方案详情

文

利用Hiden RGA残余气体分析仪可以进行各种真空状态下的残余气体分析和过程、工艺监测。可以实时在线得到实验过程的真实情况,即使反馈处理过程中出现的问题。在等离子体工艺过程中,更是可以有效地表征等离子体产生的过程。

方案详情

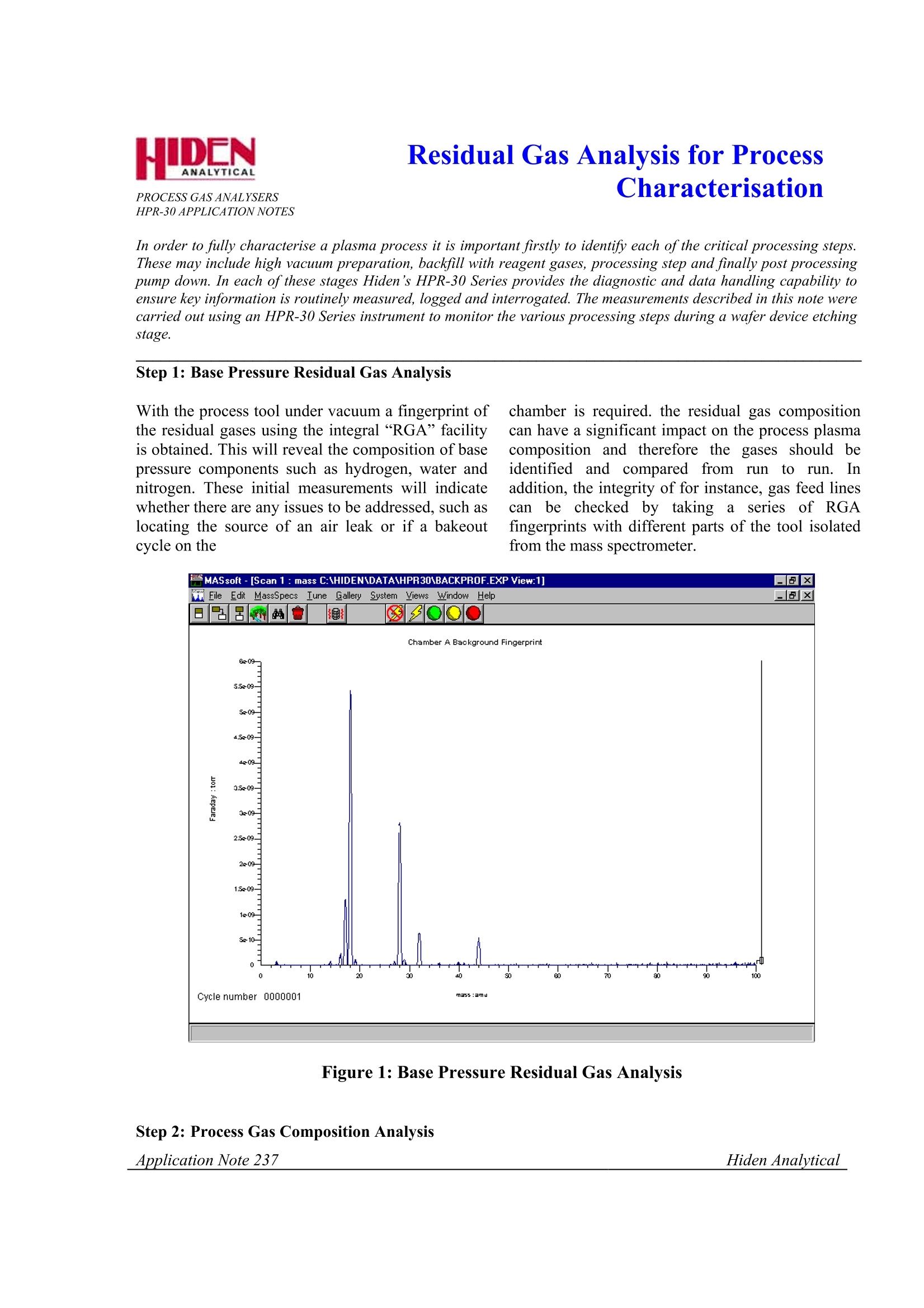

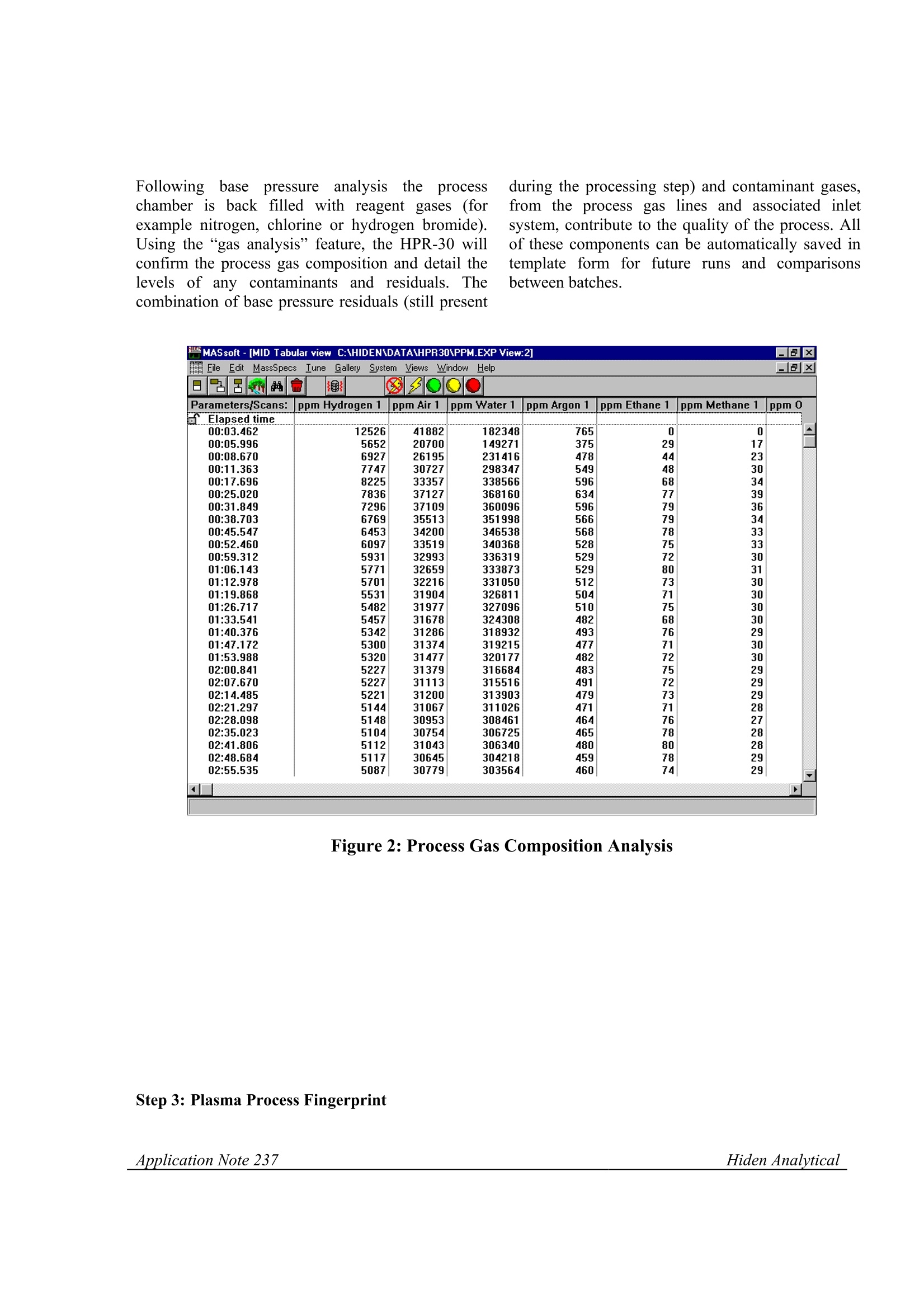

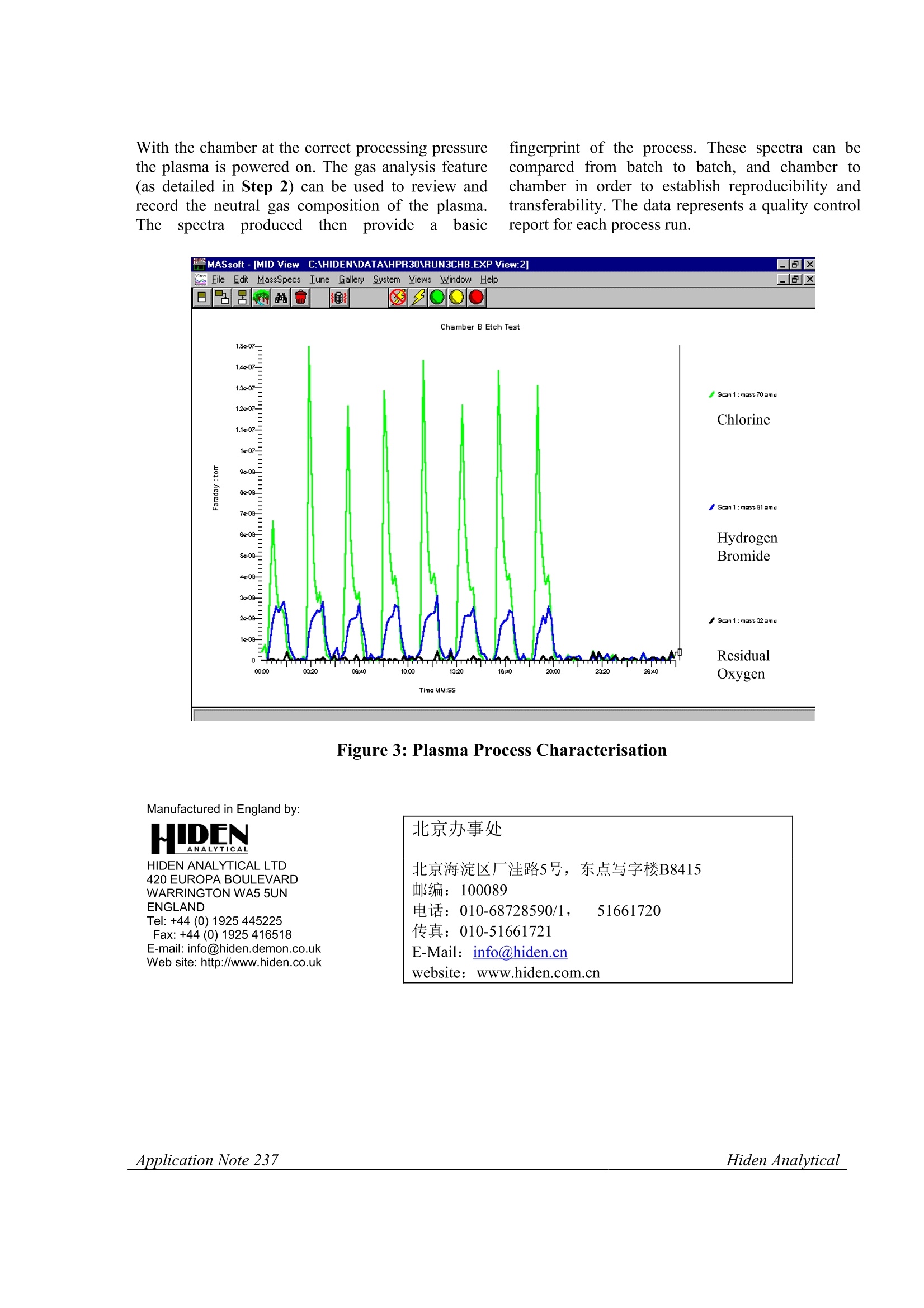

Residual Gas Analysis for ProcessCharacterisation PROCESS GAS ANALYSERSHPR-30 APPLICATION NOTES In order to fully characterise a plasma process it is important firstly to identify each of the critical processing steps.These may include high vacuum preparation, backfill with reagent gases, processing step and finally post processingpump down. In each of these stages Hiden’s HPR-30 Series provides the diagnostic and data handling capability toensure key information is routinely measured, logged and interrogated. The measurements described in this note werecarried out using an HPR-30 Series instrument to monitor the various processing steps during a wafer device etchingstage. With the process tool under vacuum a fingerprint ofthe residual gases using the integral“RGA”facilityis obtained. This will reveal the composition of basepressure components such as hydrogen, water andnitrogen. These initial measurements will indicatewhether there are any issues to be addressed, such aslocating the source of an air leak or if a bakeoutcycle on the chamber is required. the residual gas compositioncan have a significant impact on the process plasmacomposition and therefore the gases should beidentified and compared fromrunto run. Inaddition, the integrity of for instance, gas feed linescan1be checked by takingaseries of RGAfingerprints with different parts of the tool isolatedfrom the mass spectrometer. Figure 1: Base Pressure Residual Gas Analysis Step 2: Process Gas Composition Analysis Following baseeppressureeanalysisthe processchamber is tback filled with reagent gases (forexample nitrogen, chlorine or hydrogen bromide).Using the “gas analysis” feature, the HPR-30 willconfirm the process gas composition and detail thelevelss of any contaminants and residuals.. Thecombination of base pressure residuals (still present during the processing step) and contaminant gases,from the process gas lines and associated inletsystem, contribute to the quality of the process. Allof these components can be automatically saved intemplate form for future runs and comparisonsbetween batches. Figure 2: Process Gas Composition Analysis With the chamber at the correct processing pressurethe plasma is powered on. The gas analysis feature(as detailed in Step 2) can be used to review andrecord the neutral gas composition of the plasma.Thespectraproducedthenprovidelea basic fingerprint of the process. These spectra can becompared from batch to batch, and chamber tochamber in order to establish reproducibility andtransferability. The data represents a quality controlreport for each process run. Figure 3: Plasma Process Characterisation Manufactured in England by: ANALYTICALHIDEN ANALYTICAL LTD420 EUROPA BOULEVARDWARRINGTON WA5 5UNENGLANDTel: +44 (0)1925445225Fax:+44 (0) 1925 416518 Hiden AnalyticalApplication Note Step : Plasma Process FingerprintApplication Note iden Analytical

确定

还剩1页未读,是否继续阅读?

北京英格海德分析技术有限公司为您提供《气体中真空过程表征检测方案(在线质谱)》,该方案主要用于工业气体中真空过程表征检测,参考标准--,《气体中真空过程表征检测方案(在线质谱)》用到的仪器有Hiden HAL3F 四极质谱仪

推荐专场

相关方案

更多

该厂商其他方案

更多