报道了一种测量低湍流燃烧器预混合火焰结构和紊流燃烧速度的方法。研究了六种贫燃气比火焰对象。进行了OH激光诱导荧光,瑞利散射温度成像,以及PIV联合测量。

方案详情

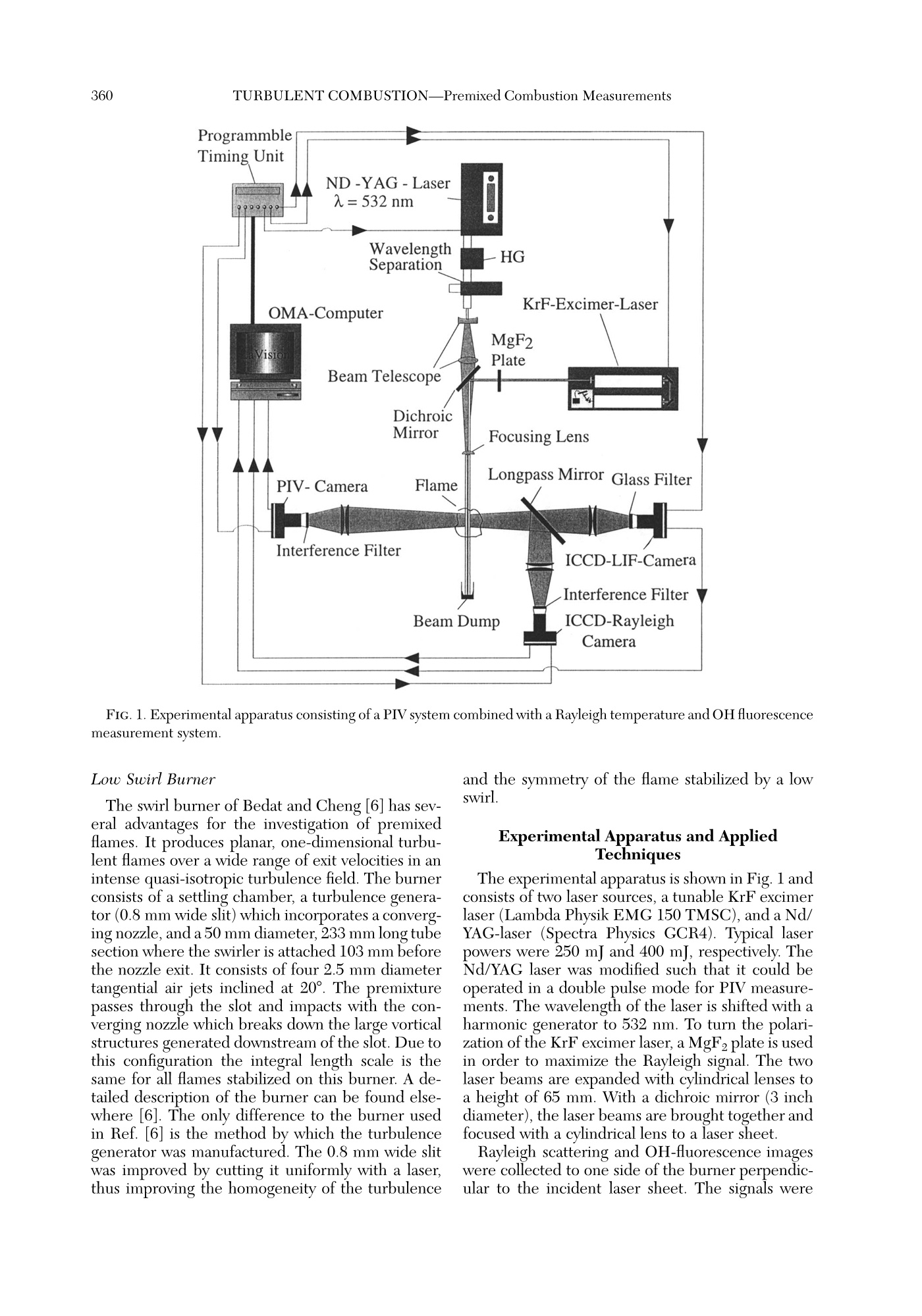

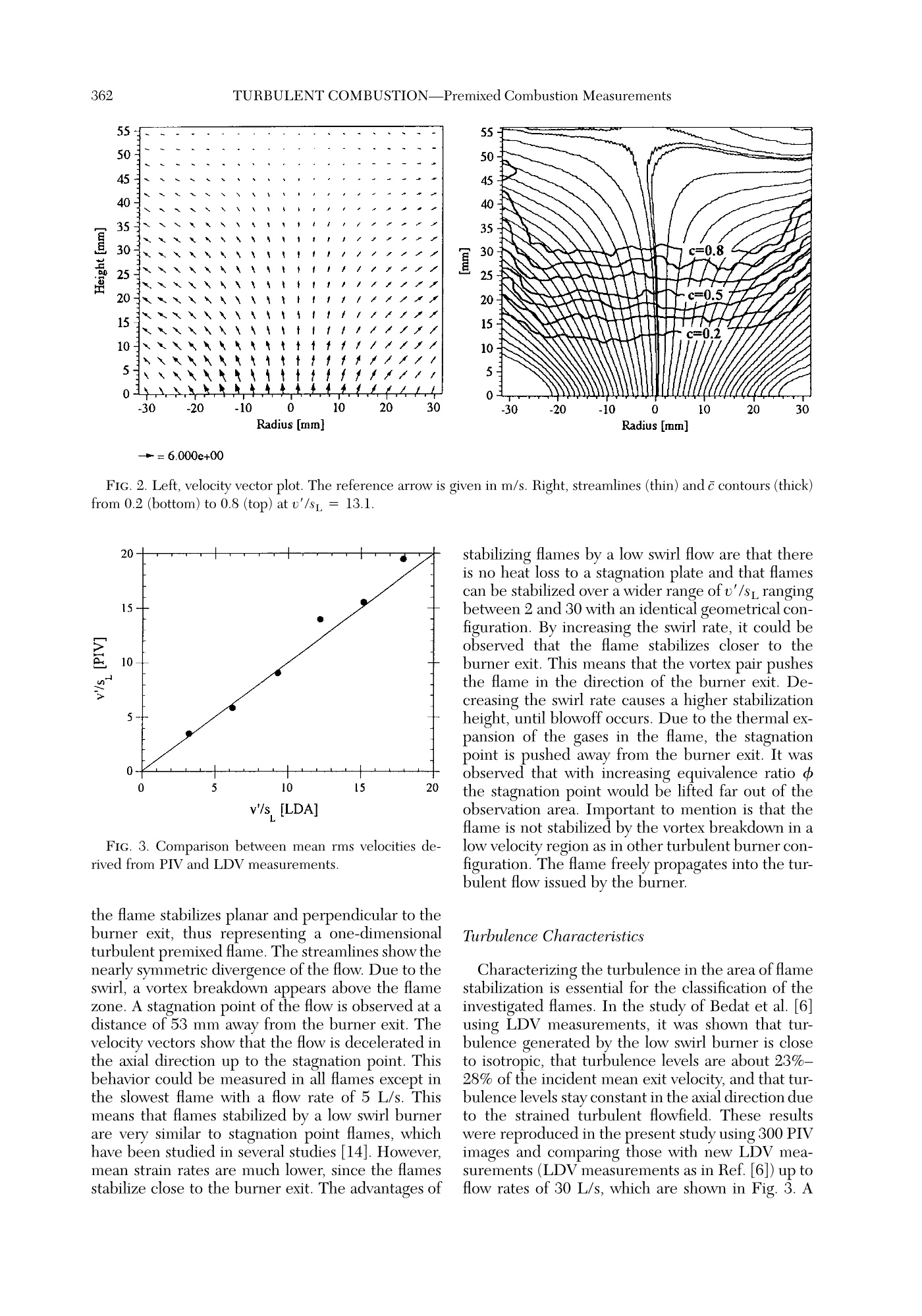

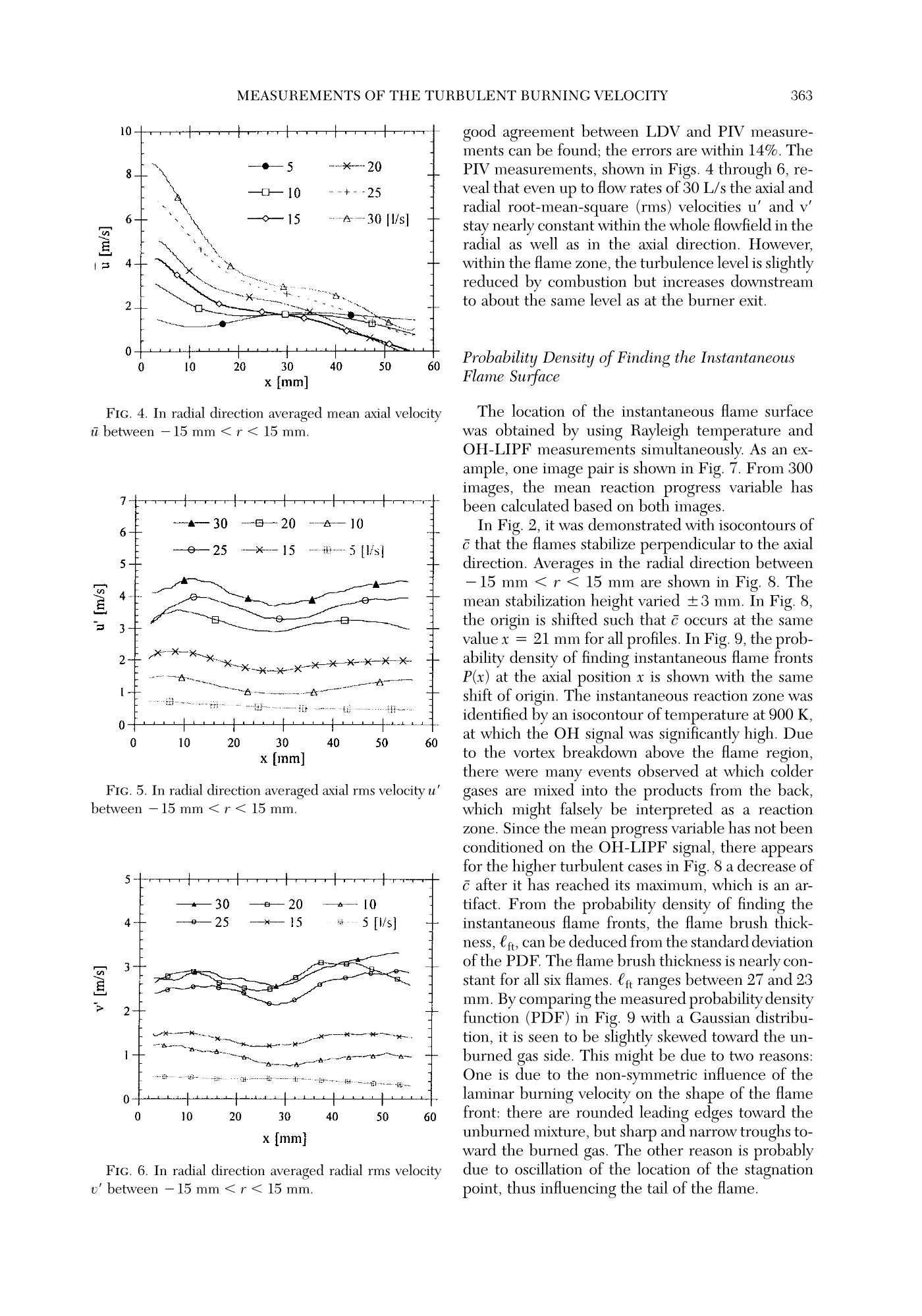

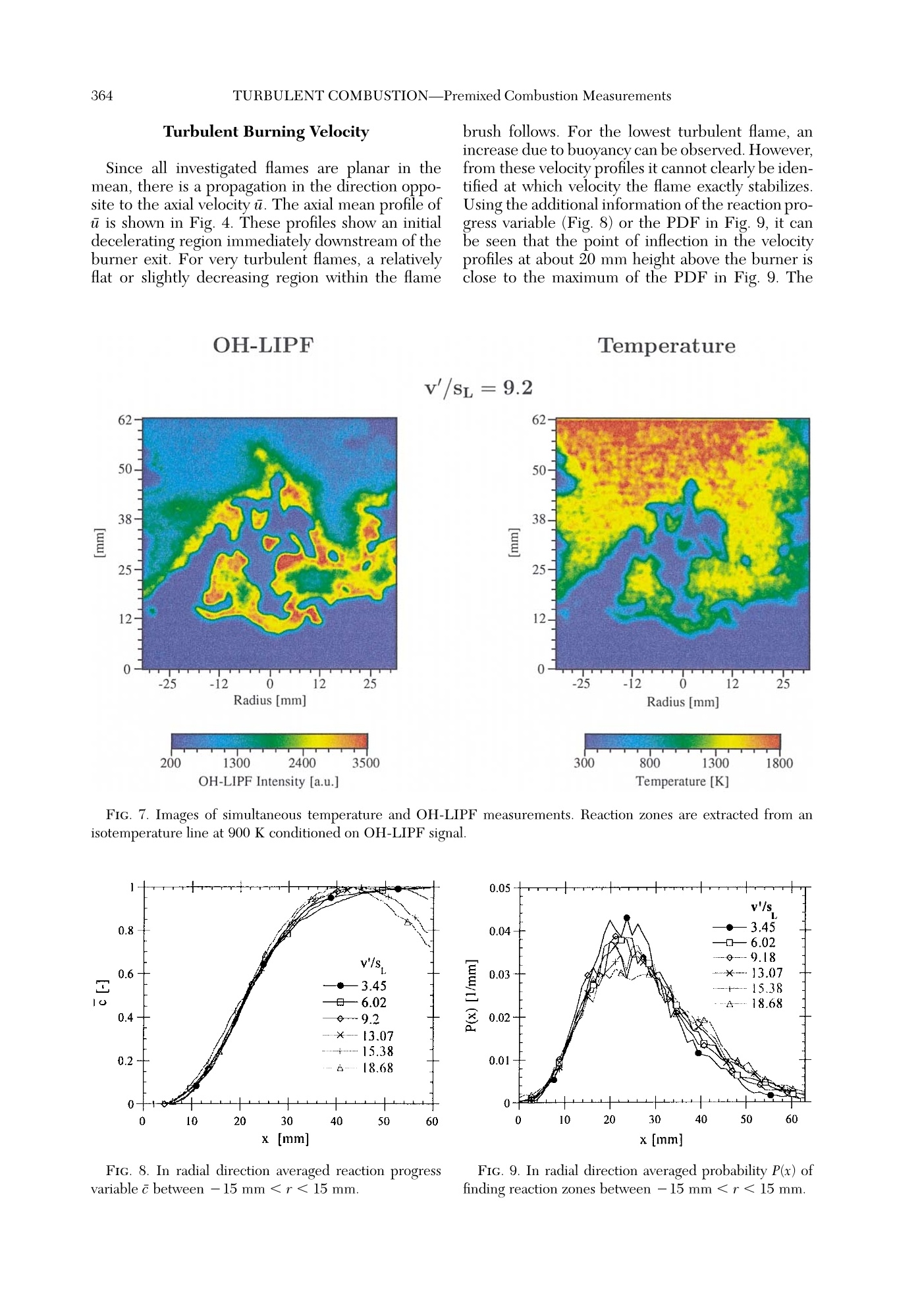

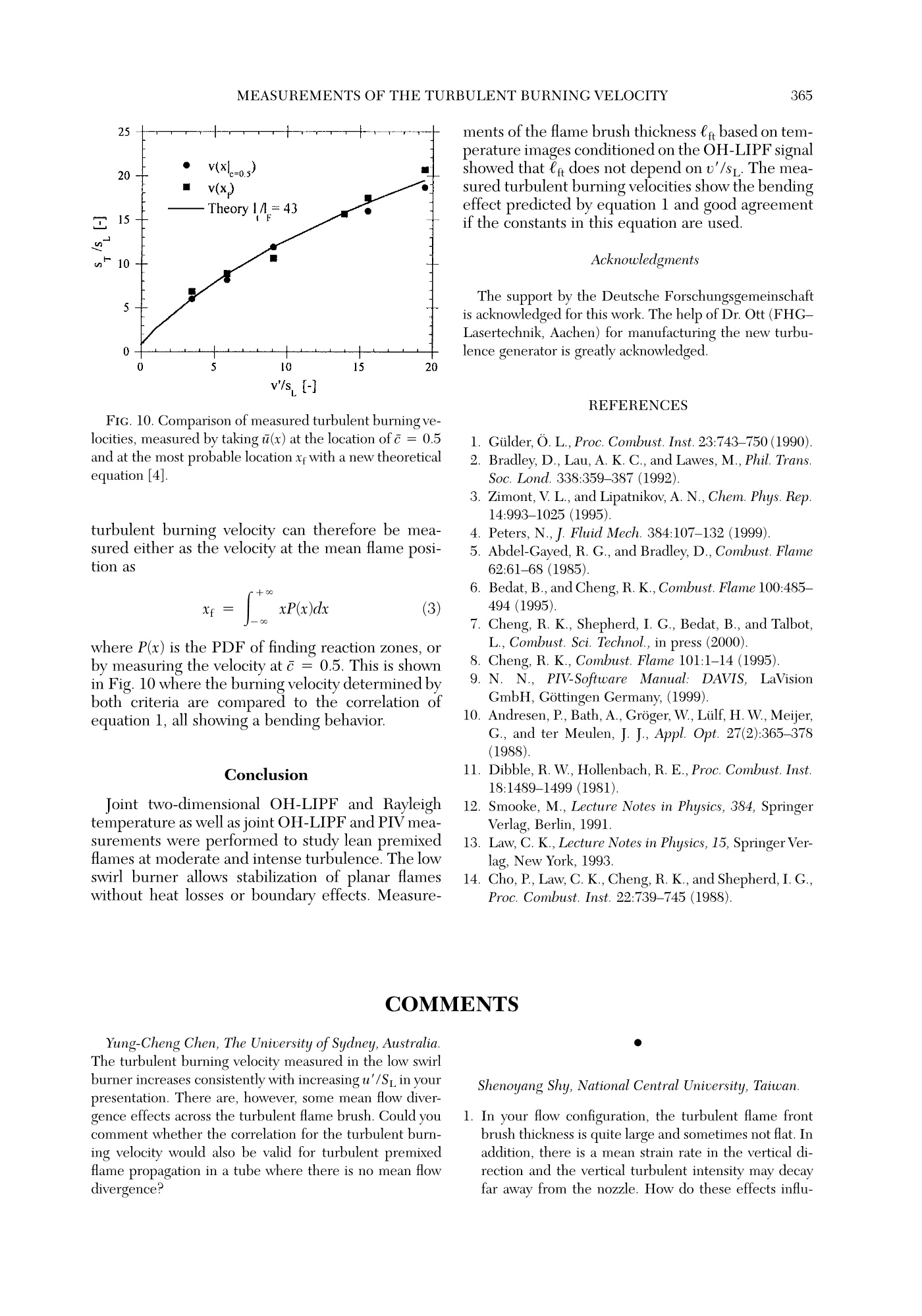

Proceedings of the Combustion Institute, Volume 28, 2000/pp.359-366 TURBULENT COMBUSTION-Premixed Combustion Measurements360 359 MEASUREMENTS OF THE TURBULENTBURNING VELOCITY AND THESTRUCTURE OF PREMIXED FLAMES ON A LOW-SWIRL BURNER T.PLESSING,I C. KORTSCHIK,N. PETERS,M.S. MANSOUR’AND R. K. CHENG Institut fir Technische Mechanik RWTH-Aachen Templergraben 64 D-52056 Aachen, Germany"Mechanical Engineering DepartmentAmerican University in Cairo Cairo,Egypt Lawrence Berkeley National Laboratory Berkeley, CA, USA A method has been developed to accurately determine the turbulent burning velocity in planar turbulentpremixed flames stabilized by a low swirl. Six lean methane/air flames have been investigated covering theflamelet as well as the thin reaction zones regime. The probability offinding the instantaneous flame frontis measured together with the velocity field by combining simultaneously OH-laser-inducedpredissociativefluorescence with either Rayleigh thermometry or particle image velocimetry (PIV). It is demonstratedthat the turbulent flame brush thickness is independent of u'/s and that the turbulent burning velocityagrees with predictions from a model equation for the flame surface area ratio using the level set approach The measurements of the two-dimensional flowfield show a recirculation zone downstream of the flamestabilization area. This exhibits a comparable flow pattern to stagnation point flames. However, mean strainrates are much lower since the flames stabilize close to the burner exit, and the flame is not influenced bythe recirculation zone. A comparison of the root-mean-square velocities obtained from Laser-DopplerAmemometry measurements to those determined by PIV show a good agreement. It can be shown thatturbulence is attenuated in the flame zone and only moderately increased behind it. Introduction The turbulent burning velocity is probably themost important quantity that needs to be known forthe design of combustion facilities operating underpremixed turbulent conditions. Many correlations ofs have been proposed in the literature [1-3] to ex-press it as functions of the laminar burning velocitysu, the turbulence intensity u’, the integral lengthscalel, the laminar flame thickness lr,and variousother quantities such as the Lewis number Le or astretch factor. Recently [4], an expression for theburning velocity ratio s/sL was derived from firstprinciples combining scaling laws valid in two dif-ferent regimes of premixed turbulent combustion,namely, the corrugated flamelet and the thin reac-tion zone regime. It reads The numerical coefficients in this expression origi-nate from comparisons with experimental data. Inspite of a fairly large experimental database [2] thatwas kindly provided to one of the authors (R.K.C.),additional validations to determine these numbersare necessary. In this paper, a new experimental approach is un-dertaken in order to measure the turbulent burningvelocity by keeping the integral length scale lcon-stant. The low-swirl burner by Bedat and Cheng [6]provides a suitable configuration for this purpose. In several previous studies on turbulent premixedflames stabilized on a low-swirl burner, the flamestructure [7] as well as velocity and scalar character-istics [6,8] have been investigated experimentally.The measurements of the turbulent burning velocitywere based on setting the mean axial velocity u up-stream of the turbulent flame brush equal to theburning velocity. The turbulent burning velocity wasfound to be proportional to the turbulence intensityand did not show a bending behavior that has beenfound by many other authors previously. In order toclarify this discrepancy, it was thought necessary toinvestigate the flowfield and flame stabilization infurther detail using advanced laser diagnostics. Low Swirl Burner The swirl burner of Bedat and Cheng [6] has sev-eral advantages for the investigation of premixedflames. It produces planar, one-dimensional turbu-lent flames over a wide range of exit velocities in anintense quasi-isotropic turbulence field. The burnerconsists of a settling chamber, a turbulence genera-tor (0.8 mm wide slit) which incorporates a converg-ing nozzle, and a50 mm diameter, 233 mm long tubesection where the swirler is attached 103 mm beforethe nozzle exit. It consists of four 2.5 mm diametertangential air jets inclined at 20°. The premixturepasses through the slot and impacts with the con-verging nozzle which breaks down the large vorticalstructures generated downstream of the slot. Due tothis configuration the integral length scale is thesame for all flames stabilized on this burner. A de-tailed description of the burner can be found else-where [6]. The only difference to the burner usedin Ref. [6] is the method by which the turbulencegenerator was manufactured. The 0.8 mm wide slitwas improved by cutting it uniformly with a laser,thus improving the homogeneity of the turbulence and the symmetry of the flame stabilized by a lowswirl. Experimental Apparatus and AppliedTechniques The experimental apparatus is shown in Fig. l andconsists of two laser sources, a tunable KrF excimerlaser (Lambda Physik EMG 150 TMSC), and a Nd/YAG-laser (Spectra Physics GCR4). Typical laserpowers were 250 mJ and 400 mJ, respectively. TheNd/YAG laser was modified such that it could beoperated in a double pulse mode for PIV measure-ments. The wavelength of the laser is shifted with aharmonic generator to 532 nm. To turn the polari-zation of the KrF excimer laser, a MgF2 plate is usedin order to maximize the Rayleigh signal. The twolaser beams are expanded with cylindrical lenses toa height of 65 mm. With a dichroic mirror (3 inchdiameter), the laser beams are brought together andfocused with a cylindrical lens to a laser sheet. Rayleigh seattering and OH-fluorescence imageswere collected to one side of the burner perpendic-ular to the incident laser sheet. The signals were TABLE lExperimental conditions and relevant parameters 5巧 separated with a long pass mirror so that the inelasticscattered Rayleigh signals could be collected with aninterference filter (bandwidth 8 nm) by one ICCDcamera (La Vision Dynamight). The second ICCDcamera (La Vision Imager with tandem lens coupledimage intensifier) was used for OH imaging. ASchott UG11 glass filter was chosen to discriminatebetween the OH signal around 298 nm and otherwavelength signals. Perpendicular to the other sideof the burner a double-shuttered non-intensifiedCCD camera (Sensicam PCO, 1024 ×1280 pixel)was mounted for particle-imaging velocimetry (PIV)measurements together with an interference filtercentered at 532 nm. The setup was controlled byLaVision DaVis software [9] together with a pro-grammable timing unit. The exposure time for allcameras was set to 400 ns in order to suppress flameluminosity. Laser-induced predissociative fuorescence(LIPF) of the OH radical was excited by tuning theUV-KrF excimer laser beam to the P(8) transitionin the [A+1, characterized by a turbulentKarlovitz number [4]. The integral length scale ehas been measured by Bedat and Cheng [6] in aprevious work to be 15 mm. The laminar flamethickness was set to 0.35 mm using the assumptionp=D/s. Calculating the diffusion coefficient de-fined as D =(A/cp)o/Pu with the formula for A/c,from page 11 of Smooke [12] at T= 1500 K andTu =300 K, one obtains D=7.2 ×10-5 m’/s.Then, the laminar flame thickness can be estimatedto (p =0.35 mm with st= 0.2 m/s at d=0.7. shas been derived from a best fit of the experimentaldata from Law [13]. The length/scale ratio e/lp isset to 43. The turbulent Reynolds number,Re,Dam-kohler number, Da, and Karlovitz number, Ka, aredefined as follows: Two-Dimensional Flow and Velocity Field The flowfield was examined for each flame by tak-ing simultaneously 300 PIV images together withOH-LIPF images. The mean two-dimensional flowpattern at v’/s_ = 13.1 is shown in Fig. 2. At theleft-hand side, mean velocity vectors are plotted. Atthe right-hand side, the streamlines are superim-posed on isocontours of the mean progress variablec=(T-T/(T-T). The isocontours of c werederived from 300 simultaneous Rayleigh tempera-ture and OH-LIPF images. The c contours showthat →=6.000e+00 FIG. 2. Left, velocity vector plot. The reference arrow is given in m/s. Right, streamlines (thin) and c contours (thick)from 0.2 (bottom) to 0.8 (top) at v'/s_= 13.1. FIG. 3. Comparison between mean rms velocities de-rived from PIV and LDV measurementsS. the flame stabilizes planar and perpendicular to theburner exit, thus representing a one-dimensionalturbulent premixed flame. The streamlines show thenearly symmetric divergence of the flow. Due to theswirl, a vortex breakdown appears above the flamezone. A stagnation point of the flow is observed at adistance of 53 mm away from the burner exit. Thevelocity vectors show that the flow is decelerated inthe axial direction up to the stagnation point. Thisbehavior could be measured in all flames except inthe slowest flame with a flow rate of 5 L/s. Thismeans that flames stabilized by a low swirl burnerare very similar to stagnation point flames, whichhave been studied in several studies [14]. However,mean strain rates are much lower, since the flamesstabilize close to the burner exit. The advantages of stabilizing flames by a low swirl flow are that thereis no heat loss to a stagnation plate and that flamescan be stabilized over a wider range of u’/s rangingbetween 2 and 30 with an identical geometrical con-figuration. By increasing the swirl rate, it could beobserved that the flame stabilizes closer to theburner exit. This means that the vortex pair pushesthe flame in the direction of the burner exit. De-creasing the swirl rate causes a higher stabilizationheight, until blowoff occurs. Due to the thermal ex-pansion of the gases in the flame, the stagnationpoint is pushed away from the burner exit. It wasobserved that with increasing equivalence ratio othe stagnation point would be lifted far out of theobservation area. Important to mention is that theflame is not stabilized by the vortex breakdown in alow velocity region as in other turbulent burner con-figuration. The flame freely propagates into the tur-bulent flow issued by the burner. Turbulence Characteristics Characterizing the turbulence in the area of flamestabilization is essential for the classification of theinvestigated flames. In the study of Bedat et al. [6]using LDV measurements, it was shown that tur-bulence generated by the low swirl burner is closeto isotropic, that turbulence levels are about 23%-28% of the incident mean exit velocity, and that tur-bulence levels stay constant in the axial direction dueto the strained turbulent flowfield. These resultswere reproduced in the present study using 300 PIVimages and comparing those with new LDV mea-surements (LDV measurements as in Ref. [6]) up toflow rates of 30 L/s, which are shown in Fig. 3. A FIG. 4. In radial direction averaged mean axial velocityu between -15mm

确定

还剩6页未读,是否继续阅读?

北京欧兰科技发展有限公司为您提供《燃烧器,预混合火焰中速度场,浓度场检测方案(粒子图像测速)》,该方案主要用于其他中速度场,浓度场检测,参考标准--,《燃烧器,预混合火焰中速度场,浓度场检测方案(粒子图像测速)》用到的仪器有德国LaVision PIV/PLIF粒子成像测速场仪、Imager sCMOS PIV相机、PLIF平面激光诱导荧光火焰燃烧检测系统

推荐专场

CCD相机/影像CCD

更多

相关方案

更多

该厂商其他方案

更多