The efficiency and mechanisms of cooling a constant heat flux surface by impinging synthetic jets were investigated experimentally and compared to cooling with continuous jets. Effects of jet formation frequency and Reynolds number at different nozzle-to-surface distances (H/d) were investigated. High formation frequency (f = 1200 Hz) synthetic jets were found to remove heat better than low frequency (f = 420 Hz) jets for small H/d, while low frequency jets are more effective at larger H/d. Moreover, synthetic jets are about three times more effective in cooling than continuous jets at the same Reynolds number. Using PIV, it was shown that the higher formation frequency jets are associated with breakdown and merging of vortices before they impinge on the surface. For the lower frequency jets, the wavelength between coherent structures is larger such that vortex rings impinge on the surface separately.

KEYWORDS:

方案详情

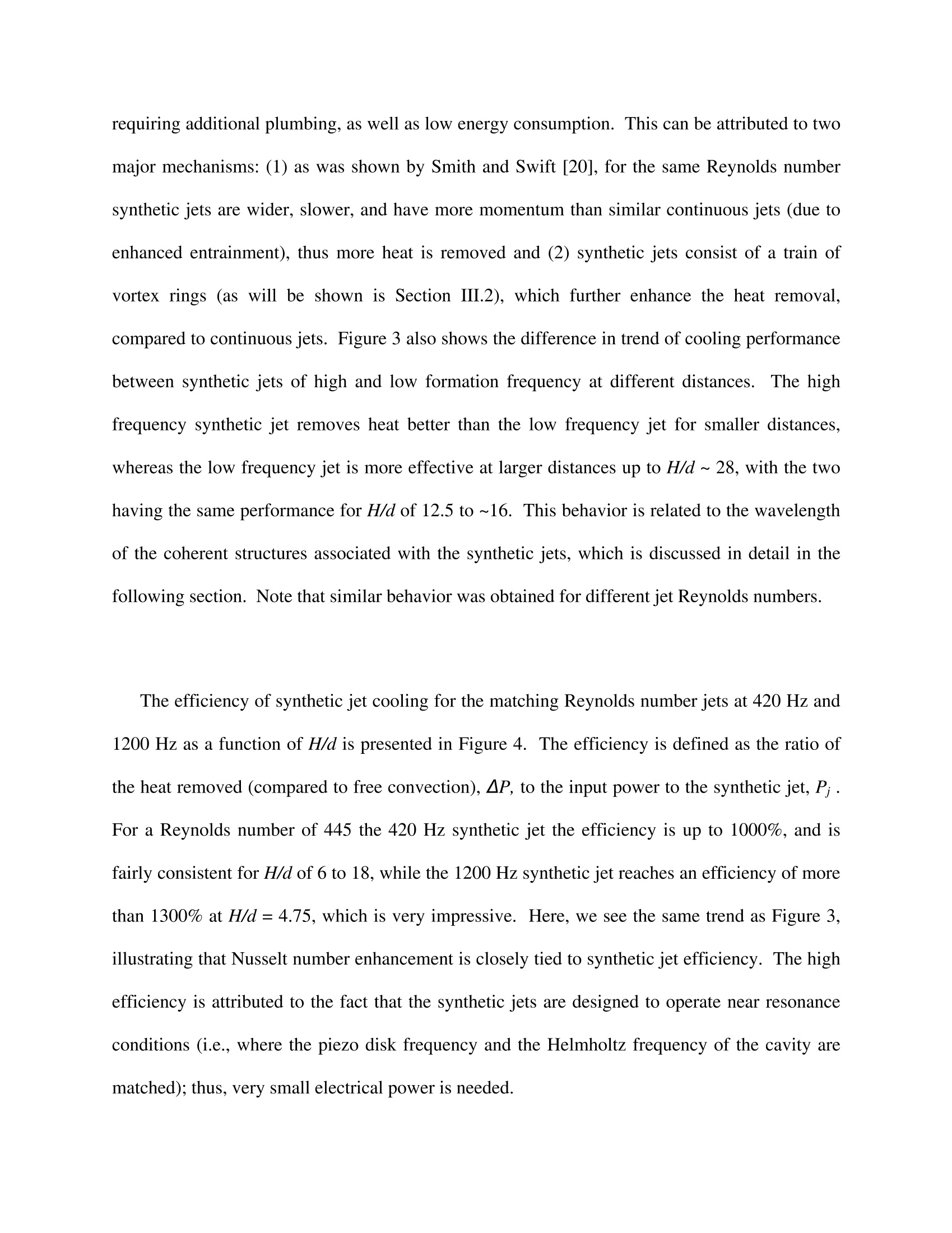

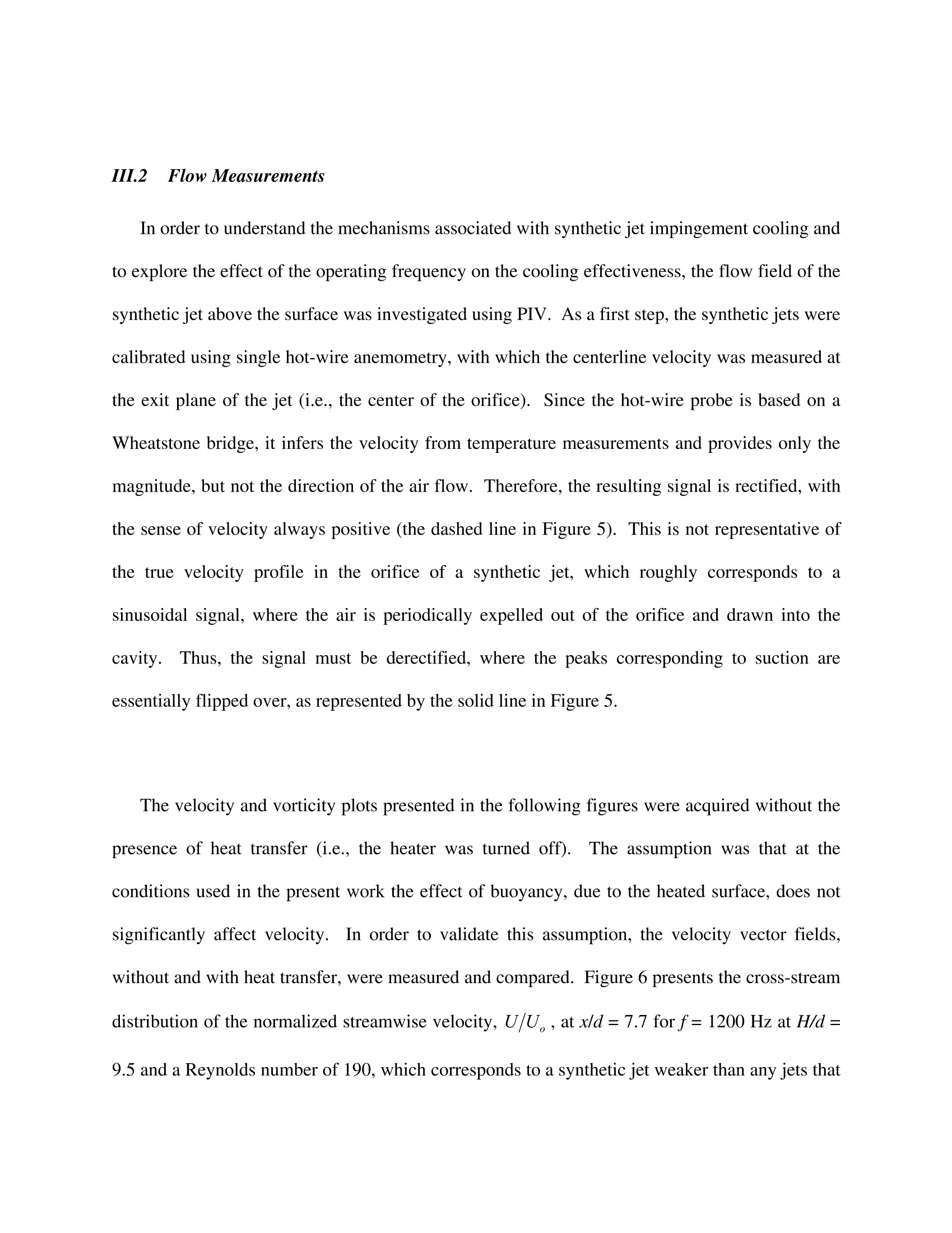

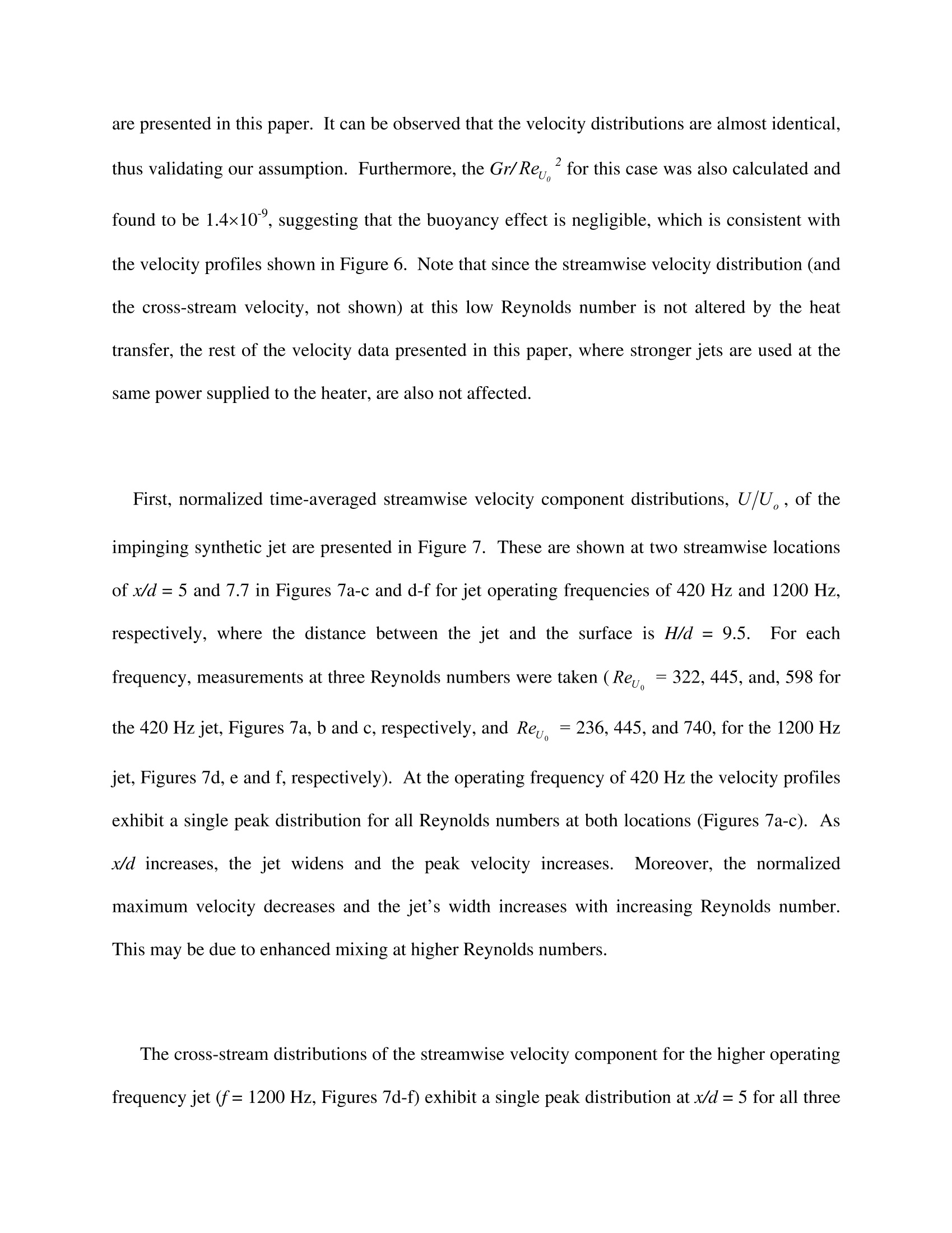

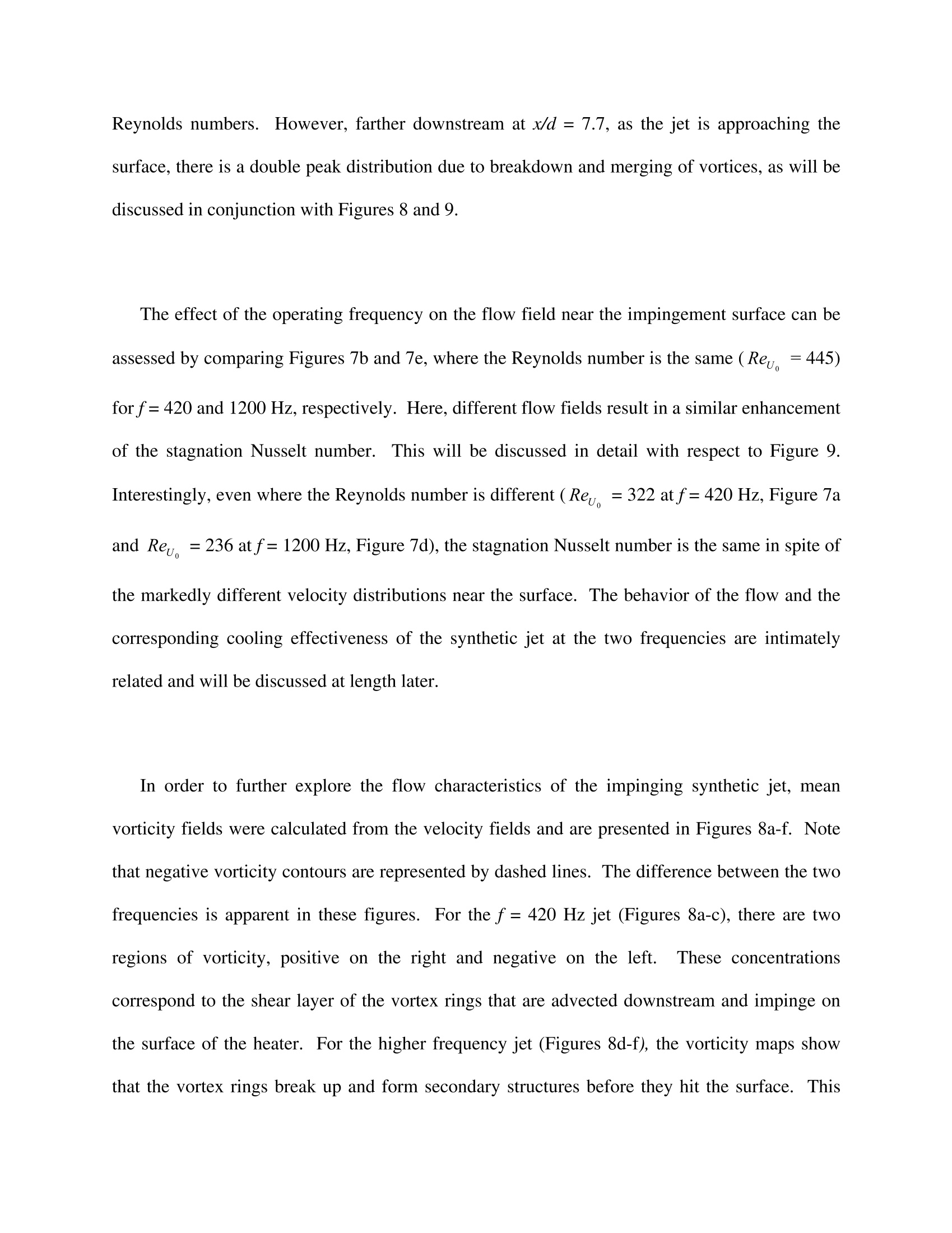

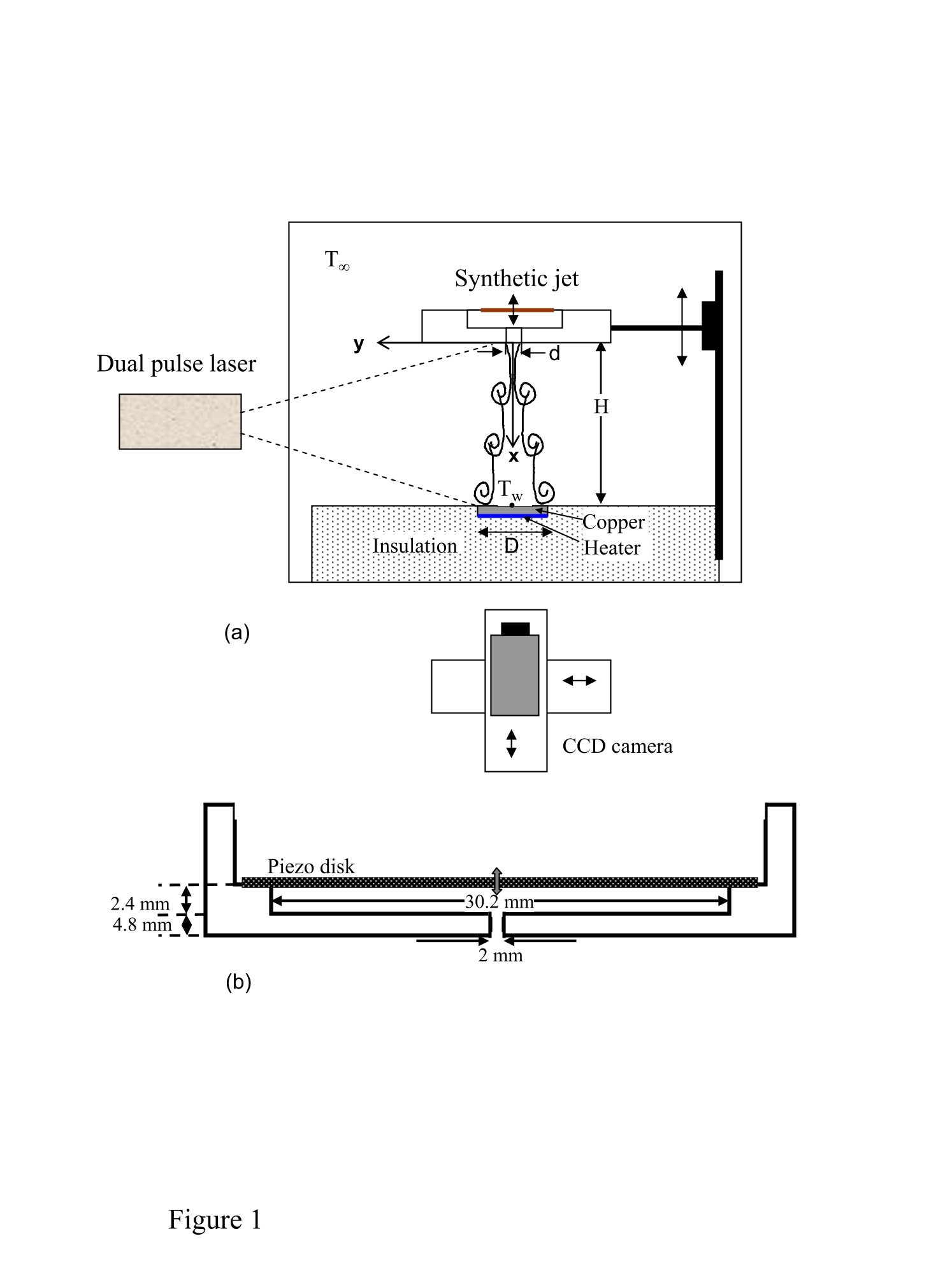

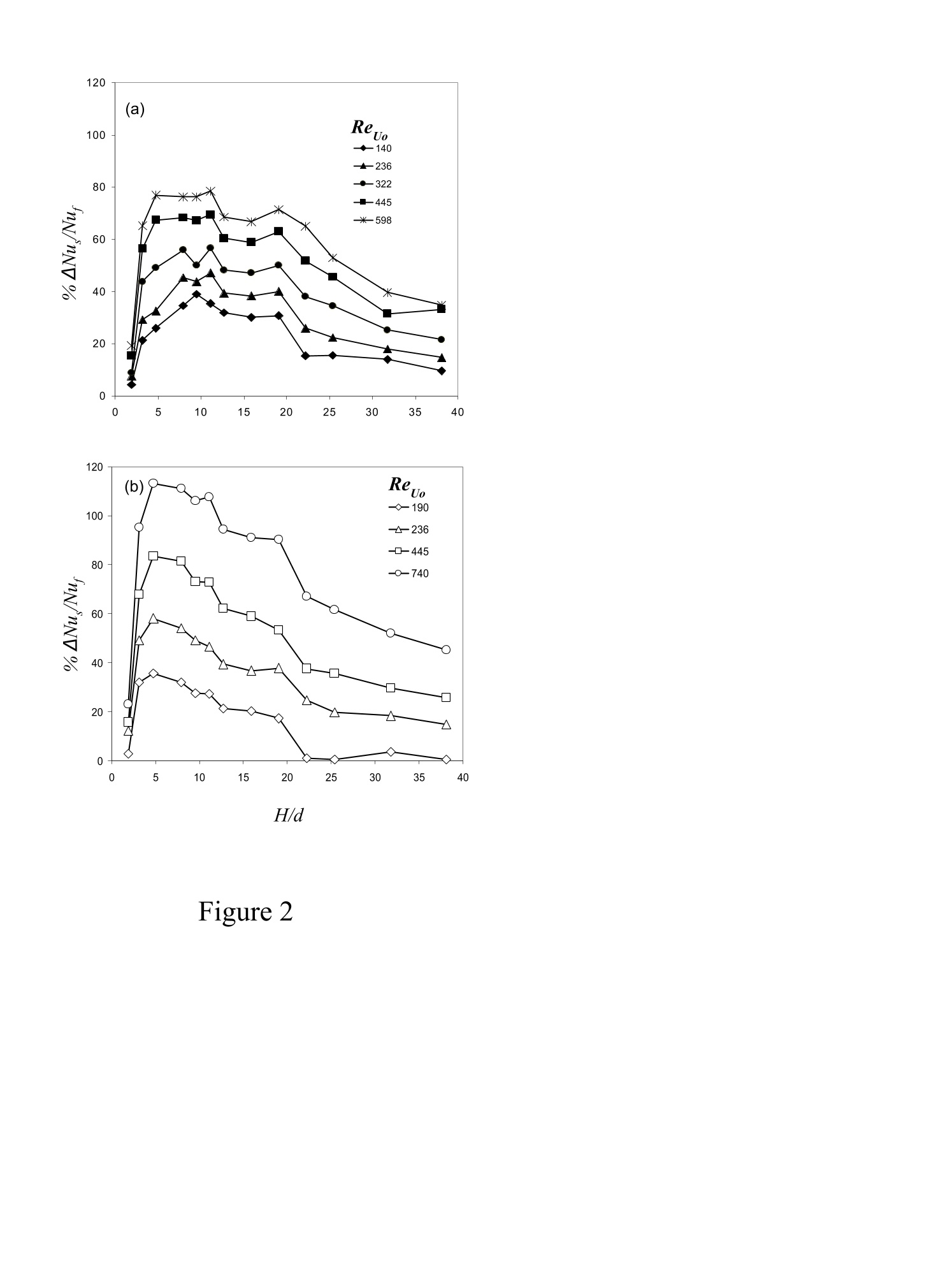

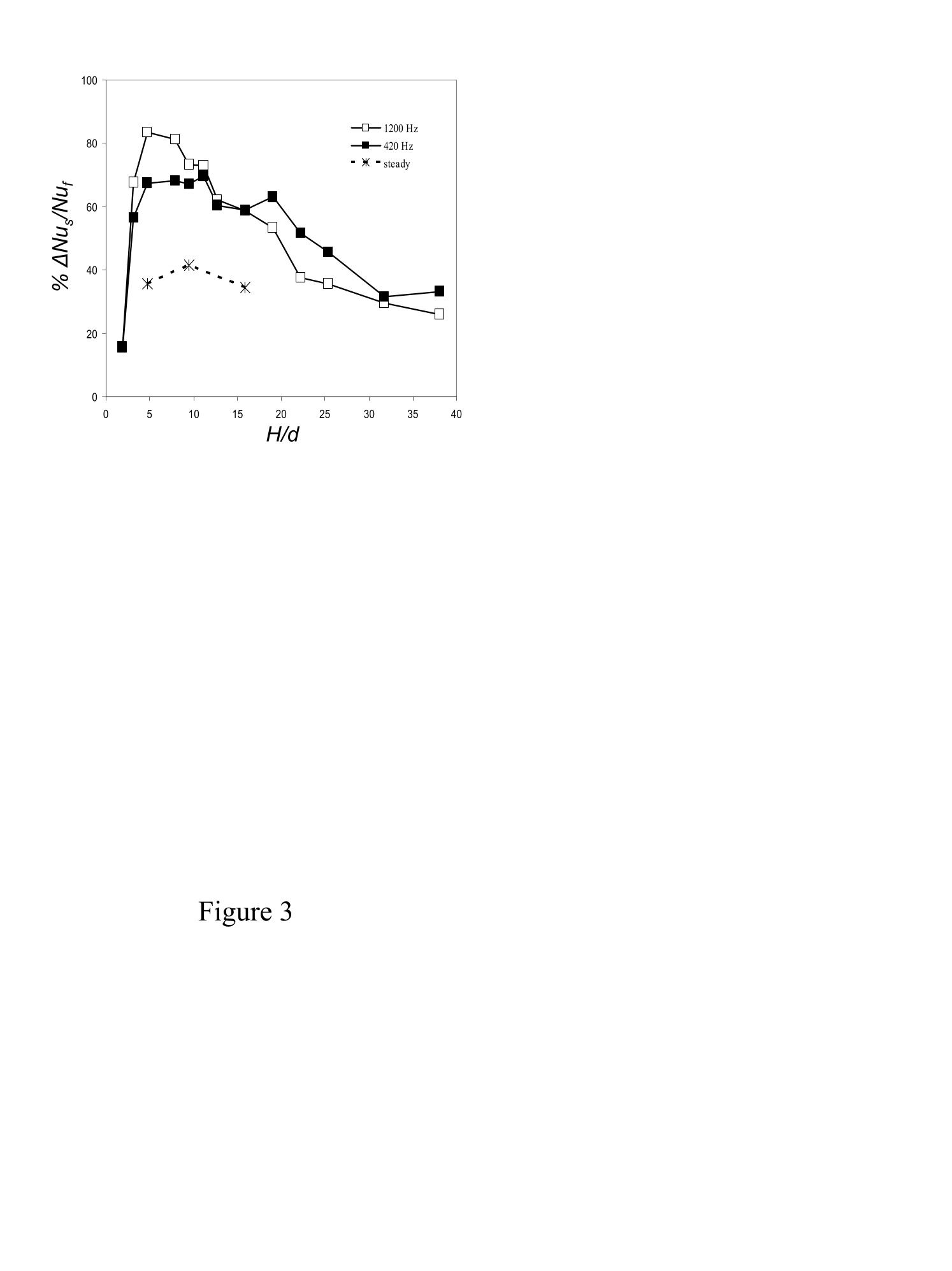

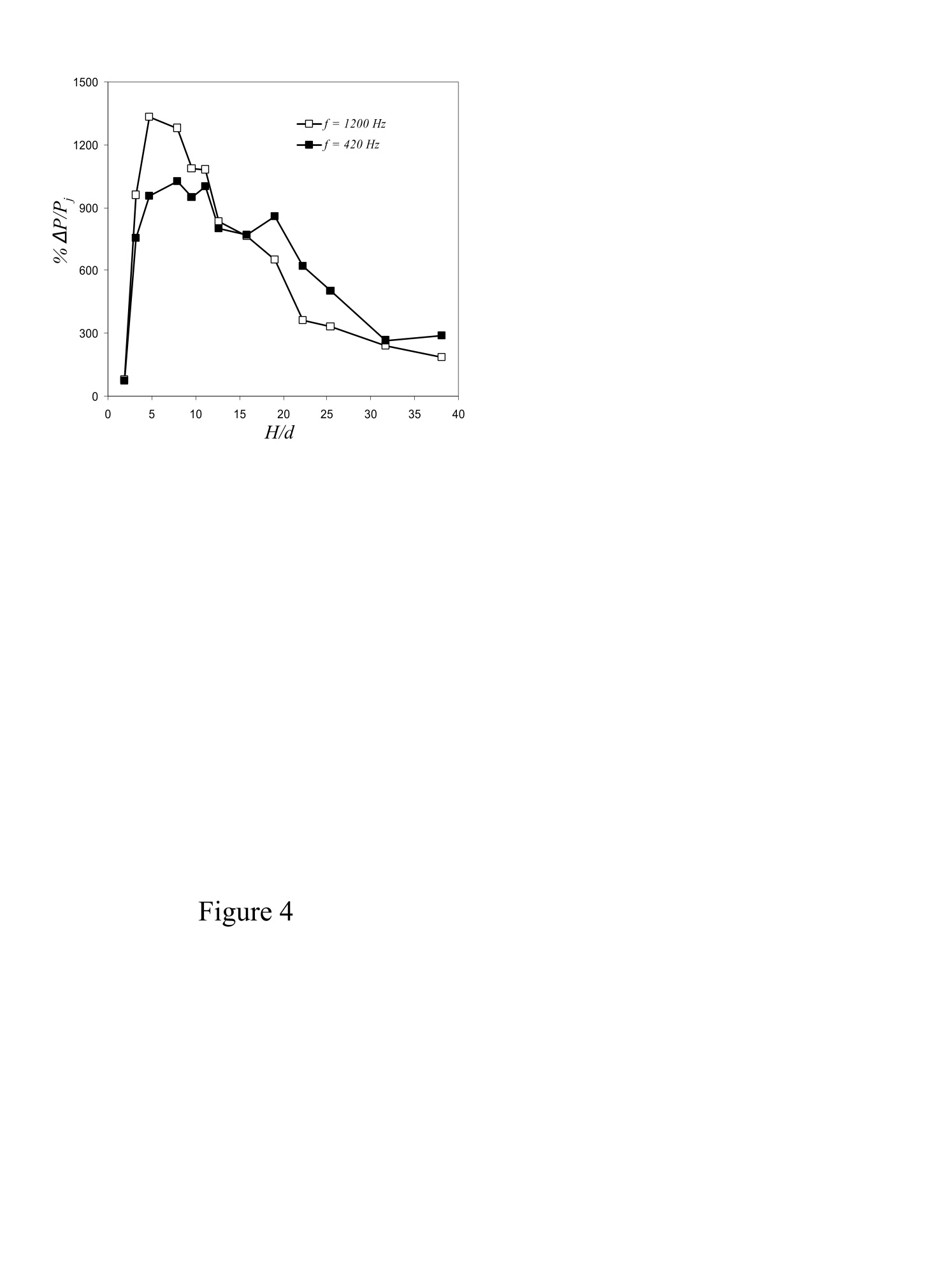

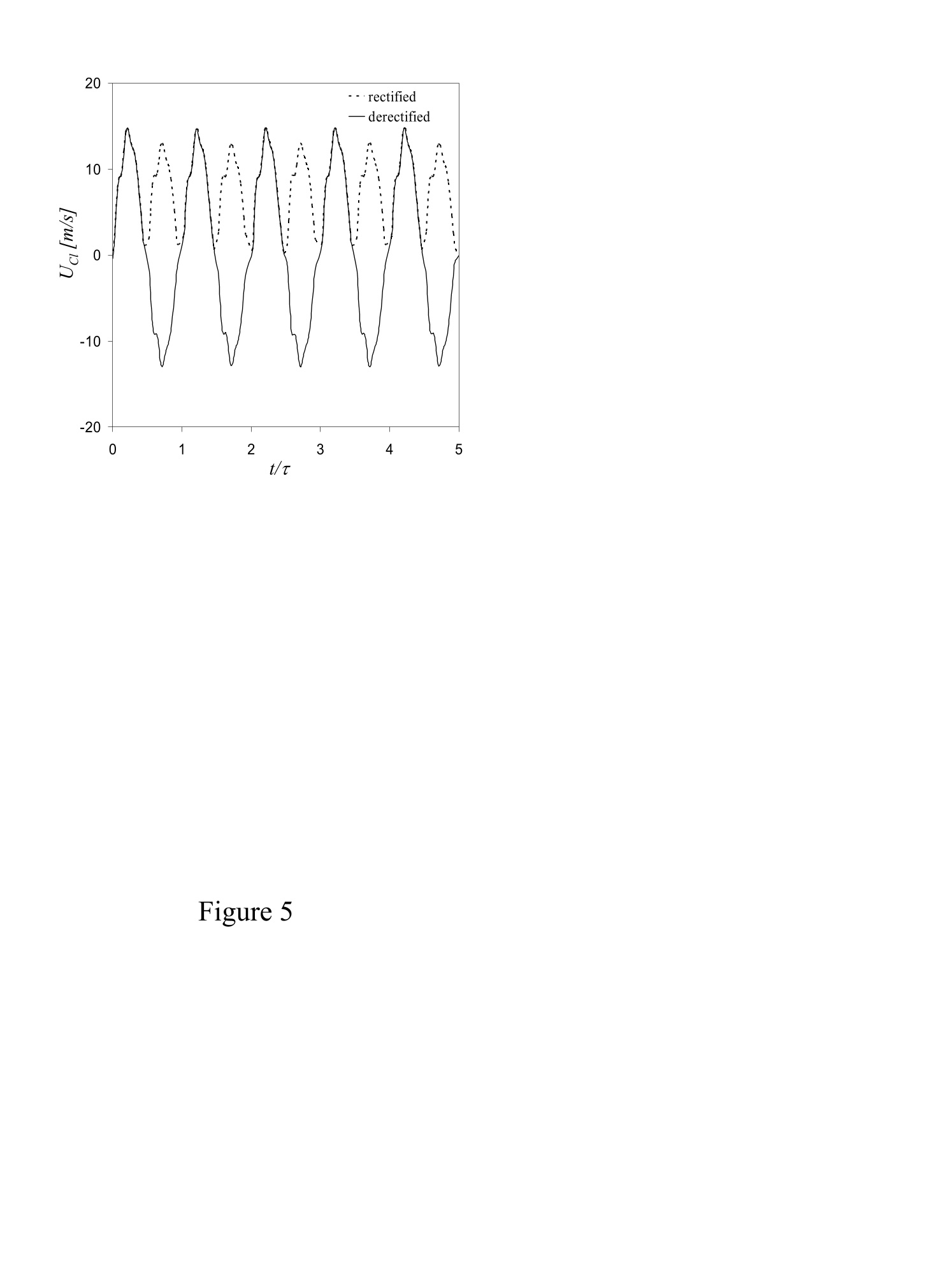

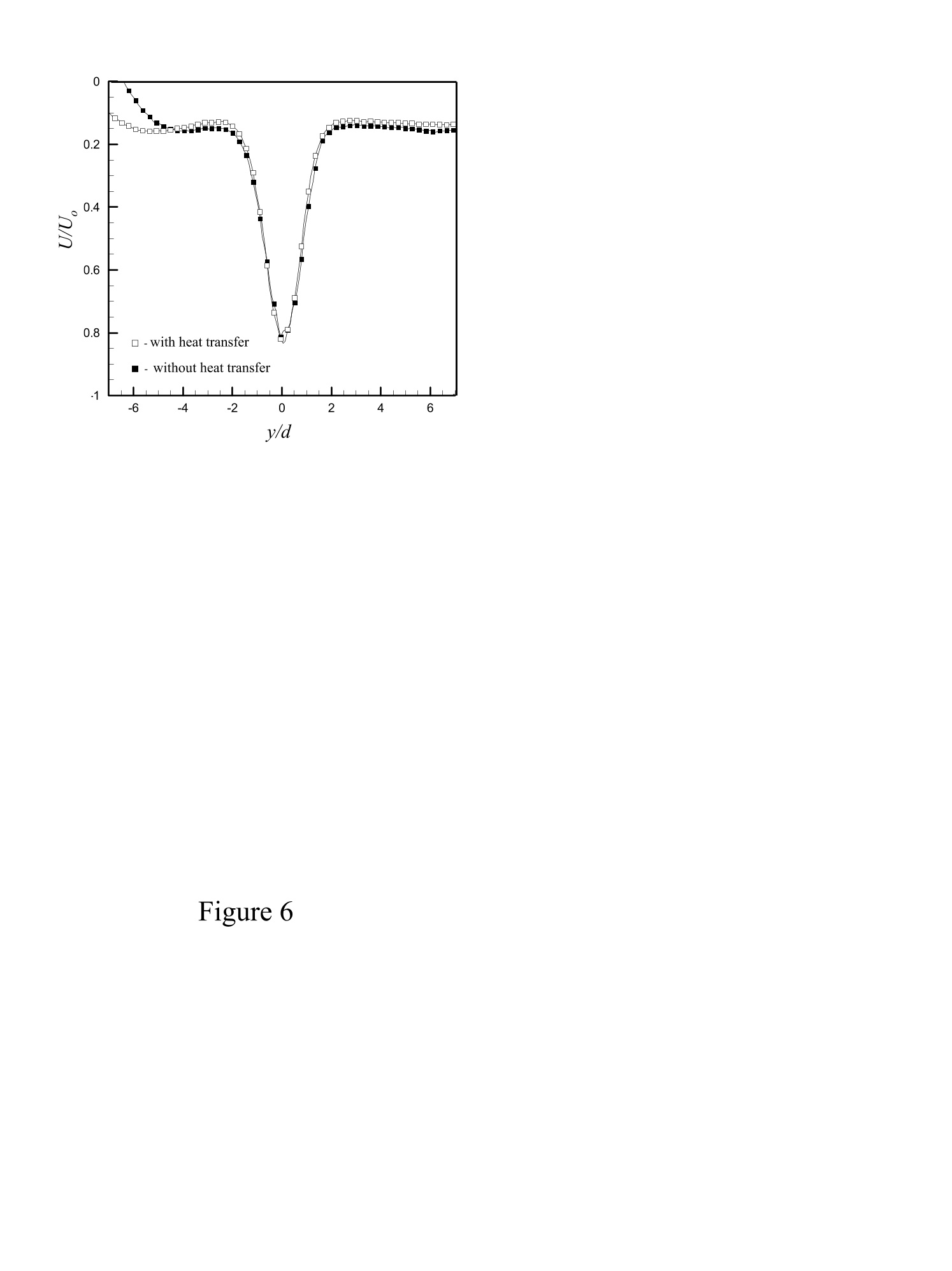

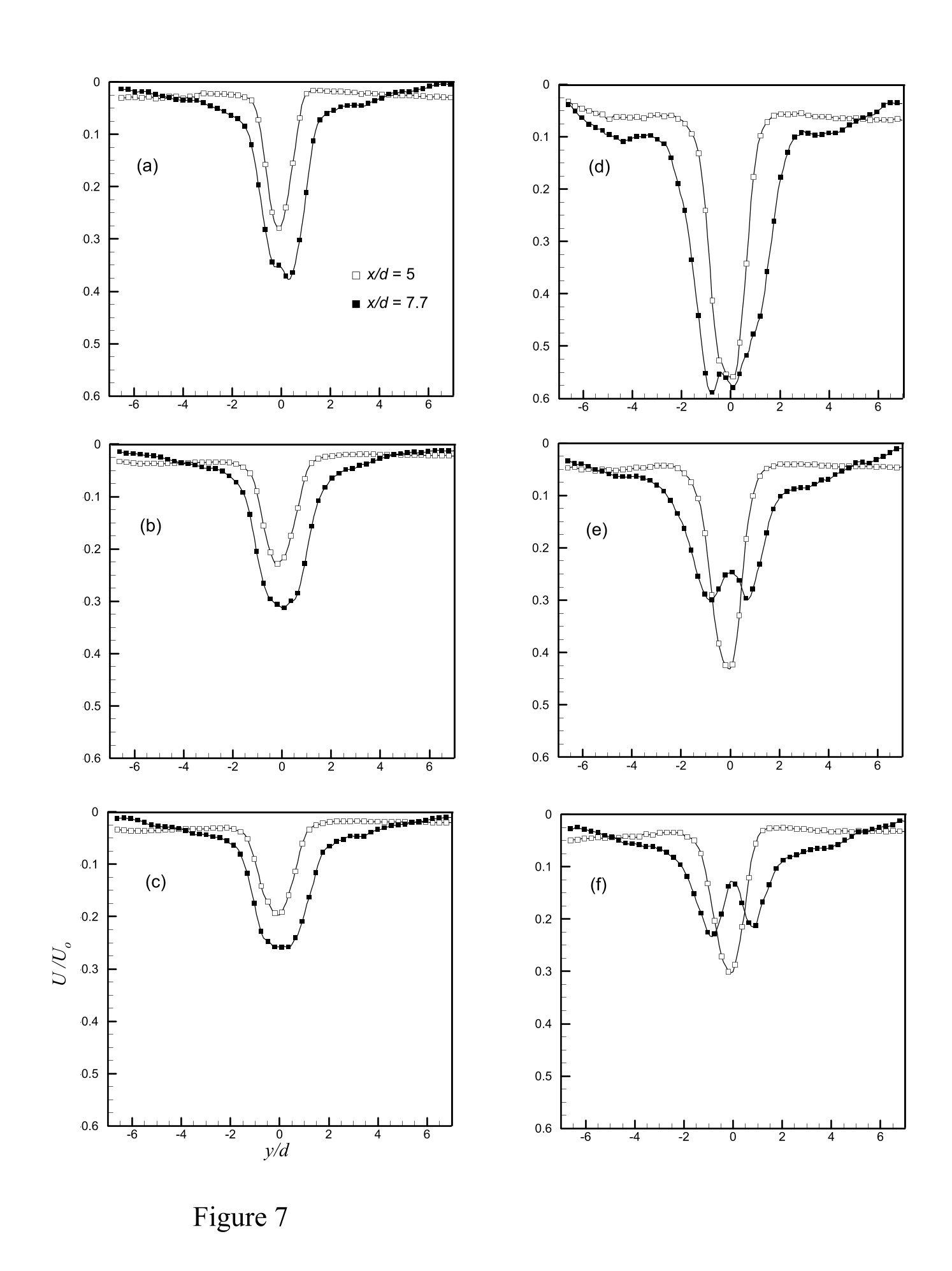

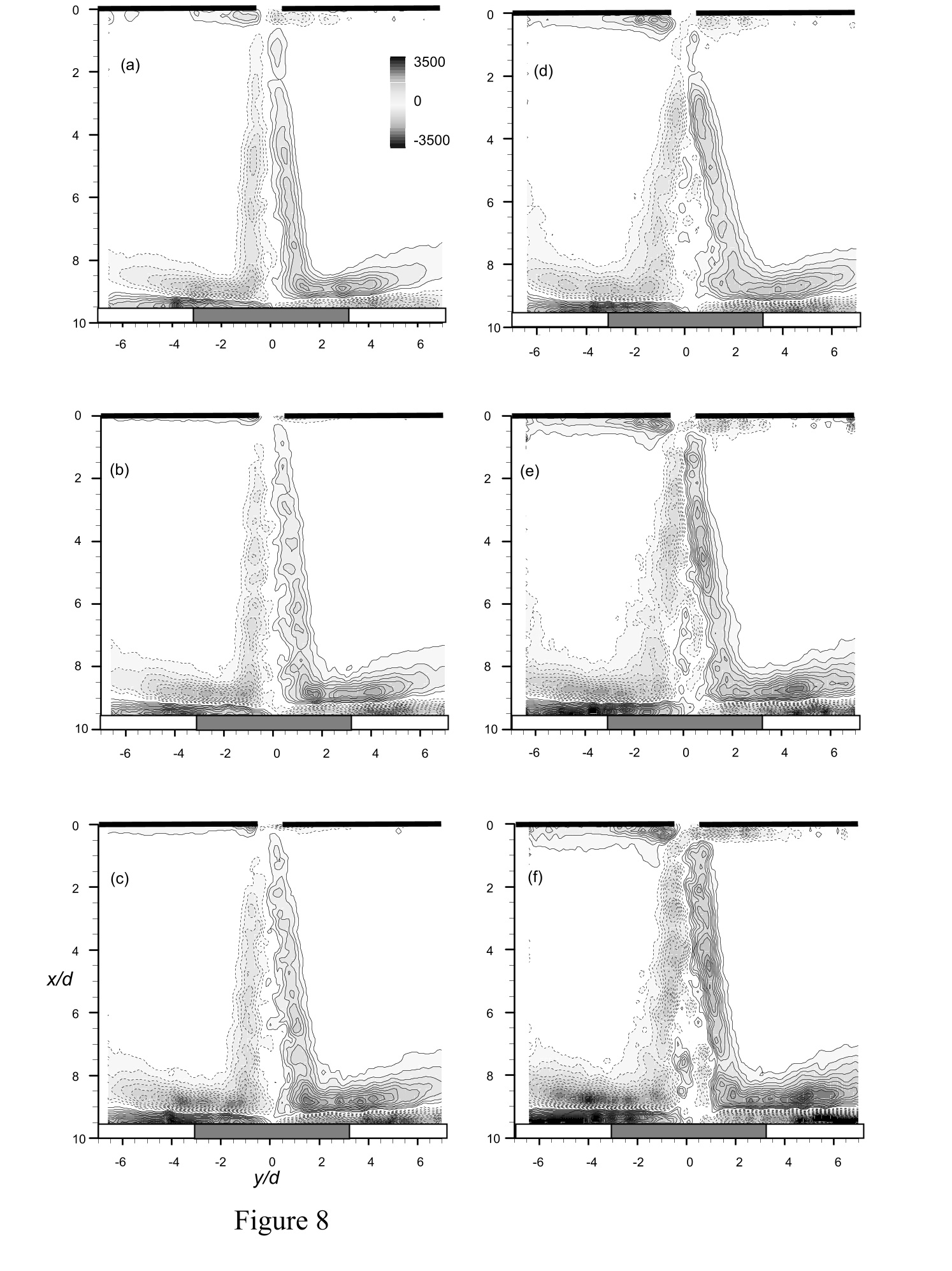

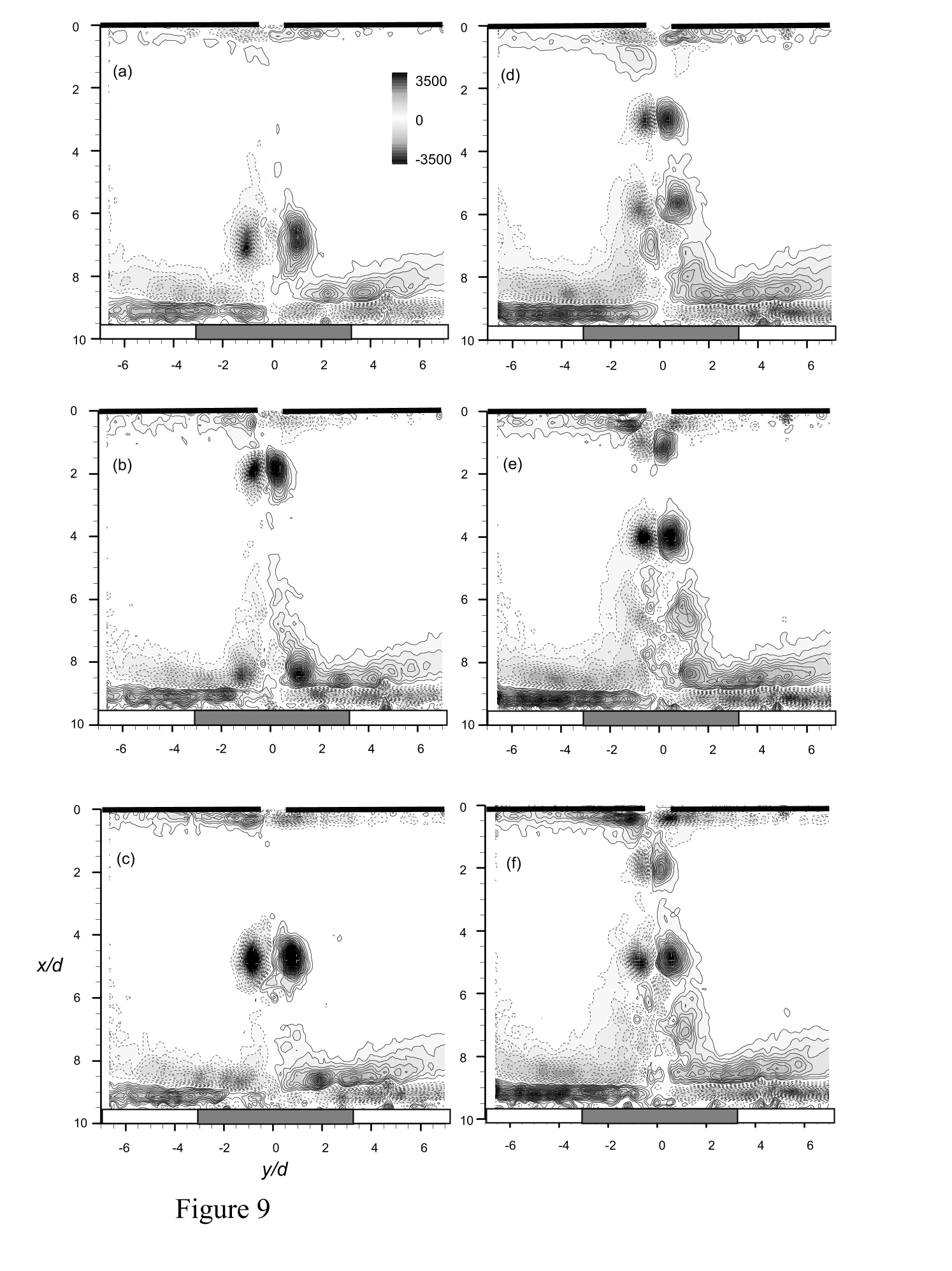

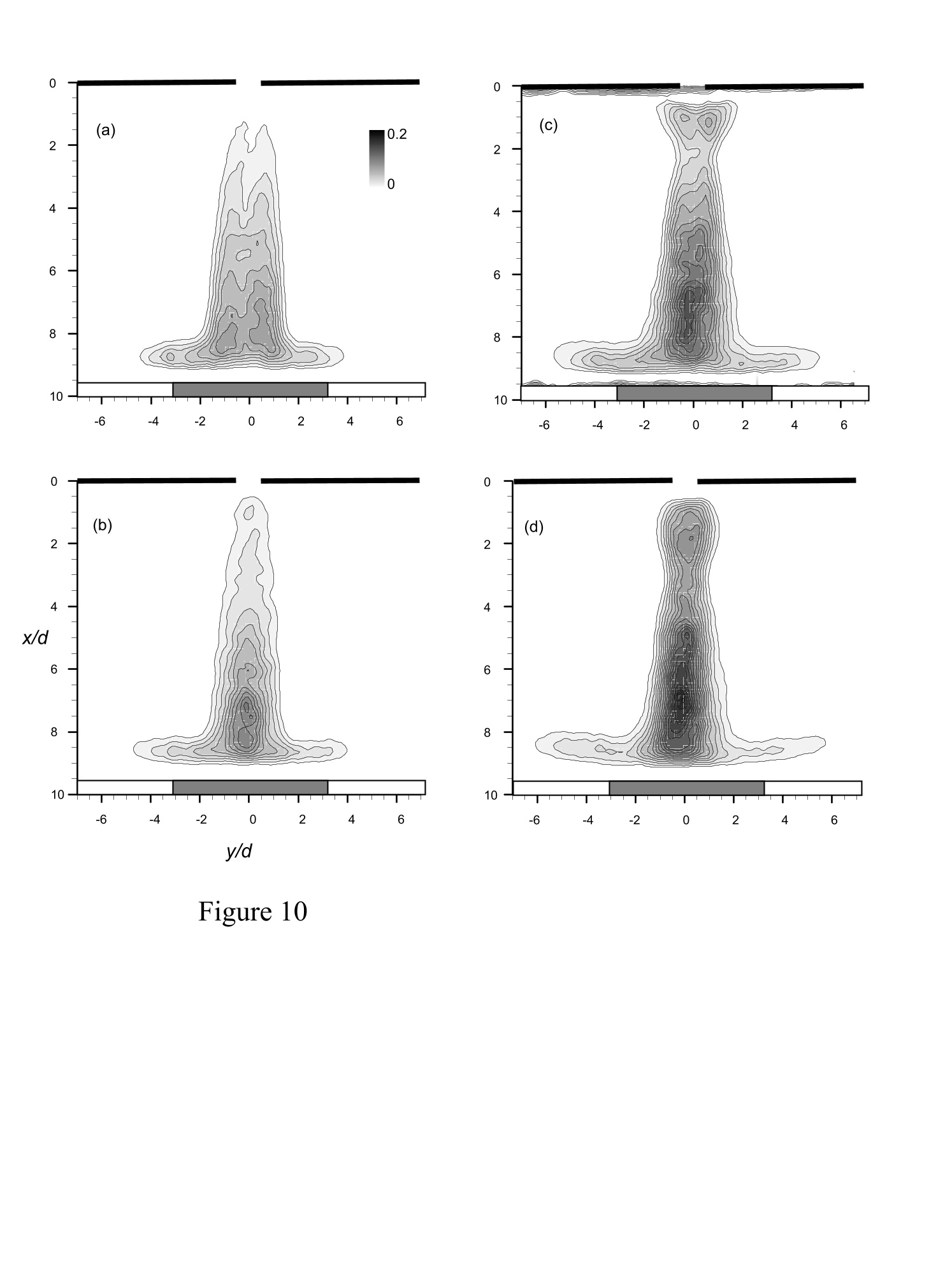

Figure 9 Electronic Cooling Using Synthetic Jet Impingement Anna Pavlova and Michael Amitay Mechanical, Aerospace and Nuclear Engineering Department Rensselaer Polytechnic Institute Troy, NY 12180 ( ' Corresponding Author, e-mail address: amitam@rpi.edu ) ABSTRACT The efficiency and mechanisms of cooling a constant heat flux surface by impingingsynthetic jets were investigated experimentally and compared to cooling with continuous jets.Effects of jet formation frequency and Reynolds number at different nozzle-to-surface distances(H/d) were investigated. High formation frequency (f= 1200 Hz) synthetic jets were found toremove heat better than low frequency (f=420 Hz) jets for small H/d, while low frequency jetsare more effective at larger H/d. Moreover,synthetic jets are about three times more effective incooling than continuous jets at the same Reynolds number. Using PIV, it was shown that thehigher formation frequency jets are associated with breakdown and merging of vortices beforethey impinge on the surface. For the lower frequency jets, the wavelength between coherentstructures is larger such that vortex rings impinge on the surface separately. KEYWORDS: synthetic jets, impingement cooling, coherent structures, operating frequencies,large-scale mixing. INTRODUCTION Current trends in electronic components show a continuously increasing need for efficientheat removal in closely packed systems, and this need is predicted to continue to grow in theforeseeable future [1]. The current method of heat removal,involving extended surfaces and fanarrays, frequently used in electronics is clearly insufficient, especiallyy aass tthe electroniccomponents become more and more powerful, dissipating more heat, whereas the space aroundthese components continues to be reduced due to miniaturization trends. On the other handimpinging jet cooling, which is the focus of the present paper, is much better at heat removalfrom electronic components. A large number of investigations have been carried out in the area of jet impingement heattransfer over the years. Most of the earlier works have focused on optimizing the transportprocesses associated with continuous impinging jets. In that context, parameters such as thespacing between the jet outlet and the impingement surface, the magnitude of the jet velocities(i.e., Reynolds number), turbulence intensity, and the angle of impingement have beenextensively studied. Much of this early research is summarized by Martin [2]. Some researchers have looked into potentially enhancing jet impingement heat transfer byexciting coherent structures in the jet flow. In 1961, Nevins and Ball [3] were among the firstwho looked into pulsed air jet impingement.TThey investigated spatially and temporallyaveraged heat transfer for an impinging pulsating circular air jet with nozzle-to-plate distance of8 to 32 nozzle diameters,Reynolds numbers ranging between 1,200 and 120,000 and Strouhal numbers ranging between 10 and 10and concluded that no heat transfer enhancement resultedfrom the pulsations in the flow. More than two decades later, the issue of flow excitation withpulses was revisited. In 1987, Kataoka and Suguro [4] used a statistical technique withconditional sampling and found that secondary flow structures help enhance heat transfer fromthe surface, showing that the stagnation point heat transfer for axisymmetric submerged jets isenhanced by large-scale structures that impinge on surface.;.In 1993, Eibeck et al. [5] usedexperiments and computations to identify secondary flow structures that were enhanced bypulsations introduced into the flow and found heat transfer enhancement in excess of 100%.attributing this to the intermittent vortex rings impinging on the surface. Heat transfeenhancement nearly by a factor of two due to pulsed impinging jets was also documented byZumbrunnen and Aziz [6], who used water as their working fluid. In 1999, Sailor et al. [7] used a square waveform signal to excite the jet and focused on theeffect of the duty cycle (the ratio of pulse cycle on-time to total cycle time), in addition to thetraditionally investigated parameters, such as jet to plate spacing, Reynolds number, and pulsefrequency. They found the duty cycle to be a contributing factor to heat transfer enhancement inthat the lower duty cycle resulted in better heat transfer results, especially at intermediatefrequencies and high flow rates. Zulkifli et al. [8] carried out experiments to study the effect ofpulsation on local and average heat transfer characteristics of a heated air jet. They consideredexcitation frequencies of 10 to 80 Hz with corresponding Strouhal numbers of 0.008 to 0.123, forReynolds numbers between 16,000 and 32,000 at a fixed nozzle-to-plate distance and a dutycycle of 33%.They found that for most pulsation frequencies heat transfer was enhanced,attributing this to increased turbulence intensity induced by the pulsations. In 2001, Hwangetal.[9] experimentally investigated the flowandd heattransfercharacteristics of an impinging jet, controlled by vortex pairing in pulsedjets. They showed thatdepending on how the flow is excited, heat transfer may be either hindered or improved. In asubsequent experimental study in 2003, Hwang and Cho [10] showed that the frequency andexcitation level of acoustically excited impinging jets are both important in heat transferenhancement. Recently, Chaniotis et al. [11] carried out a numerical investigation of pulsation on single anddual continuous slot impinging jets on a constant heat flux surface with a focus on the influenceof frequency, amplitude, and phase difference between the jets and comparing dual jets to anequivalent mass flux single continuous jet.t. TThey concluded that the strong aerodynamic andthermal interaction exhibits a non-linear system response, with an intermittency of structures thatis responsible for heat transfer enhancement. Haneda et al. [12] considered the effects of a small cylinder suspended in the jet stream onthe cooling efficiency of a two-dimensional impinging jet. They found that the insertion of arigidly suspended cylinder degrades heat transfer around the stagnation region, while enhancingheat transfer outside that region, which is due to vortex shedding from the cylinder..Heattransfer from the entire surface was enhanced when the cylinder was mounted with springs,allowing it to oscillate. Camci and Herr [13] conducted an experimental investigation of a self-oscillating impinging jet. They showed that the flapping motion of the jet enhances the heat transfer from the surface as well as the area covered by the impingement zone, compared to astationary impingement jet.These works indicate that there is potentially a great benefit inintroducing coherent structures into the flow field by applying controlled excitation to impingingjets for heat transfer enhancement. However, jet impingement cooling requires rathercomplicated plumbing, which is not always convenient. Recently, synthetic jets have been investigated for electronic component cooling, becausesynthetic jets require no plumbing associated with traditional continuous jets, as they useambient air, and, when properly designed, can be much more efficient. For example, in 2001,Vukasinovic and Glezer [14] investigated experimentally the performance of a low-profile radialcountercurrent heat sink, driven by a synthetic jet actuator at 80 Hz normally impinging on anextended surface with a power dissipation of 50 W. Flow measurements using Particle ImageVelocimetry (PIV) and temperature measurements on a test die were carried out at severaldistances between the synthetic jet and the test die.The findings of their study show thatsynthetic jets may present a viable option for the cooling of electronics where space and volumeare limited. In 2003, Kercher et al. [15] demonstrated the potential use of a synthetic microjet inconjunction with a fan, impinging on a heated surface for thermal management of electronics.More recently, Mahalingam et al. [16] also investigated synthetic jets for thermal management,using a two-dimensional synthetic jet to drive air through a rectangular channel and illustratingits potential usefulness. The motivation of the present work is to further explore the efficiency of synthetic jetimpingement cooling and understand the mechanisms by which heat is removed from a constant heat flux surface.The effects of jet formation frequency and Reynolds number at differentnozzle-to-surface distancesare investigated and compared to continuous jet impingementcooling.. The heat transfer characteristics and flow structures are explored experimentally usingthermocouples and PIV, respectively, to gain an understanding of the underlying physics of flowand heat transfer interactions in surface cooling with impinging synthetic jets. Ⅱ. EXPERIMENTAL SETUP The experiments were conducted in a special facility that was designed to house differentconfigurations of synthetic jets impinging on a heated surface within an enclosure having clearwalls and ceiling panels, such that both heat transfer and fluid dynamics measurements could beperformed in the same enclosure (Figure 1a). The enclosure features a 275 mm x 335 mm x335mm volume mounted on an optical table, facilitating precise mounting of associated opticalhardware. A cooling module was designed, which is comprised of a heated surface and syntheticjet (Figure 1b), mounted such that the jet orifice to surface distance can be controlled easilyusing a fine pitch traversing mechanism.The heater was constructed from oxygen-free copperdisk (12.7 mm in diameter and 6 mm in thickness), which was heated by a round, flexible,commercially available kapton heater attached underneath.The copper heater was centrallymounted into a block of nylon insulation (150 x 150 x 55 mm) to minimize heat losses throughthe sides and bottom. In the present experiments the heat flux generated by the heater was ~1W/cm2. Heat losses through the sides and the bottom of the insulation were estimated assuming thecopper heater is a disk at the surface of a semi-infinite insulation solid at T. [17]. The surfacetemperature of the heater was found experimentally by insulating its top. In this manner, thelosses through the sides and the bottom were found to be 20% of the power input. Because oflow temperatures involved in this experiment, heat loss from the surface due to radiation transferwas neglected, as it was calculated to be less than 3% of the power input for all cases, which iswithin the resolution of the measurements.;. The heater surface provides a constant heat flux, asthe driving power input is constant,and the flexible heater is specifically designed to provide aconstant heat flux output.. The Biot number for the copper disk in the thickness direction wascalculated and found to be at most O(103), which indicates that the conduction from the bottomsurface, where the power is introduced, to the top surface happens on a much faster time scalethan the convection from the surface. The surface temperature was measured with a T-type thermocouple, 0.127 mm in diameterthat was placed at the center of the copper disk just below the surface, 0.8 mm from the topsurface, thus providing a spatially averaged heat transfer measurement over the exposed surfaceof the copper heater. An identical thermocouple was stationed inside the enclosure away fromthe heated surface for ambient air temperature monitoring. The thermocouples were calibratedwith respect to one another at room temperature prior to the experiments. The control of the heatflux provided by the heater and the temperature data acquisition were carried out usingLabVIEW. The flow features associated with an isolated synthetic jet impinging on the surface wereinvestigated using highly resolved spatial and temporal measurements via PIV, complementedwith hot-wire anemometry.The facility was equipped with a computer-controlled traversingmechanism for the hot-wire anemometry and the PIV system. In this setup, the PIV systemallows full-resolution measurements within domains that are as small as 10 x 10 mm. The PIVsystem is based on the commercial LaVision hardware and software, which utilizes two 120 mJNd:YAG lasers and a 1376 x 1040 pixel resolution thermo-electrically cooled 12-bit CCDcamera.The flow within the enclosure was seeded using incense smoke particles that had adiameter of O(1 um). Four hundred image pairs were acquired for the time-averaged fields,while 200 image pairs were used to obtain the phase-averaged data. The streamwise and cross-stream velocity components (U, V) were computed from the cross-correlation of pairs ofsuccessive imageess wwith 50%o overlap between interrogation domains. The imageswereprocessed using an advanced multi-pass technique, where the initial and final correlation passeswere 32x32 pixels and 16x16 pixels (two passes), respectively. The resulting vector fields havea resolution of 0.2 mm. II.1 Impinging Synthetic Jets A synthetic jet is a jet that is synthesized at the edge of an orifice by a periodic motion of adiaphragm mounted on one (or more) walls of a sealed cavity. In the data presented here, thesynthetic jet was driven by a single commercially available 32 mm diameter piezo-electric diskhaving the nominal resonant frequency of 1000 Hz, with a 2 mm circular orifice (Figure 1b).When the diaphragm moves toward the orifice, a vortex ring is formed at the edge of the orifice,and it moves away with its own self-induced velocity such that when the diaphragm moves away from the orifice, the vortex ring is far enough away and is not affected by the fluid drawn into thecavity.. 'Therefore, a synthetic jet has a zero-net-mass-flux per cycle of actuation but allowsmomentum transfer to the flow. With proper design, the diaphragm and the cavity are driven atresonance; thus, only small electrical power input is needed, making the synthetic jet a veryefficient and attractive actuator for flow and heat transfer control applications. Anotheradvantage of the synthetic jet is that no plumbing or mechanical complexities are needed. In the setup of the present experiments two operating frequencies, 420 and 1200 Hz, were themost effective in cooling (at the same Reynolds number) in terms of heat removal improvement.Hence, the data associated with synthetic jet cooling at these two operating frequencies arepresented and discussed. The parameters of the jet that were varied in the experiments include14018,the performance degrades, as it does for normalized distances below 6. At a higher operatingfrequency (f=1200 Hz), the enhancement in Nus is up to 113%, where the best coolingperformance is obtained for H/d in the range of 3 to 11. COutside of this range, the coolingeffectiveness decreases. The data show that the H/d range corresponding to better cooling at thehigher frequency of synthetic jet is closer to the surface, compared to the lower frequency jet.This will be discussed in more details in Section III.2. The effect of the operating frequency of the synthetic jet on the cooling effectiveness isfurther demonstrated in Figure 3 for f=420 Hz and 1200 Hz, both at the Reynolds number of445 and is compared to the performance of a continuous jet at the same Reynolds number(represented by the dashed line). Note that the matching of the synthetic jet and the continuousjet was done based on the work of Smith and Swift [20] where the synthetic jet’s orifice velocity,U, is the same as the averaged velocity of the continuous jet at the jet exit plane, U. Thisfigure shows that both high and low frequency synthetic jets cool the surface better than thecorresponding continuous jet over the range of H/d tested (for example, at H/d=4.75 thesynthetic jet operated at 1200 Hz improved the heat transfer by a factor of 2.6, compared to thecontinuous jet). That, in itself, is very significant, as it illustrates that synthetic jets provide animpressive heat removal improvement over continuous jets, in addition to the advantages of not requiring additional plumbing, as well as low energy consumption. This can be attributed to twomajor mechanisms:(1) as was shown by Smith and Swift [20], for the same Reynolds numbersynthetic jets are wider, slower, and have more momentum than similar continuous jets (due toenhanced entrainment), thus more heat is removed and (2) synthetic jets consist of a train ofvortex rings (as will be shown is Section III.2), which further enhance the heat removal,compared to continuous jets. Figure 3 also shows the difference in trend of cooling performancebetween synthetic jets of high and low formation frequency at different distances.S.The highfrequency synthetic jet removes heat better than the low frequency jet for smaller distances,whereas the low frequency jet is more effective at larger distances up to H/d~ 28, with the twohaving the same performance for H/d of 12.5 to ~16. This behavior is related to the wavelengthof the coherent structures associated with the synthetic jets, which is discussed in detail in thefollowing section. Note that similar behavior was obtained for different jet Reynolds numbers. The efficiency of synthetic jet cooling for the matching Reynolds number jets at 420 Hz and1200 Hz as a function of H/d is presented in Figure 4. The efficiency is defined as the ratio ofthe heat removed (compared to free convection), AP, to the input power to the synthetic jet, Pj.For a Reynolds number of 445 the 420 Hz synthetic jet the efficiency is up to 1000%, and isfairly consistent for H/d of 6 to 18, while the 1200 Hz synthetic jet reaches an efficiency of morethan 1300% at H/d=4.75, which is very impressive. Here, we see the same trend as Figure 3,illustrating that Nusselt number enhancement is closely tied to synthetic jet efficiency. The highefficiency is attributed to the fact that the synthetic jets are designed to operate near resonanceconditions (i.e., where the piezo disk frequency and the Helmholtz frequency of the cavity arematched); thus, very small electrical power is needed. I.2 Flow Measurements In order to understand the mechanisms associated with synthetic jet impingement cooling andto explore the effect of the operating frequency on the cooling effectiveness, the flow field of thesynthetic jet above the surface was investigated using PIV. As a first step, the synthetic jets werecalibrated using single hot-wire anemometry, with which the centerline velocity was measured atthe exit plane of the jet (i.e., the center of the orifice). Since the hot-wire probe is based on aWheatstone bridge, it infers the velocity from temperature measurements and provides only themagnitude, but not the direction of the air flow. Therefore, the resulting signal is rectified, withthe sense of velocity always positive (the dashed line in Figure 5). This is not representative ofthe true velocity profile in the orifice of a synthetic jet, which roughly corresponds to asinusoidal signal, where the air is periodically expelled out of the orifice and drawn into thecavity. .Thus, the signal must be derectified, where the peaks corresponding to suction areessentially flipped over, as represented by the solid line in Figure 5. The velocity and vorticity plots presented in the following figures were acquired without thepresence of heat transfer (i.e., the heater was turned off).).The assumption was that at theconditions used in the present work the effect of buoyancy, due to the heated surface, does notsignificantly affect velocity. In order to validate this assumption, the velocity vector fields,without and with heat transfer, were measured and compared. Figure 6 presents the cross-streamdistribution of the normalized streamwise velocity, U/U,, at x/d=7.7 for f= 1200 Hz at H/d= 9.5 and a Reynolds number of 190, which corresponds to a synthetic jet weaker than any jets that are presented in this paper. It can be observed that the velocity distributions are almost identical,thus validating our assumption. Furthermore, the Gr/ Re2 for this case was also calculated andfound to be 1.4x10°, suggesting that the buoyancy effect is negligible, which is consistent withthe velocity profiles shown in Figure 6. Note that since the streamwise velocity distribution (andthe cross-stream velocity, not shown) at this low Reynolds number is not altered by the heattransfer, the rest of the velocity data presented in this paper, where stronger jets are used at thesame power supplied to the heater, are also not affected. First, normalized time-averaged streamwise velocity component distributions, UjU,, of theimpinging synthetic jet are presented in Figure 7. These are shown at two streamwise locationsof x/d=5 and 7.7 in Figures 7a-c and d-f for jet operating frequencies of 420 Hz and 1200 Hz,respectively, where the distance between the jet and the surface is H/d = 9.5. For eachfrequency, measurements at three Reynolds numbers were taken (Rer==322,445, and, 598 forthe 420 Hz jet, Figures 7a, b and c, respectively, and Re=236, 445, and 740, for the 1200 Hzjet, Figures 7d, e and f, respectively). At the operating frequency of 420 Hz the velocity profilesexhibit a single peak distribution for all Reynolds numbers at both locations (Figures 7a-c). Asx/d increases, the jet widens and the peak velocity increases. Moreover, the normalizedmaximum velocity decreases and the jet’s width increases with increasing Reynolds number.This may be due to enhanced mixing at higher Reynolds numbers. The cross-stream distributions of the streamwise velocity component for the higher operatingfrequency jet (f= 1200 Hz, Figures 7d-f) exhibit a single peak distribution at x/d=5 for all three Reynolds numbers. However, farther downstream at x/d= 7.7, as the jet is approaching thesurface, there is a double peak distribution due to breakdown and merging of vortices, as will bediscussed in conjunction with Figures 8 and 9. The effect of the operating frequency on the flow field near the impingement surface can beassessed by comparing Figures 7b and 7e, where the Reynolds number is the same (Rey=445)for f= 420 and 1200 Hz, respectively. Here, different flow fields result in a similar enhancementof the stagnation Nusselt number. This will be discussed in detail with respect to Figure 9.Interestingly, even where the Reynolds number is different (Reu = 322 at f= 420 Hz, Figure 7aand Rer =236 at f= 1200 Hz, Figure 7d), the stagnation Nusselt number is the same in spite ofthe markedly different velocity distributions near the surface. The behavior of the flow and thecorresponding cooling effectiveness of the synthetic jet at the two frequencies are intimatelyrelated and will be discussed at length later. In order to further explore the flow characteristics of the impinging synthetic jet, meanvorticity fields were calculated from the velocity fields and are presented in Figures 8a-f. Notethat negative vorticity contours are represented by dashed lines. The difference between the twofrequencies is apparent in these figures. For the f= 420 Hz jet (Figures 8a-c), there are tworegions of vorticity, positive on the right and negative on the left.These concentrationscorrespond to the shear layer of the vortex rings that are advected downstream and impinge onthe surface of the heater. For the higher frequency jet (Figures 8d-f), the vorticity maps showthat the vortex rings break up and form secondary structures before they hit the surface. This occurs at x/d= 4 for the weakest jet at 1200 Hz (Figure 8d) and is delayed until fartherdownstream for the higher Reynolds number jets (8e and f). However, the smaller structures thatresult from the breakup of vortex rings are clearly visible in all three cases. The vortex ringbreakup and formation of secondary structures are responsible for the decrease in the streamwisevelocity at the center of the flow, which was observed in Figures 7d-f at x/d= 7.7. Clearly, theheat removal mechanisms are different for the two frequencies. When the synthetic jet is drivenat the low operating frequency, the vortex rings impinge on the surface individually; thus, theselarge-scale coherent structures are responsible for the enhanced heat removal (compared tocontinuous jet). At the high operating frequency, the vortex rings merge and break into smallersecondary structures before reaching the surface;hence the heat removal is enhanced by mixingof smaller scale structures. To further explore the flow field of the impinging synthetic jets and the formation of thecoherent structures at both operating frequencies, phase-locked velocity fields were measured.The phase-locked spanwise vorticity contour maps of the jet for H/d=9.5 are presented inFigures 9a-c and 9d-f (for f= 420 Hz and 1200 Hz, respectively, at three phases along theactuation cycle). Both jets have the same Reynolds number of 445, which, at this H/d, results ina similar heat transfer enhancement of ~70% (Figure 3). For the 420 Hz synthetic jet, at the beginning of the blowing portion of the cycle (=0°,Figure 9a) a vortex ring is starting to emerge from the orifice, while the vortex ring from theprevious cycle is located at x/d=7.2. Also, vortex rings formed in preceding cycles that alreadyimpinged on the surface and broke into smaller vortices are clearly visible.As the cycle continues (= 120° and 240°, Figures 9b and c, respectively), the vortex ring, formed at the edgeof the orifice, moves downstream toward the impingement surface, such that near the end of theblowing cycle (d=120°, Figure 9b) the vortex ring is at x/d=2. During this time, the previousvortex ring impinges on the surface and breaks up into smaller vortex rings that roll outwardalong the surface into the wall jet region. The phase-locked vorticity field at the higher formation frequency, (f= 1200 Hz, Figures 9d-f) exhibits a notably different behavior. Here, the vortex ring that is formed at the edge of theorifice moves downstream (Figures 9d and e), and it is located at x/d= 1.1 at b=120°(Figure9b). Note that the vortex ring for the lower frequency jet is located at x/d= 2 at 0=120° (Figure9b) due to the larger wavelength. Furthermore, while at the lower formation frequency thevortex rings impact the surface individually, at the higher formation frequency vortex ringsmerge and break into smaller vortical structures with opposite sense before they impinge on thesurface. The different formation and advection of the coherent structures shown in Figure 9 canexplain the effect of the formation frequency on the synthetic jet cooling at other Hld, asillustrated in Figure 3 above. When the high frequency jet is used, it is more effective at smallH/d because of accumulation of vortices that impact the surface as they gain strength and breakinto smaller structures.. At large H/d the vortex rings merge, lose their coherence, and breakdown into a quasi-steady jet (see Smith and Glezer [18]), thus the additional heat removalcapabilities due to the enhanced mixing by the coherent structures are reduced. The low frequency jet is more effective at large H/d, due to the larger wavelength that results in mergingof the vortices (similar to the high frequency jet at low Hid), while at low H/d, each vortex ringimpinges on the surface individually, which is not as effective. The mechanisms associated with the enhanced heat removal at the two operatingfrequencies were also examined by comparing the turbulent quantities. Figures 10a and b and10c and d show the three turbulent quantities at Reynolds number of 445, with operatingfrequencies of 420 Hz and 1200 Hz, respectively. The contour plots of the normalizedstreamwise normal stress, u U, at operating frequencies of 420 Hz and 1200 Hz and H/d=9.5 are presented in Figures 10a and c, respectively. At the low operating frequency (f= 420 Hz,Figure 10a) there is high concentration of uU along two cross-stream regions (one on eachside of the centerline at y/d=±1), corresponding to the shear layers of the vortex ring, where thehighest concentration is slightly above the surface at x/d ~8.5. At the higher operating frequency (f= 1200 Hz, Figure 10c) there are two distinct peaksin the cross stream distribution only near the orifice (at x/d~1). Farther downstream, the doublepeak distribution becomes a single peak distribution due to the merging of vortex rings that breakinto smaller structures, as was shown in Figure 9. At this operating frequency, the higheststreamwise normal stress values are concentrated in a narrow region (at y/d=+0.5) right abovethe point of impingement, while at the 420 Hz case, the highest normal stresses are concentratedin two regions.. This, again, supports our previous conclusion that if the vortex rings do notmerge (as in the 420 Hz case), the heat removal is associated with large-scale mixing, while merging of vortex rings (which accelerates their breakdown into smaller less coherent vortices,as in the 1200 Hz case) results in a smaller-scale mixing.This can explain the similar heatremoval enhancement of the low and high frequency jets at this height (see Figure 3), as the 420Hz jet has lower streamwise mixing that covers a larger area of the heater, while the 1200 Hz jethas higher streamwise mixing that covers a smaller portion of the heater. Figures 10b and d show the normalized cross-stream normal stress, v/u, for the lowerand higher frequency jets, respectively. Figure 10b illustrates that there is no double peak in thedistribution of the cross-stream normal stress, where the highest values appear to be right abovethe impingement surface. The distribution of the cross-stream normal stress for a synthetic jetwith an operating frequency of 1200 Hz (Figure 10d) is a similar to that of the 420 Hz case.However, the highest magnitude of the normal stresses expands along a larger streamwise region(from x/d of about 4.5 to the impingement surface), and throughout the flow the magnitudes ofv/u,are larger for the higher frequency case. VI.CONCLUSIONS The efficiency of synthetic jet impingement cooling and the mechanisms associated with theremoval of heat from a constant heat flux surface were investigated experimentally usingthermocouples and Particle Image Velocimetry.V.The effects of jet formation frequency andReynolds number at different nozzle-to-surface distances were investigated and compared tocontinuous impingement jet cooling. In the experiments, the synthetic jet was operated at two separate frequencies, 420 Hz and1200 Hz, which were found to be the most effective (for the Reynolds number range used) interms of the heat removal improvement. The jet parameters that were varied in the experimentsinclude 140

确定

还剩37页未读,是否继续阅读?

北京欧兰科技发展有限公司为您提供《合成冲击射流,电子冷却机理中速度场检测方案(粒子图像测速)》,该方案主要用于其他中速度场检测,参考标准--,《合成冲击射流,电子冷却机理中速度场检测方案(粒子图像测速)》用到的仪器有德国LaVision PIV/PLIF粒子成像测速场仪、Imager sCMOS PIV相机

推荐专场

相关方案

更多

该厂商其他方案

更多