NOx,氮氧化物,光学透明发动机中光谱,浓度场,尾气排放,污染物检测方案(尾气检测)

Growing environmental concerns, such as global warming due to the emission of the

greenhouse gas CO2 by automotive power plants, lead to the need for cleaner and fuel

saving combustion systems. Direct injection combustion systems applied to the spark

ignited engine might be a way to improve the efficiency particularly by reducing

pumping and heat losses during part load while maintaining the advantages of high power

density and engine speeds during high loads [Zhao, Lai et al., 1999]. Initially, wall

guided combustion systems were pursued, but high hydrocarbon and soot emissions led

to the investigation of spray guided systems. Here a higher degree of stratification is

possible, which yields improved emissions [Drake, Fansler et al., 2004; Honda,

Kawamoto et al., 2004]. Nonetheless, due to high oxygen availability and locally rich

mixture, the nitric oxide formation is comparably high. This is detrimental as the widely

employed exhaust aftertreatment by a three way catalytic converter is inefficient for

overall lean mixtures. NO storage catalytic converters are widely employed, but require

rich exhaust gas to reduce the stored NO. This is generated by operating the engine

homogeneous-rich for a brief period of time, which of course comes with a fuel

consumption penalty [Tamura, Kikuchi et al., 2001; Krebs, Pott et al., 2002]. A reduction

of in-cylinder nitric oxide is desirable to minimize the number of regeneration cycles.

Hence the understanding of in-cylinder NO formation is important, so that the necessary

scientific background for improvement of the combustion system is provided. An

assessment of the NO formation process inside the engine exclusively by drawing

conclusions from engine out emissions is difficult, because of the highly inhomogeneous

nature of the stratified charge combustion process. Also, due to high cyclic variability

cycle resolved measurements are desirable, which conventional emissions analyzers are

not capable of.

检测样品:

汽车电子电器

检测项:

理化分析

北京欧兰科技发展有限公司

查看联系电话

前往展位

真实发动机,缸内流动结构,发动机中流场,速度场检测方案(粒子图像测速)

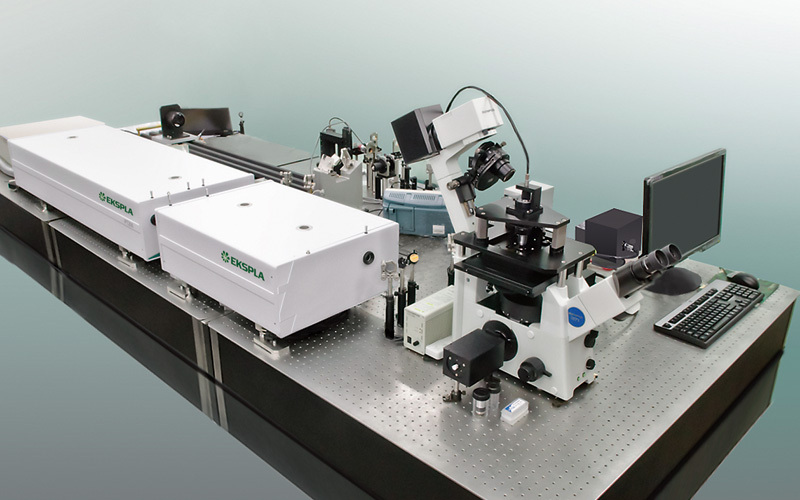

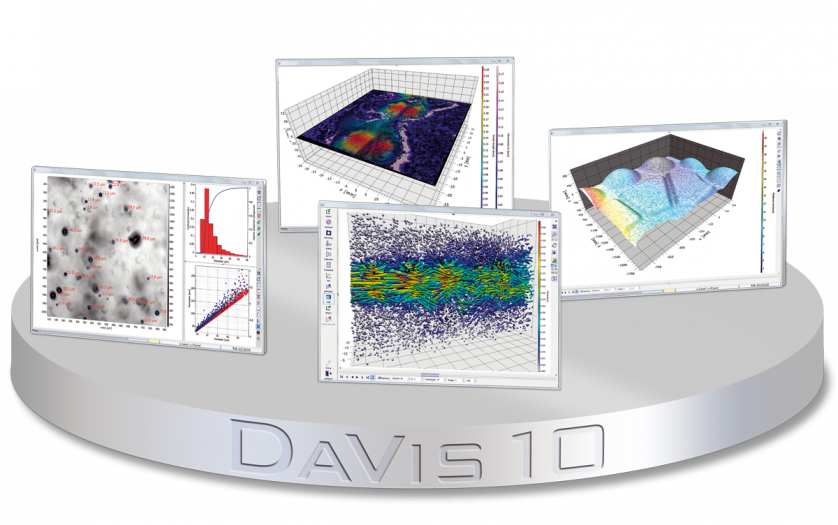

In-cylinder PIV measurements have been made during the latter half of the intake stroke on a

plane between the inlet valves for a single cylinder optical engine operating at engine speeds of 750, 2000

and 3500 rpm. Mean vector fields for an area of 42 mm by 34 mm have been produced with vectors at

approximately 1 mm resolution. The vector fields show the development of the flow field in 1.6°, 2.4° and

3.2° steps for the three respective engine speeds.

Tumble ratios have been calculated from these vector fields which show that a change in the flow regime

occurs between 2000 and 3500 rpm. This is caused by one of rotating vortices becoming detached from the

descending piston at the highest engine speed.

检测样品:

汽车电子电器

检测项:

其他

北京欧兰科技发展有限公司

查看联系电话

前往展位

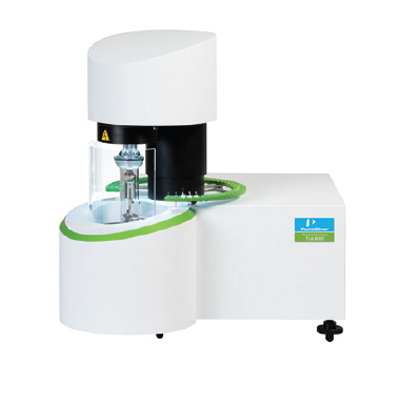

气缸和缸套中表面轮廓和结构检测方案

WLICyl是用于气缸和缸套的非接触3D表面轮廓和结构测量仪,既可用于实验室研发也可用于生产检测环节。

WLICyl最大特点是设计紧凑,坚固耐用,有着很高的横向和垂直分辨率。设备简单易用,无需维护,配置由专业工程师开发的人性化软件。使用合适的安装板放置在缸体上,便于定中心和重复定位。

测量头由精密电机驱动,可实现轴向旋转和横向移动,能够精确测量气缸内的任意位置。可使用操纵杆手动定位传感器,也可使用软件进行自动控制。此外,测量头末端还附带一个小型照相机,可观测约5 mm2的区域。可使用它寻找表面的特殊结构和缺陷,随后进行测量。使用WLICyl可在短时间内对发动机气缸表面粗糙度参数、涂层缺陷和特定参数进行高精度定量测量。使用选配的分析软件可测量珩磨沟槽和气孔的体积、金属撕裂和折叠、扩张脊、大理石花纹、粗糙度以及更多的细节。分析软件还可将数据文件分解成气孔图像、珩磨沟槽图像、金属撕裂和折叠图像等等。

检测样品:

汽车电子电器

检测项:

理化分析

佰汇兴业(北京)科技有限公司

查看联系电话

前往展位

发动机,燃烧,柴油,喷射中浓度场,空燃比检测方案(尾气检测)

Development of Optical Diagnostic Techniques to Correlate Mixing and Auto-Ignition

Processes in High Pressure Diesel Jets — A tracer laser-induced fluorescence (LIF) technique for the

visualization of fuel distribution in the presence of oxygen was developed and then used sequentially with

high speed chemiluminescence imaging to study the correlation between the mixing and auto-ignition

processes of high pressure Diesel jets. A single hole common rail Diesel injector allowing high injection

pressures up to 150 MPa was used. The reacting fuel spray was observed in a high pressure, high temperature

cell that reproduces the thermodynamic conditions which exist in the combustion chamber of a

Diesel engine during injection. Both free jet and flat wall impinging jet configurations were studied.

Several tracers were first considered with the objective of developing a tracer-LIF technique in the presence

of oxygen. 5-nonanone was selected for its higher fluorescence efficiency. This technique was subsequently

combined with high speed chemiluminescence imaging to study the correlation between mixing

and auto-ignition. In the free jet configuration and for the parameter range studied, it was found that

auto-ignition is preferentially located in rich regions of the upstream mixing zone. Also, in the jet wall

configuration, auto-ignition appears in the centre of the jet and propagates towards the periphery, in the

vicinity of the wall.

检测样品:

汽车电子电器

检测项:

其他

北京欧兰科技发展有限公司

查看联系电话

前往展位

喷嘴中火焰浮起长度检测方案(尾气检测)

This paper reports on the experimental investigation of the flame lift-off length for five different orifice

diameters (.0.100, .0.130, .0.160, .0.190, and .0.227 mm) of a diesel injector nozzle. The flame lift-off

was determined from the measurement of 308 nm OH chemiluminescence for different fuel injection pressures

using commercial diesel fuel and a Common Rail fuel injection equipment of passenger car size. The fuel

injection pressures were 450, 900, and 1350 bar. The experiments were conducted at air pressures of 30, 50, 70,

and 90 bar and at an air temperature of 750 K in a constant pressure spray chamber. It was observed that the

flame lift-off length increases with increased injection pressure and increased orifice diameter.

检测样品:

汽车电子电器

检测项:

热性能

北京欧兰科技发展有限公司

查看联系电话

前往展位

柴油发动机中NO的激光诊断检测方案(尾气检测)

In 1897 Rudolf Diesel (1858-1913) demonstrated a new type of internal combustion (i.c.)

engine in which the high compression pressure of about 35 times the atmospheric pressure

led to a sufficiently high temperature to cause the auto-ignition of kerosine. Ever since

diesel engines remained popular owing to their relatively high efficiencies and their ability

to combust a large variety of fuels predominantly containing heavier crude oil components

(i.e., longer aliphatic hydrocarbon chains). The original engines were 4-stroke engines in

which one complete engine cycle takes two revolutions of the crank shaft. The latter

transforms the translational energy of the piston in the cylinder into more convenient

rotational energy with respect to vehicle propulsion. As schematically depicted in figure

1.1, in the first stroke the piston moves downwards in the cylinder and ambient air is

taken in above the piston (inlet stroke). In the second stroke the inlet valve is closed and

the piston moves upwards compressing the intake air (compression stroke). Just before the

piston reaches its Top Dead Centre (TDC) fuel is sprayed in the combustion chamber and

combustion takes place driving the piston downwards again in the third stroke (expansion

stroke). Finally, the exhaust valve opens and the piston moves upwards again in the fourth

stroke (exhaust stroke) pushing the combustion gases out of the cylinder. In later years 2-

stroke diesel engines were developed in which, by using the space of the crank case below

the piston as well, the work usually done in four strokes is now performed by one

revolution of the crank shaft. Around 1940 the first turbo-charging diesel engines were

developed in which the energy contained in the exhaust gases is used to compress the

intake air in order to boost the power of the engines.

检测样品:

汽车电子电器

检测项:

NO的激光诊断

北京欧兰科技发展有限公司

查看联系电话

前往展位

内燃机中时间分辨空燃比分布,激光诱导荧光,PLIF检测方案(其它光谱仪)

This study presents planar laser induced fluorescence data recorded within an optically accessible spray-guided direct-injection

spark-ignition internal combustion engine at a repetition rate of 6 kHz. The data is calibrated to estimate the local distribution of

the equivalence ratio within the combustion chamber from 50-10. BTDC. A standard reference fuel was used as a tracer. Cyclic

fluctuations of the transient and spatial fuel distributions are presented.

检测样品:

汽车电子电器

检测项:

其他

北京欧兰科技发展有限公司

查看联系电话

前往展位

汽车发动机中空燃比,空间分辨空燃比,燃料浓度检测方案(尾气检测)

The present work describes a new method which allows the spatially resolved quantitative determination of gaseous hydrocarbon densities in droplet laden flows. The technique is especially dedicated to a quantitative and linearly spatially resolved measurement of air/fuel ratio (λ-value) in direct injection Otto engines under stratified

operation and by use of regular gasoline (Euro Super). The new method is based on spontaneous Raman scattering. It is applied to the investigation of the air/fuel ratio distribution inside and in the close surroundings of the spray cone of different DI-fuel injectors under stratified and homogeneous engine operation conditions. Both crank angle resolved snap shot and cyclical averaged measurements are presented. Simultaneously the planar gasoline distribution is detected by LIF of aromatic hydrocarbons which are native constituents of regular gasoline. It is shown, that the

linear spatially resolved air/fuel distributions measured by means of LIF correlate well with the Raman data.

检测样品:

汽车电子电器

检测项:

空燃比,空间分辨空燃比,燃料浓度

北京欧兰科技发展有限公司

查看联系电话

前往展位

汽车发动机中流场,滚流检测方案(粒子图像测速)

This paper deals with the experimental investigations

of the in-cylinder tumble flows in an unfired internal combustion

engine with a flat piston at the engine speeds ranging from 400 to

1000 rev/min., and also with the dome and dome-cavity pistons at an

engine speed of 1000 rev/min., using particle image velocimetry.

From the two-dimensional in-cylinder flow measurements, tumble

flow analysis is carried out in the combustion space on a vertical

plane passing through cylinder axis. To analyze the tumble flows,

ensemble average velocity vectors are used and to characterize it,

tumble ratio is estimated. From the results, generally, we have found

that tumble ratio varies mainly with crank angle position. Also, at the

end of compression stroke, average turbulent kinetic energy is more

at higher engine speeds. We have also found that, at 330 crank angle

position, flat piston shows an improvement of about 85 and 23% in

tumble ratio, and about 24 and 2.5% in average turbulent kinetic

energy compared to dome and dome-cavity pistons respectively.

检测样品:

汽车电子电器

检测项:

流场,滚流

北京欧兰科技发展有限公司

查看联系电话

前往展位

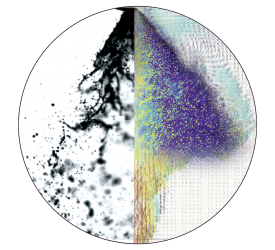

汽车发动机中采用结构化片光照明抑制多重散射-应用与柴油和汽油喷雾的首次评估检测方案(尾气检测)

For dense sprays such as those encountered in diesel or gasoline direct injection, the interpretation of spray images

is complicated by the fact that most of the light reaches the detectors after multiple scattering events within the

spray. This may introduce severe errors when extracting quantitative or even qualitative information from these

images as many diagnostics rely on the assumption of single photon scattering.

It has recently been shown that the multiple scattering component of spray images can be effectively suppressed if

sets of structured light sheets are used to illuminate the spray. The aim of this report is to illustrate the potential

and the limitations of this technique for the visualization of sprays from modern diesel and gasoline injectors

at elevated atmospheric pressures. The results clearly show that conventionally recorded images are dominated

by multiple scattering, causing the light sheet to widen substantially and obscuring details within the light sheet

plane. In contrast, multiple scattering and indirect reflections can be suppressed using structured light sheets and

proper image processing. Careful interpretation of the corresponding images reveals details of the inner spray

structure and thus contributes to the understanding of the complicated spray break-up and atomization processes.

检测样品:

汽车电子电器

检测项:

采用结构化片光照明抑制多重散射-应用与柴油和汽油喷雾的首次评估

北京欧兰科技发展有限公司

查看联系电话

前往展位

油浸式变压器中糠醛检测方案(液相色谱仪)

目前,国内电力变压器的纸质绝缘材料主要以木材纸浆为原料,主要成分是纤维素,当

绝缘纸劣化时,纤维素降解生成一部分 D-葡萄糖单体,D-葡萄糖单体在变压器运行条件下易

分解,最后产生一系列溶解在变压器油中的氧杂环化合物,糠醛是纤维素大分子降解后形成

的一种主要氧杂环化合物。

合格的新变压器油不含糠醛,变压器内部非纤维素绝缘材料老化也不产生糠醛,变压器

油中的糠醛是唯有纸绝缘老化才生成的产物。因此,测试油中糠醛含量,可以反映变压器纸

绝缘的老化情况。

依利特公司,参考电力行业相关标准和文献资料对实验条件进行了摸索、优化,提出了

变压器油中糠醛检测解决方案。

检测样品:

汽车电子电器

检测项:

理化分析

大连依利特分析仪器有限公司

查看联系电话

前往展位

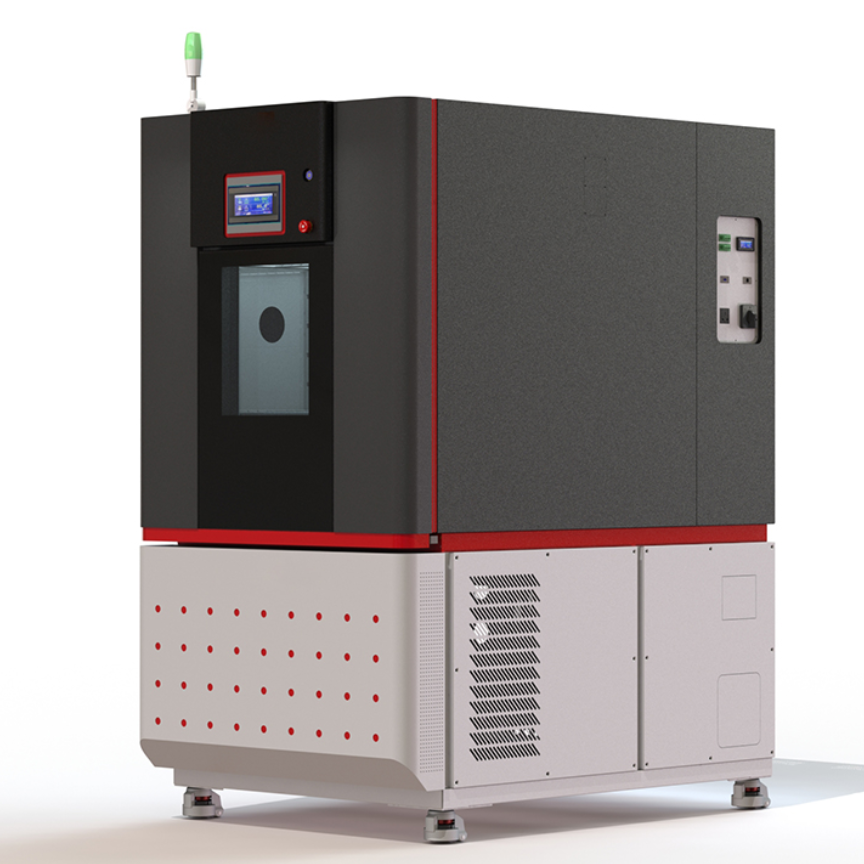

制动片,刹车片中导热系数检测方案(导热仪)

制动片,也叫刹车片,在汽车的制动系统中,制动片是最关键的安全零件,所有刹车效果的好坏都是制动片起着决定性的作用。两个制动片位于卡钳和转子之间。当踩下制动踏板以停止车辆时,制动衬块挤压制动转子,从而将压力和摩擦施加到转子上。其结果是通过摩擦将转子的动能转化为热能。制动片的导热特性对于保持制动系统的最大性能是重要的。快速导热仪可以对刹车片的导热系数进行质量控制。快速导热系数仪具有优异的操作性,并且可以容易且快速地测量。仅需将将传感器置于温度均匀的样品表面,测量时间仅需60秒。

检测样品:

汽车电子电器

检测项:

理化分析

可睦电子(上海)商贸有限公司-日本京都电子(KEM)

查看联系电话

前往展位

雷达传感器中精度检测方案(激光干涉仪)

自动驾驶是目前汽车工业为前沿和火热的研究,而自动驾驶尤为重要的是需要可靠和高分辨率的距离测量雷达。德国弗劳恩霍夫高频物理和雷达技术研究所(Wachtberg,D)Nils Pohl教授和波鸿鲁尔大学(Bochum,D)的研究小组提出了一种全集成硅锗基调频连续波雷达传感器(FMCW),工作频率为224 GHz,调谐频率为52 GHz。通过使用德国attocube公司的皮米精度激光干涉仪FPS1010(新版本为IDS3010)证明了测量系统在-3.9μm至+2.8μm之间达到了-0.5-0.4μm的超高精度。这种全新的高精度雷达传感器将会应用于许多全新的汽车自动驾驶领域。

检测样品:

汽车电子电器

检测项:

其他

QUANTUM量子科学仪器贸易(北京)有限公司

查看联系电话

前往展位

仪器信息网行业应用栏目为您提供114篇汽车电子电器检测方案,可分别用于可靠性能检测、热性能检测、电学性能检测,参考标准主要有等