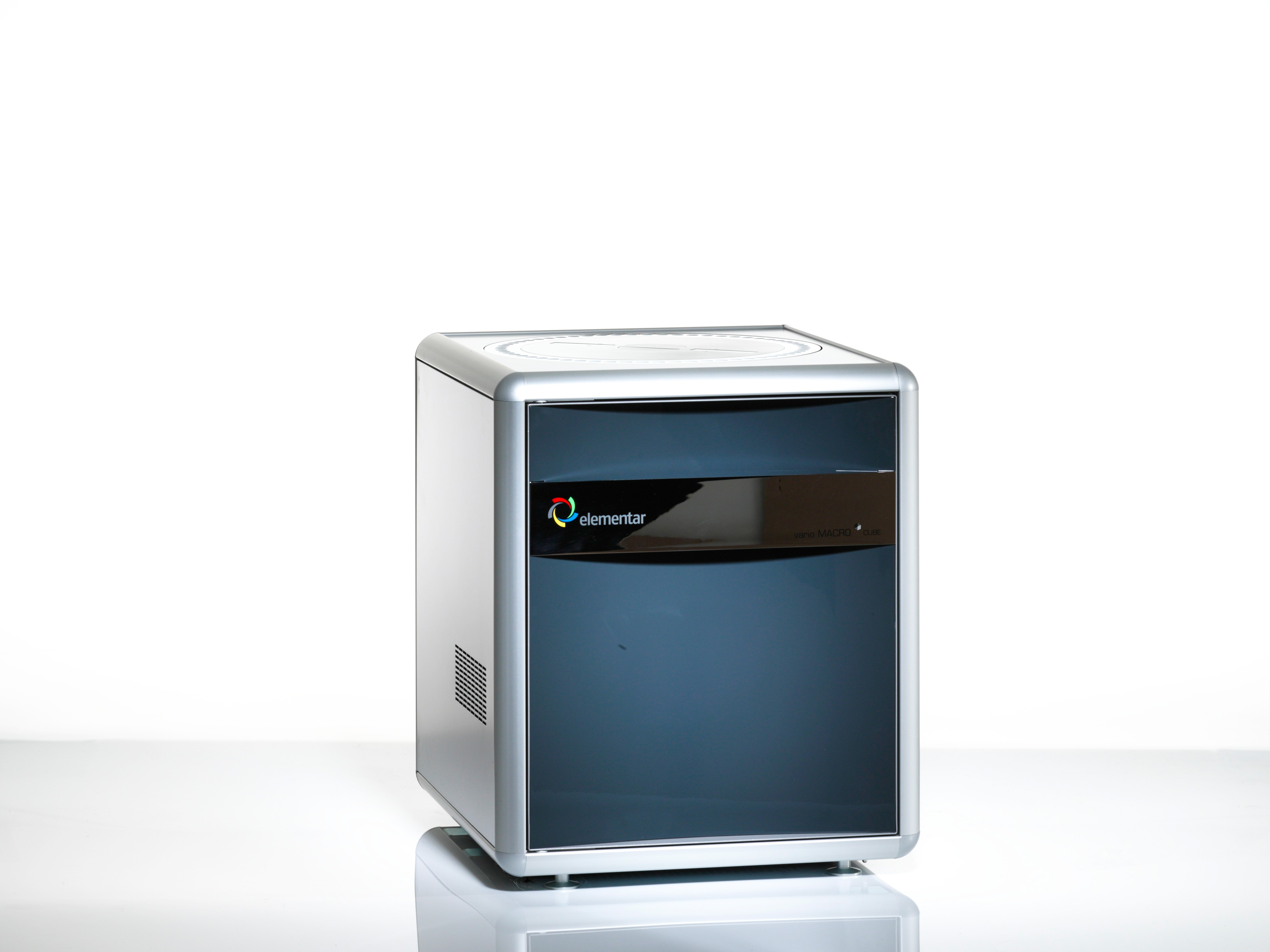

本文针对气体,液化气样品中的硫元素分析进行了研究,主要利用德国耶拿公司的元素分析仪EA5000,配置GSS/LPG(气体,液化气综合自动进样系统)进样器系统。GSS/LPG模块可以灵活应用于不同压力气体,液化气的自动测量,无需样品的前处理,可以根据待测样品的不同浓度,灵活改变不同体积进样(1-50ul的LPG,1-20ml的气体),在最短的分析时间内,得到最佳的分析结果。

方案详情

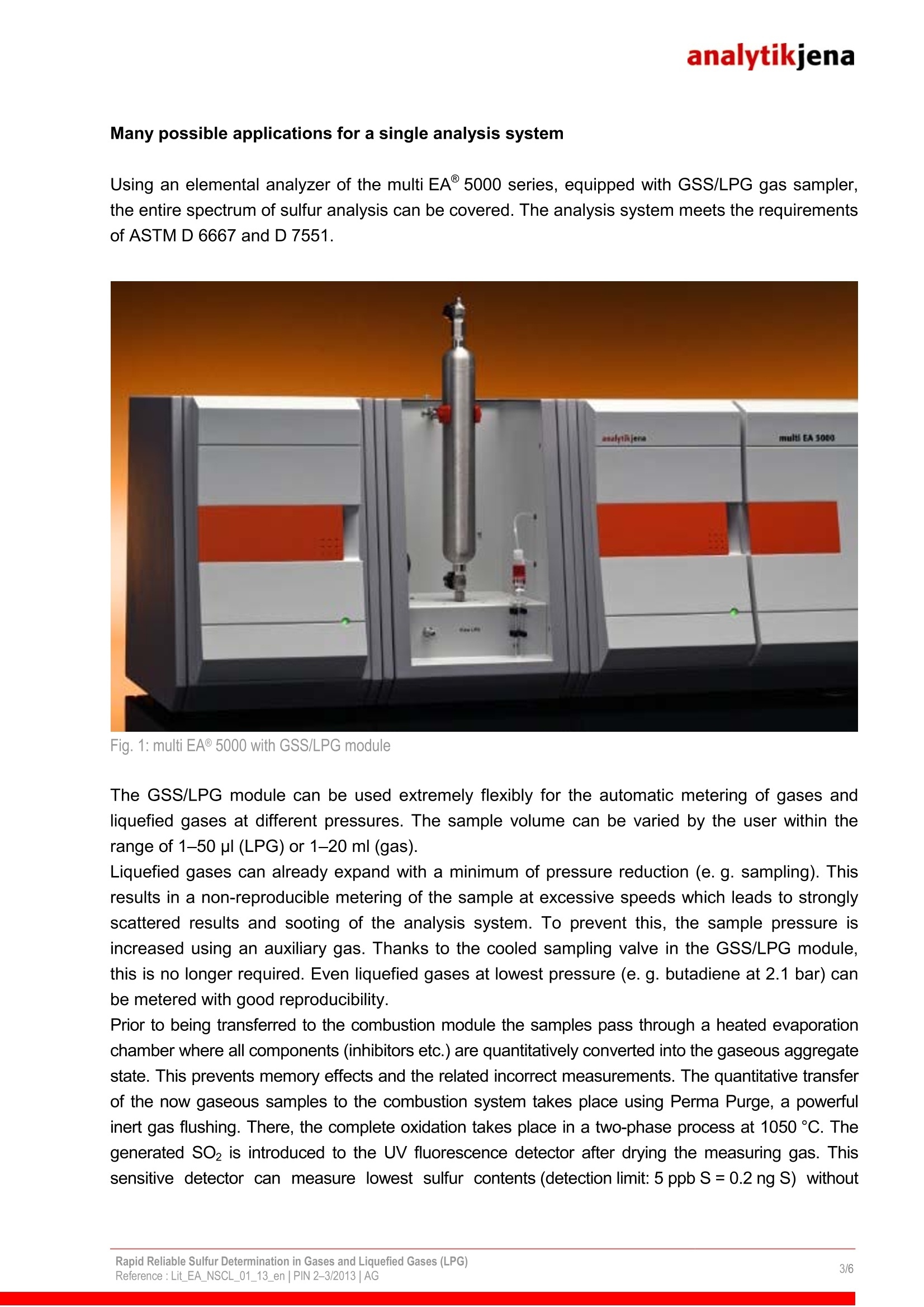

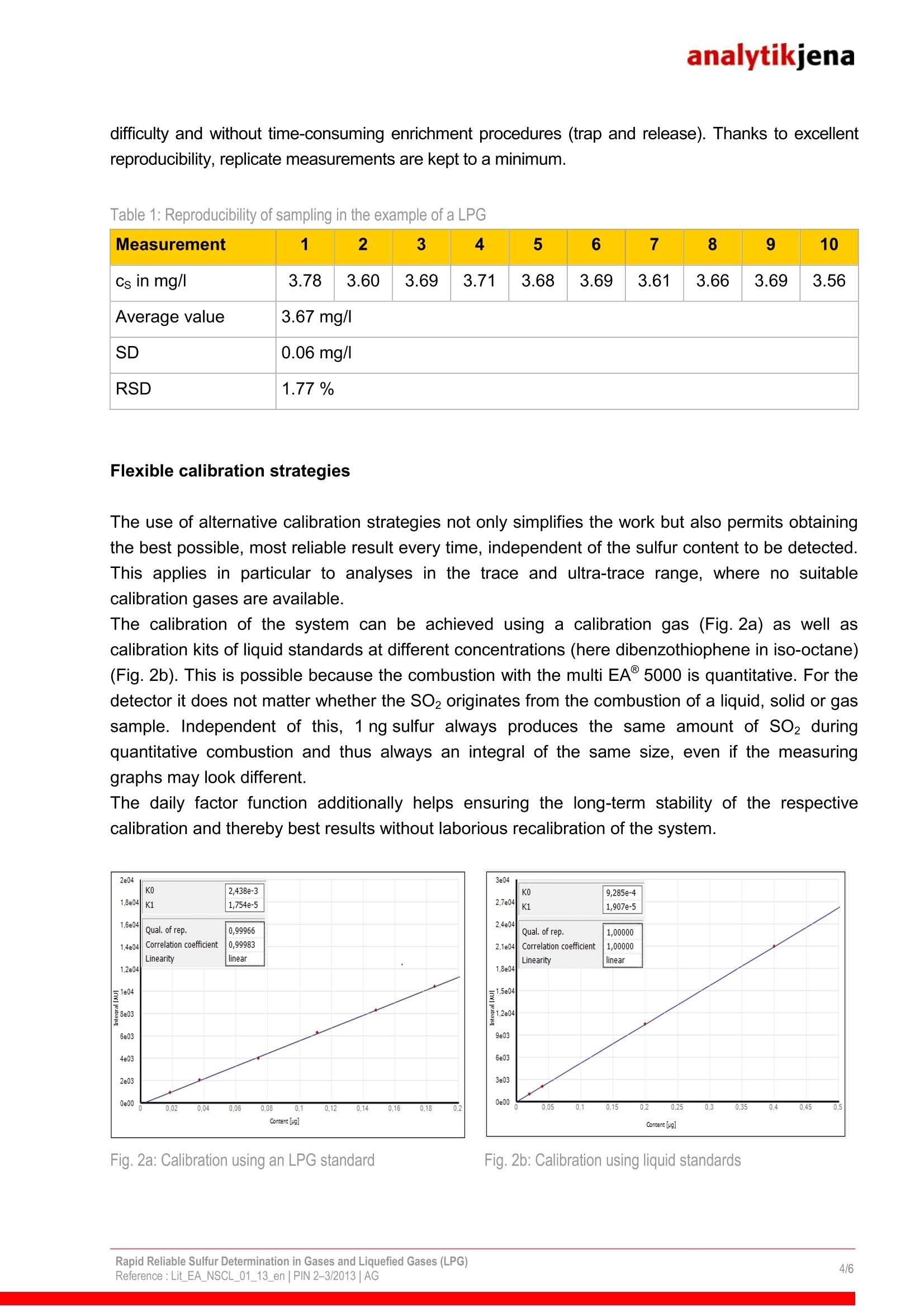

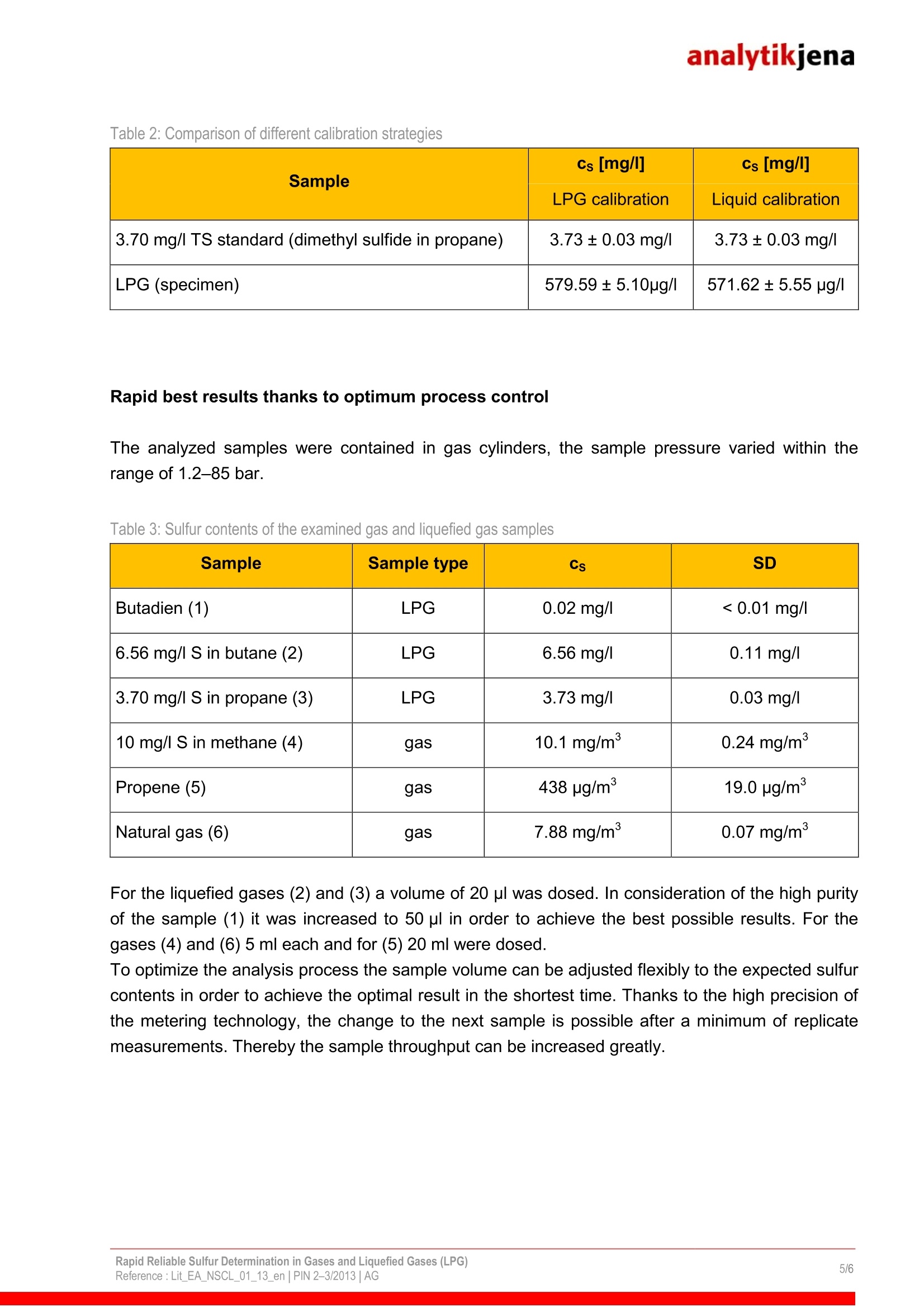

analytikjena coccFields of Application/Industry:oo Chemistry/Polymer Industry Clinical Chemistry/Medicine/Hygiene/Health Care Electronics Semi-Conductor Technology Energy Environment/Water/Waste Geology/Mining Food/Agriculture Metallurgy/Galvanization Refineries/Petrochemistry Pharmacy Cosmetics Material Analysis Others 气体和液化气(LPG)中硫的快速、可靠测量方冬梅 德国耶拿分析仪器股份公司 摘要: 在制药和化妆品行业,气态碳氢链的增加,对材料合成工艺,燃料,能量载体和辅助材料有很重要的意义。生产中的质量控制,主要集中在杂质含量的测定,特别是硫含量。原料气中硫含量有严格的限制,否则会引起催化剂的中毒,不需要的副产物,从而增加生产的成本。为了精确测量气体中硫元素的含量,需要一个强有力的测量技术,包括完全定量的燃烧、高灵敏的检测器。为了精确定量,需要对采集的含硫气体立即测定。 本文针对气体,液化气样品中的硫元素分析进行了研究,主要利用德国耶拿公司的元素分析仪 EA5000, 配置 GSS/LPG (气体,液化气综合自动进样系统)进样器系统。GSS/LPG 模块可以灵活应用于不同压力气体,液化气的自动测量,无需样品的前处理,可以根据待测样品的不同浓度,灵活改变不同体积进样(1-50ul 的 LPG, 1-20ml的气体),在最短的分析时间内,得到最佳的分析结果。 通常情况下,测量液化气时,由于过程中样品压力的变化导致测量结果重现性差,积碳等问题。 GSS/LPG 模块自带冷却装置,可消除压力变化对测量带来的影响。即使是最低压力下(2.1bar) 液化气丁二烯的分析。另外, GSS/LPG模块内置样品加热蒸发室,所有组分在此都能定量转化为气体状态,到燃烧模块,减少记忆效应和错误的测量。1050℃下的高温燃烧,保证样品氧化完全,经过净化、干燥后到紫外荧光硫检测器(UVFD),测量最低含量的硫(检出出:5ppb=0.2ng)。本文对 LPG 样品中硫元素重复测量10次, RSD 为 1.77%,重现性高,精确性好。 具有选择性的校正策略不仅能满足简单的操作,也能获得最可靠的结果。本文分别利用气体标准物质和液体标准物质做标准曲线,通过测量丙烷中的二甲基硫醚(LPG标准物质, Cs=3.7 mg/L)及其他标准物质,结果一致性高,证明该放法准确性高。因此,不适合用气体标准校正的痕量和超痕量分析就可选择液体标准进行校正。软件的日因子功能增加了标准曲线长期的稳定性,无需重复做标准曲线,此分析方法符合 ASTM, DIN标准。 Rapid Reliable Sulfur Determination in Gases and Liquefied Gases (LPG) Dr. Angela Grobel, product manager, Analytik Jena AG, Analytical Instrumentation, Konrad-Zuse-Str. 1,07745 Jena,www.analytik-jena.com This article was published in PETRO Industry News, issue 2-3/2013 The possible applications of gases are just as versatile as the requirements for instrumentteechnology.The properties of this matrix type affect the safety, the required effort, thecompleteness of sample digestion and thus the quality of the results. High precision meteringtechnology and intelligent safety functions integrated into the instrument, such as the Self CheckSystem, are ttherefore essential.With the GSS/LPG module and the analysis systemmulti EA 5000 gases and liquefied gases can be analyzed in the shortest possible time withoutany sample preparation. Gas analysis -a wide field of application Gaseous hydrocarbons increasingly gain in importance. They are valuable source materials forsynthesis processes, fuels, energy carriers or auxiliary materials in pharmaceutics and cosmetics.Their purity plays an important role. In addition to the general composition the quality control alsofocuses on their content of undesirable components - especially sulfur compounds. For the use as propellant gas freedom from sulfur is a must (c<100 ppb). The same applies to theuse for the synthesis of high molecular compounds (e. g. polyethylene). Here, sulfur compoundscause catalyst contamination,undesirable byproducts and increased production costs. To detectsulfur traces with precision, powerful metering technology, quantitative combustion and highlysensitive detectors are important requirements. For the use of fuels (LPG, CNG) other guidelines apply. Of course, the limits applicable to sulfurmust not be exceeded. In addition it must be ensured by adding sulfurous odorants that escapinggas is detected immediately. To guarantee optimum product quality andinstanttiprocessoptimization, the rapid detection of high sulfur contents is required. Many possible applications for a single analysis system Using an elemental analyzer of the multi EA5000 series, equipped with GSS/LPG gas sampler,the entire spectrum of sulfur analysis can be covered. The analysis system meets the requirementsof ASTM D 6667 and D 7551. Fig. 1: multi EA 5000 with GSS/LPG module The GSS/LPG module can be used extremely flexibly for the automatic metering of gases andliquefied gases at different pressures. The sample volume can be varied by the user within therange of 1-50 pl(LPG) or 1-20 ml (gas). Liquefied gases can already expand with a minimum of pressure reduction (e. g.sampling). Thisresults in a non-reproducible metering of the sample at excessive speeds which leads to stronglyscattered results and sooting of the analysis system. To prevent this, the sample pressure isincreased using an auxiliary gas. Thanks to the cooled sampling valve in the GSS/LPG module,this is no longer required. Even liquefied gases at lowest pressure (e. g. butadiene at 2.1 bar) canbe metered with good reproducibility. Prior to being transferred to the combustion module the samples pass through a heated evaporationchamber where all components (inhibitors etc.) are quantitatively converted into the gaseous aggregatestate. This prevents memory effects and the related incorrect measurements. The quantitative transferof the now gaseous samples to the combustion system takes place using Perma Purge, a powerfulinert gas flushing. There, the complete oxidation takes place in a two-phase process at 1050C. Thegenerated SO2 is introduced to the UV fluorescence detector after drying the measuring gas. Thissensitive detector can measure lowest sulfur contents (detection limit: 5 ppb S = 0.2 ng S) without difficulty and without time-consuming enrichment procedures (trap and release). Thanks to excellentreproducibility, replicate measurements are kept to a minimum. Table1: Reproducibility of sampling in the example of a LPG Measurement 1 2 3 4 5 6 7 8 9 10 cs in mg/l 3.78 3.60 3.69 3.71 3.68 3.69 3.61 3.66 3.69 3.56 Average value 3.67 mg/l SD 0.06 mg/l RSD 1.77% Flexible calibration strategies The use of alternative calibration strategies not only simplifies the work but also permits obtainingthe best possible, most reliable result every time, independent of the sulfur content to be detected.This applies in particular to analyses in the trace and ultra-trace range, where no suitablecalibration gases are available. The calibration of the system can be achieved using a calibration gas (Fig.2a) as well ascalibration kits of liquid standards at different concentrations (here dibenzothiophene in iso-octane)(Fig. 2b). This is possible because the combustion with the multi EA5000 is quantitative. For thedetector it does not matter whether the SO2 originates from the combustion of a liquid, solid or gassample. Independent of this, 1 ng sulfur always produces the same amount of SO2 duringquantitative combustion and thus always an integral of the same size, even if the measuringgraphs may look different. The daily factor function additionally helps ensuring the long-term stability of the respectivecalibration and thereby best results without laborious recalibration of the system. Fig. 2a: Calibration using an LPG standard Fig. 2b: Calibration using liquid standards Table 2:Comparison of different calibration strategies Sample Cs [mg/l]LPG calibration cs [mg/] Liquid calibration 3.70 mg/I TS standard (dimethyl sulfide in propane) 3.73±0.03 mg/I 3.73±0.03 mg/l LPG (specimen) 579.59±5.10pg/l 571.62±5.55 pg/I Rapid best results thanks to optimum process control The analyzed samples were contained in gas cylinders, the sample pressure varied within therange of 1.2-85 bar. Table 3:Sulfur contents of the examined gas and liquefied gas samples Sample Sample type Cs SD Butadien (1) LPG 0.02 mg/l <0.01 mg/1 6.56 mg/l S in butane (2) LPG 6.56 mg/I 0.11 mg/l 3.70 mg/l S in propane (3) LPG 3.73 mg/l 0.03 mg/l 10 mg/l S in methane (4) gas 10.1 mg/m* 0.24 mg/m Propene (5) gas 438 ug/m 19.0 pg/m° Natural gas (6) gas 7.88 mg/m° 0.07 mg/m° For the liquefied gases (2) and (3) a volume of 20 pl was dosed. In consideration of the high purityof the sample (1) it was increased to 50 pl in order to achieve the best possible results. For thegases (4) and (6) 5 ml each and for (5) 20 ml were dosed. To optimize the analysis process the sample volume can be adjusted flexibly to the expected sulfurcontents in order to achieve the optimal result in the shortest time. Thanks to the high precision ofthe metering technology, the change to the next sample is possible after a minimum of replicatemeasurements. Thereby the sample throughput can be increased greatly. Fig. 3a: Sample 3-LPG Fig. 3b: Sample 4- gas Figures 3a and 3b show typical measuring graphs. The measuring duration depends on the sulfurcontent and metering volume and is between 150-420 seconds. Reliably simple-simply reliable The sulfur detection using the multi EA" 5000 provides results of the highest precision independentof the sample pressure and element content. Variable sample volumes and an optimumcombustion lead to short measuring times. The easy to operate multiWin software with a richlibrary of ASTM and DIN compliant methods prevents operating errors and dangerous situationsalready in advance. Additional functions, such as the integrated filter system and the purge tool for preventative care,significantly minimize the maintenance effort. The easy to operate hardware and top safetystandards permit the use during shift operations and in analysis centers with the highest possiblesample throughput. Printout and further use permitted with reference to the source. C 2013 Analytik Jena AG Publisher: Analytik Jena AG Konrad-Zuse-Str. 1 Phone +49 (0) 36 4177-70 07745 Jena Fax +49 (0) 36 41 77-92 79 www.analytik-jena.cominfo@analytik-jena.de Rapid Reliable Sulfur Determination in Gases and Liquefied Gases (LPG)Reference : Lit _EA_NSCL_en|PIN -/AG/

确定

还剩5页未读,是否继续阅读?

耶拿分析仪器(北京)有限公司为您提供《液化气中硫元素含量检测方案(有机元素分析)》,该方案主要用于天然气/燃气中硫元素含量检测,参考标准--,《液化气中硫元素含量检测方案(有机元素分析)》用到的仪器有multi EA® 5000碳、氮、硫、氯 元素分析仪

推荐专场

相关方案

更多

该厂商其他方案

更多