方案详情

文

A method for the rapid, safe hydrogenation of alkenes and deprotection of benzyl ethers and carboxybenzyl amides is described using catalytic transfer hydrogenation under microwave heating conditions. Commonly available Pd/C catalyst is extremely effective with 1,4-cyclohexadiene as the hydrogen transfer source. In general, the reactions are complete within five minutes at 100 ℃.

方案详情

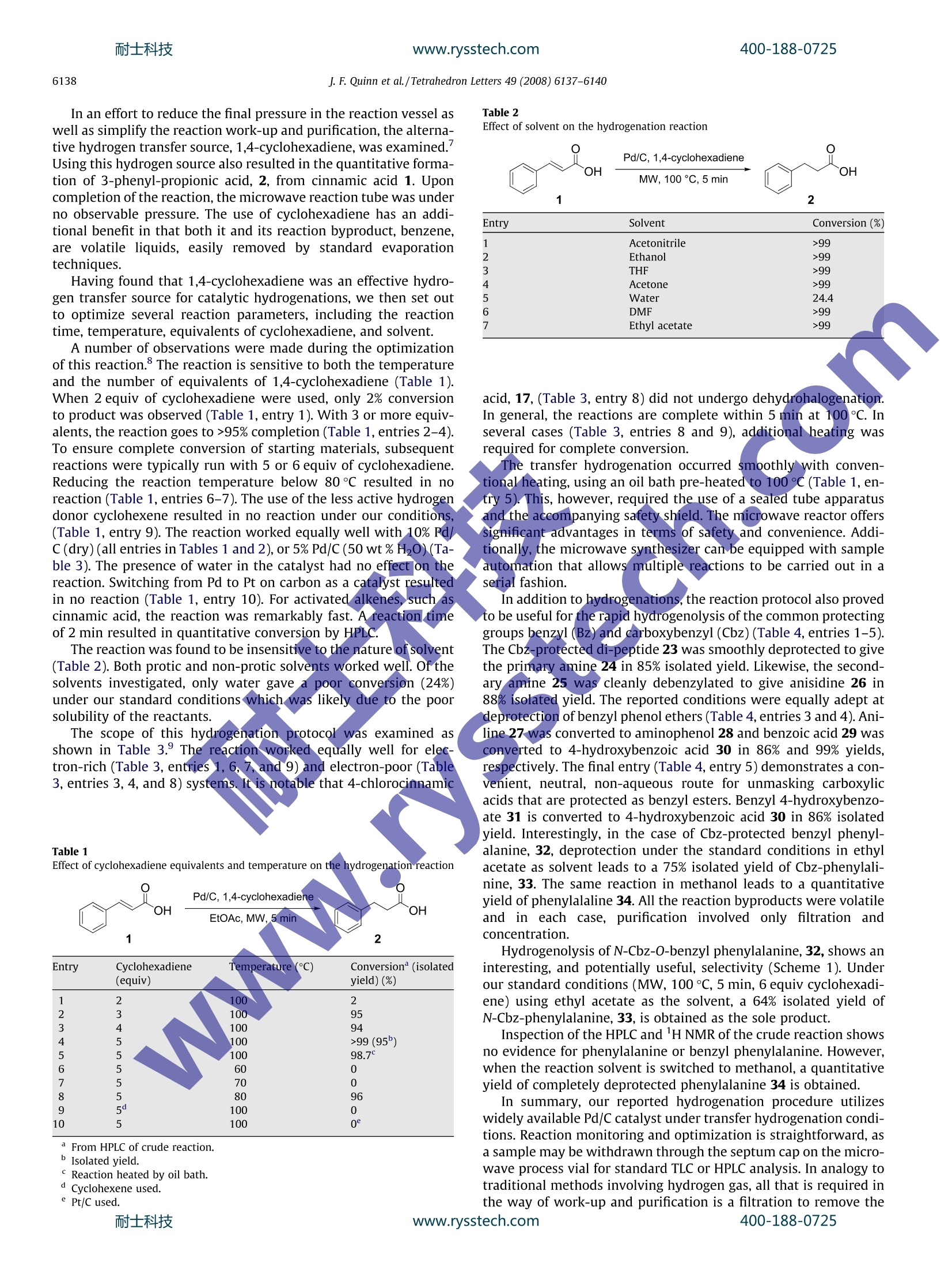

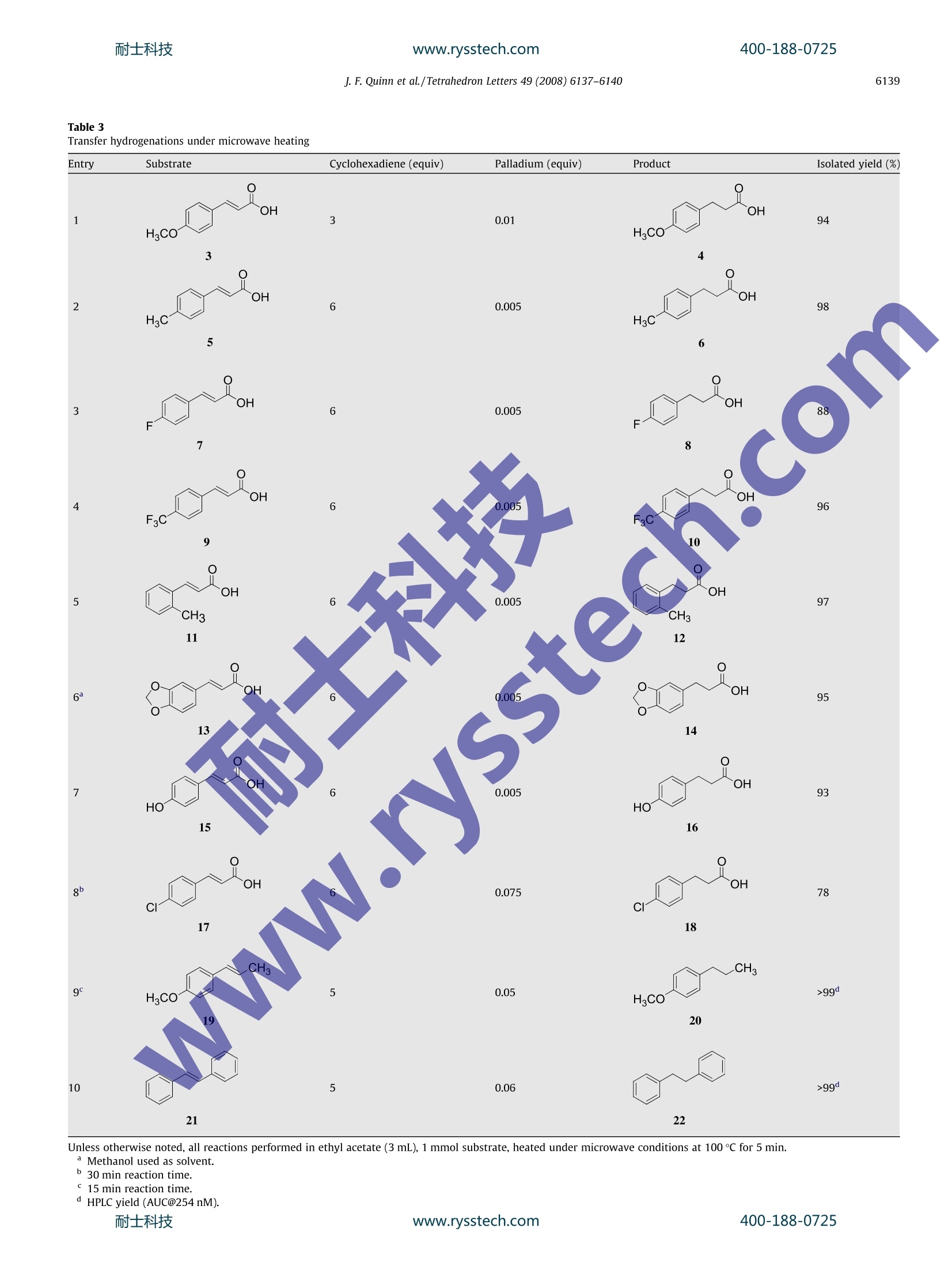

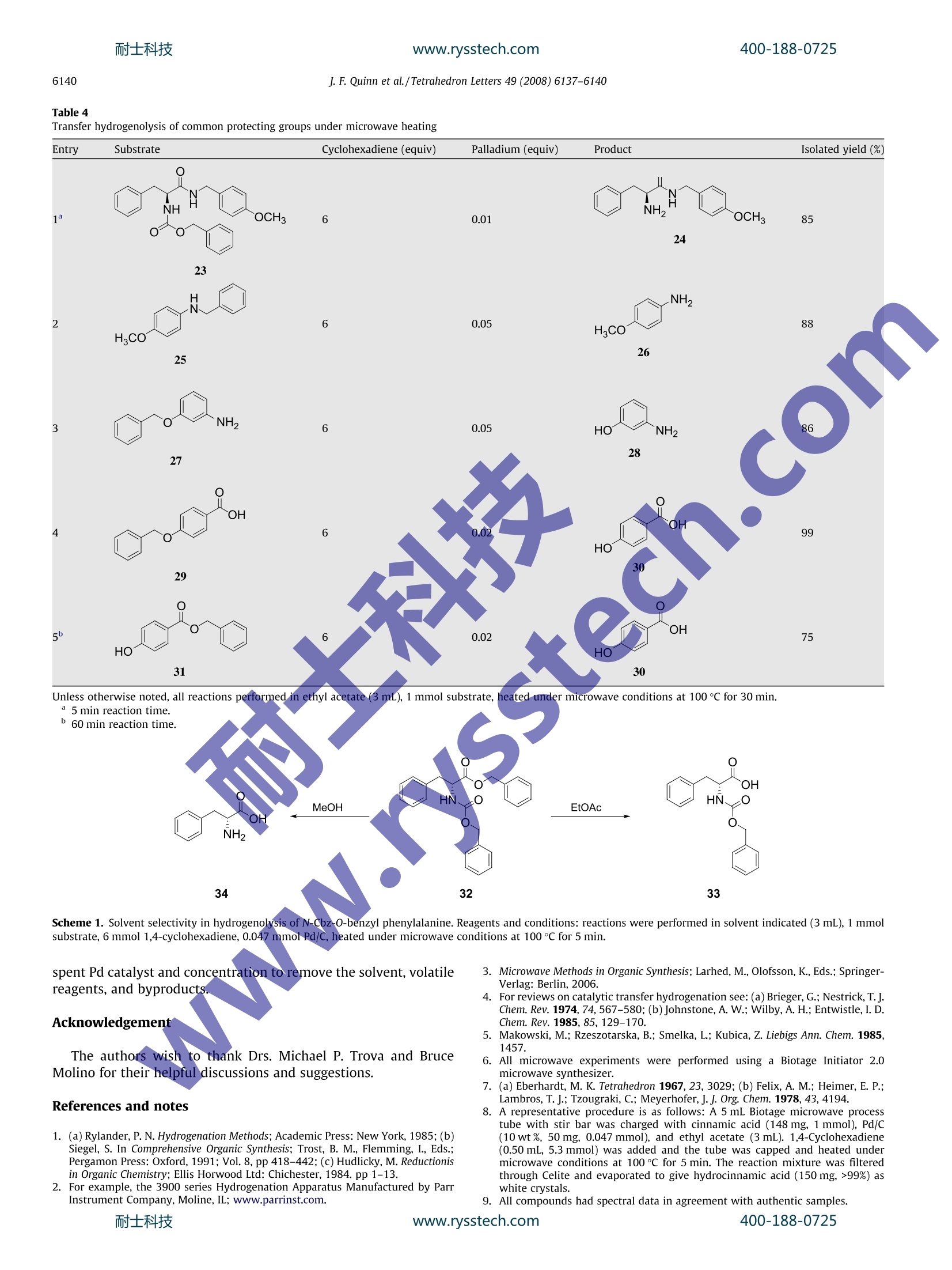

耐士科技www.rysstech.comTetrahedron Letters 49 (2008) 6137-6140400-188-0725 耐士科技400-188-0725www.rysstech.comJ. F. Quinn et al./Tetrahedron Letters 49 (2008)6137-61406138 Contents lists available at ScienceDirect Tetrahedron Letters ELSEVIER journal homepage: www.elsevier.com/locate/tetlet 1,4-Cyclohexadiene with Pd/C as a rapid, safe transferhydrogenation system with microwave heating John F. Quinn*, Dana A. Razzano, Kathryn C. Golden, Brian T. Gregg AMRI, Medicinal Chemistry Department, 26 Corporate Circle, PO Box 15098, Albany, NY 12212-5098, USA ARTICL E INFO ABSTRACT Article history:Received 21 May 2008Revised 31 July 2008Accepted 6 August 2008Available online 23 August 2008 A method for the rapid, safe hydrogenation of alkenes and deprotection of benzyl ethers and carboxy-benzyl amides is described using catalytic transfer hydrogenation under microwave heating conditions.Commonly available Pd/C catalyst is extremely effective with 1,4-cyclohexadiene as the hydrogen trans-fer source. In general, the reactions are complete within five minutes at 100C. @ 2008 Elsevier Ltd. All rights reserved. Catalytic hydrogenation is a mainstay in the synthetic chemist’sarmamentarium. It has a long list of advantages, including opera-tional simplicity, chemoselectivity, and high chemical yields.Oftentimes all that is required in the way of reaction work-upand purification is a simple filtration to remove the spent catalystand removal of the solvent.In spite of these advantages thereremain a number of drawbacks, including the inconvenience ofmonitoring reaction progress, the need for specialized apparatus,safety issues involved with pressurized reaction vessels and usinghighly flammable hydrogen gas in the laboratory. While hydro-genation reactions are commonly carried out at high pressuresand temperatures in an industrial setting, this is seldom the casein the small-scale discovery laboratory. The most common reactionset-up in the small-scale discovery lab is either a balloon’ ofhydrogen at essentially atmospheric pressure and ambient tem-perature, or a commercial hydrogenator, operating at 40-60 psigH2, also at ambient temperature. In either case it is inconvenientto monitor reaction progress by standard methods such as TLC orLC-MS. Removal of an aliquot for analysis involves disrupting thehydrogen atmosphere,which must then be re-established if thereaction is to continue. It is also inconvenient to run laboratoryscale hydrogenation reactions at elevated temperatures when thereaction does not proceed at ambient temperature. We report herein an operationally simple, safe, and fast proce-dure for the catalytic hydrogenation of alkenes to alkanes as well * Corresponding author. Tel.: +1 518 464 0279; fax: +1 518 464 0289. ( E -mail addresses: john. q u i nn@a m rig lo bal.com, jf-q u inn-1@alum n i.uc h i ca go.edu(J. F. Quinn). ) as removal of the common protecting groups benzyl (Bz) and carb-oxybenzyl (Cbz). Our goal was to develop a robust hydrogenationprotocol that minimized or eliminated the disadvantages enumer-ated above, while maintaining the ease of work-up and purificationthat are hallmarks of the traditional hydrogenation procedure. Microwave heating technology has revolutionized many syn-thetic procedures in the laboratory, enabling access to high tem-peratures and pressures that can dramatically shorten reactiontimes.Additionally, microwave reactors are designed to work athigh pressures and engineered to contain debris in the event of afailure. We felt that microwave technology was ideally suited forthe development of an improved hydrogenation procedure. A long standing interest in parallel, high-throughput synthesisguided our initial choices of reaction protocols, where excess start-ing materials and reaction byproducts would be easily separatedfrom the compounds of interest. Our initial experiments focusedon the replacement of hydrogen gas with a hydrogen transfersource. Ammonium formate is a commonly used hydrogen donorthat fulfils these requirements. When cinnamic acid, 1, washeated in a microwave reactor at 100C with Pd/C and ammo-nium formate, quantitative conversion to 3-phenyl propionic acid,2, was observed in the crude HPLC. The use of ammonium formate,however, had a number of drawbacks. Although ammonium for-mate is a very active hydrogen donor source, its reaction byprod-ucts are gaseous (carbon dioxide and ammonia) and its useresulted in considerable pressure build-up by the end of the reac-tion. This required a manual venting of the reaction vessel forsafety purposes before the microwave cavity could be opened.Additionally, the excess ammonium formate required an aqueousextraction as a part of the reaction work-up. In an effort to reduce the final pressure in the reaction vessel aswell as simplify the reaction work-up and purification, the alterna-tive hydrogen transfer source, 1,4-cyclohexadiene, was examined.Using this hydrogen source also resulted in the quantitative forma-tion of 3-phenyl-propionic acid, 2, from cinnamic acid 1. Uponcompletion of the reaction, the microwave reaction tube was underno observable pressure. The use of cyclohexadiene has an addi-tional benefit in that both it and its reaction byproduct, benzene,are volatile liquids, easily removed by standard evaporationtechniques. Having found that 1,4-cyclohexadiene was an effective hydro-gen transfer source for catalytic hydrogenations, we then set outto optimize several reaction parameters, including the reactiontime, temperature, equivalents of cyclohexadiene, and solvent. A number of observations were made during the optimizationof this reaction. The reaction is sensitive to both the temperatureand the number of equivalents of 1,4-cyclohexadiene (Table 1).When 2 equiv of cyclohexadiene were used, only 2% conversionto product was observed (Table 1, entry 1). With 3 or more equiv-alents, the reaction goes to >95% completion (Table 1, entries 2-4).To ensure complete conversion of starting materials, subsequentreactions were typically run with 5 or 6 equiv of cyclohexadiene.Reducing the reaction temperature below 80℃ resulted in noreaction (Table 1, entries 6-7). The use of the less active hydrogendonor cyclohexene resulted in no reaction under our conditions,(Table 1, entry 9). The reaction worked equally well with 10% PdC (dry) (all entries in Tables 1 and 2), or 5% Pd/C (50wt%H20) (Ta-ble 3). The presence of water in the catalyst had no effect on thereaction. Switching from Pd to Pt on carbon as a catalyst resultedin no reaction (Table 1, entry 10). For activated alkenes, such ascinnamic acid, the reaction was remarkably fast. A reaction timeof 2 min resulted in quantitative conversion by HPLC. The reaction was found to be insensitive to the nature of solvent(Table 2). Both protic and non-protic solvents worked well. Of thesolvents investigated, only water gave a jpoor conversion (24%)under our standard conditions which was likely due to the poorsolubility of the reactants. The scope of this hydrogenation protocol was examined asshown in Table 3. The reaction worked equally well for elec-tron-rich (Table 3, entries 1,6, and9)) and electron-poor (Table3, entries 3, 4, and 8) systems. It is notable that 4-chlorocinnamic Entry Cyclohexadiene Temperature (C) Conversion(isolated (equiv) yield)(%) 2 100 2 3 100 3 4 100 4 5 100 >99(95b) 5 5 100 98.7° 6 7 5 5 5d 100 10 5 100 Table 2Effect of solvent on the hydrogenation reaction 0 Pd/C, 1,4-cyclohexadiene OH OH MW, 100°C,5 min 2 Entry Solvent Conversion (%) 1 Acetonitrile >99 2 Ethanol >99 3 THF >99 4 Acetone >99 5 Water 24.4 6 DMF >99 7 Ethyl acetate >99 acid, 17, (Table 3, entry 8) did not undergo dehydrohalogenation.In general, the reactions are complete within 5 min at 100 C. Inseveral cases (Table 3, entries 8 and 9), additional heating wasrequired for complete conversion. The transfer hydrogenation occurredsmoothly with conven-tional heating, using an oil bath pre-heated to 100 °℃ (Table 1, en-try 5). This, however, required the use of a sealed tube apparatusand the accompanying safety shield. The microwave reactor offerssignificant advantages in terms of safety and convenience. Addi-tionally, the microwave synthesizer can be equipped with sampleautomation that allows multiple reactions to be carried out in aserial fashion. In addition to ]hydrogenations, the reaction protocol also provedto be useful for the rapid hydrogenolysis of the common protectinggroups benzyl (Bz) and carboxybenzyl (Cbz) (Table 4, entries 1-5).The Cbz-protected di-peptide 23 was smoothly deprotected to givethe primary amine 24 in 85% isolated yield. Likewise, the second-aryamine 25 was cleanly debenzylated to give anisidine 26 in88% isolated yield. The reported conditions were equally adept atdeprotection of benzyl phenol ethers (Table 4, entries 3 and 4). Ani-line 27 was converted to aminophenol 28 and benzoic acid 29 wasconverted to 4-hydroxybenzoic acid 30 in 86% and 99% yields,respectively. The final entry (Table 4, entry 5) demonstrates a con-venient, neutral, non-aqueous route for unmasking carboxylicacids that are protected as benzyl esters. Benzyl 4-hydroxybenzo-ate 31 is converted to 4-hydroxybenzoic acid 30 in 86% isolatedyield. Interestingly, in the case of Cbz-protected benzyl phenyl-alanine, 32, deprotection under the standard conditions in ethylacetate as solvent leads to a 75% isolated yield of Cbz-phenylali-nine, 33. The same reaction in methanol leads to a quantitativeyield of phenylalaline 34. All the reaction byproducts were volatileand in each case, purification involved only filtration andconcentration. Hydrogenolysis of N-Cbz-O-benzyl phenylalanine,32, shows aninteresting, and potentially useful, selectivity (Scheme 1). Underour standard conditions (MW,100℃, 5 min, 6 equiv cyclohexadi-ene) using ethyl acetate as the solvent, a 64% isolated yield ofN-Cbz-phenylalanine,33, is obtained as the sole product. Inspection of the HPLC and 'H NMR of the crude reaction showsno evidence for phenylalanine or benzyl phenylalanine. However,when the reaction solvent is switched to methanol, a quantitativeyield of completely deprotected phenylalanine 34 is obtained. In summary, our reported hydrogenation procedure utilizeswidely available Pd/C catalyst under transfer hydrogenation condi-tions. Reaction monitoring and optimization is straightforward, asa sample may be withdrawn through the septum cap on the micro-wave process vial for standard TLC or HPLC analysis. In analogy totraditional methods involving hydrogen gas, all that is required inthe way of work-up and purification is a filtration to remove the J. F. Quinn et al./Tetrahedron Letters 49 (2008) 6137-6140 Table 3Transfer hydrogenations under microwave heating Unless otherwise noted, all reactions performed in ethyl acetate (3 mL), 1 mmol substrate, heated under microwave conditions at 100℃ for 5 min.Methanol used as solvent. ( 30 min reaction t ime. ) ( 15 min reaction t ime. ) ( HPLC y i eld (AUC@254nM). ) J. F. Quinn et al./Tetrahedron Letters 49 (2008) 6137-6140 Table 4 Unless otherwise noted, all reactions performed in ethyl acetate (3 mL), 1 mmol substrate, heated under microwave conditions at 100 ℃ for 30 min. d 5 min reaction time. 60 min reaction time. Scheme 1. Solvent selectivity in hydrogenolysis of N-Cbz-O-benzyl phenylalanine. Reagents and conditions: reactions were performed in solvent indicated (3 mL), 1 mmolsubstrate, 6 mmol 1,4-cyclohexadiene, 0.047 mmol Pd/C, heated under microwave conditions at 100 ℃ for 5 min. spent Pd catalyst and concentration to remove the solvent, volatilereagents, and byproducts. Acknowledgement The authors wish to thank Drs. Michael P. Trova and BruceMolino for their helpful discussions and suggestions. References and notes 1. (a)Rylander,P. N. Hydrogenation Methods; Academic Press: New York, 1985;(b)Siegel, S. In Comprehensive Organic Synthesis; Trost, B. M., Flemming, I., Eds.;Pergamon Press: Oxford, 1991; Vol.8, pp 418-442;(c) Hudlicky, M. Reductionisin Organic Chemistry; Ellis Horwood Ltd: Chichester, 1984. pp 1-13. 2. For example,the 3900 series Hydrogenation Apparatus Manufactured by Parr Instrument Company, Moline, IL;www.parrinst.com. 3. Microwave Methods in Organic Synthesis; Larhed, M., Olofsson, K.,Eds.;Springer-Verlag: Berlin, 2006. 4. For reviews on catalytic transfer hydrogenation see: (a) Brieger, G.; Nestrick, T. J.Chem. Rev. 1974, 74,567-580;(b)Johnstone, A. W.; Wilby, A. H.; Entwistle, I. D.Chem. Rev.1985, 85, 129-170. 5. Makowski, M.; Rzeszotarska, B.; Smelka, L.; Kubica, Z. Liebigs Ann. Chem. 1985,1457. 6. All microwave experiments were performed using a Biotage Initiator 2.0microwave synthesizer. 7. (a) Eberhardt, M. K. Tetrahedron 1967, 23, 3029; (b) Felix, A. M.; Heimer, E. P.;Lambros, T. J.; Tzougraki, C.; Meyerhofer, J.J. Org. Chem. 1978,43,4194. 8.. A representative procedure is as follows: A 5 mL Biotage microwave processtube with stir bar was charged with cinnamic acid (148 mg, 1 mmol), Pd/C(10 wt%, 50 mg, 0.047 mmol), and ethyl acetate (3mL). 1,4-Cyclohexadiene(0.50 mL, 5.3 mmol) was added and the tube was capped and heated undermicrowave conditions at 100 °C for 5 min. The reaction mixture was filteredthrough Celite and evaporated to give hydrocinnamic acid (150 mg,>99%) aswhite crystals. 400-188-0725 $ -see front matter @ Elsevier Ltd. All rights reserved.doi:j.tetlet.ww.rysstech.com耐士科技 www.rysstech.com

确定

还剩2页未读,是否继续阅读?

上海鑫欣生物科技有限公司为您提供《化学药中特殊物质和基团检测方案 》,该方案主要用于化药新药研发中其他检测,参考标准--,《化学药中特殊物质和基团检测方案 》用到的仪器有

相关方案

更多

该厂商其他方案

更多