方案详情

文

The Letter describes the investigation of an industrial reaction of N-methylphenylpiperazine and chloro nicotinonitrile, under microwave heating. Besides the formation of the expected 2-(4-methyl-2-phenylpiperazinyl)pyridine-3-carbonitrile (4), extension of the scale leads to unexpected by-products. A specific pathway due to the formation of a reactive ‘ionic alkylating intermediate’ formed in situ under microwave conditions is proposed to explain the results observed.

方案详情

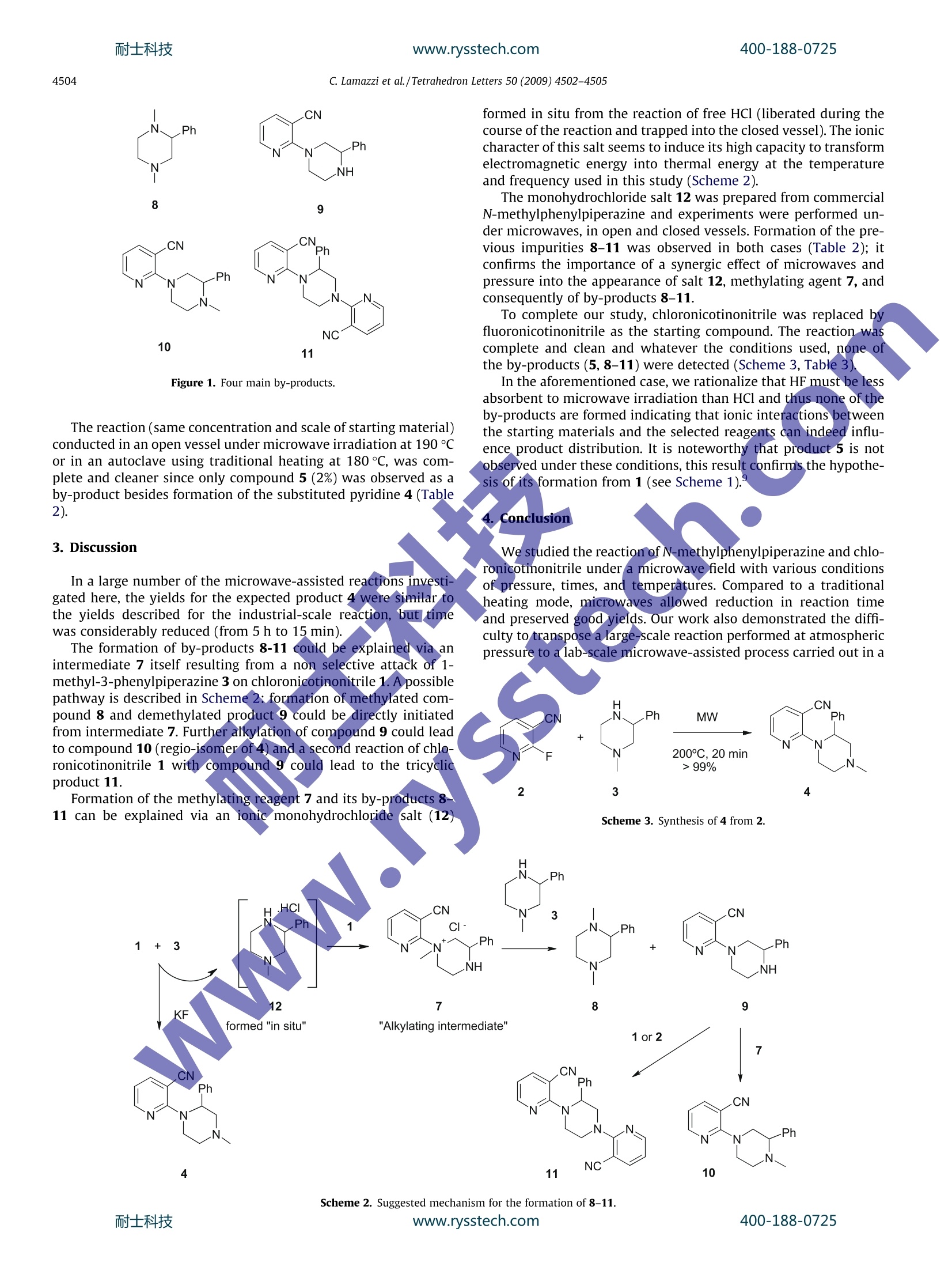

耐士科技400-188-0725www.rysstech.comTetrahedron Letters 50 (2009) 4502-4505 耐士科技400-188-0725www.rysstech.com4503 Contents lists available at ScienceDirect Tetrahedron Letters journalhomepage: www.elsevier.com/locate/tetlet Microwave-induced by-products in the synthesis of 2-(4-methyl-2-phenylpiperazinyl)pyridine-3-carbonitrile Christelle Lamazzia*, Armelle Dreau, Christel Bufferne, Christine Flouzat, Patrick Carlier,Rob ter Halle, Thierry Bessonb,* aDepartment of Development Chemistry, Centre de Developpement Preclinique, Schering-Plough, 22 rue Henri Goudier, 63203 Riom cedex 2, FranceUniversite de Rouen, UMR CNRS 6014-C.O.B.R.A.-IRCOF, UFR Medecine-Pharmacie, 22 boulevard Gambetta, F-76183 Rouen cedex 1, France ARTICLEINFO ABSTRACT Article history:Received 4 March 2009Revised 19 May 2009Accepted 20 May 2009Available online 25 May 2009 Keywords:Microwave irradiationPiperazinoazepine derivativesPiperazines 1. Introduction The use of adapted reactants and techniques offering opera-tional, economic, and environmental benefits over conventionalmethods, is becoming crucial in the preparation and developmentof biologically active molecules. Microwave irradiation has gainedpopularity throughout both industry and academia since it wasfound to be an effective heating source applicable to a wide rangeof reactions.2The main benefits of microwaves are significant rateenhancements, higher product yields, and easier handling of reac-tion mixtures. The release of dedicated instruments for organicsynthesis in the market has allowed a rapid development of micro-wave-assisted organic synthesis. Experiments can be carried out inmonomode or multimode devices using different techniques suchas open or sealed conditions, solyent-less procedures or solventconditions. Our research project consisted of developing an easy access topiperazinoazepines with pharmaceutical interest and we wereparticularly interested in finding a rapid preparation method of2-(4-methyl-2-phenylpiperazinyl)pyridine-3-carbonitrile 4. Tradi-tional synthetic methods allowing access to this scaffold involvea preliminary N-alkylation of the piperazine scaffold and a subse-quent cyclization into the corresponding pyrido-azepine. Thisspecific alkylation is a key step in the preparation of the antide- ( * C orresponding authors. T e l.: + 33 4 73 33 3 9 1 6 ; f a x: +33 4 7 3 33 39 34 (C . L.),tel .: +33 2 35 14 83 99; fax: + 33 2 35 14 84 23 (T.B.). ) ( E-mail a ddresses: c hri s telle.lamazzi@spco r p.c o m (C . Lam a zzi), th i erry.bess o n@ u niv-rouen. f r (T. B esson). ) pressant mirtazapine. This reaction is generally performed withbases, transition metal-catalyzed processes, phase transfer cata-lysts or solid phase synthesis. Long reaction times and high tem-peratures are often required. In the current industrial context, weneed to manage well-established procedures and methodologies,with environmental and safe benefits over conventional methods.Improving chemistry in a ‘green approach’ suggests exploringmicrowave heating. The aim of our work was to reinvestigate un-der microwaves an industrial reaction in order to identify whatthe advantages of these novel conditions are over classical condi-tions, with expectation for further developments. This down-scal-ing approach is not common and the main work published in theliterature consists in transferring traditional lab-scale reactionsinto microwave reactors or domestic ovens. This Letter describesour work and the surprising results obtained. 2. Results The reaction investigated was the synthesis of 2-(4-methyl-2-phenylpiperazinyl)pyridine-3-carbonitrile 4 via condensation ofchloronicotinonitrile 1 and 1-methyl-3-phenylpiperazine 3 indimethylformamide (DMF) in the presence of potassium fluoride.This reaction has been previously optimized and is performed onindustrial scale. Using traditional heating, the reaction is com-pleted after 5 h in refluxing DMF in an isolated yield of 73%. It pro-ceeds via an intermediate 2-fluoronicotinonitrile 2 (Scheme 1).7.8During the process, reaction of water with compound 1(the pres-ence of water being brought by moist KF) and further condensation ( 0040-4039/$ - s ee front ma t ter C 200 9 Else v ier Ltd. All rights reserved. doi:10.101 6 /j.tetlet.2009.05.068 ) C. Lamazzi et al./Tetrahedron Letters 50 (2009) 4502-4505 of the hydrolyzed intermediate on nicotinonitrile derivative 1leadto low quantities of a by-product characterized as 1-(2-cyanophenyl)-2-oxohydropyridine-3-carbonitrile (5 in Scheme i1)9.10 In the case studied, apart from some general microwave-as-sisted N-alkylations,only one method of preparation ofmono-N-substituted piperazines combining solid phases synthesis andmicrowave heating has been reported.12The preparation of N-aryl-piperazinones has also been described via microwave-enhancedGoldberg reactions. Initial microwave experiments were performedat 150°C inDMF on 1 mmol scale on a monomode system and a control oftemperature by infraredpyrometer. After optimization, the reac-tion reached completion after1 h of irradiation and the desiredproduct 4 was isolated in 78% yield. As expected, an enhancementin the reaction rate andl aasshorter reaction time were observed.Experiments carried out in the presence of DMF at higher temper-atures (>150℃) were not successful. Another by-productt wasdetected and identified as the 2-(N,N-dimethylamine)-3-pyridine-carbonitrile 6.° Formation of this product probably results fromreaction of 1 (or 2) with dimethylamine generated bymicro-wave-accelerated thermal degradation of DMF intothe mixture(Scheme 1). This phenomenon was recently reported for reactantslike DMSO,14 formamide,15 and DMF which has been yet utilized asa liquid source of carbon monoxide and dimethylamine in micro-wave-accelerated aminocarbonylations of aryl halides. Investigation of microwave-assisted synthesis of 4 from chloronicotinonitrile 19.18 S.M. Microwave reaction conditions Product 4° (%) 1+3 NMP,150°C,30 min 73 1+3 NMP.180°℃, 30 min 88 1+3 NMP, 200°C, 15 min 99 S.M.: starting material. Performed on 1 mmol scale on monomode system (300W), under sealed vials.Product conversion (%) based on the GC and GC/MS analysis after work-up. N-Methylpyrrolidone (NMP), another polar aprotic solvent, isnow a common replacement for DMF in pharmaceutical industry.It allows working at 200°C and is known for its efficiency to trans-form electromagnetic energy into thermal energy.Investigatingvarious parameters (time, temperature, and power input) weobserved that the reaction time decreased by increasing the tem-perature (200C). Under these conditions, completion of the reac-tion was possible within 15 min,as indicated in Table 1. Large-scale experiments (15 mmol scale) were carried out insealed vials in a multimode microwave device.18 Various tempera-tures (180, 190, and 200℃) were attempted and the results com-pared with data obtained in the previous monomode trials. Besidesformation of the expected compound 4, and the usual carbonitrile5, four novel by-products 8-11° were detected in all cases (Table 2and Fig. 1). Table 2 Extension of the scale of microwave experiments starting from 1 and 1-methyl-3-phenylpiperazine 3 or salt derivative 12 S.M. Reactor Temperature and time Product 3h(%) Product 4(%) Side-products: 8,10,11(%) Side-products: 5/9(%) 1+3 Sealed 200°C, 15 min 2 37 5,10,16 8 1+3 Sealed 190℃, 15 min 4 51 3, 4,6 8 1+3 Sealed 180C, 15 min 3 50 2,3,4 7 1+3 Open 190℃, 15 min <1 84 2 (5 only) 1+3 Sealed 180C, 120 min 4 85 2(5 only) 1+12 Open 190°C, 15 min <1 64 1,<1,3 4 1+12 Sealed 200℃, 15 min <1 58 1,3,6 7 aPerformed on 15 mmol scale from 1+3 or 1+12 on multimode system. D% Based on the GC/MS analysis after work-up, residual of 1 and 2 not included, retention times of 5 and 9 were identical in GC analysis. Autoclave, use of traditional heating. Figure 1. Four main by-products. The reaction (same concentration and scale of starting material)conducted in an open vessel under microwave irradiation at 190℃or in an autoclave using traditional heating at 180℃, was com-plete and cleaner since only compound 5(2%) was observed as aby-product besides formation of the substituted pyridine 4 (Table2). formed in situ from the reaction of free HCl (liberated during thecourse of the reaction and trapped into the closed vessel). The ioniccharacter of this salt seems to induce its high capacity to transformelectromagnetic energy into thermal energy at the temperatureand frequency used in this study (Scheme 2). The monohydrochloride salt 12 was prepared from commercialN-methylphenylpiperazine and experiments were performed un-der microwaves, in open and closed vessels. Formation of the pre-vious impurities 8-11 was observed in both cases (Table 2); itconfirms the importance of a synergic effect of microwaves andpressure into the appearance of salt 12, methylating agent 7, andconsequently of by-products 8-11. To complete our study, chloronicotinonitrile was replaced byfluoronicotinonitrile as the starting compound. The reaction wascomplete and clean and whatever the conditions used, none ofthe by-products (5, 8-11) were detected (Scheme 3, Table 3) In the aforementioned case,we rationalize that HF must be lessabsorbent to microwave irradiation than HCl and thus none of theby-products are formed indicating that ionic interactions betweenthe starting materials and the selected reagents can indeed influ-ence product distribution. It is noteworthy that product 5 is notobserved under these conditions, this result confirms the hypothe-sis of its formation from 1 (see Scheme 1). 3. Discussion In a large number of the microwave-assisted reactions investi-gated here, the yields for the expected product 4 were similar tothe yields described for the industrial-scale reaction, but timewas considerably reduced (from 5 h to 15 min). The formation of by-products 8-11 could be explained via anintermediate 7 itself resulting from a non selective attack of 1-methyl-3-phenylpiperazine 3 on chloronicotinonitrile 1. Apossiblepathway is described in Scheme 2: formation of methylated com-pound 8 and demethylated product 9 could be directly initiatedfrom intermediate 7. Further alkylation of compound 9 could leadto compound 10 (regio-isomer of 4) and a second reaction of chlo-ronicotinonitrile 1 with compound 9icouldlead to the tricyclicproduct 11. Formation of the methylating reagent 7 and its by-products 8-11 can be explained via an ionic monohydrochloride salt (12) Conclusion We studied the reaction of N-methylphenylpiperazine and chlo-.........ronicotinonitrile under a microwave field with various conditionsof pressure, times, and temperatures. Compared to a traditionalheating mode, microwaves allowed reduction in reaction timeand preserved good yields.Our work also demonstrated the diffi-culty to transpose a large-scale reaction performed at atmosphericpressure to a lab-scale microwave-assisted process carried out in a Scheme 3. Synthesis of 4 from 2. Scheme 2. Suggested mechanism for the formation of 8-11.www.rysstech.com Microwave experiments starting from 2-fluoro-3-pyridinecarbonitrile2 and 1-methyl-3-phenylpiperazine 318 S.M. Reactor Reaction conditions 4(%) 2+3 Sealed 200℃(MW), 20 min >99 2+3 Sealed 200°C (MW), 20 min >99 2+3 Sealed 190℃, 20 min >99 a Performed on 6 mmol scale. Product conversion (%) and selectivity based on the GC and GC/MS analysis afterwork-up.Performed on monomode system.Performed on multimode system.Preheated oil bath, preheating time not included: 30 min. sealed vessel. The presence of unexpected by-products was specif-ically observed under these microwave conditions and not in usualthermal processes. In contrast, working under microwaves atatmospheric pressure gave very satisfactory results and data col-lected in this study show the real interest to use microwave forenhancing processes. In our case, the use of microwaves suggeststhe existence of ‘ionic alkylating intermediates’ which have animportant role in the mechanism of the reaction and therefore,intoformation of by-products. Acknowledgments We wish to thank Dr F. Kaspersen (Schering Plough) for his ad-vice and helpful discussions, and I. Bourgeois, F. Ranoux-Julien, G.Martin for their contribution to the analytical data. T. Bessonthanks Milestone S.r.l. (Italy) for financial and technical support. Supplementary data Supplementary data associated with this article canbe found, inthe online version, at doi:10.1016/j.tetlet.2009.05.068. References and notes 1. For a recent book see: Microwaves in Organic Synthesis; Loupy, A., Ed.; Wiley-VCH Verlag Gmbh & Co. KGaA: Weinhein, 2006 2. FFor recent reviews see: (a) Lidstrom, P.. Tierney, J; Wathey, B.; Westmam, J.Tetrahedron 2001, 57,9225-9283; (b) BogdaI, D.; Penczek, P.; Pielichowski,J; Prociak, A. Adv. Polym. Sci. 2003, 163, 193-263;(c) Kappe, C. O. Angew. Chem.,Int. Ed. 2004, 43,6250-6284;(d) De la Hoz, A.; Diaz-Ortiz, A.; Moreno, A. Chem.Soc. Rev. 2005, 34,164-178. 3. C(omplete descriptions of all of these instruments were published. For CEM (a)Ferguson, J. D. Mol. Divers. 2003, 7, 281-286; For Milestone: (b) Favretto, L. Mol.Divers. 2003,7,287-291; For Biotage: (c)Schanche, J.-S. Mol. Divers. 2003, 7,293-300:. 4.(a) Handa, V. K. U.S. Patent 10,648,636,2003.; (b) Wieringa, J. H. Eur. Patent051357,2004.;(c) Houghton A. Eur. Patent 054872,2007. 5van der Burgh, W. J. U.S. Patent 38,60,606,1976.6Murty, M. S. R. Synth. Commun. 2003, 33,2483-2486. 7.DIetails for the conversion of chloropyridine to fluoropyridines are describedin the following references: (a) Chambers, R. D.; Parsons, M.; Sandford, G.;Skinner, C. J; Atherton, M. J.; Moilliet, J. S. J. Chem. Soc., Perkin Trans. 1 1999,7, 803-810; (b) Boudakian, M.; Olin, M. J. Heterocycl. Chem. 1967, 4, 381-384. 8.Briner, G. P.; Miller,J.; Liveris, M.; Lutz, P. G. J. Chem. Soc. 1954,1265. 9. MNicrowave-assisted procedures and selected data for 1-(2-cyanophenyl)-2-oxohydropyridine-3-carbonitrile 5, 2-(N,N-dimethylamine)-3-pyridinecarboni- trile 6 and compounds 8-11 are available as Supplementary data.10.Lavecchia, G.; Berteina-Raboin, S.; Guillaumet,G. Tetrahedron Lett. 2004, 45, 6633-6636. 11. Gawley, R. E. Tetrahedron Lett. 2004,45, 757-759. 12.Macleod, C. j. Comb. Chem. 2006,8,132-140. 13. LaInge,J. H. M. Tetrahedron Lett. 2002, 43, 1101-1104. 14.M1esangeau, C.; Yous,S.; Peres, B.; Lesieur, D.; Besson, T. Tetrahedron Lett. 2005,46,2465-2468. Nouira, I.; Kostakis, I. K.; Dubouilh, C.; Chosson, E.; Iannelli, M.; Besson, T.Tetrahedron Lett. 2008, 49,7033-7036. 16.Wan, Y.; Alterman, M.; Larhed, M.; Hallberg, A. J. Org. Chem. 2002,67,6232-6235. 17.(a) Moseley,J.D.; Lenden, P.; Lockwood, M.; Ruda, K.; Sherlock,J. P.; Thomson,A. D.; Gilday,J. P. Org. Process Res. Dev.2008, 12,30-40;(b) Samaroo,D.; Soll, C. E.; Todaro, L. J.; Drain, C. M. Org. Lett. 2006,8,4985-4988. 18. ( M icrowave experiments: Reactions in 1 sealed vessel s were conducted in t wo c o mmercial m i crowave sy s tems: One single mo d e (In i tiator E X P 60 f rom B iotage) with a power o utput r anging from 0 to 300W and one m ultimode cavity ( E thos Mic r oSynth from Milestone) with a microwave power deliver y s ys tem ranging f rom 0 to 10 0 0 W. Ex p eriments in the single mode w e re performed i n 2-5 mL glass vials. The temperature was monitored v v i i a a a n IR sensor located on t h e side of t he v essel. The vessel co n tent w ere stirred by means o f a r o tating magnetic p l ate l o cated belo w t he m icrowave cavities a nd T e flon-coated magnetic stir ba r s i n s ide the vess el . Experiments in multimode systems w ere c a rried o ut i n c lose d 1 0 o r 2 5 mL reactors made o f q u artz o r glass. O p en v e s sel e xperiment was carried out i n a 2 50 mL round b o ttomed f l ask f itted w i th a r eflux condenser. The t emperature was monitored vi a a f ib e r- op ti c C c o ntact thermometer protected i n a T e flon-coated c e ramic ga i n i nserted directl y int o the reactio n mixture . The vessel contents were stirr e d by means of an a d justable r o tating magnetic p l ate l o cated b e low t he f loor of the microwave cavity and a T e flon-coated magnetic s t ir b ar i nside the ve ssel. T e mperature, , p F ressure, and p ower p r ofiles w eremonitored usingcommercially availabl e s oftwares p rovided by themanufacturers. ) ww.rysstech.com耐士科技 www.rysstech.com士科技

确定

还剩2页未读,是否继续阅读?

上海鑫欣生物科技有限公司为您提供《化学药中特殊物质和基团检测方案 》,该方案主要用于化药新药研发中其他检测,参考标准--,《化学药中特殊物质和基团检测方案 》用到的仪器有

相关方案

更多

该厂商其他方案

更多