Composite materials are

used in land, sea and air

vehicles in high performance applications, particularly where speed and

manoevrability are primary

considerations. Full-field

data-rich imaging techniques are used to provide a better understanding of the behaviour

of composite materials subjected to high strain rate loading, such

as those experienced during shock and blast loading. The project

has particular application to protection of personnel and equipment

helping to reduce serious injuries and damage to costly equipment.

方案详情

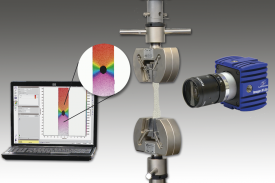

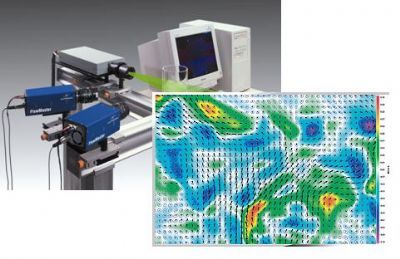

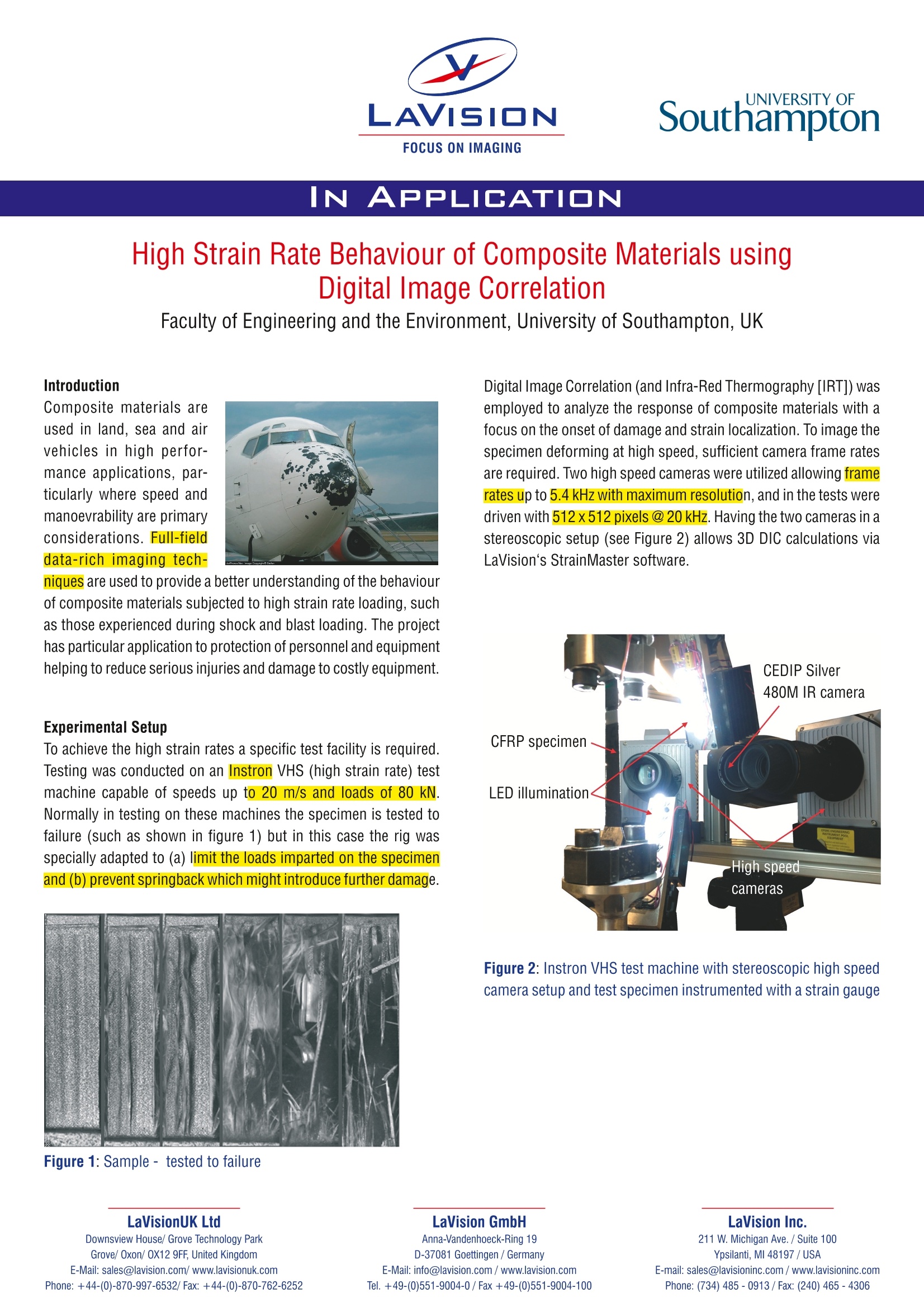

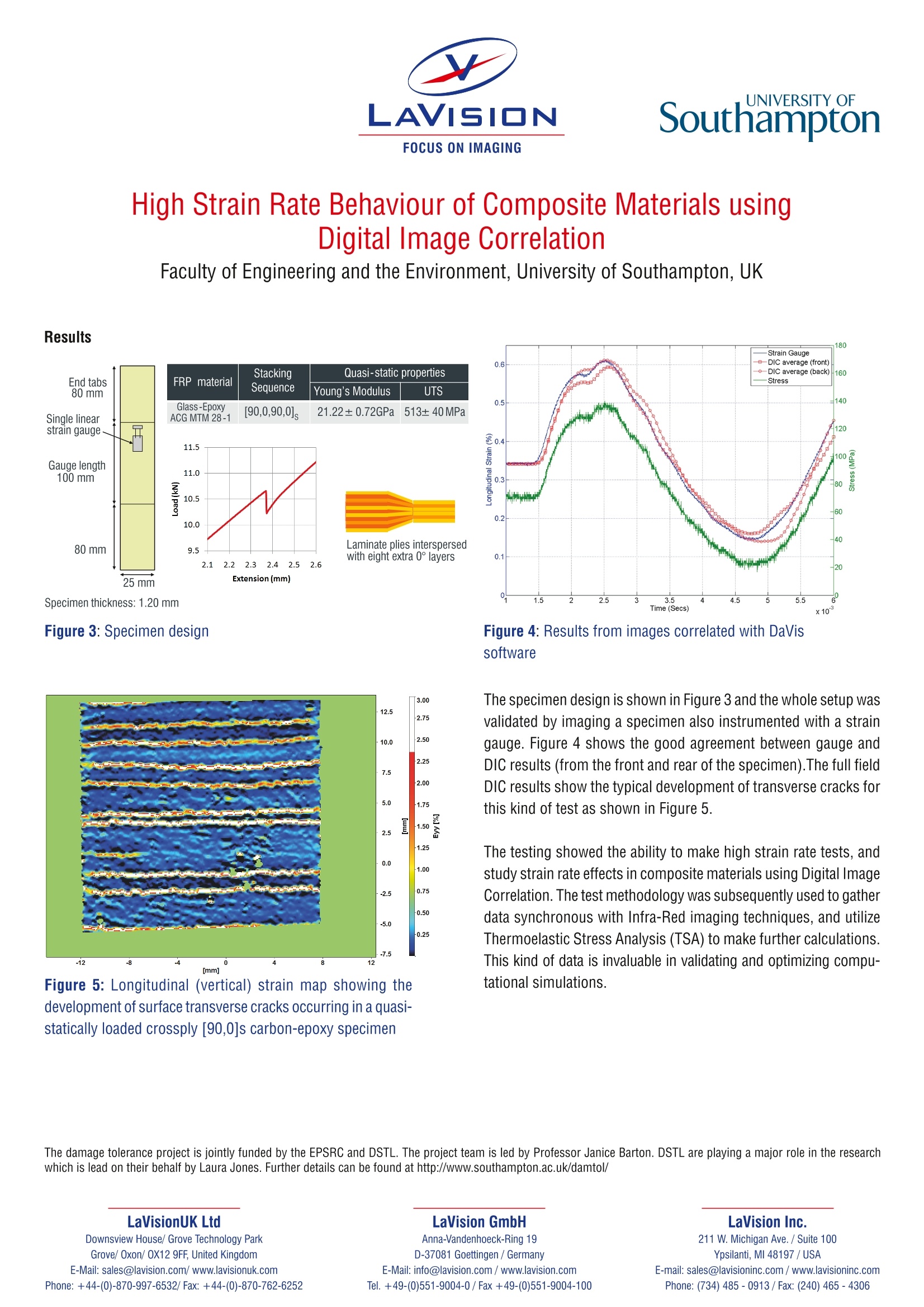

UNIVERSITY OFSouthamptonFOCUS ON IMAGING FOCUS ON IMAGING IN APPLICATION High Strain Rate Behaviour of Composite Materials usingDigital Image Correlation Faculty of Engineering and the Environment, University of Southampton, UK Introduction Composite materials areused in land, sea and airvehicles in high perfor-mance applications, par-ticularly where speed andmanoevrability are primaryconsiderations. Full-fielddata-rich imaging tech- niques are used to provide a better understanding of the behaviourof composite materials subjected to high strain rate loading, suchas those experienced during shock and blast loading. The projecthas particular application to protection of personnel and equipmenthelping to reduce serious injuries and damage to costly equipment. Experimental Setup To achieve the high strain rates a specific test facility is required.Testing was conducted on an|i Instron VHS (high strain rate) testmachine capable of speeds up to 20 m/s and loads of 80 kN.Normally in testing on these machines the specimen is tested tofailure (such as shown in figure 1) but in this case the rig wasspecially adapted to (a) limit the loads imparted on the specimenand (b) prevent springback which might introduce further damage. Figure 1: Sample- tested to failure LaVisionUK Ltd Downsview House/ Grove Technology ParkGrove/ Oxon/ OX12 9FF, United KingdomE-Mail: sales@lavision.com/www.lavisionuk.com Phone: +44-(0)-870-997-6532/Fax: +44-(0)-870-762-6252 Digital Image Correlation (and Infra-Red Thermography [IRT]) wasemployed to analyze the response of composite materials with afocus on the onset of damage and strain localization. To image thespecimen deforming at high speed, sufficient camera frame ratesare required. Two high speed cameras were utilized allowinggffrramerates up to 5.4 kHz with maximum resolution, and in the tests weredriven with 512x512 pixels @ 20 kHz. Having the two cameras in astereoscopic setup (see Figure 2) allows 3D DIC calculations viaLaVision's StrainMaster software. Figure 2: Instron VHS test machine with stereoscopic high speedcamera setup and test specimen instrumented with a strain gauge LaVision GmbH LaVision Inc. Anna-Vandenhoeck-Ring 19 211 W. Michigan Ave./ Suite 100 ( Ypsilant i , MI 48197/ U SA ) High Strain Rate Behaviour of Composite Materials usingDigital Image Correlation Faculty of Engineering and the Environment, University of Southampton, UK Results Specimen thickness: 1.20 mm Figure 3: Specimen design Figure 4: Results from images correlated with DaVissoftware The specimen design is shown in Figure 3 and the whole setup wasvalidated by imaging a specimen also instrumented with a straingauge. Figure 4 shows the good agreement between gauge andDIC results (from the front and rear of the specimen).The full fieldDIC results show the typical development of transverse cracks forthis kind of test as shown in Figure 5. The testing showed the ability to make high strain rate tests, andstudy strain rate effects in composite materials using Digital ImageCorrelation. The test methodology was subsequently used to gatherdata synchronous with Infra-Red imaging techniques, and utilizeThermoelastic Stress Analysis (TSA) to make further calculations.This kind of data is invaluable in validating and optimizing compu-tational simulations. Figure 5: Longitudinal (vertical) strain map showing thedevelopment of surface transverse cracks occurring in a quasi-statically loaded crossply [90,0]s carbon-epoxy specimen The damage tolerance project is jointly funded by the EPSRC and DSTL. The project team is led by Professor Janice Barton. DSTL are playing a major role in the researchwhich is lead on their behalf by Laura Jones. Further details can be found at http://www.southampton.ac.uk/damtol/ LaVisionUK Ltd ( LaVision GmbH A nna-Vandenhoeck-Ring1 9 D - 3 7081 G oettingen / Ge r man y E - Ma il : i nfo@lavi s i o n.com/www.l avi sio n .co m ) ( LaVision Inc. ) ( 2 11 W . M ichigan Ave. / Suite 100 ) ( Ypsilant i , MI 48197/ U SA ) ( E - m a i l : s a l es@lavisi o ni n c.com/www.lavis i oninc .c om ) D-Goettingen / GermanyE-mail: sales@lavisioninc.com/www.lavisioninc.comE-Mail: info@lavision.com /www.lavision.comTel. +()Fax +()hone: ( / Fax: ( Downsview House/ Grove Technology ParkGrove/ Oxon/ OXF, United KingdomE-Mail: sales@lavision.com/www.lavisionuk.comPhone: ( / Fax: ( hone: +()-Fax: +()-el.+()Fax +()

确定

还剩1页未读,是否继续阅读?

北京欧兰科技发展有限公司为您提供《金属材料中高温下材料的应变分析检测方案(其它无损检测仪器/设备)》,该方案主要用于其他中高温下材料的应变分析检测,参考标准--,《金属材料中高温下材料的应变分析检测方案(其它无损检测仪器/设备)》用到的仪器有LaVision StrainMaster材料应变形变成像测量系统、Imager sCMOS PIV相机、德国LaVision PIV/PLIF粒子成像测速场仪

推荐专场

CCD相机/影像CCD

更多

相关方案

更多

该厂商其他方案

更多