几种动物的冷冻干燥保存Preservation of some species of animals through cryodessication

方案详情

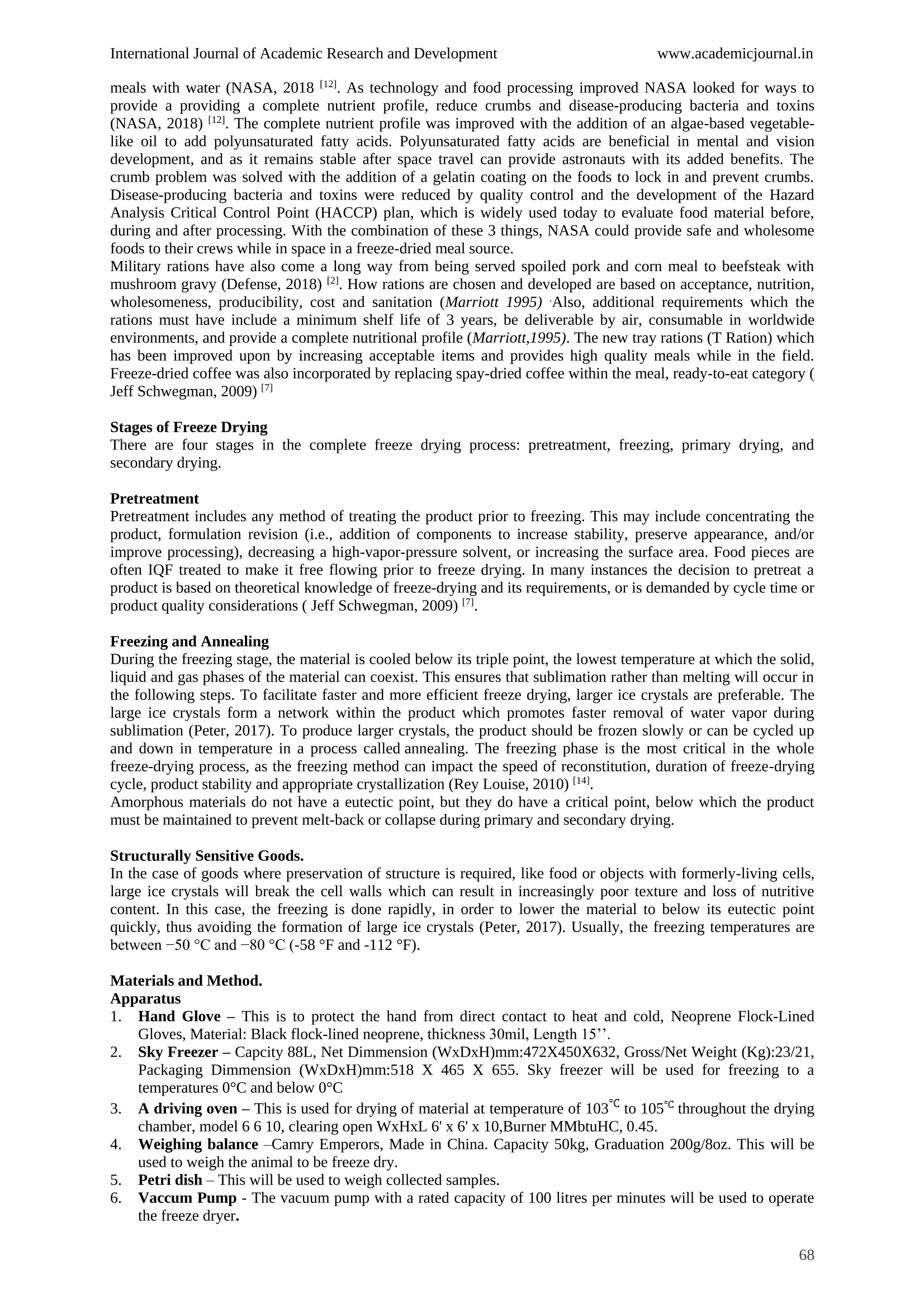

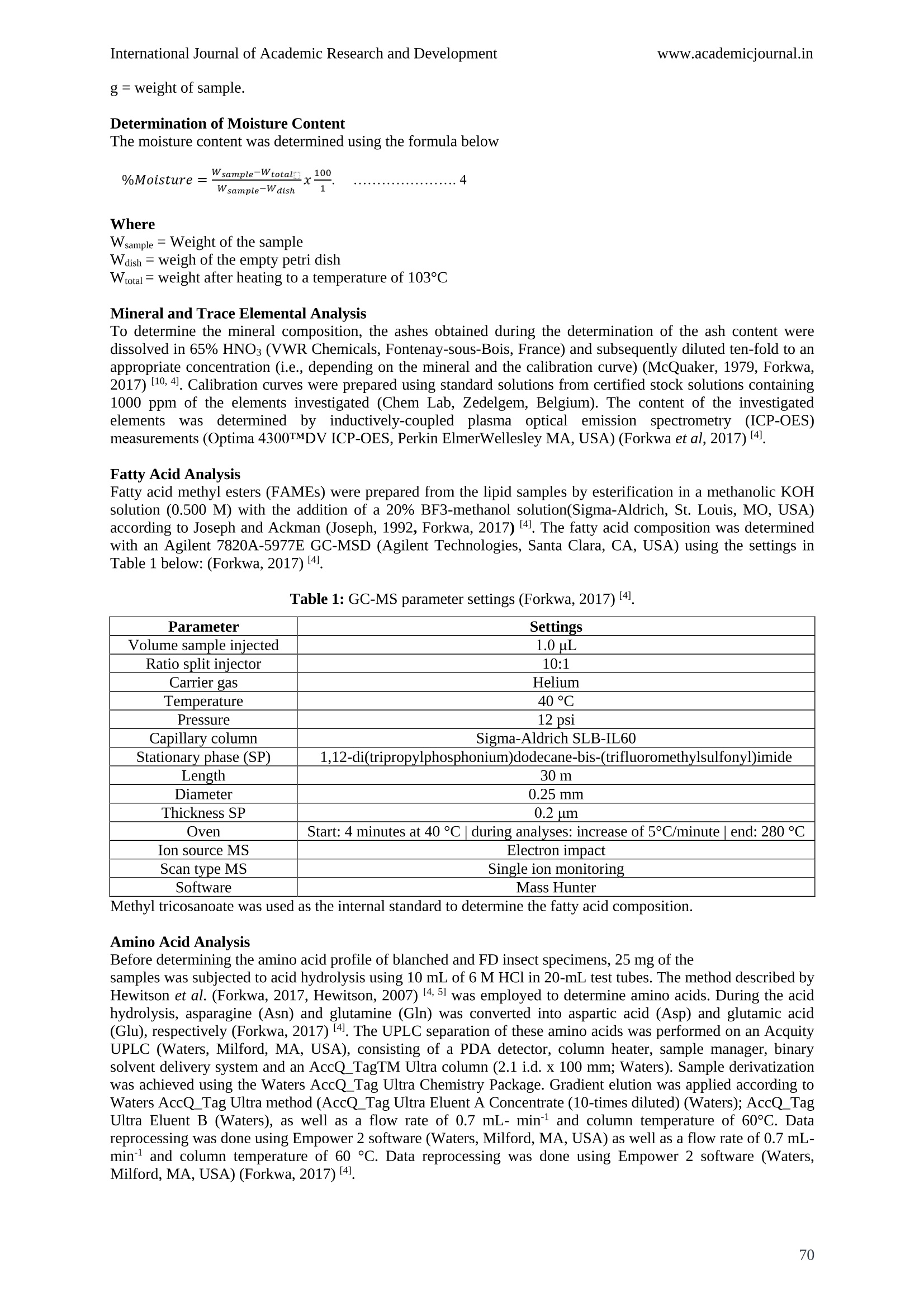

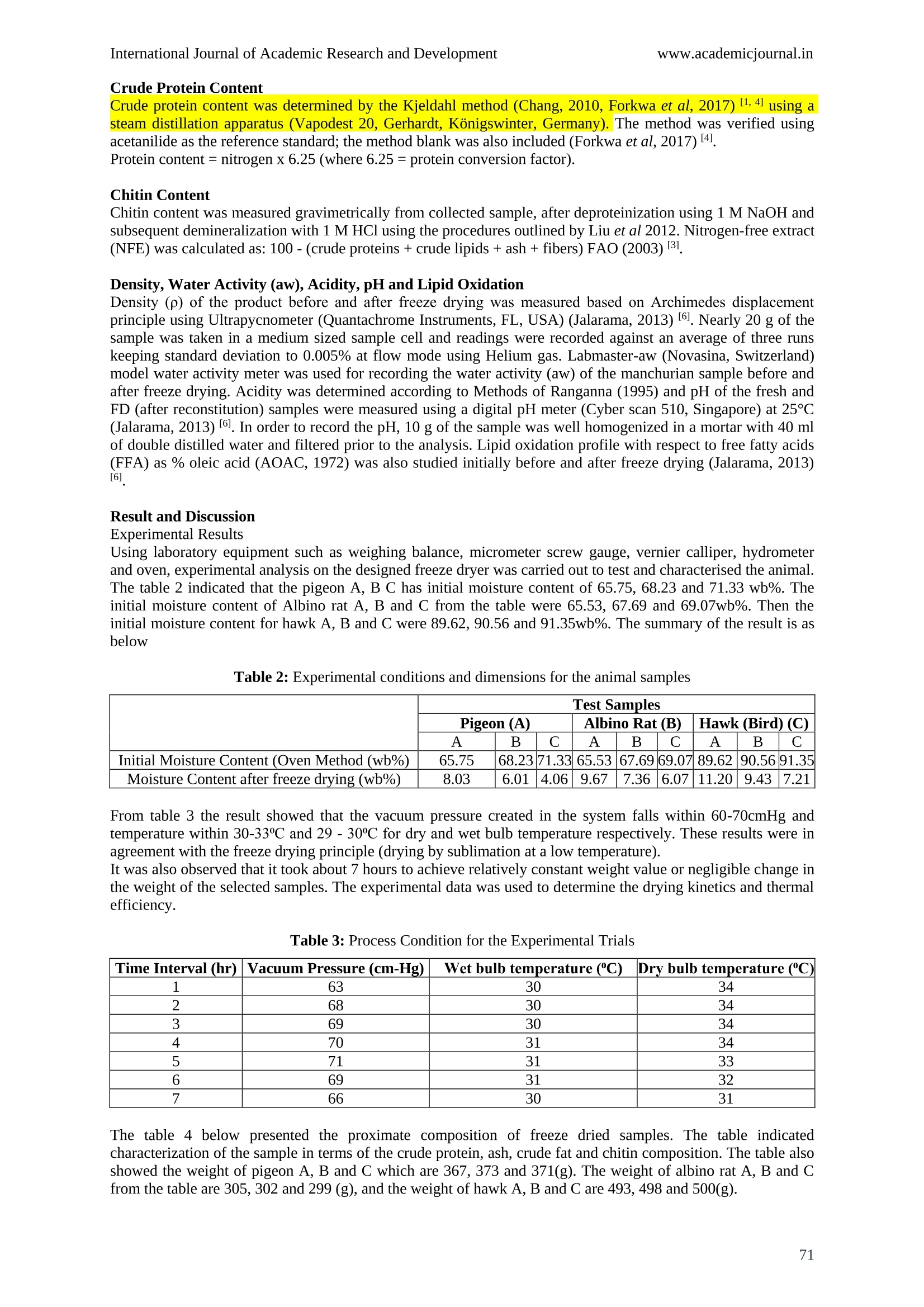

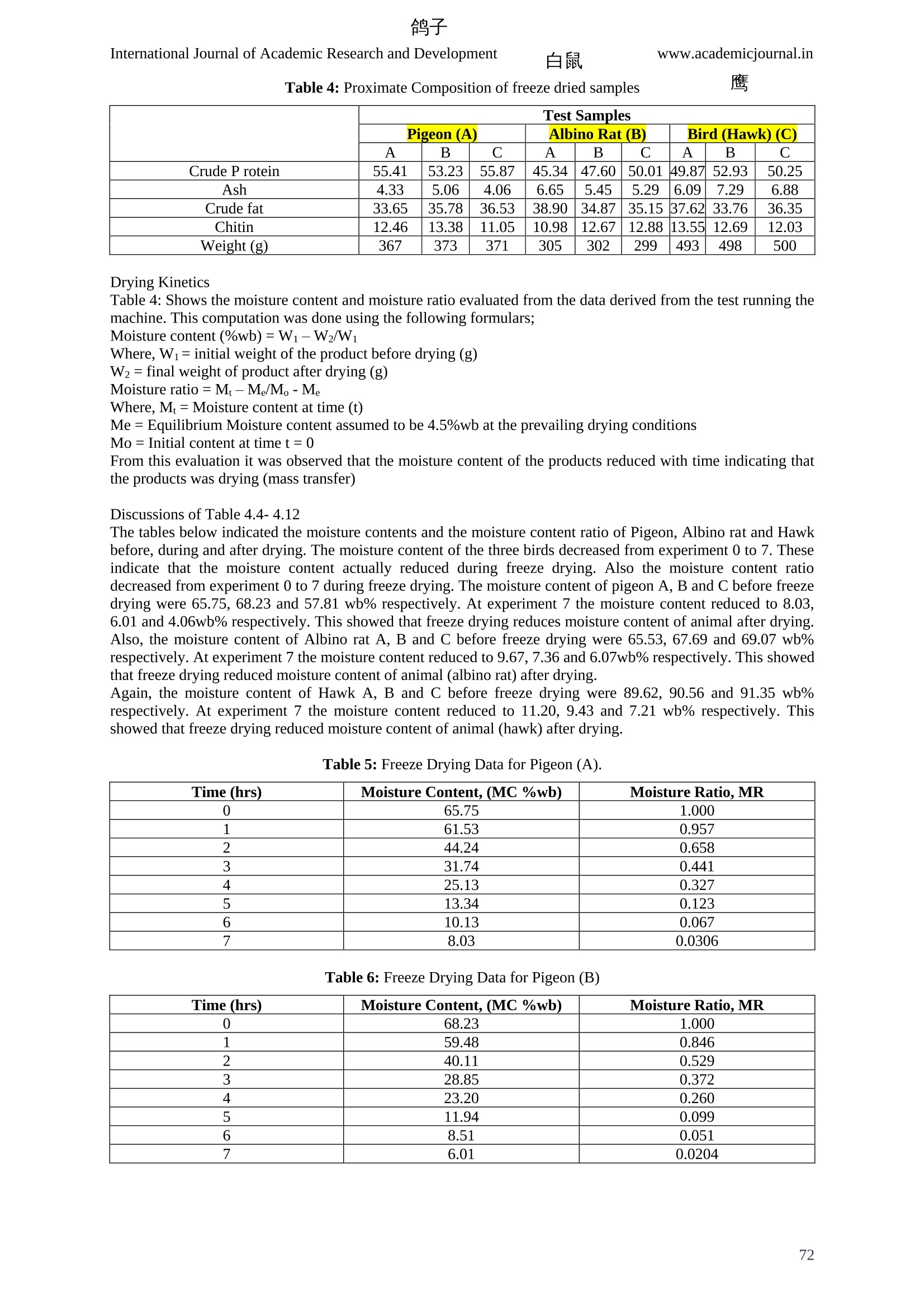

几种动物的冷冻干燥保存Preservation of some species of animals through cryodessicationInternational Journal of Academic Research and Development www.academicjournal.in ISSN: 2455-4197Received: 26-05-2022, Accepted: 11-06-2022, Published: 28-06-2022Volume 7, Issue 3, 2022, Page No. 67-74 International Journal of Academic Research and Developmentwww.academicjournal.in 几种动物的冷冻干燥保存 Preservation of some species of animals through cryodessication 尼日利亚埃努古国立科技大学机械工程系 Asanya Emeka1, Ugwuoke E C2, Ezeigwe C P3, Audu Ibrahim Ali4, Ononobi Uchenna Chamberline51 Department of Mechanical Engineering, Enugu State University of Science and Technology, Nigeria 2 Projects Development Institute (PRODA), Enugu, Nigeria 3 Science Laboratory Technology, Federal Polytechnic Oko, Anambra State, Nigeria 4 Department of Mechanical Engineering, The Federal Polytechnic Idah, Kogi State, Nigeria 5 Safety and Engineering Department, Federal Road Safety Corps Ojota Lagos, Nigeria Abstract The main aim of this work is preservation of Animal and bird product through cryodesiccation. Freeze drying, also known as lyophilisation or cryodessication, is a low temperature dehydration process which involves freezing the product, lowering pressure, then removing the ice by sublimation. This is in contrast to dehydration by most conventional methods that evaporate water using heat. Freeze drying results in a high quality product because of the low temperature used in processing. The original shape of the product is maintained and quality of the rehydrated product is excellent. Primary applications of freeze drying include biological (e.g. birds, animals, bacteria and yeasts), biomedical (e.g. surgical transplants), and food processing (e.g. coffee). The average weight of the pigeon used in this work was 370g; the albino rat has average weight of 302g, while hawks average weight was 497g. The moisture content of pigeon A dropped from 65.75 – 8.03%wb, albino rat moisture content decreased from 65.53 – 9.67%wb and the hawk moisture content also declined in the range of 89.62 – 11.20%wb. The proximate analysis of the crude protein content of the animal indicated pigeon has the highest value in the range of 53.23 – 55.87; hawk crude protein content was slightly higher than the albino rat in the range of 49.87 – 50.25, the crude protein content of the albino rat was in the range of 45.34 – 50.01. Keywords: cryodessication, temperature, animal, moisture and sublimation Introduction Freeze dryinginvolvesthe removalofwateror other solventfromafrozen productbyaprocesscalled sublimation (Labconco, 2004) [9]. Sublimation occurs when a frozen liquid goes directly to the gaseous state without passing through the liquid phase. In contrast, drying at ambient temperatures from the liquid phase usually results in changes in the product, and may be suitable only for some materials. However, in freeze drying, the material does not go through the liquid phase, and it allows the preparation of a stable product that is easy to use and aesthetic in appearance (Labconco, 2004) [9]. The first applications of the freeze-drying process were in the Andes where Indigenous people would take low-land tubers up to high altitudes and leave them to freeze (Wikipedia, 2018). The potatoes were squashed to facilitate the water loss but when left to freeze at night and exposed through the days, the mash would lose its water while the nutrients were preserved through the lyophilization process. This resulted in a product called chuño which was a long shelf life food eaten well past its seasonal availability and also stored for emergency rations, if needed. Freeze drying as an industrial process began in as early as 1890 by Richard Altmann who devised a method to freeze dry tissues (either plant or animal), but went virtually unnoticed until the 1930s (Meryman, 1976) [11]. In 1909, Shackell independently created the vacuum chamber by using an electrical pump (Corver, Jos). However, no further data on freeze drying was documented until Tival in 1927 and Elser in 1934 had patented freeze drying systems with improvements to freezing and condenser steps (Corver, Jos). A significant turning point for freeze drying occurred during World War II because blood plasma and penicillin were needed to treat the wounded within the field because of the lack of simultaneous refrigeration and transport, many serum supplies were spoiling before reaching their intended recipients. The freeze-drying process was developed as a commercial technique that enabled blood plasma and penicillin to be rendered chemically stable and viable without having to be refrigerated. In the 1950s-60s, freeze drying began to be viewed for its multi-purpose application to both pharmaceuticals and food processing. Early uses in food Freeze-drying products became a major commodity for astronauts and military food rations. What began for astronaut crews as tubed meals and freeze-dried snacks that were difficult to rehydrate (NASA, 2018) [12], they are now able to enjoy warm hot meals while in space by improving the easability for rehydrating free-dried meals with water (NASA, 2018 [12]. As technology and food processing improved NASA looked for ways to provide a providing a complete nutrient profile, reduce crumbs and disease-producing bacteria and toxins (NASA, 2018) [12]. The complete nutrient profile was improved with the addition of an algae-based vegetable-like oil to add polyunsaturated fatty acids. Polyunsaturated fatty acids are beneficial in mental and vision development, and as it remains stable after space travel can provide astronauts with its added benefits. The crumb problem was solved with the addition of a gelatin coating on the foods to lock in and prevent crumbs. Disease-producing bacteria and toxins were reduced by quality control and the development of the Hazard Analysis Critical Control Point (HACCP) plan, which is widely used today to evaluate food material before, during and after processing. With the combination of these 3 things, NASA could provide safe and wholesome foods to their crews while in space in a freeze-dried meal source. Military rations have also come a long way from being served spoiled pork and corn meal to beefsteak with mushroom gravy (Defense, 2018) [2]. How rations are chosen and developed are based on acceptance, nutrition, wholesomeness, producibility, cost and sanitation (Marriott 1995) .Also, additional requirements which the rations must have include a minimum shelf life of 3 years, be deliverable by air, consumable in worldwide environments, and provide a complete nutritional profile (Marriott,1995). The new tray rations (T Ration) which has been improved upon by increasing acceptable items and provides high quality meals while in the field. Freeze-dried coffee was also incorporated by replacing spay-dried coffee within the meal, ready-to-eat category (Jeff Schwegman, 2009) [7] Stages of Freeze Drying Therearefourstagesinthecompletefreezedryingprocess:pretreatment,freezing,primarydrying,and secondary drying. Pretreatment Pretreatment includes any method of treating the product prior to freezing. This may include concentrating the product, formulation revision (i.e., addition of components to increase stability, preserve appearance, and/or improve processing), decreasing a high-vapor-pressure solvent, or increasing the surface area. Food pieces are often IQF treated to make it free flowing prior to freeze drying. In many instances the decision to pretreat a product is based on theoretical knowledge of freeze-drying and its requirements, or is demanded by cycle time or product quality considerations ( Jeff Schwegman, 2009) [7]. Freezing and Annealing During the freezing stage, the material is cooled below its triple point, the lowest temperature at which the solid, liquid and gas phases of the material can coexist. This ensures that sublimation rather than melting will occur in the following steps. To facilitate faster and more efficient freeze drying, larger ice crystals are preferable. The large ice crystals form a network within the product which promotes faster removal of water vapor during sublimation (Peter, 2017). To produce larger crystals, the product should be frozen slowly or can be cycled up and down in temperature in a process called annealing. The freezing phase is the most critical in the whole freeze-drying process, as the freezing method can impact the speed of reconstitution, duration of freeze-drying cycle, product stability and appropriate crystallization (Rey Louise, 2010) [14]. Amorphous materials do not have a eutectic point, but they do have a critical point, below which the product must be maintained to prevent melt-back or collapse during primary and secondary drying. Structurally Sensitive Goods. In the case of goods where preservation of structure is required, like food or objects with formerly-living cells, large ice crystals will break the cell walls which can result in increasingly poor texture and loss of nutritive content. In this case, the freezing is done rapidly, in order to lower the material to below its eutectic point quickly, thus avoiding the formation of large ice crystals (Peter, 2017). Usually, the freezing temperatures are between −50 °C and −80 °C (-58 °F and -112 °F). Materials and Method. Apparatus 1. Hand Glove – This is to protect the hand from direct contact to heat and cold, Neoprene Flock-Lined Gloves, Material: Black flock-lined neoprene, thickness 30mil, Length 15’’. 2. Sky Freezer – Capcity 88L, Net Dimmension (WxDxH)mm:472X450X632, Gross/Net Weight (Kg):23/21, PackagingDimmension(WxDxH)mm:518X465X655.Skyfreezerwillbeusedforfreezingtoa temperatures 0°C and below 0°C 3. A driving oven – This is used for drying of material at temperature of 103 to 105 throughout the drying chamber, model 6 6 10, clearing open WxHxL 6' x 6' x 10,Burner MMbtuHC, 0.45. 4. Weighing balance –Camry Emperors, Made in China. Capacity 50kg, Graduation 200g/8oz. This will be used to weigh the animal to be freeze dry. 5. Petri dish – This will be used to weigh collected samples. 6. Vaccum Pump - The vacuum pump with a rated capacity of 100 litres per minutes will be used to operate the freeze dryer. 7. Animals and Birds Used- Hawk, Pigeon and Albino rat a. Hawk - This subfamily are mainly woodland birds with long tails and high visual acuity. They hunt by dashing suddenly from a concealed perch b. P P i i g g e e o o n n -- P P i i g g e e o o n n s s a a r r e e g g e e n n t t l l e e ,, p p l l u u m m p p ,, s s m m a a l l l l --b b i i l l l l e e d d b b i i r r d d s s w w i i t t h h a a s s k k i i n n s s a a d d d d l l e e ((c c e e r r e e )) b b e e t t w w e e e e n n t t h h e e b b i i l l l l a a n n d d forehead. All pigeons strut about with a characteristic bobbing of the head. Because of their long wings and powerful flight muscles, they are strong, swift fliers. c. Albino rat -The rat has short hair, a long naked tail, rounded erect ears, protruding eyes, a pointed snout with long whisker (vibrissae) and five toes on each foot. Albino rats have poor eyesight and depend on facial vibrissae and olfaction for sensory input. Ash Content Determination The residue remaining after all the moisture have been removed and the fats, proteins, carbohydrates, vitamins and organic acids burnt away by ignition at about 600oC is called ash. It is usually taken as a measure of the mineral content of the raw waste. Using AOAC (1990) method (Ugwuoke, 2016) [15], 1g of the finely ground samples were weighed into porcelain crucibles which have been washed, dried in an oven at 100oC, cooled in a desiccator and weighed. They will be placed inside a muffle furnace and heated at 600oC for 4 hours. After this, they were removed and cooled in a desiccator and then weighed. A = Weight of crucible + ash B = Weight of crucible C = Weight of original sample Fat Content Determination Pearson (1976) method was used (Ugwuoke, 2016) [15]. This involves the use of Soxhlet extraction apparatus. This method involves continuous extraction of waste with organic solvent such as petroleum ether for 4 hours or so depending on the volume of sample. To carry out the extraction, the flask was washed and dried in an oven. It was then cooled in a desiccator and weighed. 1g of the ground collected sample was accurately weighed and transferred into a rolled filter paper and then placed inside the extraction thimble. The thimble was placed inside the extractor. Some quantity of petroleum ether were poured inside the extraction flask (usually three-quarter of the volume of flask). The condenser and the flask were connected to the extractor. The whole unit was place on a heating mantle for 4 hours after which the petroleum ether will be recovered. The oil collected in the flask will be dried in an oven at 105oC. It is then weighed and the percentage fat calculated as shown below. C = weight of flask +oil A = weight of empty flask B = weight of original sample. Determination of Carbohydrate Content This was determined by difference which was done by subtracting the sum of % ash, % protein, % fat, %moisture and % crude fibre from 100 (Ugwuoke, 2016) [15]. Energy Content Determination A.O.A.C (1975) method will be used (Ugwuoke, 2016) [15]. This was done with bomb calorimeter (model XRY-1A, make: Shanghai Changji, China). It involves igniting the collected sample in oxygen bomb calorimeter (under a high pressure of oxygen gas). The heat energy that was released was absorbed by the surrounding water inside the bomb calorimeter. This gave rise to a temperature increase of the surrounding water and this was used to estimate the energy value of the sample. 1g of the sample was pelleted and turned in the oxygen bomb calorimeter. The heat of combustion was calculated as the gross energy. Where E = energy equivalent of the calorimeter ΔT = temperature rise L = length of burnt wire V = titration volume International Journal of Academic Research and Development g = weight of sample. Determination of Moisture Content The moisture content was determined using the formula below Where Wsample = Weight of the sample Wdish = weigh of the empty petri dish Wtotal = weight after heating to a temperature of 103°C Mineral and Trace Elemental Analysis To determine the mineral composition, the ashes obtained during the determination of the ash content were dissolved in 65% HNO3 (VWR Chemicals, Fontenay-sous-Bois, France) and subsequently diluted ten-fold to an appropriate concentration (i.e., depending on the mineral and the calibration curve) (McQuaker, 1979, Forkwa,2017) [10, 4]. Calibration curves were prepared using standard solutions from certified stock solutions containing 1000 ppm of the elements investigated (Chem Lab, Zedelgem, Belgium). The content of the investigated elements was determined by inductively-coupled plasma optical emission spectrometry (ICP-OES) measurements (Optima 4300™DV ICP-OES, Perkin ElmerWellesley MA, USA) (Forkwa et al, 2017) [4]. Fatty Acid Analysis Fatty acid methyl esters (FAMEs) were prepared from the lipid samples by esterification in a methanolic KOH solution (0.500 M) with the addition of a 20% BF3-methanol solution(Sigma-Aldrich, St. Louis, MO, USA) according to Joseph and Ackman (Joseph, 1992, Forkwa, 2017) [4]. The fatty acid composition was determined with an Agilent 7820A-5977E GC-MSD (Agilent Technologies, Santa Clara, CA, USA) using the settings in Table 1 below: (Forkwa, 2017) [4]. Table 1: GC-MS parameter settings (Forkwa, 2017) [4]. Parameter Settings Volume sample injected 1.0 μL Ratio split injector 10:1 Carrier gas Helium Temperature 40 °C Pressure 12 psi Capillary column Sigma-Aldrich SLB-IL60 Stationary phase (SP) 1,12-di(tripropylphosphonium)dodecane-bis-(trifluoromethylsulfonyl)imide Length 30 m Diameter 0.25 mm Thickness SP 0.2 μm Oven Start: 4 minutes at 40 °C| |during analyses: increase of 5°C/minute |end: 280 °C Ion source MS Electron impact Scan type MS Single ion monitoring Software Mass Hunter Methyl tricosanoate was used as the internal standard to determine the fatty acid composition. Amino Acid Analysis Before determining the amino acid profile of blanched and FD insect specimens, 25 mg of the samples was subjected to acid hydrolysis using 10 mL of 6 M HCl in 20-mL test tubes. The method described by Hewitson et al. (Forkwa, 2017, Hewitson, 2007) [4, 5] was employed to determine amino acids. During the acid hydrolysis, asparagine (Asn) and glutamine (Gln) was converted into aspartic acid (Asp) and glutamic acid (Glu), respectively (Forkwa, 2017) [4]. The UPLC separation of these amino acids was performed on an Acquity UPLC (Waters, Milford, MA, USA), consisting of a PDA detector, column heater, sample manager, binary solvent delivery system and an AccQ_TagTM Ultra column (2.1 i.d. x 100 mm; Waters). Sample derivatization was achieved using the Waters AccQ_Tag Ultra Chemistry Package. Gradient elution was applied according to Waters AccQ_Tag Ultra method (AccQ_Tag Ultra Eluent A Concentrate (10-times diluted) (Waters); AccQ_Tag Ultra Eluent B (Waters), as well as a flow rate of 0.7 mL- min-1 and column temperature of 60°C. Data reprocessing was done using Empower 2 software (Waters, Milford, MA, USA) as well as a flow rate of 0.7 mL-min-1 and column temperature of 60 °C. Data reprocessing was done using Empower 2 software (Waters, Milford, MA, USA) (Forkwa, 2017) [4]. Crude Protein Content Crude protein content was determined by the Kjeldahl method (Chang, 2010, Forkwa et al, 2017) [1, 4] using a steam distillation apparatus (Vapodest 20, Gerhardt, Königswinter, Germany). The method was verified using acetanilide as the reference standard; the method blank was also included (Forkwa et al, 2017) [4]. Protein content = nitrogen x 6.25 (where 6.25 = protein conversion factor). Chitin Content Chitin content was measured gravimetrically from collected sample, after deproteinization using 1 M NaOH and subsequent demineralization with 1 M HCl using the procedures outlined by Liu et al 2012. Nitrogen-free extract (NFE) was calculated as: 100 - (crude proteins + crude lipids + ash + fibers) FAO (2003) [3]. Density, Water Activity (aw), Acidity, pH and Lipid Oxidation Density (ρ) of the product before and after freeze drying was measured based on Archimedes displacement principle using Ultrapycnometer (Quantachrome Instruments, FL, USA) (Jalarama, 2013) [6]. Nearly 20 g of the sample was taken in a medium sized sample cell and readings were recorded against an average of three runs keeping standard deviation to 0.005% at flow mode using Helium gas. Labmaster-aw (Novasina, Switzerland) model water activity meter was used for recording the water activity (aw) of the manchurian sample before and after freeze drying. Acidity was determined according to Methods of Ranganna (1995) and pH of the fresh and FD (after reconstitution) samples were measured using a digital pH meter (Cyber scan 510, Singapore) at 25°C (Jalarama, 2013) [6]. In order to record the pH, 10 g of the sample was well homogenized in a mortar with 40 ml of double distilled water and filtered prior to the analysis. Lipid oxidation profile with respect to free fatty acids (FFA) as % oleic acid (AOAC, 1972) was also studied initially before and after freeze drying (Jalarama, 2013)[6]. Result and Discussion Experimental Results Using laboratory equipment such as weighing balance, micrometer screw gauge, vernier calliper, hydrometer and oven, experimental analysis on the designed freeze dryer was carried out to test and characterised the animal. The table 2 indicated that the pigeon A, B C has initial moisture content of 65.75, 68.23 and 71.33 wb%. The initial moisture content of Albino rat A, B and C from the table were 65.53, 67.69 and 69.07wb%. Then the initial moisture content for hawk A, B and C were 89.62, 90.56 and 91.35wb%. The summary of the result is as below Table 2: Experimental conditions and dimensions for the animal samples Test Samples Pigeon (A) Albino Rat (B) Hawk (Bird) (C) A B C A B C A B C Initial Moisture Content (Oven Method (wb%) 65.75 68.23 71.33 65.53 67.69 69.07 89.62 90.56 91.35 Moisture Content after freeze drying (wb%) 8.03 6.01 4.06 9.67 7.36 6.07 11.20 9.43 7.21 From table 3 the result showed that the vacuum pressure created in the system falls within 60-70cmHg and temperature within 30-33⁰C and 29 - 30⁰C for dry and wet bulb temperature respectively. These results were in agreement with the freeze drying principle (drying by sublimation at a low temperature). It was also observed that it took about 7 hours to achieve relatively constant weight value or negligible change in the weight of the selected samples. The experimental data was used to determine the drying kinetics and thermal efficiency. Table 3: Process Condition for the Experimental Trials Time Interval (hr) Vacuum Pressure (cm-Hg) Wet bulb temperature (⁰C) Dry bulb temperature (⁰C) 1 63 30 34 2 68 30 34 3 69 30 34 4 70 31 34 5 71 31 33 6 69 31 32 7 66 30 31 The table 4 below presented the proximate composition of freeze dried samples. The table indicated characterization of the sample in terms of the crude protein, ash, crude fat and chitin composition. The table also showed the weight of pigeon A, B and C which are 367, 373 and 371(g). The weight of albino rat A, B and C from the table are 305, 302 and 299 (g), and the weight of hawk A, B and C are 493, 498 and 500(g). International Journal of Academic Research and Development 白鼠 www.academicjournal.in Table 4: Proximate Composition of freeze dried samples 鹰 Test Samples Pigeon (A) Albino Rat (B) Bird (Hawk) (C) A B C A B C A B C Crude P rotein 55.41 53.23 55.87 45.34 47.60 50.01 49.87 52.93 50.25 Ash 4.33 5.06 4.06 6.65 5.45 5.29 6.09 7.29 6.88 Crude fat 33.65 35.78 36.53 38.90 34.87 35.15 37.62 33.76 36.35 Chitin 12.46 13.38 11.05 10.98 12.67 12.88 13.55 12.69 12.03 Weight (g) 367 373 371 305 302 299 493 498 500 Drying Kinetics Table 4: Shows the moisture content and moisture ratio evaluated from the data derived from the test running the machine. This computation was done using the following formulars; Moisture content (%wb) = W1 – W2/W1 Where, W1 = initial weight of the product before drying (g) W2 = final weight of product after drying (g) Moisture ratio = Mt – Me/Mo - Me Where, Mt = Moisture content at time (t) Me = Equilibrium Moisture content assumed to be 4.5%wb at the prevailing drying conditions Mo = Initial content at time t = 0 From this evaluation it was observed that the moisture content of the products reduced with time indicating that the products was drying (mass transfer) Discussions of Table 4.4- 4.12 The tables below indicated the moisture contents and the moisture content ratio of Pigeon, Albino rat and Hawk before, during and after drying. The moisture content of the three birds decreased from experiment 0 to 7. These indicatethatthemoisturecontentactuallyreducedduringfreezedrying.Alsothemoisturecontentratio decreased from experiment 0 to 7 during freeze drying. The moisture content of pigeon A, B and C before freeze drying were 65.75, 68.23 and 57.81 wb% respectively. At experiment 7 the moisture content reduced to 8.03,6.01 and 4.06wb% respectively. This showed that freeze drying reduces moisture content of animal after drying. Also, the moisture content of Albino rat A, B and C before freeze drying were 65.53, 67.69 and 69.07 wb%respectively. At experiment 7 the moisture content reduced to 9.67, 7.36 and 6.07wb% respectively. This showed that freeze drying reduced moisture content of animal (albino rat) after drying. Again, the moisture content of Hawk A, B and C before freeze drying were 89.62, 90.56 and 91.35 wb%respectively. At experiment 7 the moisture content reduced to 11.20, 9.43 and 7.21 wb% respectively. This showed that freeze drying reduced moisture content of animal (hawk) after drying. Table 5: Freeze Drying Data for Pigeon (A). Time (hrs) Moisture Content, (MC %wb) Moisture Ratio, MR 0 65.75 1.000 1 61.53 0.957 2 44.24 0.658 3 31.74 0.441 4 25.13 0.327 5 13.34 0.123 6 10.13 0.067 7 8.03 0.0306 Table 6: Freeze Drying Data for Pigeon (B) Time (hrs) Moisture Content, (MC %wb) Moisture Ratio, MR 0 68.23 1.000 1 59.48 0.846 2 40.11 0.529 3 28.85 0.372 4 23.20 0.260 5 11.94 0.099 6 8.51 0.051 7 6.01 0.0204 Table 7: Freeze Drying Data for Pigeon (C) Time (hrs) Moisture Content, (MC %wb) Moisture Ratio, MR 0 71.33 1.000 1 57.81 0.716 2 38.24 0.403 3 26.37 0.250 4 21.30 0.192 5 9.23 0.0671 6 6.85 0.034 7 4.06 0.0184 Conclusion and Recommendation Based on the results of the present study, it was concluded that freeze-drying of pigeon, white rat and bird (hawk) could be an efficient method for preserving some of these animal for further use. It was also observed that the nutrient values of the animals were maintained to a large extent after freeze drying. The protein and carbohydrate content were determined after freeze drying. It was discovered that the protein and carbohydrate content of the animal were retained to a large extent after the experiment. The mass value and moisture content of the animal were measured after the experiment, there was loss in mass value and moisture content of the animal after freeze drying. Freeze drying process is an expensive and complex method of dehydration but it effectiveness and efficiency in conservation of the quality of product (especially sensitive product) makes it an attractive and important method. Different approach has been used in it design and fabrication of this machine over the years at the method employed in this project is the most simplified, relatively less expensive and components locally accessible. If they are well defined they may indeed affect the quality of the final product. Due to high porosity of dried materials, it has a negative effect on storage stability. Thus, freeze-dried materials need to be store in a hermetic package. This machined as fabricated and characterized has evidently ascertained it advantages in agricultural and biomaterial processing for both household and commercial purposes in comparison with other method of dehydration. Thus open for further research, development and usage in Nigeria higher institutions, industries and home. Recommendation The following recommendation are made for further research work 1. The portability, time and cost effectiveness of the machine should be considered. New technical solutions are applied to modify the freeze drying process and make it time, size and cost effective, eg if we replace traditional heating source by microwaves radiation or we use a spray nozzle in dryer chamber. Another solution to limit process time is to use pre-treatment as blanching, dehydration by infrared radiation or osmotic dehydration. Also, introducing the compressor, heater, vacuum pump, cold trap and drying chamber as one component encourage it portability. 2. Alternative energy source such as solar, hydro, wind energy etc could be employed to conserve power and reduce inefficiency due to electrical power failure in Nigeria. 3. In characterising the machine and optimising it effectiveness, proximity analysis can be carried out. 4. Variation of temperature and pressure within the systems can also be considered to determine the optimal parameters value that gives effective and efficiency drying. 5. Comparative analysis of the effect of different methods of drying such as open sun drying, oven drying, solar drying etc can be further carried out to show the advantage and disadvantage of freeze drying methods. References 1. Chang SKC. Protein analysis. In Food Analysis, 4th ed.; Nielsen, S.S., Ed.; Springer: New York, NY, USA,2010:9:133-146. 2. Defense.gov News Article New Rations in Pipeline for Service Members". archive.defense.gov. Retrieved,2018. 3. Food and Agriculture Organization, FAO. Foodenergy—Methodsof analysis andconversion factors. Report of a technical workshop. In Food and Agriculture Organization of the United Nations Technical Workshop Report 77; Food and Nutrition Paper; FAO: Rome, Italy, 2003. 4. Forkwa Tengweh Fombong, Mik Van Der Borght, and Jozef Vanden Broeck Influence of Freeze-Drying and Oven-Drying Post Blanching on the Nutrient Composition of the Edible Insect Ruspolia differens, Insects,2017:8:102. 5. Hewitson H, Wheat T, Diehl D. Amino acid analysis of pure protein hydrolysate with waters UPLC amino acid analysis solution; Waters: Milford, MA, USA, 2007. 6. Jalarama Reddy K, Pandey MC, Harilal PT, Radhakrishna K. Optimization and quality evaluation of freeze dried mutton Manchurian, International Food Research Journal,2013:20(6):3101-3106. 7. Jeff Schwegman. "Basic Cycle Development Techniques for Lyophilized Products", 2009. 8. Joseph JD, Ackman RG. Capillary column gas chromatographic method for analysis of encapsulated fish oils and fish oil ethyl esters: Collaborative study. J. AOAC Int,1992:75:488-506. 9. Labconco. A guild to freeze drying for laboratory, Labconco Corporation, USA, 2004. 10. McQuaker NR, Kluckner PD, Chang GN. Calibration of an inductively coupled plasma-atomic emission spectrometer for the analysis of environmental materials. Anal. Chem,1979:51:888-895. 11. Meryman HT. "Historical recollections of freeze-drying". Developments in Biological Standardization,1976:36:29-32. ISSN 0301-5149. PMID 801137. 12. NASA. - Food for Space Flight"). www.nasa.gov. SpaceFlight:JSC. Retrieved, 2018. 13. Ranganna S. Hand Book of Analysis and Quality control of Fruit and Vegetable Products. Tata McGraw–Hill Publishing Company Limited, 1995, 105-106. 14. Rey, Louis, May, Joan C, Joan Christine. (3rd ed.) Freeze drying/lyophilization of pharmaceutical and biological products. New York: Informa Healthcare. 2010. ISBN 9781439825761. OCLC 664125915. 15. Ugwuoke EC, Aburu CM, Iloani IC, Ezeigwe CP, Okoro PN. Production of biogas from goat dung by anaerobic digestion, International Journal of Research in Advanced Engineering and Technology, 2016.

确定

还剩6页未读,是否继续阅读?

中国格哈特为您提供《冻干鸽子、白鼠以及鹰中蛋白质和脂肪含量的检测》,该方案主要用于其他肉制品中营养成分检测,参考标准《GB 5009.5 食品安全国家标准 食品中蛋白质的测定》,《冻干鸽子、白鼠以及鹰中蛋白质和脂肪含量的检测》用到的仪器有格哈特带自动进样器凯氏定氮仪VAP500C、格哈特全自动超级总脂肪测定系统HT6+SOX416、格哈特传统经典索氏提取/萃取仪EV6 AII16、格哈特自动升降凯氏定氮电热消解仪KT-L 20s、格哈特维克松废气实验室废物处理系统涤气VS、德国移液器MM、凯氏定氮催化剂5.0g K2SO4+0.5g CuSO4 x 5H2O

相关方案

更多

该厂商其他方案

更多