使用格哈特公司杜马斯燃烧法蛋白质测定仪 杜马森DUMATHERM和纤维仪器检测豆粕、发酵豆粕、排泄物、日粮的蛋白质和粗纤维含量。

方案详情

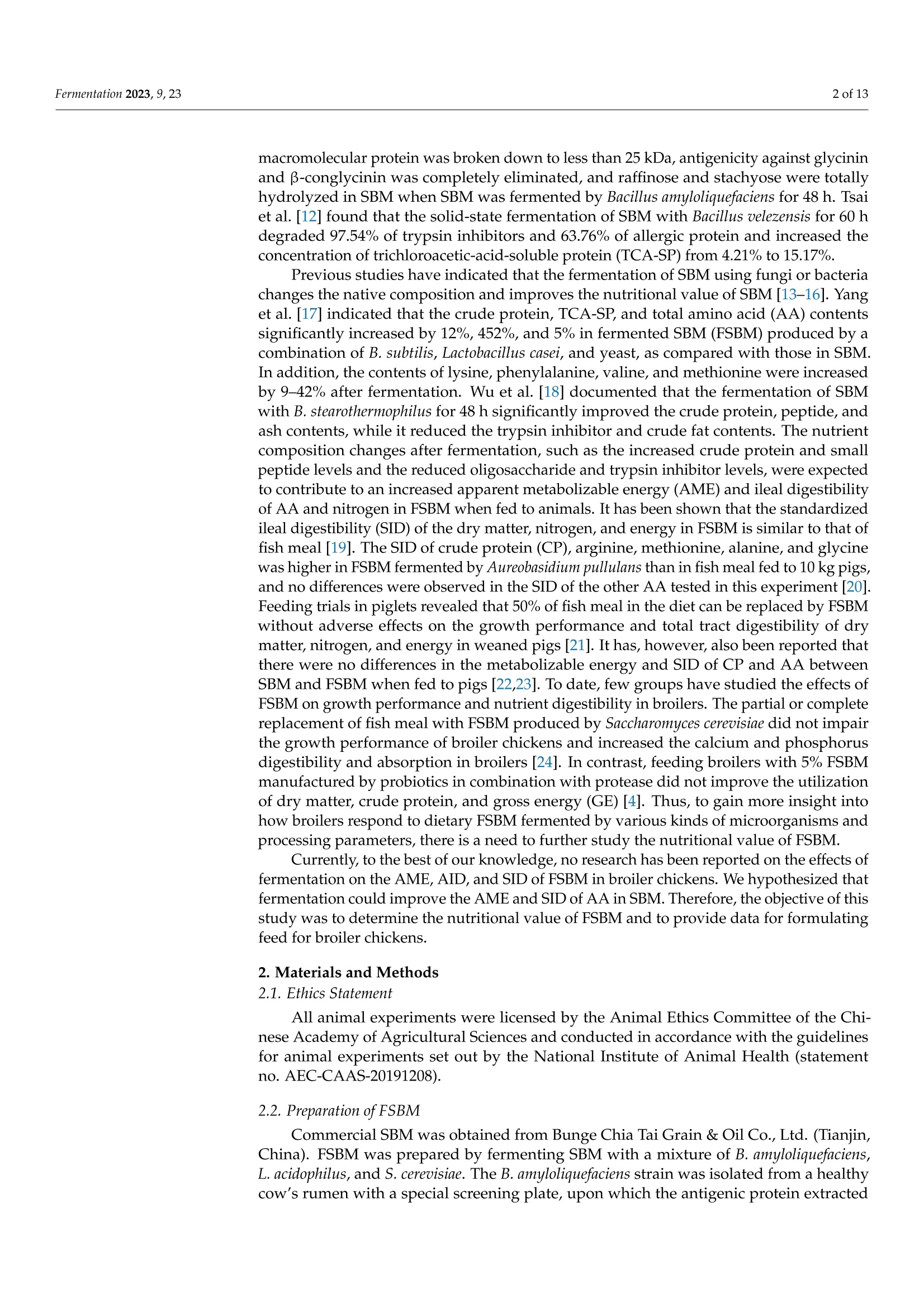

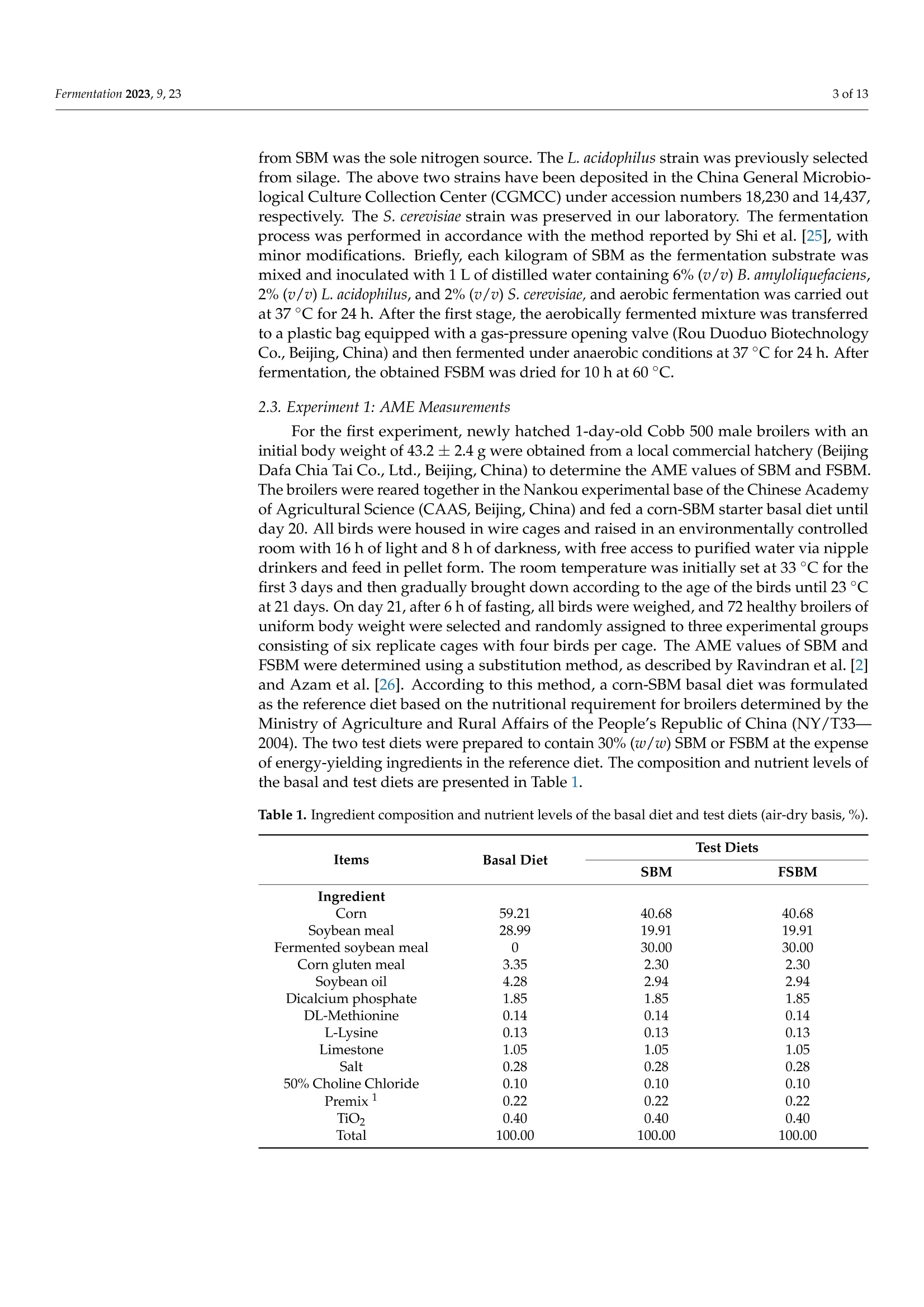

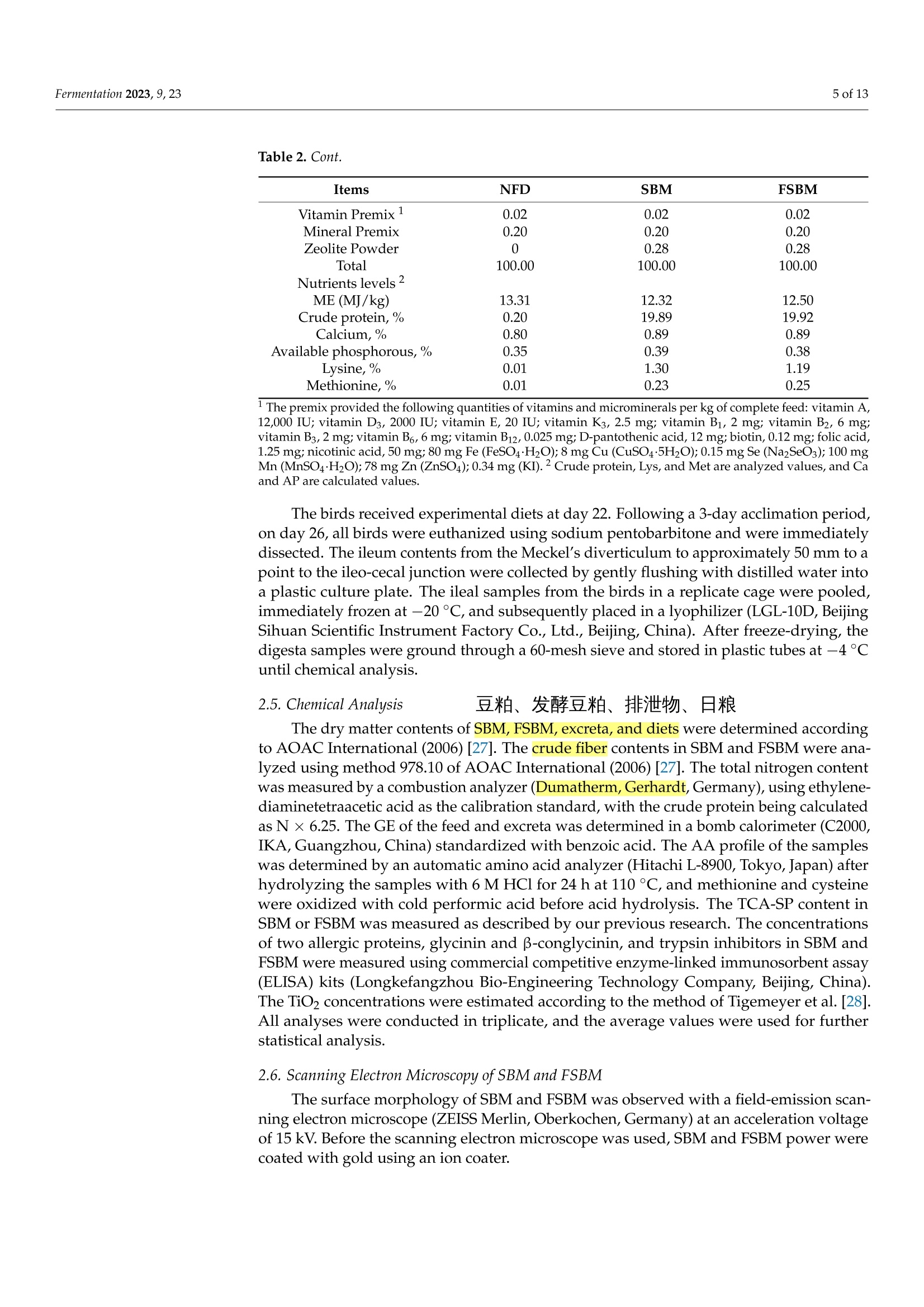

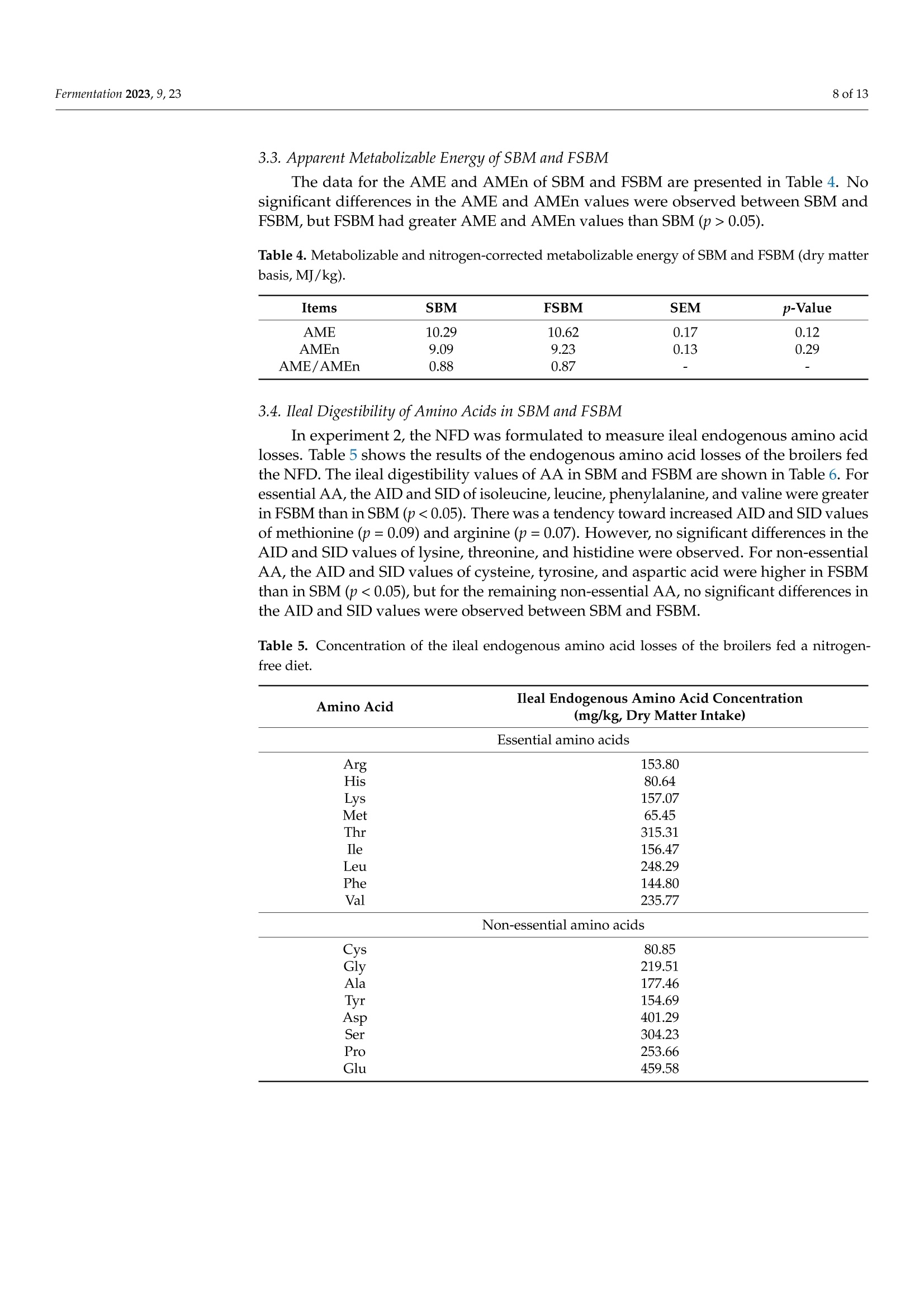

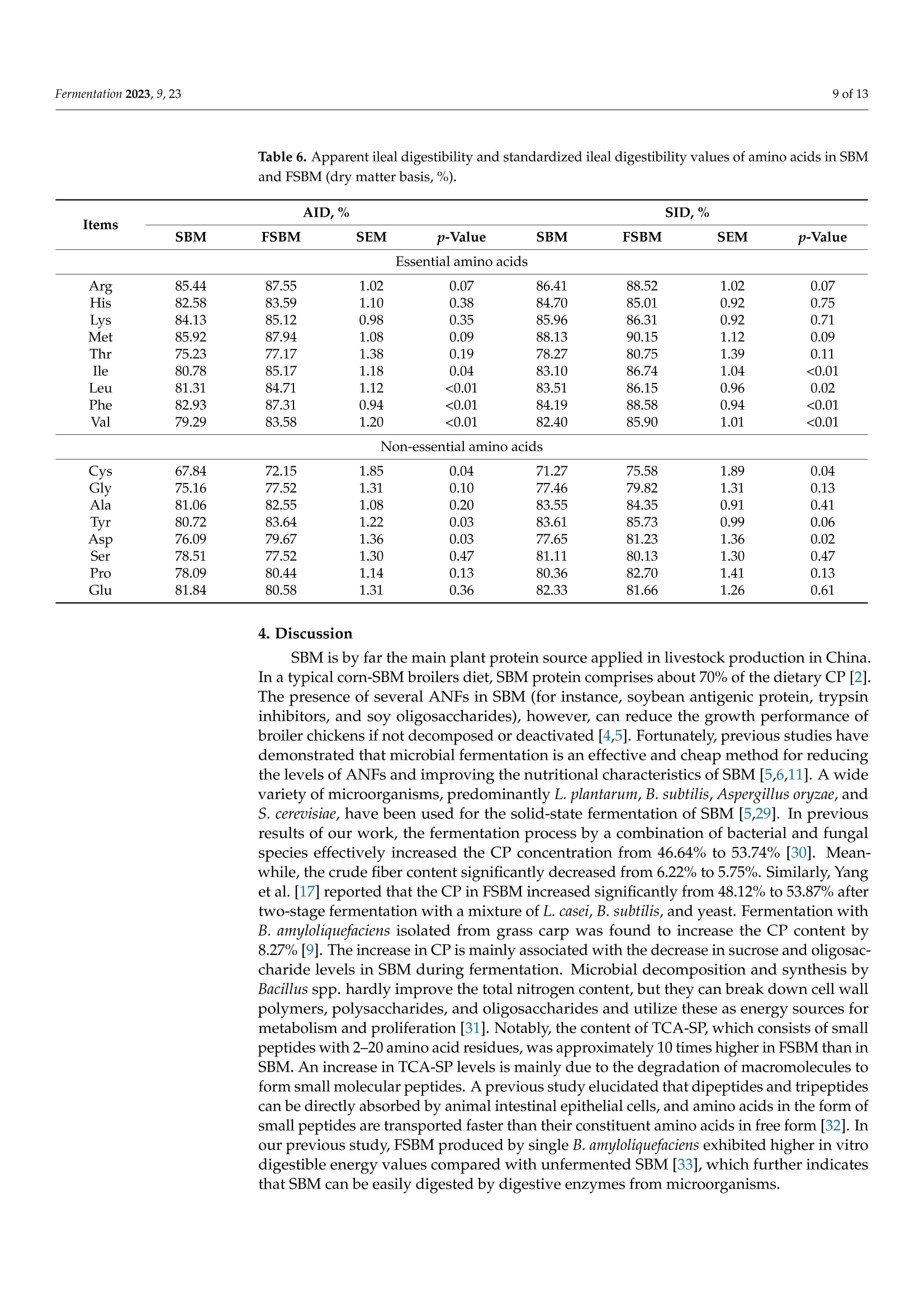

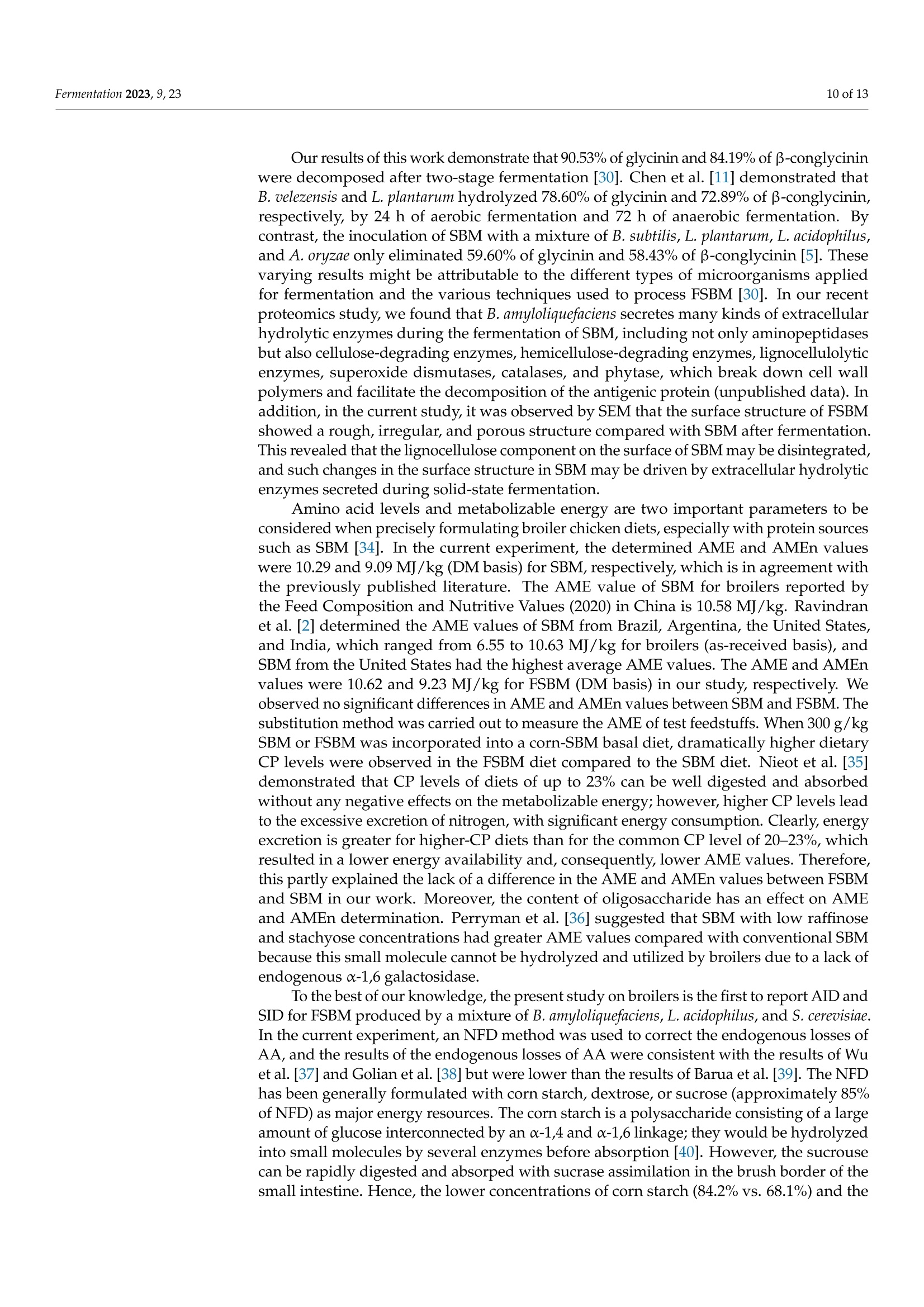

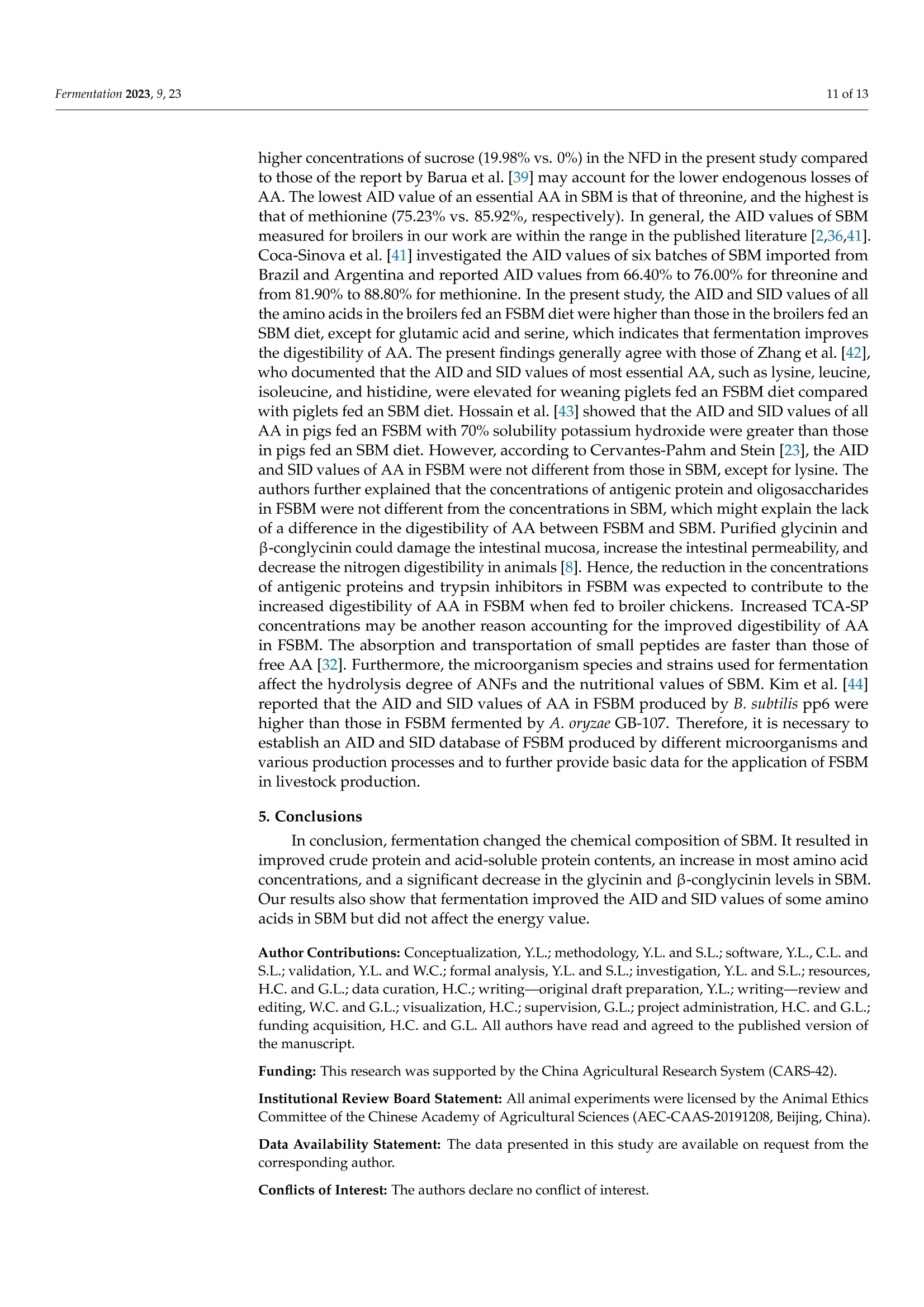

使用格哈特公司杜马斯燃烧法蛋白质测定仪 杜马森DUMATHERM和纤维仪器检测豆粕、发酵豆粕、排泄物、日粮的蛋白质和粗纤维含量。MDPIfermentation 2 of 13Fermentation 2023,9,23 Citation: Li, Y.; Li, S.; Li, C.;Chang,W.; Cai, H.; Liu, G. Effects ofFermentation on the ApparentMetabolizable Energy andStandardized Ileal Digestibility ofAmino Acids in Soybean Meal Fed toBroiler Chickens. Fermentation 2023,9,23. https://doi.org/10.3390/ fermentation9010023 Academic Editor: Michela Verni Received: 15 November 2022 Revised: 19 December 2022 Accepted: 20 December 2022 Published: 27 December 2022 Copyright: @ 2022 by the authors.Licensee MDPI, Basel, Switzerland.This article is an open access articledistributed under the terms andconditions of the Creative CommonsAttribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/) The Key Laboratory of Feed Biotechnology of Ministry of Agriculture, National Engineering Research Centerof Biological Feed, Feed Research Institute, Chinese Academy of Agricultural Sciences, Beijing 100081, China 2 Precision Livestock and Nutrition Laboratory, Teaching and Research Centre (TERRA), Gembloux Agro-BioTech, University of Liege, 5030 Gembloux, Belgium *Correspondence: liuguohua@caas.cn; Tel.: +86-10-8210-7727十 These authors contributed equally to this work. Abstract: Two experiments were conducted to test the hypothesis that the apparent metabolizableenergy (AME) and standardized ileal digestibility (SID) of amino acids (AA) in fermented soybeanme (FSBM)) .are greater than those in soybean meal (SBM). FSBM was produced by fermentingSBM with a mixture of Bacillus amyloliquefaciens, Lactobacillus acidophilus, and Saccharomyces cerevisiae.The fermentation process decreased trypsin inhibitor and crude fiber levels by 67.80% and 7.56%,while it increased the total amino acid content by 2.56%. In the first experiment, a substitutionmethod was used to determine the AME and nitrogen-corrected AME (AMEn) of SBM and FSBM. Acorn-SBM basal diet and two test diets consisting of 70% of the basal diet plus 30% SBM or FSBMwere formulated. The results show that fermentation did not have an effect on the AME and AMEnconcentrations of SBM (p >0.05); the respective AME and AMEn values were 10.29 and 10.62 MJ/kg(DM basis) and 9.09 and 9.23 MJ/kg for SBM and FSBM. In the second experiment, a nitrogen-free dietwas formulated to measure the endogenous AA flow, and the other two semi-purified diets containingSBM or FSBM as the sole source of AA were formulated. The results show that the AID and SID ofisoleucine, leucine, phenylalanine, valine, cysteine, tyrosine, and aspartic acid were greater in FSBMthan in SBM (p<0.05). In conclusion, the fermentation of SBM by a mixture of B. amyloliquefaciens,L. acidophilus, and S. cerevisiae can improve its nutritional values and is a promising protein resourcefor broiler production. Keywords: soybean meal; fermentation; metabolizable energy; standardized ileal digestibility ofamino acids; broilers 1. Introduction Soybean meal (SBM), a remaining byproduct after oil extraction from soy seed, is themost widely used plant-derived protein source in the food and feed industries because ofits relatively well-balanced amino acid profile, low price, and steady supply [1-3]. How-ever, SBM contains a variety of anti-nutritional factors (ANFs), such as soybean antigenicproteins, non-starch polysaccharides, trypsin inhibitors, and other factors that can impedethe digestion, absorption, and utilization of its nutrients and have detrimental effects onanimal health, especially on young animals [4-6]. The antigenic proteins glycinin andB-conglycinin are known to directly affect intestinal epithelial permeability by inhibitingthe proliferation and destroying the cytoskeleton of intestinal cells, and they elicit an inflam-matory response via promoting the secretion of inflammatory cytokines [7,8]. Extensivestudies have shown that solid-state microbial fermentation is an effective technique forimproving the nutritional quality of SBM by decreasing the concentration of ANFs andincreasing nutrient bioavailability [9-12]. According to Medeiros et al. [9], the soybean macromolecular protein was broken down to less than 25 kDa, antigeniICciittyy against glycininand B-conglycinin was completely eliminated, and raffinose and stachyose were totallyhydrolyzed in SBM when SBM was fermented by Bacillus amyloliquefaciens for 48 h. Tsaiet al. [12] found that the solid-state fermentation of SBM with Bacillus velezensis for 60 hdegraded 97.54% of trypsin inhibitors and 63.76% of allergic protein and increased theconcentration of trichloroacetic-acid-soluble protein (TCA-SP) from 4.21% to 15.17%. Currently, to the best of our knowledge, no research has been reported on the effects offermentation on the AME, AID, and SID of FSBM in broiler chickens. We hypothesized thatfermentation could improve the AME and SID of AA in SBM. Therefore, the objective of thisstudy was to determine the nutritional value of FSBM and to provide data for formulatingfeed for broiler chickens. 2. Materials and Methods 2.1. Ethics Statement All animal experiments were licensed by the Animal Ethics Committee of the Chi-nese Academy of Agricultural Sciences and conducted in accordance with the guidelinesfor animal experiments set out by the National Institute of Animal Health (statementno.AEC-CAAS-20191208). 2.2. Preparation ofFSBM Commercial SBM was obtained from Bunge Chia Tai Grain & Oil Co., Ltd. (Tianjin,China). FSBM was prepared by fermenting SBM with a mixture of B. amyloliquefaciens,L. acidophilus, and S. cerevisiae. The B. amyloliquefaciens strain was isolated from a healthycow's rumen with a special screening plate, upon which the antigenic protein extracted from SBM was the sole nitrogen source. The L. acidophilus strain was previously selectedfrom silage. The above two strains have been deposited in the China General Microbio-logical Culture Collection Center (CGMCC) under accession numbers 18,230 and 14,437,respectively. The S. cerevisiae strain was preserved in our laboratory. The fermentationprocess was performed in accordance with the method reported by Shi et al. [25], withminor modifications. Briefly, each kilogram of SBM as the fermentation substrate wasmixed and inoculated with 1 L of distilled water containing 6% (v/v) B. amyloliquefaciens,2%(v/v) L. acidophilus, and 2% (v/v) S. cerevisiae, and aerobic fermentation was carried outat 37 °C for 24 h. After the first stage, the aerobically fermented mixture was transferredto a plastic bag equipped with a gas-pressure opening valve (Rou Duoduo BiotechnologyCo., Beijing, China) and then fermented under anaerobic conditions at 37 °C for 24 h. Afterfermentation, the obtained FSBM was dried for 10 h at 60°C. 2.3. Experiment 1: AME Measurements For the first experiment, newly hatched 1-day-old Cobb 500 male broilers with aninitial body weight of 43.2 ± 2.4 g were obtained from a local commercial hatchery (BeijingDafa Chia Tai Co., Ltd., Beijing, China) to determine the AME values of SBM and FSBM.The broilers were reared together in the Nankou experimental base of the Chinese Academyof Agricultural Science (CAAS, Beijing, China) and fed a corn-SBM starter basal diet untilday 20. All birds were housed in wire cages and raised in an environmentally controlledroom with 16 h of light and 8 h of darkness, with free access to purified water via nippledrinkers and feed in pellet form. The room temperature was initially set at 33℃ for thefirst 3 days and then gradually brought down according to the age of the birds until 23°℃at 21 days. On day 21, after 6 h of fasting, all birds were weighed, and 72 healthy broilers ofuniform body weight were selected and randomly assigned to three experimental groupsconsisting of six replicate cages with four birds per cage. The AME values of SBM andFSBM were determined using a substitution method, as described by Ravindran et al. [2]and Azam et al. [26]. According to this method, a corn-SBM basal diet was formulatedas the reference diet based on the nutritional requirement for broilers determined by theMinistry of Agriculture and Rural Affairs of the People's Republic of China (NY/T332004). The two test diets were prepared to contain 30% (w/w) SBM or FSBM at the expenseof energy-yielding ingredients in the reference diet. The composition and nutrient levels ofthe basal and test diets are presented in Table 1. Table 1. Ingredient composition and nutrient levels of the basal diet and test diets (air-dry basis,%). ltems Basal Diet Test Diets SBM FSBM Ingredient Corn 59.21 40.68 40.68 Soybean meal 28.99 19.91 19.91 Fermented soybean meal 0 30.00 30.00 Corn gluten meal 3.35 2.30 2.30 Soybean oil 4.28 2.94 2.94 Dicalcium phosphate 1.85 1.85 1.85 DL-Methionine 0.14 0.14 0.14 L-Lysine 0.13 0.13 0.13 Limestone 1.05 1.05 1.05 Salt 0.28 0.28 0.28 50% Choline Chloride 0.10 0.10 0.10 Premix· 0.22 0.22 0.22 TiO2 0.40 0.40 0.40 Total 100.00 100.00 100.00 Table 1. Cont. ltems Basal Diet Test Diets SBM FSBM Nutrient level AME (MJ/kg) 12.96 11.95 11.95 Crude protein, 20.00 27.73 29.86 Calcium,% 0.90 0.87 0.87 Available phosphorous,% 0.40 0.38 0.38 Lysine,% 1.00 1.53 1.53 Methionine,% 0.40 0.51 0.51 1The premix provided the following quantities of vitamins and microminerals per kg of complete feed: vitamin A,12,000 IU; vitamin D3, 2000 IU; vitamin E, 20 IU; vitamin K3, 2.5 mg; vitamin B1, 2 mg; vitamin B2, 6 mg;vitamin B3, 2 mg; vitamin B6, 6 mg; vitamin B12, 0.025 mg; D-pantothenic acid, 12 mg; biotin, 0.12 mg; folic acid,1.25 mg; nicotinic acid, 50 mg; 80 mg Fe (FeSO H2O);8 mg Cu (CuSO45H2O); 0.15 mg Se (NazSeO3);100 mgMn (MnSO4·H2O);78 mg Zn (ZnSO4); 0.34 mg (KI). 2 Crude protein is the analyzed value, and Ca, AP, Lys, andMet are the calculated values. The AME was measured using the classical total excreta collection method. Thebirds were provided experimental diets at 22 days, followed by a 4-day adaptation period.From 26 to 30 days, the total excreta were collected daily (free from feed and feathercontamination), weighed, pooled within a cage, and stored at -20 °C. The collected excretawere pooled and thoroughly mixed for each cage over 4 days and then oven-dried. Thedried excreta were ground, passed through a 60-mesh screen, and stored at 4°C beforelaboratory analysis. The average daily feed intake was monitored for each treatment. 2.4. Experiment 2: Ileal Digestibility Measurements For the second experiment, 120 1-day-old Cobb 500 male broilers were purchased froma local commercial hatchery (Beijing Dafa Chia Tai Co., Ltd., Beijing, China) to measurethe ileal digestibility of the AA in SBM and FSBM. All broilers were raised together andreceived a corn-SBM basal diet from 1 to 22 days. On day 22, after 6 h of fasting, allbirds were weighed, and 108 healthy broilers with a similar average body weight wereselected and randomly allocated to three experimental groups consisting of six replicatecages with six birds per cage. A nitrogen-free diet (NFD) was formulated to measure theendogenous AA flow, and the other two semi-purified diets were formulated to contain20% crude protein, resulting in inclusion levels of 42.62% and 36.86% for SBM and FSBM,respectively. All experimental diets were balanced in terms of phosphorus and calciumand supplemented with equal contents of mineral and vitamin premix. Each diet contained0.4% titanium dioxide (TiO2) as an exogenous digestible marker. The composition andnutrient levels of the NFD and experimental diets are shown in Table 2. The broilers’feeding conditions were consistent with those in Experiment 1. Table 2. Ingredient composition and nutrient levels of the nitrogen-free, soybean meal, and fermentedsoybean meal diets (air-dry basis,%). ltems NFD SBM FSBM Soybean meal 42.62 C Fermented soybean meal 00 0 36.86 Corn starch 68.10 40.18 45.94 Sucrose 19.98 10.00 10.00 Crystallitic cellulose 5.00 0 C0 Soybean oil 3.00 3.00 3.00 Dicalcium phosphate 1.90 1.90 1.90 Limestone 1.00 1.00 1.00 Salt 0.30 0.30 0.30 50% Choline 0.10 0.10 0.10 TiO2 0.40 0.40 0.40 Table 2. Cont. ltems NFD SBM FSBM Vitamin Premix· 0.02 0.02 0.02 Mineral Premix 0.20 0.20 0.20 Zeolite Powder 0 0.28 0.28 Total 100.00 100.00 100.00 Nutrients levels ME (MJ/kg) 13.31 12.32 12.50 Crude protein,% 0.20 19.89 19.92 Calcium,% 0.80 0.89 0.89 Available phosphorous,% 0.35 0.39 0.38 Lysine,% 0.01 1.30 1.19 Methionine,% 0.01 0.23 0.25 The premix provided the following quantities of vitamins and microminerals per kg of complete feed: vitamin A,12,000 IU; vitamin D3, 2000 IU; vitamin E, 20 IU; vitamin K3, 2.5 mg; vitamin B1, 2 mg; vitamin B2, 6 mg;vitamin B3, 2 mg; vitamin B6,6 mg; vitamin B12, 0.025 mg; D-pantothenic acid, 12 mg; biotin, 0.12 mg; folic acid,1.25 mg; nicotinic acid, 50 mg;80 mg Fe (FeSO4H2O);8 mg Cu (CuSO45H2O);0.15 mg Se (NazSeO3);100 mgMn (MnSO4H2O);78 mg Zn (ZnSO4); 0.34 mg (KI).2 Crude protein, Lys, and Met are analyzed values, and Caand AP are calculated values. The birds received experimental diets at day 22. Following a 3-day acclimation period,on day 26, all birds were euthanized using sodium pentobarbitone and were immediatelydissected. The ileum contents from the Meckel’s diverticulum to approximately 50 mm to apoint to the ileo-cecal junction were collected by gently flushing with distilled water intoa plastic culture plate. The ileal samples from the birds in a replicate cage were pooled,immediately frozen at -20 C, and subsequently placed in a lyophilizer (LGL-10D, BeijingSihuan Scientific Instrument Factory Co., Ltd., Beijing, China). After freeze-drying, thedigesta samples were ground through a 60-mesh sieve and stored in plastic tubes at -4℃until chemical analysis. 2.5. Chemical Analysis 豆粕、发酵豆粕、排泄物、日粮 The dry matter contents of SBM, FSBM, excreta, and diets were determined accordingto AOAC International (2006) [27]. The crude fiber contents in SBM and FSBM were ana-lyzed using method 978.10 of AOAC International (2006) [27]. The total nitrogen contentwas measured by a combustion analyzer (Dumatherm, Gerhardt, Germany), using ethylene-diaminetetraacetic acid as the calibration standard, with the crude protein being calculatedas N × 6.25. The GE of the feed and excreta was determined in a bomb calorimeter (C2000,IKA, Guangzhou, China) standardized with benzoic acid. The AA profile of the sampleswas determined by an automatic amino acid analyzer (Hitachi L-8900, Tokyo, Japan) afterhydrolyzing the samples with 6 M HCl for 24 h at 110 °C, and methionine and cysteinewere oxidized with cold performic acid before acid hydrolysis. The TCA-SP content inSBM or FSBM was measured as described by our previous research. The concentrationsof two allergic proteins, glycinin and B-conglycinin, and trypsin inhibitors in SBM andFSBM were measured using commercial competitive enzyme-linked immunosorbent assay(ELISA) kits (Longkefangzhou Bio-Engineering Technology Company, Beijing, China).The TiO2 concentrations were estimated according to the method of Tigemeyer et al. [28].All analyses were conducted in triplicate, and the average values were used for furtherstatistical analysis. 2.6. Scanning Electron Microscopy of SBM and FSBM The surface morphology of SBM and FSBM was observed with a field-emission scan-ning electron microscope (ZEISS Merlin, Oberkochen, Germany) at an acceleration voltageof 15 kV. Before the scanning electron microscope was used, SBM and FSBM power werecoated with gold using an ion coater. 2.7. Calculations The AME values of SBM and FSBM were calculated using the following formulas: AMEdiet (MJ/kg)= ((feed intake x GEdiet) - (excreta output xGEexcreta))/feed intake(1) AMEn (MJ/kg)=AMESBM or FSBM -8.22×((feed intake ×Ndiet) - (excreta output xNexcreta))/feed intake(3) where GE is the gross energy and N is the nitrogen content. AMEn is the apparent metaboliz-able energy of diets corrected by N, and 8.22 is the nitrogen correction factor for broilers. The AID values of SBM and FSBM were calculated as follows: AID (%)=1 - (TiO2 in diet/TiO2 in ileal digesta) × (amino acid in ileal digesta/amino acid in diet) (4) The AID values were converted to SID values using the basal endogenous ileal aminoacid loss values obtained from the birds fed the NFD diet: ileal amino acid content (mg/kg,DM intake)=(amino acid in ileal digesta) x (TiO2 in diet/TiO2 in ileal digesta) (5) SID (%)= AID (%)+(ileal amino acid content/amino acid in raw material)×100%(6) 2.8. Statistical Analysis All statistical analyses were performed with SPSS 19.0 (SPSS Inc., Chicago,IL, USA).The data for the chemical composition of SBM and FSBM, the AME measurements, and theileal digestibility measurements were analyzed using Student's t-test. Differences betweenthe means were considered significant at p <0.05. 3. Results 3.1. Effects of Fermentation on the Chemical Composition and Total Amino Acids of SBM Table 3 shows the chemical composition and total amino acids of SBM and FSBM. Thetrypsin inhibitor and crude fiber contents in FSBM were significantly decreased by 67.80%and7.56%, respectively, compared with SBM. An increase of 2.56% in the total amino acid contentwas found in FSBM compared with SBM. Among the essential amino acids, the methionine,isoleucine, leucine, phenylalanine, and valine contents in FSBM were significantly increasedby 17.47%, 5.04%, 5.42%, 11.03%, and 9.05%, respectively. Among non-essential aminoacids, the glycine, alanine, tyrosine, proline, and glutamic acid contents were increasedby 5.01%,13.64%,5.52%,11.47%,and 12.98%, respectively, as compared to those in SBM.However, the arginine, threonine, cysteine, and serine contents were lower in FSBM. Table 3. The crude protein, TCA-SP, antigenic protein, and amino acid contents of SBM and FSBM(air-dry basis, %). Items SBM FSBM Change,% Trypsion inhibitors, mg/g Crude fiber,% 25.87 8.33 -67.80 6.22 5.75 -7.56 Essential amino acid Arg 3.65 2.85 -21.73 His 1.31 1.33 1.73 Lys 3.06 3.12 1.80 Met 0.47 0.55 17.47 Thr 2.08 1.94 -6.79 Ile 2.38 2.50 5.04 Leu 4.03 4.25 5.42 Phe 2.55 2.83 11.03 Val 2.68 2.92 9.05 Table 3. Cont. ltems SBM FSBM Change,% Non-essential amino acids Cys 0.89 0.56 -37.76 Gly 2.21 2.32 5.01 Ala 2.26 2.57 13.64 Tyr 1.63 1.72 5.52 Asp 5.99 6.05 0.97 Ser 2.75 2.14 -22.04 Pro 2.54 2.84 11.47 Glu 9.92 11.21 12.98 EAA 22.20 22.28 0.39 NEAA 28.20 29.40 4.27 Total 50.39 51.68 2.56 3.2. Microscopic Obseruation Scanning electron microscopy (SEM) was carried out to assess the physical structuresof SBM and FSBM. Figure 1 shows the morphological features of SBM and FSBM atmagnification factors of 400× and 3000×. It can be seen that FSBM had fragmental,cracked, and plurilocular structures, whereas SBM had relatively large, compact, andsmooth structures. Figure 1. Scanning electron microscopy images of SBM and FSBM: (A) unfermented SBM (400×),(B) unfermented SBM (3000×), (C) FSBM (400×), (D) FSBM (3000×). 3.3. Apparent Metabolizable Energy of SBM and FSBM The data for the AME and AMEn of SBM and FSBM are presented in Table 4. Nosignificant differences in the AME and AMEn values were observed between SBM andFSBM, but FSBM had greater AME and AMEn values than SBM (p>0.05). Table 4. Metabolizable and nitrogen-corrected metabolizable energy of SBM and FSBM (dry matterbasis,MJ/kg). Items SBM FSBM SEM p-Value AME 10.29 10.62 0.17 0.12 AMEn 9.09 9.23 0.13 0.29 AME/AMEn 0.88 0.87 一 3.4. Ileal Digestibility of Amino Acids in SBM and FSBM In experiment 2, the NFD was formulated to measure ileal endogenous amino acidlosses. Table 5 shows the results of the endogenous amino acid losses of the broilers fedthe NFD. The ileal digestibility values of AA in SBM and FSBM are shown in Table 6. Foressential AA, the AID and SID of isoleucine, leucine, phenylalanine, and valine were greaterin FSBM than in SBM (p <0.05). There was a tendency toward increased AID and SID valuesof methionine (p=0.09) and arginine (p=0.07). However, no significant differences in theAID and SID values of lysine, threonine, and histidine were observed. For non-essentialAA, the AID and SID values of cysteine, tyrosine, and aspartic acid were higher in FSBMthan in SBM (p<0.05), but for the remaining non-essential AA, no significant differences inthe AID and SID values were observed between SBM and FSBM. Table 5. Concentration of the ileal endogenous amino acid losses of the broilers fed a nitrogen-free diet. Amino Acid Ileal Endogenous Amino Acid Concentration(mg/kg, Dry Matter Intake) Essential amino acids Arg 153.80 His 80.64 Lys 157.07 Met 65.45 Thr 315.31 Ile 156.47 Leu 248.29 Phe 144.80 Val 235.77 Non-essential amino acids Cys 80.85 Gly 219.51 Ala 177.46 lyr 154.69 Asp 401.29 Ser 304.23 Pro 253.66 Glu 459.58 Table 6. Apparent ileal digestibility and standardized ileal digestibility values of amino acids in SBMand FSBM (dry matter basis,%). Items AID,% SID,% SBM FSBM SEM p-Value SBM FSBM SEM p-Value Essential amino acids Arg 85.44 87.55 1.02 0.07 86.41 88.52 1.02 0.07 His 82.58 83.59 1.10 0.38 84.70 85.01 0.92 0.75 Lys 84.13 85.12 0.98 0.35 85.96 86.31 0.92 0.71 Met 85.92 87.94 1.08 0.09 88.13 90.15 1.12 0.09 Thr 75.23 77.17 1.38 0.19 78.27 80.75 1.39 0.11 Ile 80.78 85.17 1.18 0.04 83.10 86.74 1.04 <0.01 Leu 81.31 84.71 1.12 <0.01 83.51 86.15 0.96 0.02 Phe 82.93 87.31 0.94 <0.01 84.19 88.58 0.94 <0.01 Val 79.29 83.58 1.20 <0.01 82.40 85.90 1.01 <0.01 Non-essential amino acids Cys 67.84 72.15 1.85 0.04 71.27 75.58 1.89 0.04 Gly 75.16 77.52 1.31 0.10 77.46 79.82 1.31 0.13 Ala 81.06 82.55 1.08 0.20 83.55 84.35 0.91 0.41 Tyr 80.72 83.64 1.22 0.03 83.61 85.73 0.99 0.06 Asp 76.09 79.67 1.36 0.03 77.65 81.23 1.36 0.02 Ser 78.51 77.52 1.30 0.47 81.11 80.13 1.30 0.47 Pro 78.09 80.44 1.14 0.13 80.36 82.70 1.41 0.13 Glu 81.84 80.58 1.31 0.36 82.33 81.66 1.26 0.61 4. Discussion SBM is by far the main plant protein source applied in livestock production in China.In a typical corn-SBM broilers diet, SBM protein comprises about 70% of the dietary CP [2].The presence of several ANFs in SBM (for instance, soybean antigenic protein, trypsininhibitors, and soy oligosaccharides), however, can reduce the growth performance ofbroiler chickens if not decomposed or deactivated [4,5]. Fortunately, previous studies havedemonstrated that microbial fermentation is an effective and cheap method for reducingthe levels of ANFs and improving the nutritional characteristics of SBM [5,6,11]. A widevariety of microorganisms, predominantly L. plantarum, B. subtilis, Aspergillus oryzae, andS. cerevisiae, have been used for the solid-state fermentation of SBM [5,29]. In previousresults of our work, the fermentation process by a combination of bacterial and fungalspecies effectively increased the CP concentration from 46.64% to 53.74% [30]. Mean-while, the crude fiber content significantly decreased from 6.22% to 5.75%. Similarly, Yanget al. [17] reported that the CP in FSBM increased significantly from 48.12% to 53.87% aftertwo-stage fermentation with a mixture of L. casei, B. subtilis, and yeast. Fermentation withB. amyloliquefaciens isolated from grass carp was found to increase the CP content by8.27%[9]. The increase in CP is mainly associated with the decrease in sucrose and oligosac-charide levels in SBM during fermentation. Microbial decomposition and synthesis byBacillus spp. hardly improve the total nitrogen content, but they can break down cell wallpolymers, polysaccharides, and oligosaccharides and utilize these as energy sources formetabolism and proliferation [31]. Notably, the content of TCA-SP, which consists of smallpeptides with 2-20 amino acid residues, was approximately 10 times higher in FSBM than inSBM. An increase in TCA-SP levels is mainly due to the degradation of macromolecules toform small molecular peptides. A previous study elucidated that dipeptides and tripeptidescan be directly absorbed by animal intestinal epithelial cells, and amino acids in the form ofsmall peptides are transported faster than their constituent amino acids in free form [32]. Inour previous study, FSBM produced by single B. amyloliquefaciens exhibited higher in vitrodigestible energy values compared with unfermented SBM [33], which further indicatesthat SBM can be easily digested by digestive enzymes from microorganisms. Our results of this work demonstrate that 90.53% of glycinin and 84.19% of B-conglycininwere decomposed after two-stage fermentation [30]. Chen et al. [11] demonstrated thatB. velezensis and L. plantarum hydrolyzed 78.60% of glycinin and 72.89% of B-conglycinin,respectively, by 24 h of aerobic fermentation and 72 h of anaerobic fermentation. Bycontrast, the inoculation of SBM with a mixture of B. subtilis, L. plantarum, L. acidophilus,and A. oryzae only eliminated 59.60% of glycinin and 58.43% of β-conglycinin [5]. Thesevarying results might be attributable to the different types of microorganisms appliedfor fermentation and the various techniques used to process FSBM [30]. In our recentproteomics study, we found that B. amyloliquefaciens secretes many kinds of extracellularhydrolytic enzymes during the fermentation of SBM, including not only aminopeptidasesbut also cellulose-degrading enzymes, hemicellulose-degrading enzymes, lignocellulolyticenzymes, superoxide dismutases, catalases, and phytase, which break down cell wallpolymers and facilitate the decomposition of the antigenic protein (unpublished data). Inaddition, in the current study, it was observed by SEM that the surface structure of FSBMshowed a rough, irregular, and porous structure compared with SBM after fermentation.This revealed that the lignocellulose component on the surface of SBM may be disintegrated,and such changes in the surface structure in SBM may be driven by extracellular hydrolyticenzymes secreted during solid-state fermentation. Amino acid levels and metabolizable energy are two important parameters to beconsidered when precisely formulating broiler chicken diets, especially with protein sourcessuch as SBM [34]. In the current experiment, the determined AME and AMEn valueswere 10.29 and 9.09 MJ/kg (DM basis) for SBM, respectively, which is in agreement withthe previously published literature. The AME value of SBM for broilers reported bythe Feed Composition and Nutritive Values (2020) in China is 10.58 MJ/kg. Ravindranet al. [2] determined the AME values of SBM from Brazil, Argentina, the United States,and India, which ranged from 6.55 to 10.63 MJ/kg for broilers (as-received basis), andSBM from the United States had the highest average AME values. The AME and AMEnvalues were 10.62 and 9.23 MJ/kg for FSBM (DM basis) in our study, respectively. Weobserved no significant differences in AME and AMEn values between SBM and FSBM. Thesubstitution method was carried out to measure the AME of test feedstuffs. When 300 g/kgSBM or FSBM was incorporated into a corn-SBM basal diet, dramatically higher dietaryCP levels were observed in the FSBM diet compared to the SBM diet. Nieot et al. [35]demonstrated that CP levels of diets of up to 23% can be well digested and absorbedwithout any negative effects on the metabolizable energy; however, higher CP levels leadto the excessive excretion of nitrogen, with significant energy consumption. Clearly, energyexcretion is greater for higher-CP diets than for the common CP level of 20-23%, whichresulted in a lower energy availability and, consequently, lower AME values. Therefore,this partly explained the lack of a difference in the AME and AMEn values between FSBMand SBM in our work. Moreover, the content of oligosaccharide has an effect on AMEand AMEn determination. Perryman et al. [36] suggested that SBM with low raffinoseand stachyose concentrations had greater AME values compared with conventional SBMbecause this small molecule cannot be hydrolyzed and utilized by broilers due to a lack ofendogenous α-1,6 galactosidase. higher concentrations of sucrose (19.98% vs. 0%) in the NFD in the present study comparedto those of the report by Barua et al. [39] may account for the lower endogenous losses ofAA. The lowest AID value of an essential AA in SBM is that of threonine, and the highest isthat of methionine (75.23% vs. 85.92%, respectively). In general, the AID values of SBMmeasured for broilers in our work are within the range in the published literature [2,36,41].Coca-Sinova et al. [41] investigated the AID values of six batches of SBM imported fromBrazil and Argentina and reported AID values from 66.40% to 76.00% for threonine andfrom 81.90% to 88.80% for methionine. In the present study, the AID and SID values of allthe amino acids in the broilers fed an FSBM diet were higher than those in the broilers fed anSBM diet, except for glutamic acid and serine, which indicates that fermentation improvesthe digestibility of AA. The present findings generally agree with those of Zhang et al. [42],who documented that the AID and SID values of most essential AA, such as lysine, leucine,isoleucine, and histidine, were elevated for weaning piglets fed an FSBM diet comparedwith piglets fed an SBM diet. Hossain et al. [43] showed that the AID and SID values of allAA in pigs fed an FSBM with 70% solubility potassium hydroxide were greater than thosein pigs fed an SBM diet. However, according to Cervantes-Pahm and Stein [23], the AIDand SID values of AA in FSBM were not different from those in SBM, except for lysine. Theauthors further explained that the concentrations of antigenic protein and oligosaccharidesin FSBM were not different from the concentrations in SBM, which might explain the lackof a difference in the digestibility of AA between FSBM and SBM. Purified glycinin andB-conglycinin could damage the intestinal mucosa, increase the intestinal permeability, anddecrease the nitrogen digestibility in animals [8]. Hence, the reduction in the concentrationsof antigenic proteins and trypsin inhibitors in FSBM was expected to contribute to theincreased digestibility of AA in FSBM when fed to broiler chickens. Increased TCA-SPconcentrations may be another reason accounting for the improved digestibility of AAin FSBM. The absorption and transportation of small peptides are faster than those offree AA [32]. Furthermore, the microorganism species and strains used for fermentationaffect the hydrolysis degree of ANFs and the nutritional values of SBM. Kim et al. [44]reported that the AID and SID values of AA in FSBM produced by B. subtilis pp6 werehigher than those in FSBM fermented by A. oryzae GB-107. Therefore, it is necessary toestablish an AID and SID database of FSBM produced by different microorganisms andvarious production processes and to further provide basic data for the application of FSBMin livestock production. 5. Conclusions In conclusion, fermentation changed the chemical composition of SBM. It resulted inimproved crude protein and acid-soluble protein contents, an increase in most amino acidconcentrations, and a significant decrease in the glycinin and β-conglycinin levels in SBM.Our results also show that fermentation improved the AID and SID values of some aminoacids in SBM but did not affect the energy value. Author Contributions: Conceptualization, Y.L.; methodology, Y.L. and S.L.; software, Y.L., C.L. andS.L.; validation, Y.L. and W.C.; formal analysis, Y.L. and S.L.; investigation, Y.L. and S.L.; resources,H.C. and G.L.; data curation, H.C.; writing-original draft preparation, Y.L.; writing-review andediting, W.C. and G.L.; visualization, H.C.; supervision, G.L.; project administration, H.C. and G.L.;funding acquisition, H.C. and G.L. All authors have read and agreed to the published version ofthe manuscript. Funding: This research was supported by the China Agricultural Research System (CARS-42). Institutional Review Board Statement: All animal experiments were licensed by the Animal EthicsCommittee of the Chinese Academy of Agricultural Sciences (AEC-CAAS-20191208, Beijing, China). Data Availability Statement: The data presented in this study are available on request from thecorresponding author Conflicts of Interest: The authors declare no conflict of interest. References 1 Yang, H.; Qu, Y.; Li, J.; Liu, X.; Wu, R.; Wu,J. Improvement of the protein quality and degradation of allergens in soybean meal bycombination fermentation and enzymatic hydrolysis. LWT 2020, 128,109442. [CrossRef] 2 Ravindran, V.; Abdollahi, M.R.; Bootwalla, S.M. Nutrient analysis, metabolizable energy, and digestible amino acids of soybeanmeals of different origins for broilers. Poult. Sci. 2014,93,2567-2577.[CrossRef] 3. Liu, W.; Liu, G.H.; Liao, R.B.; Chang, Y.L.; Huang, X.Y.; Wu, Y.B.; Yang, H.M.; Yan, H.J.;Cai, H.Y. Apparent metabolizable and netenergy values of corn and soybean meal for broiler breeding cocks. Poult. Sci. 2017, 96, 135-143.[CrossRef] [PubMed] 4. Cheng, Y.; Hsiao, F.S.; Wen, C.; Wu, C.; Dybus, A.; Yu, Y.; Yu, Y. Mixed fermentation of soybean meal by protease and probioticsand its effects on the growth performance and immune response in broilers. J. Appl. Anim. Res. 2019,47,339-348. [CrossRef] 5. Soumeh, E.A.; Mohebodini, H.; Toghyani, M.; Shabani, A.; Ashayerizadeh, A.; Jazi, V. Synergistic effects of fermented soybeanmeal and mannan-oligosaccharide on growth performance, digestive functions, and hepatic gene expression in broiler chickens.Poult. Sci. 2019, 98, 6797-6807. [CrossRef 6. Catalán, N.; Villasante, A.; Wacyk, J.; Ramirez, C.; Romero,J. Fermented Soybean Meal Increases Lactic Acid Bacteria in GutMicrobiota of Atlantic Salmon (Salmo salar). Probiotics Antimicrob. Proteins 2018,10,566-576.[CrossRef] 7. Peng, C.;Cao, C.; He, M.; Shu, Y.;Tang, X.; Wang, Y.; Zhang, Y.; Xia, X.; Li, Y; Wu, J. Soybean Glycinin- and B-Conglycinin-InducedIntestinal Damage in Piglets via the p38/JNK/NF-KB Signaling Pathway. J. Agric. Food Chem. 2018, 66,9534-9541. [CrossRef] 8. Wu, JJ; Zhang, Y.; Dong, J.H.; Cao, C.M.; Li, B.; Feng, S.B.; Ding, H.Y.; Ma, L.Y.; Wang, X.C.; Li, Y. Allergens and intestinaldamage induced by soybean antigen proteins in weaned piglets. Ital. J. Anim. Sci. 2016,15,437-445. [CrossRef] 9. Medeiros, S.; Xie, J; Dyce, P.W.; Cai, H.Y.; Delange, K.; Zhang, H.; Li, J. Isolation of bacteria from fermented food and grass carpintestine and their efficiencies in improving nutrient value of soybean meal in solid state fermentation. J. Anim. Sci. Biotechnol.2018,9,29. [CrossRef] 10. Zhang, Y.; Shi, C.; Wang, C.; Lu, Z.; Wang, F.; Feng,J; Wang, Y. Effect of soybean meal fermented with Bacillus subtilis BS12 ongrowth performance and small intestinal immune status of piglets. Food Agric. Immunol.2018, 29, 133-146.[CrossRef] 11. Chen, L.;Zhao,Z.; Yu, W.; Zheng, L.;Li, L.; Gu, W.;Xu,H.; Wei, B.; Yan, X. Nutritional quality improvement of soybean meal byBacillus velezensis and Lactobacillus plantarum during two-stage solid- state fermentation. AMB Express 2021, 11, 23.[CrossRef][PubMed] 12. Tsai, C.F.; Lin, L.J.; Wang, C.H.; Tsai, C.S.; Chang, S.C.; Lee, T.T. Assessment of Intestinal Immunity and Permeability of Broilerson Partial Replacement Diets of Two-Stage Fermented Soybean Meal by Bacillus velezensis and Lactobacillus brevis ATCC 367.Animals 2021, 11,2336.[CrossRef] [PubMed] 13. Seo, S.; Cho, S. Changes in allergenic and antinutritional protein profiles of soybean meal during solid-state fermentation withBacillus subtilis. LWT 2016, 70,208-212. [CrossRef] 14. Wongputtisin, P.; Khanongnuch, C.; Khongbantad, W.; Niamsup, P.; Lumyong, S. Screening and selection of Bacillus spp. forfermented corticate soybean meal production. J. Appl. Microbiol. 2012,113,798-806. [CrossRef] [PubMed] 15. Upadhaya, S.D.; Kim, I.H. Ileal digestibility of nutrients and amino acids in unfermented, fermented soybean meal and canolameal for weaning pigs. Anim. Sci. J. 2015, 86,408-414. [CrossRef] [PubMed] 16. Sharawy, Z.; Goda,A.M.A.S.; Hassaan, M.S. Partial or total replacement of fish meal by solid state fermented soybean meal withSaccharomyces cerevisiae in diets for Indian prawn shrimp, Fenneropenaeus indicus, Postlarvae. Anim. Feed. Sci. Technol. 2016, 212,90-99. [CrossRef| 17. Yang, A.; Zuo, L.; Cheng, Y.; Wu, Z.; Li, X.; Tong, P.; Chen, H. Degradation of major allergens and allergenicity reduction ofsoybean meal through solid-state fermentation with microorganisms. Food Funct. 2018,9,1899-1909. [CrossRef] 18. Wu, P.; Guo, Y.; Golly, M.K.; Ma, H.; He, R.; Luo, S.; Zhang, C.; Zhang, L.; Zhu, J. Feasibility study on direct fermentation ofsoybean meal by Bacillus stearothermophilus under non-sterile conditions. J. Sci. Food Agric. 2019,99,3291-3298. [CrossRef] 19. Jeong, J.S.; Park, J.W.; Lee, S.I.; Kim, I.H. Apparent ileal digestibility of nutrients and amino acids in soybean meal, fish meal,spray-dried plasma protein and fermented soybean meal to weaned pigs. Anim. Sci. J. 2016,87,697-702.[CrossRef] 20. Sinn, S.M.; Gibbons, W.R.; Brown, M.L.; Derouchey, J.M.; Levesque, C.L. Evaluation of microbially enhanced soybean meal as analternative to fishmeal in weaned pig diets. Animal 2017,11,784-793.[CrossRef] 21. Jeong, J.S.; Kim, I.H. Comparative efficacy of up to 50% partial fish meal replacement with fermented soybean meal or enzymati-cally prepared soybean meal on growth performance, nutrient digestibility and fecal microflora in weaned pigs. Anim. Sci. J.2015,86,624-633.[CrossRef] [PubMed] 22. Espinosa, C.D.; Oliveira, M.S.F.; Lagos, L.V; Weeden, T.L.; Mercado, A.J.; Stein, H.H. Nutritional value of a new source offermented soybean meal fed to growing pigs. J. Anim. Sci. 2020,98,skaa357.[CrossRef] [PubMed] 23. Cervantes-Pahm, S.K.; Stein, H.H. Ileal digestibility of amino acids in conventional, fermented, and enzyme-treated soybean mealand in soy protein isolate, fish meal, and casein fed to weanling pigs. J. Anim. Sci. 2010, 88, 2674-2683.[CrossRef] [PubMed] 24. Premathilaka, K.T.; Nawarathne, S.R.; Nambapana, M.N.; Macelline, S.P.; Wickramasuriya,S.S.; Ang, L.; Jayasena, D.D.; Heo, J.M.Partial or complete replacement of fishmeal with fermented soybean meal on growth performance, fecal composition, and meatquality in broilers. J. Anim. Sci. Technol. 2020, 62,824-839. [CrossRef] [PubMed] 26. Azam, F.; Qaisrani, S.N.; Khalique, A.; Bibi, F; Akram, C.A.;Naveed, S.; Pasha, T.N. Exploring nutritive profile, metabolizableenergy, protein, and digestible amino acids contents of indigenous protein sources of different locations for male broilers.Poult. Sci. 2019,98,4664-4672. [CrossRef] 27. AOAC. Official Methods of Analysis of AOAC International, 18th ed.; Association of Official Analytical Chemists: Gaithersburg, MD,USA, 2006. 28. Titgemeyer, E.C.; Armendariz, C.K.; Bindel, D.J.; Greenwood,R.H.; L Est, C.A. Evaluation of titanium dioxide as a digestibilitymarker for cattle. J. Anim. Sci. 2001, 79,1059.[CrossRef] 29. Mukherjee, R.; Chakraborty, R.; Dutta, A. Role of Fermentation in Improving Nutritional Quality of Soybean Meal-A Review.Asian Austral. J. Anim. 2016,29,1523-1529. [CrossRef] 30. Li, Y.; Guo, B.; Wu, Z.; Wang, W.; Li, C.; Liu, G.; Cai, H. Effects of Fermented Soybean Meal Supplementation on the GrowthPerformance and Cecal Microbiota Community of Broiler Chickens. Animals 2020, 10,1098. [CrossRef] 31..Zhang, Y.; Ishikawa,M.; Koshio, S.; Yokoyama, S.; Dossou, S.; Wang, W.; Zhang, X.;Shadrack, R.S.; Mzengereza, K.; Zhu, K.; et al.Optimization of Soybean Meal Fermentation for Aqua-Feed with Bacillus subtilis natto Using the Response Surface Methodology.Fermentation 2021,7,306. [CrossRef] 32. Gilbert, E.R.; Wong, E.A.; Webb, K.E., Jr. Board-invited review: Peptide absorption and utilization: Implications for animalnutrition and health. J. Anim. Sci. 2008,86,2135-2155. [CrossRef] [PubMed] 33. Li, Y.; Guo, B.; Li, C.; Wang, W.; Wu, Z.; Liu, G.; Cai, H. Isolation of a Highly Efficient Antigenic-Protein-DegradingBacillus amyloliquefaciens and Assessment of Its Safety. Animals 2020, 10, 1144. [CrossRef] [PubMed] 34. Olukomaiya,O.; Fernando, C.; Mereddy, R.; Li, X.; Sultanbawa, Y. Solid-state fermented plant protein sources in the diets ofbroiler chickens: A review. Anim. Nutr. 2019,5,319-330. [CrossRef] [PubMed] 35. Nieto, R.; Miranda, A.; Garcia, M.A.; Aguilera, J.F. The effect of dietary protein content and feeding level on the rate of protein deposition and energy utilization in growing Iberian pigs from 15 to 50 kg body weight. Brit. J. Nutr. 2002, 88, 39-49. [CrossRef] 36. Perryman, K.R.; Dozier, W.A. Apparent metabolizable energy and apparent ileal amino acid digestibility of low and ultra-lowoligosaccharide soybean meals fed to broiler chickens. Poultry Sci. 2012,91,2556-2563.[CrossRef] 37. Wu, Z.; Liu, J.; Chen, J.;Pirzado,S.A.; Li, Y.; Cai, H.; Liu, G. Effects of Fermentation on Standardized Ileal Digestibility of AminoAcids and Apparent Metabolizable Energy in Rapeseed Meal Fed to Broiler Chickens. Animals 2020, 10,1774. [CrossRef] 38. Golian, A.; Guenter, W.; Hoehler, D.;Jahanian, H.; Nyachoti, C.M. Comparison of various methods for endogenous ileal aminoacid flow determination in broiler chickens. Poult. Sci. 2008,87,706-712. [CrossRef] 39. Barua,M.; Abdollahi, M.R.; Zaefarian, F.; Wester, T.J.; Girish, C.K.; Chrystal, P.V.; Ravindran, V. Basal ileal endogenous amino acidflow in broiler chickens as influenced by age. Poult. Sci. 2021,100,101269.[CrossRef] 40. Kong, C.; Adeola, O. Ileal endogenous amino acid flow response to nitrogen-free diets with differing ratios of corn starch todextrose in broiler chickens. Poult. Sci. 2013,92,1276-1282. [CrossRef] 41. de Coca-Sinova, A.; Valencia, D.G.; Jimenez-Moreno, E.; Lazaro, R.; Mateos, G.G. Apparent Ileal Digestibility of Energy, Nitrogen,and Amino Acids of Soybean Meals of Different Origin in Broilers. Poult. Sci. 2008,87,2613-2623.[CrossRef] 42. Zhang, H.Y.; Yi,J.Q.; Piao, X.S.; Li, P.F.; Zeng, Z.K.; Wang, D.; Liu, L.; Wang, G.Q.; Han, X. The metabolizable energy value,standardized ileal digestibility of amino acids in soybean meal, soy protein concentrate and fermented soybean meal, and theapplication of these products in early-weaned piglets. Asian Australas. J. Anim. Sci. 2013,26, 691.[CrossRef] [PubMed 43. Hossain, M.M.; Begum, M.; Park, J.H.; Lee,S.J;Jang, K.H.; Hong, Y.H.; Cho, S.J.; Kim, I.H. Apparent total tract digestibility andileal digestibility of dry matter, nitrogen, energy and amino acids in conventional, Bacillus subtilis-fermented and enzyme-treatedsoybean meal fed to weanling pigs. Vet. Med. 2016,12,669-680.[CrossRef] 44. Kim, D.H.; Heo, P.S.; Jang, J.C.; Jin, S.S.; Hong, J.S.; Kim, Y.Y. Effect of different soybean meal type on ileal digestibility of aminoacid in weaning pigs. J. Anim. Sci. Technol. 2015, 57, 11. [CrossRef][PubMed] Disclaimer/Publisher's Note: The statements, opinions and data contained in all publications are solely those of the individualauthor(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury topeople or property resulting from any ideas, methods, instructions or products referred to in the content.

确定

还剩11页未读,是否继续阅读?

中国格哈特为您提供《豆粕、发酵豆粕、排泄物、日粮的蛋白质和粗纤维含量检测》,该方案主要用于饲料中营养成分检测,参考标准--,《豆粕、发酵豆粕、排泄物、日粮的蛋白质和粗纤维含量检测》用到的仪器有格哈特杜马斯定氮仪DT N Pro、格哈特全自动型纤维分析仪FT12

相关方案

更多

该厂商其他方案

更多