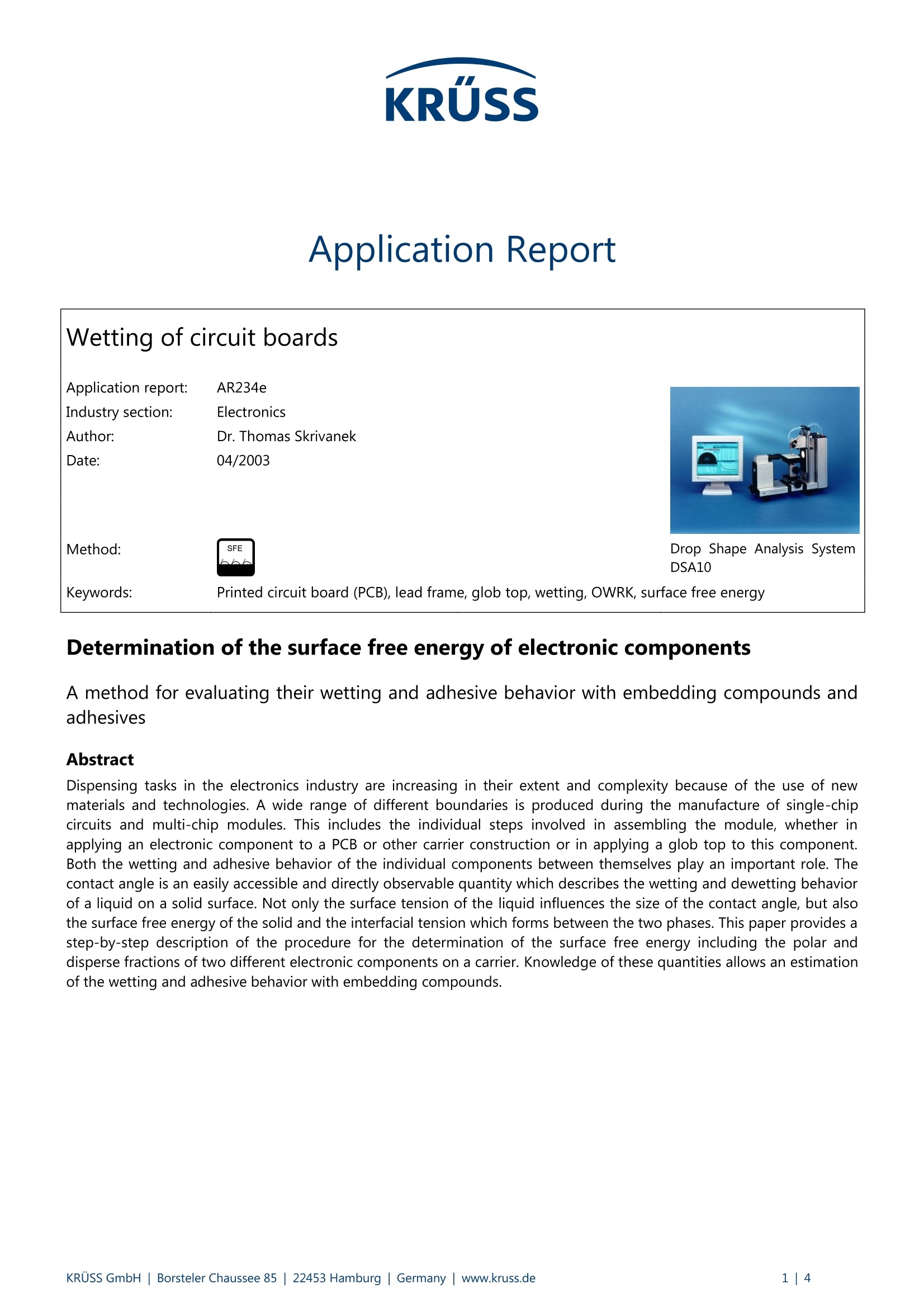

由于新的材料和技术,电子行业范围和复杂性日益增加。电子元件的润湿和粘合行为显得尤为重要。这就要求我们必须测得接触角及极性部分以评价嵌入部分的润湿和粘合性。

方案详情

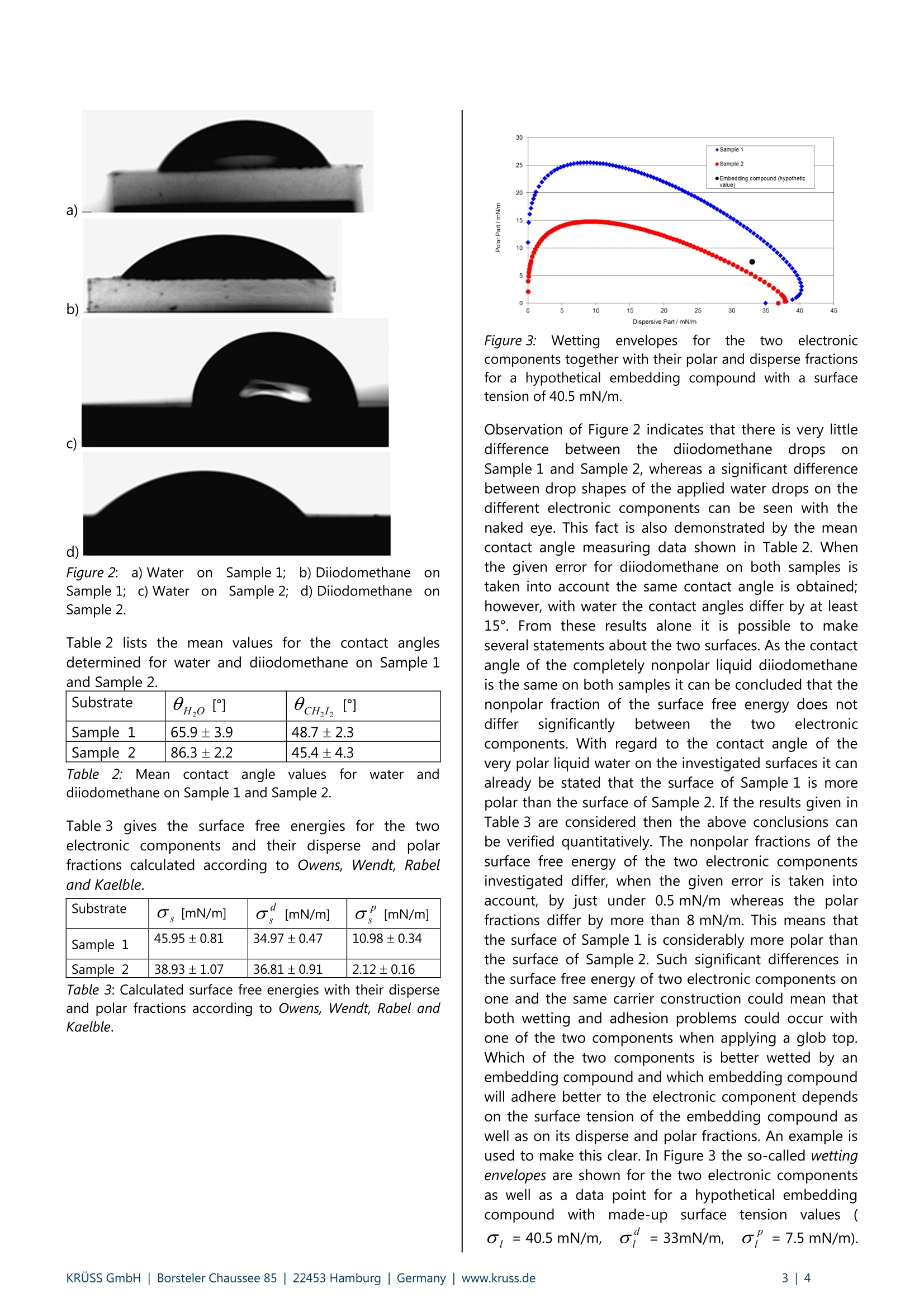

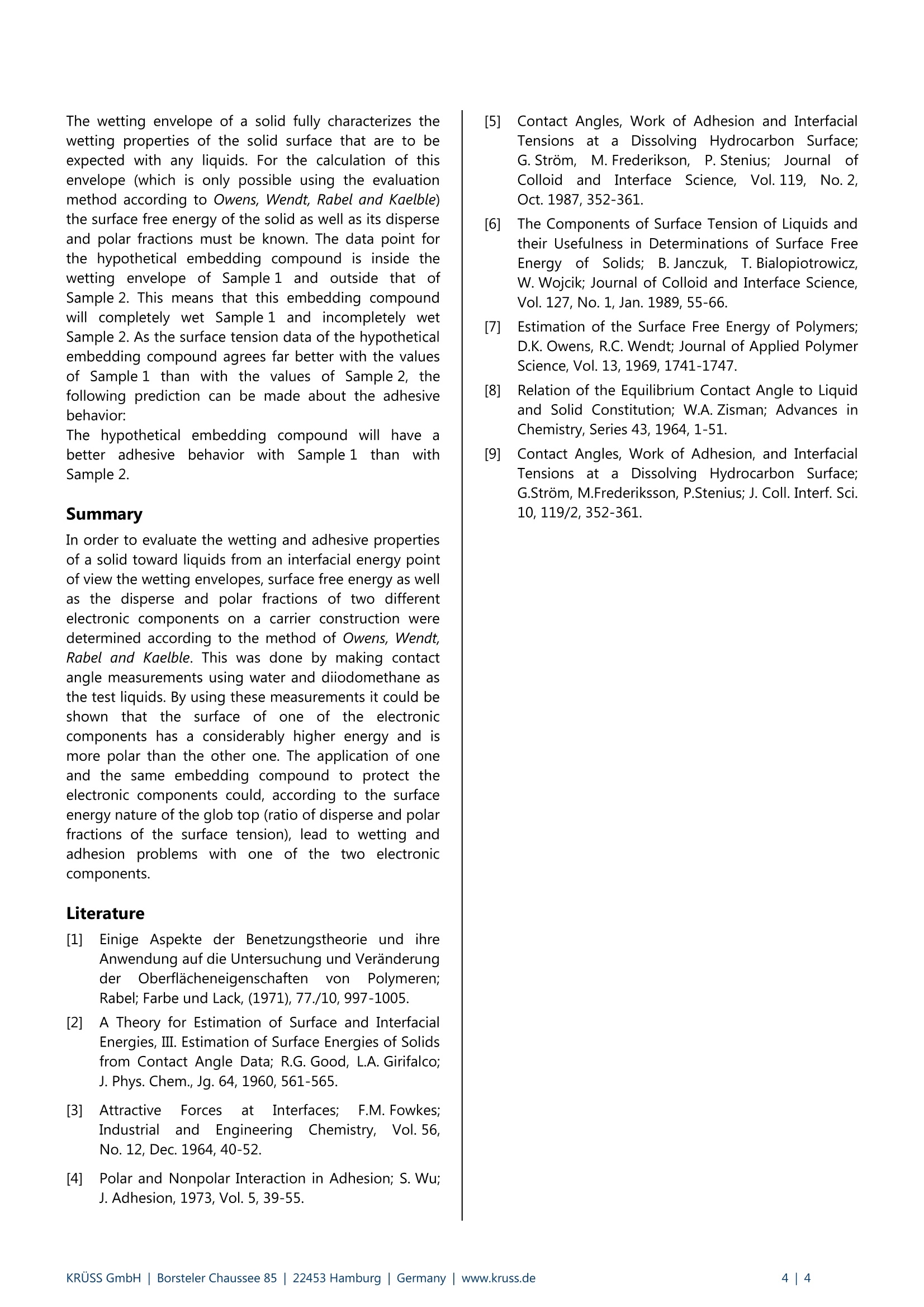

KRUSS Application Report Wetting of circuit boards Application report: AR234e Industry section: Electronics Author: Dr. Thomas Skrivanek Date: 04/2003 Method: SFE Drop Shape Analysis SystemDSA10 Keywords: Printed circuit board (PCB), lead frame, glob top, wetting,OWRK, surface free energy Printed circuit board (PCB), lead frame, glob top, wetting,OWRK, surface free energy Determination of the surface free energy of electronic components A method for evaluating their wetting and adhesive behavior with embedding compounds andadhesives Abstract Dispensing tasks in the electronics industry are increasing in their extent and complexity because of the use of newmaterials and technologies. A wide range of different boundaries is produced during the manufacture of single-chipcircuits and multi-chip modules. This includes the individual steps involved in assembling the module, whether inapplying an electronic component to a PCB or other carrier construction or in applyinga glob top to this component.Both the wetting and adhesive behavior of the individual components between themselves play an important role. Thecontact angle is an easily accessible and directly observable quantity which describes the wetting and dewetting behaviorof a liquid on a solid surface. Not only the surface tension of the liquid influences the size of the contact angle, but alsothe surface free energy of the solid and the interfacial tension which forms between the two phases. This paper provides astep-by-step description of the procedure for the determination of the surface free energy including the polar anddisperse fractions of two different electronic components on a carrier. Knowledge of these quantities allows an estimationof the wetting and adhesive behavior with embedding compounds. Introduction The marketing successsofan electronic product isstrongly dependent: on its reliability and customersatisfaction. The flat assemblies of electronic instrumentsmust therefore meet the highest demands. In order to beable to guarantee that electronic components willfunction properly for a long time they must be protectedagainst all possible types of environmental influences,such as vibration, impact or moisture. With wire-bondedelectronic components on carriers this can be achievedby applying an embedding compound,a so-called globtop. In this case not only the wetting behavior plays adecisive role, but also the adhesive behavior of theembedding compound towards the carrier, the electroniccomponent and the bonding wire. An effective means ofobtaining detailed information in advance about thewetting and adhesive behavior between the glob topcompound and, for example, an electronic component isthiee surface tension and contact anglee measuringtechnique. In this way the decisive parameter, the surfacefree energy o, of a solid including its disperse o andpolarfractions o.and the surface tensionof aliquid o, (e.g. embedding compound) can bedetermined. The procedure for the determination of o,o and o” is described in this paper using twodifferent electronic components attached to a carrier asan example. Theory Whereas the surface tension of liquids can be measureddirectly (e.g. with ring or plate), the surface free energy ofsolids ("surface tension of the solid") must be calculatedassolids are notcapable: ofreversible elasticdeformation. Since the start of the twentieth centuryvarious scientists have developed evaluation methods forcalculating the surface free energy [1-8]. By measuring the contact angle 0 of at least two testliquids (a-,o-and o"-values must be known) onthe solid surface to be analyzed the surface free energyof the solid surface () including the disperse (o")and polar fractions (o") of the surface free energy canbe determined. The fact that only those interactionsalong the boundary in which both phases are involvedare of any importance is decisive for solving wetting andadhesion problems. This means that if two liquids or asolid and a liquid are in contact then, at the phaseboundary, only an interaction between the two polar andthe two disperse fractions of the interfacial tension of theparticipating phases occurs. This is the very reason whythe knowledge of the polar and disperse fractions is sovery important. Experimental part The surface free energy according to Owens, Wendt,Rabel and Kaelble is to be determined together with thepolar and disperse fractions by optical contact anglemeasurements on two different electronic componentson a carrier construction. The measuring system used isthe Drop Shape Analysis System DSA10DO4 from KrussGmbH (see Figure 1). Figure 1: Drop Shape Analysis SystemmDSA10DO4 fromKRUSS GmbH Water and diiodomethane are used as the standard testliquids. Surface tension values are listed in Table 1. Liquid o, [mN/m] o[mN/m] o[mN/m] Water 72.80 21.80 51.00 Diiodo-methane 50.80 50.80 0.00 Table 1 Test liquid data according to Strom [9] The samples to be investigated (Sample 1 and Sample 2)were measured at room temperature without any pre-treatment. For each sample three to five contact anglemeasurements with water and diiodomethane weremade at different locations on the electronic compo-nents. Assample 1 only hadaan area ofT iapprox.3 mm x3 mm very small drop volumes were used (0.5 ul). Results and discussion Figure 2 shows examples of a water drop andadiiodomethane drop on each of the electroniccomponents. d)l Figure 2: a)Waterron .Sample1; b) Diiodomethanee onSample 1; c) Water on Sample 2; d) Diiodomethane onSample 2. Table 2 lists the mean values for the contact anglesdetermined for water and diiodomethane on Sample 1and Sample 2. Substrate H,0] CHI Sample 1 65.9±3.9 48.7±2.3 Sample 2 86.3±2.2 45.4±4.3 Table 2: Mean contact angle values 1forwateranddiiodomethane on Sample 1and Sample 2. Table 3 gives the surface free energies for the twoelectronic components and their disperse and polarfractions calculated according to Owens, Wendt, Rabeland Kaelble. Substrate o, [mN/m] o[mN/m] o[mN/m] Sample 1 45.95±0.81 34.97±0.47 10.98±0.34 Sample 2 38.93±1.07 36.81±0.91 2.12±0.16 Table 3: Calculated surface free energies with their disperseand polar fractions according to Owens, Wendt, Rabel andKaelble. Figure 3: Wettingenvelopesfor thetwo electroniccomponents together with their polar and disperse fractionsfor a hypothetical embedding compound with a surfacetension of 40.5 mN/m. Observation of Figure 2 indicates that there is very littledifference between the diiodomethane dropsonSample 1 and Sample 2, whereas a significant differencebetween drop shapes of the applied water drops on thedifferent electronic components can be seen with thenaked eye. This fact is also demonstrated by the meancontact angle measuring data shown in Table 2. Whenthe given error for diiodomethane on both samples istaken into account the same contact angle is obtained;however, with water the contact angles differ by at least15°. From these results alone it is possible to makeseveral statements about the two surfaces. As the contactangle of the completely nonpolar liquid diiodomethaneis the same on both samples it can be concluded that thenonpolar fraction of the surface free energy does notdiffer Ssignificantly between the two electroniccomponents. With regard to the contact angle of thevery polar liquid water on the investigated surfaces it canalready be stated that the surface of Sample 1 is morepolar than the surface of Sample 2. If the results given inTable 3 are considered then the above conclusions canbe verified quantitatively. The nonpolar fractions of thesurface free energy of the two electronic componentsinvestigated differ, when the given error is taken intoaccount, by just under 0.5 mN/m whereas the polarfractions differ by more than 8 mN/m. This means thatthe surface of Sample 1 is considerably more polar thanthe surface of Sample 2. Such significant differences inthe surface free energy of two electronic components onone and the same carrier construction could mean thatboth wetting and adhesion problems could occur withone of the two components when applying a glob top.Which of the two components is better wetted by anembedding compound and which embedding compoundwill adhere better to the electronic component dependson the surface tension of the embedding compound aswell as on its disperse and polar fractions. An example isused to make this clear. In Figure 3 the so-called wettingenvelopes are shown for the two electronic componentsas well as a data point for a hypothetical embeddingcompound with made-up surface tension values ( o=40.5 mN/m,(o;=33mN/m,o"=7.5mN/m). The wetting envelope of a solid fully characterizes thewetting properties of the solid surface that are to beexpected with any liquids. For the calculation of thisenvelope (which is only possible using the evaluationmethod according to Owens, Wendt, Rabel and Kaelble)the surface free energy of the solid as well as its disperseand polar fractions must be known. The data point forthe hypothetical embedding compound is inside thewetting envelope of Sample 1 and outside that ofSample 2. This means that this embedding compoundwill completely wet Sample 1 and incompletely wetSample 2. As the surface tension data of the hypotheticalembedding compound agrees far better with the valuesof Sample 1 than with the values of Sample 2, thefollowing prediction can be made about the adhesivebehavior: The hypothetical embedding compound will have abetter adhesivebehavior with Sample 1 than withSample 2. Summary In order to evaluate the wetting and adhesive propertiesof a solid toward liquids from an interfacial energy pointof view the wetting envelopes, surface free energy as wellas the disperse and polar fractions of two differentelectronic components on a carrier construction weredetermined according to the method of Owens, Wendt,Rabel and Kaelble. This was done by making contactangle measurements using water and diiodomethane asthe test liquids. By using these measurements it could beshown that the surface of one of the electroniccomponents has a considerably higher energy and ismore polar than the other one. The application of oneand the same embedding compound to protect theelectronic components could, according to the surfaceenergy nature of the glob top (ratio of disperse and polarfractions of the surface tension), lead to wetting andadhesion problems with one of the two electroniccomponents. Literature ( [1] Einige Aspekte d er Benetzungstheorie und ih r e Anwendung auf die Untersuchung und Veranderung der Oberflacheneigenschaften 1 von Polymeren;Rabel; Farbe u nd Lack,( 1 971), 77./10, 997-1005. ) ( [2] A Theory for Estimation o f S u rface and InterfacialEnergies, III. Estimation of Surface Energies of So l ids from C ontact A n gle Da t a; R.G. Go o d, L.A . Girifalco; J. Phys. Chem., Jg. 64, 1960, 561-565. ) ( [3] Attractive Forces at I nterfaces; F.M. Fowkes; Industrial and E EngineeringChemistry, Vol.56, No. 12, Dec. 1964, 40-52. ) ( [4] Polar and Nonpolar Interaction i n Adhesion; S. Wu; J. Adhesion, 1 973, Vol. 5 , 39-55. ) ( [5] 1C Contact A ngles, W ork of Adhesion and Interfacial Tensions at a D issolving Hydrocarbon Su r face; G. Strom, M. Frederikson, P. Stenius; Journa l o of Colloid d and Interfac e Science , V ol.119. No.2. Oct. 1987,352-361. ) [6] The Components of Surface Tension of Liquids andtheir Usefulness in Determinations of Surface FreeEnergy of Solids; B. Janczuk,T.Bialopiotrowicz,W. Wojcik; Journal of Colloid and Interface Science,Vol. 127,No. 1, Jan.1989,55-66. ( [7] Estimation of the Surface Free Energy of Polymers; D.K. Owens, R.C. Wendt; Journal of Applied P olymer Science, Vol.13,1969,1741-1747. ) ( [8] Relation of the Equilibrium Contact A ngle to Liquid and Solid C onstitution; W.A. Zisman; Advances i n Chemistry, Series 43, 1964,1-51. ) ( [9] Contact Angles, Work of Adhesion, and Interfacial Tensions at a a Dissolving H ydrocarbon Su rface; G.Strom,M . Frederiksson,P.S t enius; J. Coll. Interf. Sci. 10,119/2,352-361. ) KRUSS GmbH|lBorsteler Chaussee Hamburg| Germany|www.kruss.de|

确定

还剩2页未读,是否继续阅读?

克吕士科学仪器(上海)有限公司为您提供《PCB中表面能检测方案(接触角测量仪)》,该方案主要用于电子元器件产品中表面能检测,参考标准--,《PCB中表面能检测方案(接触角测量仪)》用到的仪器有KRUSS DSA100接触角测量仪

推荐专场

相关方案

更多