方案详情

文

During the course of a hypothetical severe accident in a nuclear Pressurized Water Reactor (PWR),

hydrogen may be produced by the reactor core oxidation and distributed into the containment. Spray

systems are used in order to limit overpressure, to enhance the gas mixing to avoid hydrogen

accumulation, and to wash out the fission products. In order to simulate these phenomena with CFD

codes, it is first necessary to know the droplet size and velocity distributions close to the outlet nozzle.

Furthermore, since most of the phenomena relative to droplets (condensation, gas entrainment,

collision) are of particular importance in the region below the nozzle, accurate input data are needed

for real-scale PWR calculations. The objective is therefore to determine experimentally these input

data.

Experimental measurements were performed on a single spray nozzle which is routinely used in many

PWRs. This nozzle is generally used with water at a relative pressure supply of 350 kPa, producing a

mass flow rate of approximately 1 kg/s. At a distance of 20 cm, where atomization is just achieved, it

is found that geometric mean diameter varies from 305 to 366 μm, Sauter mean diameter from 430 to

600 μm and mean axial velocity from 14.1 to 18.4 m/s.

方案详情

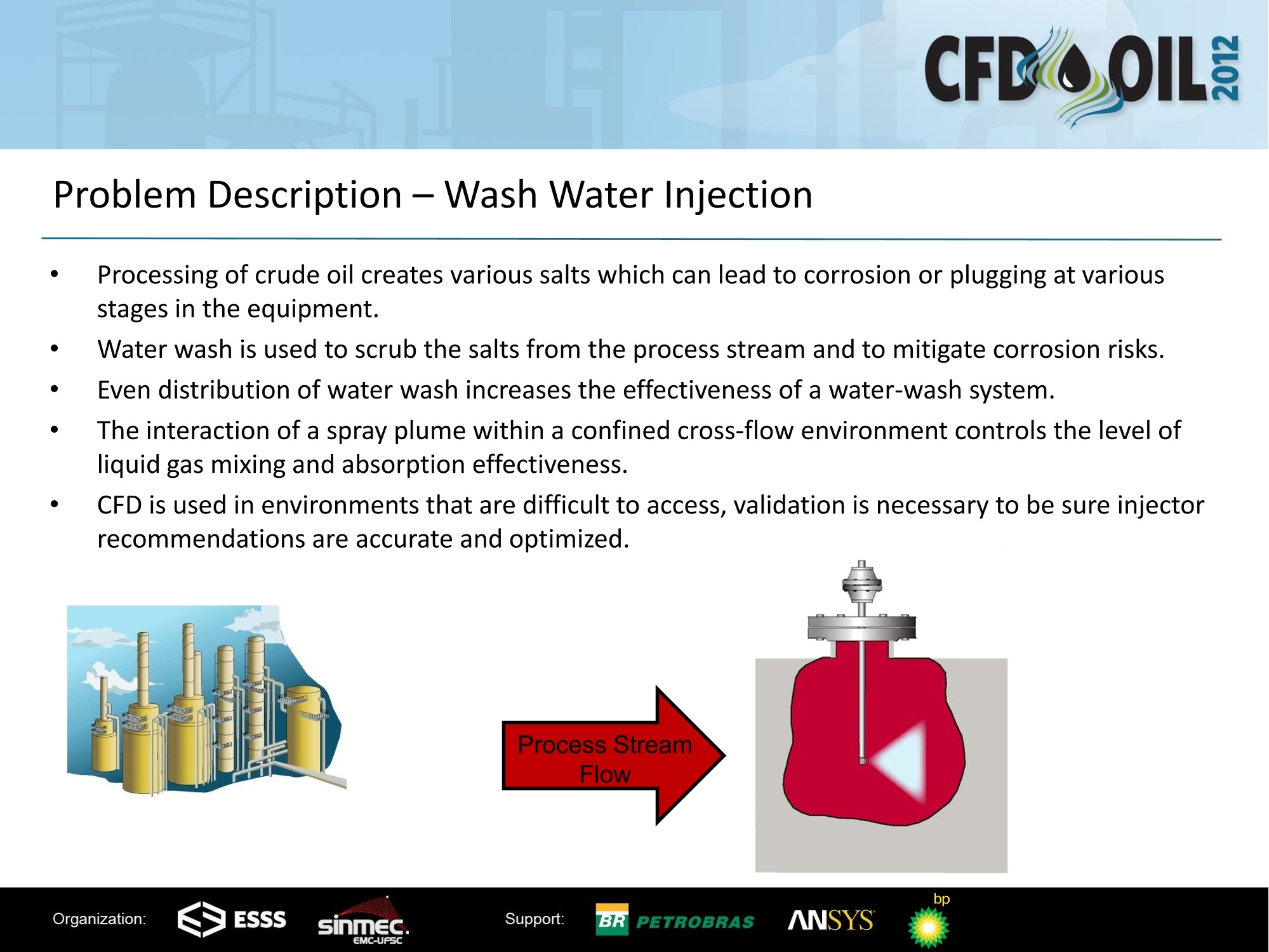

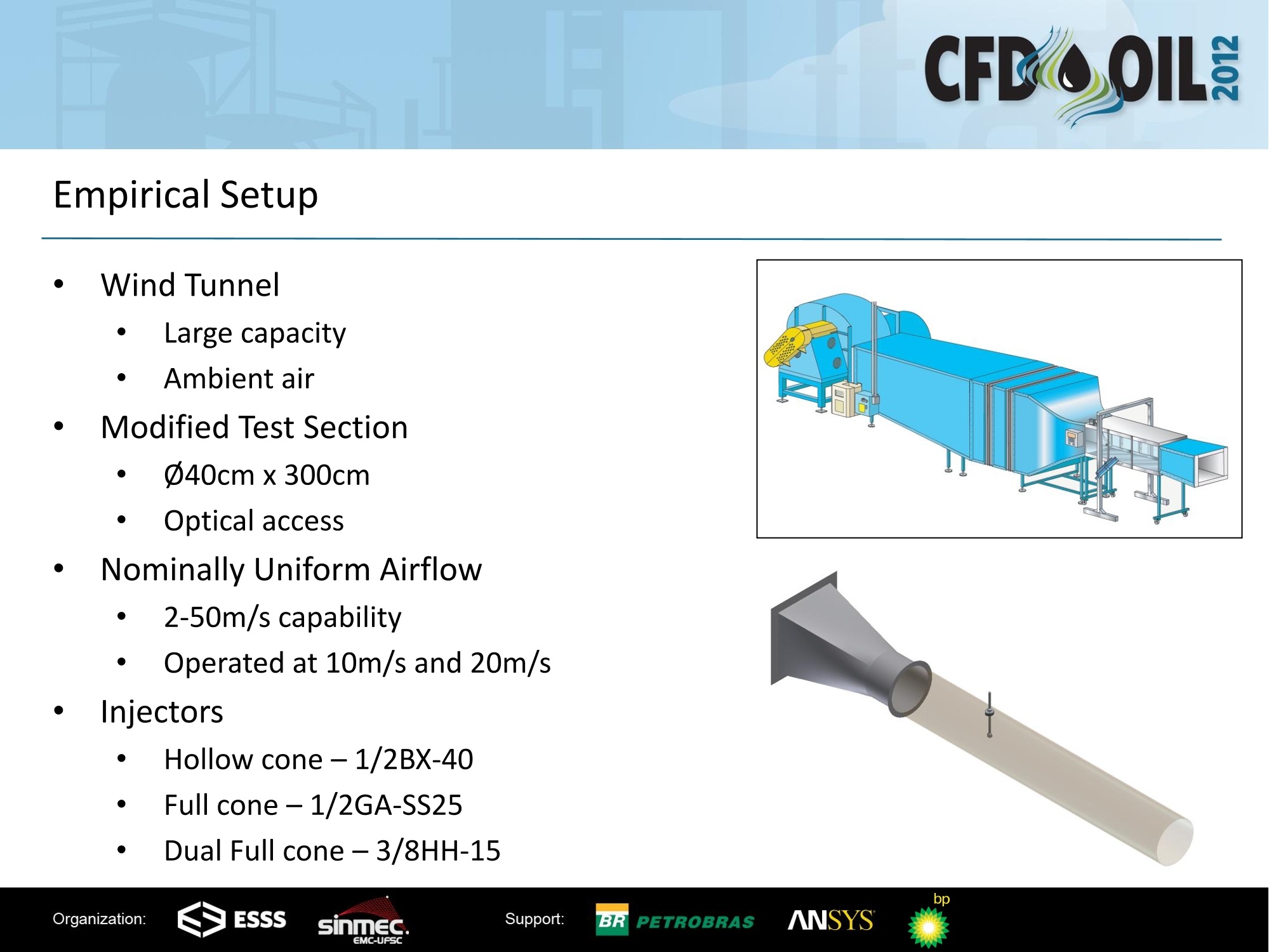

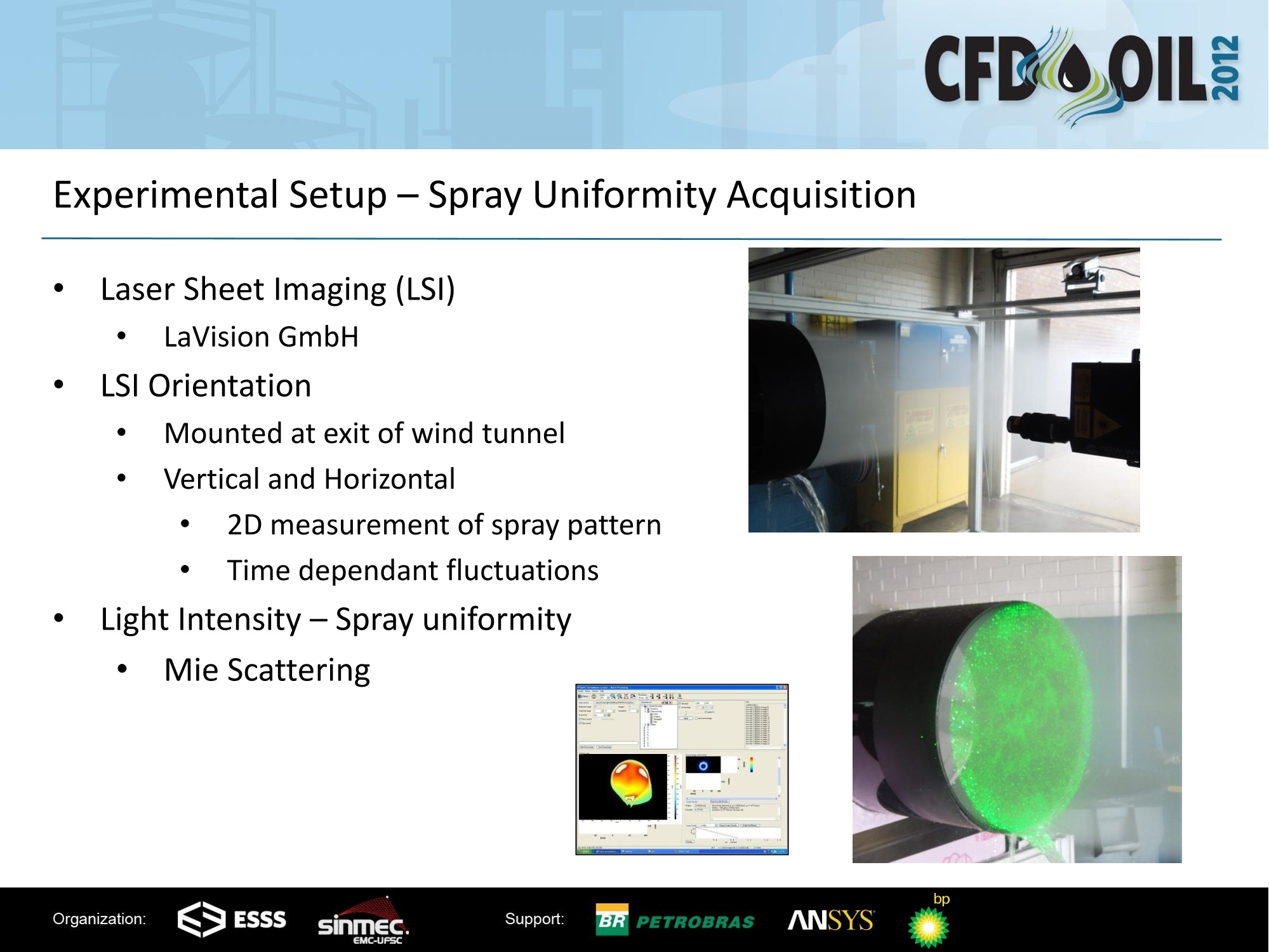

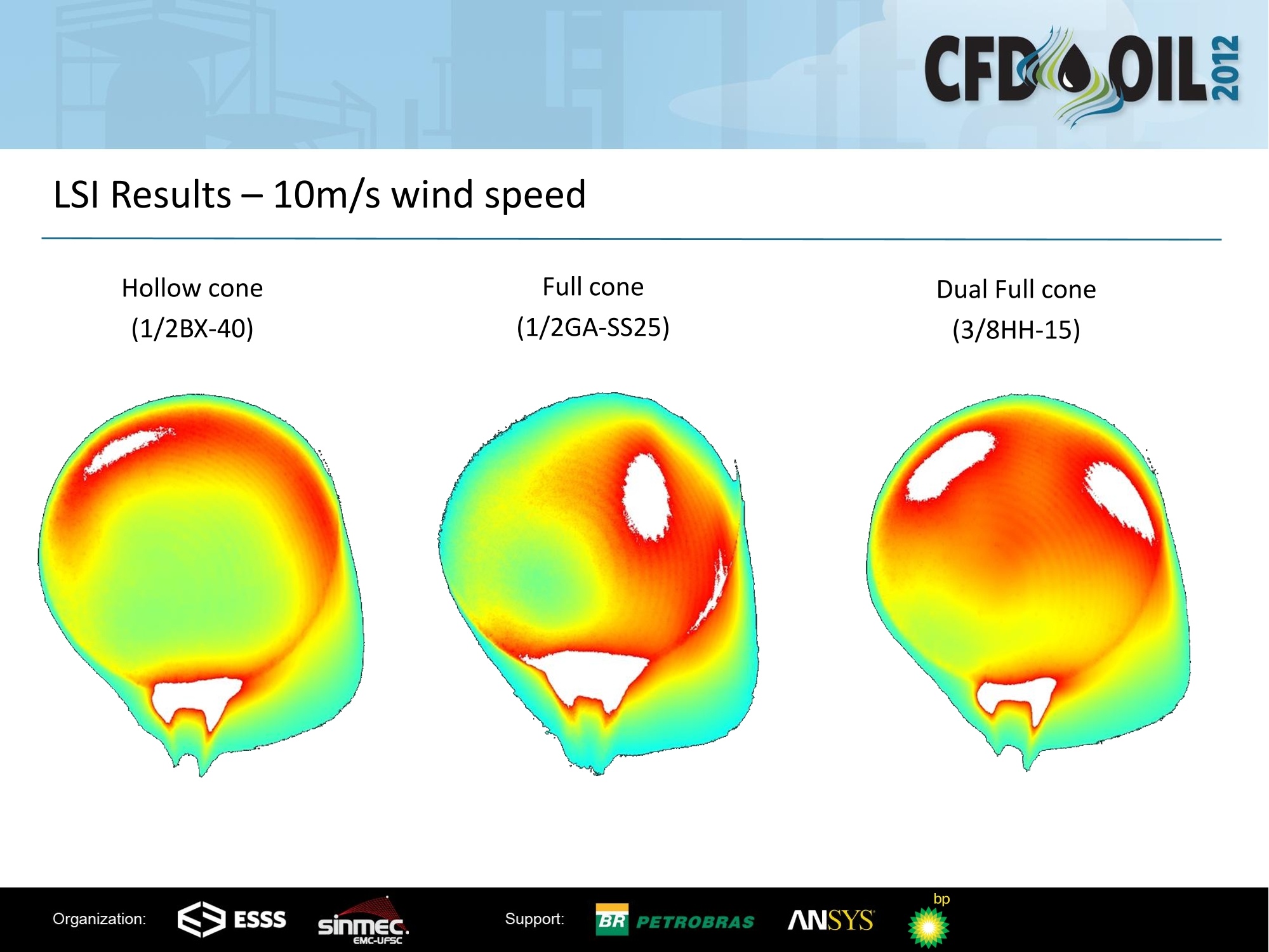

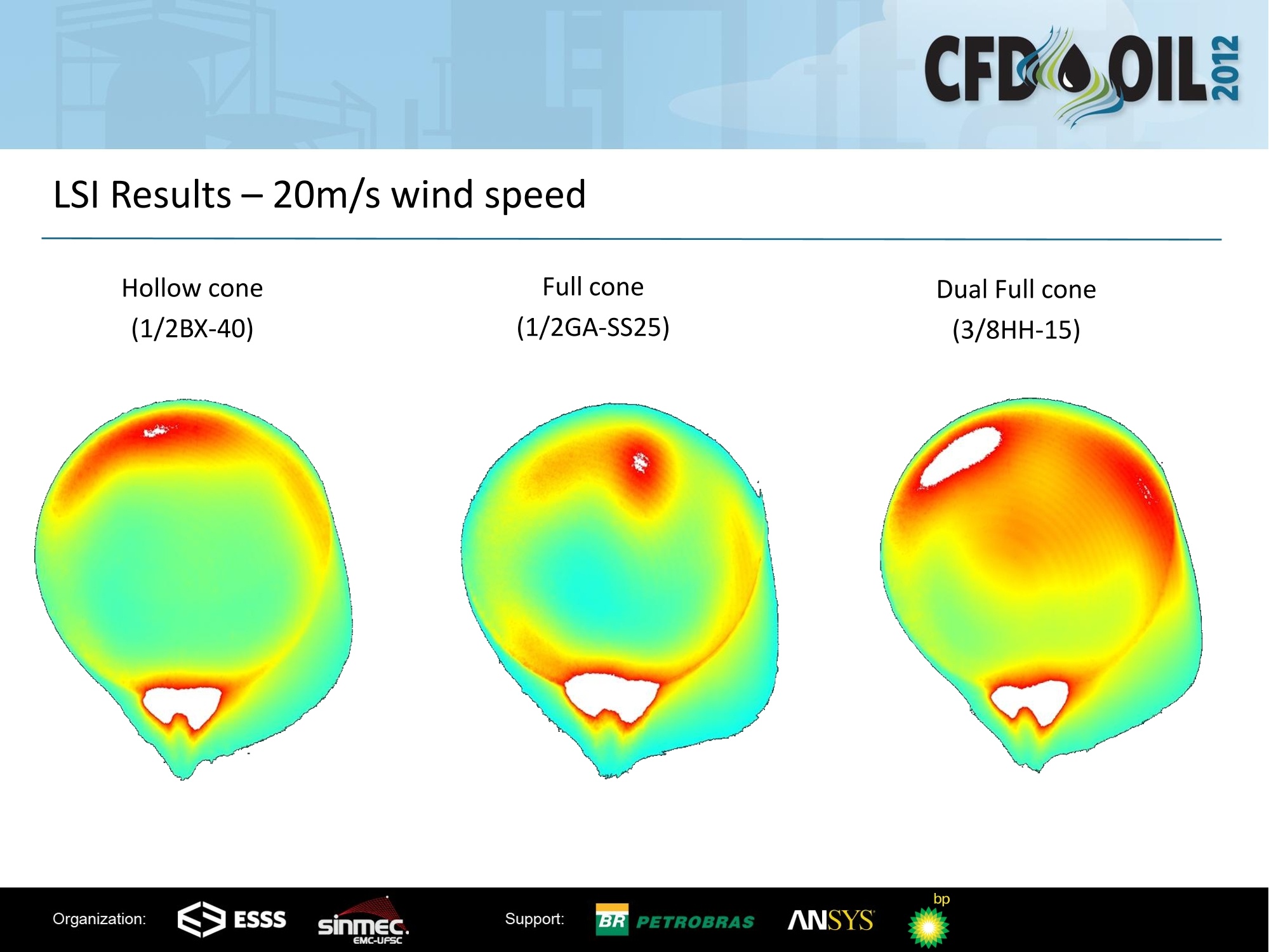

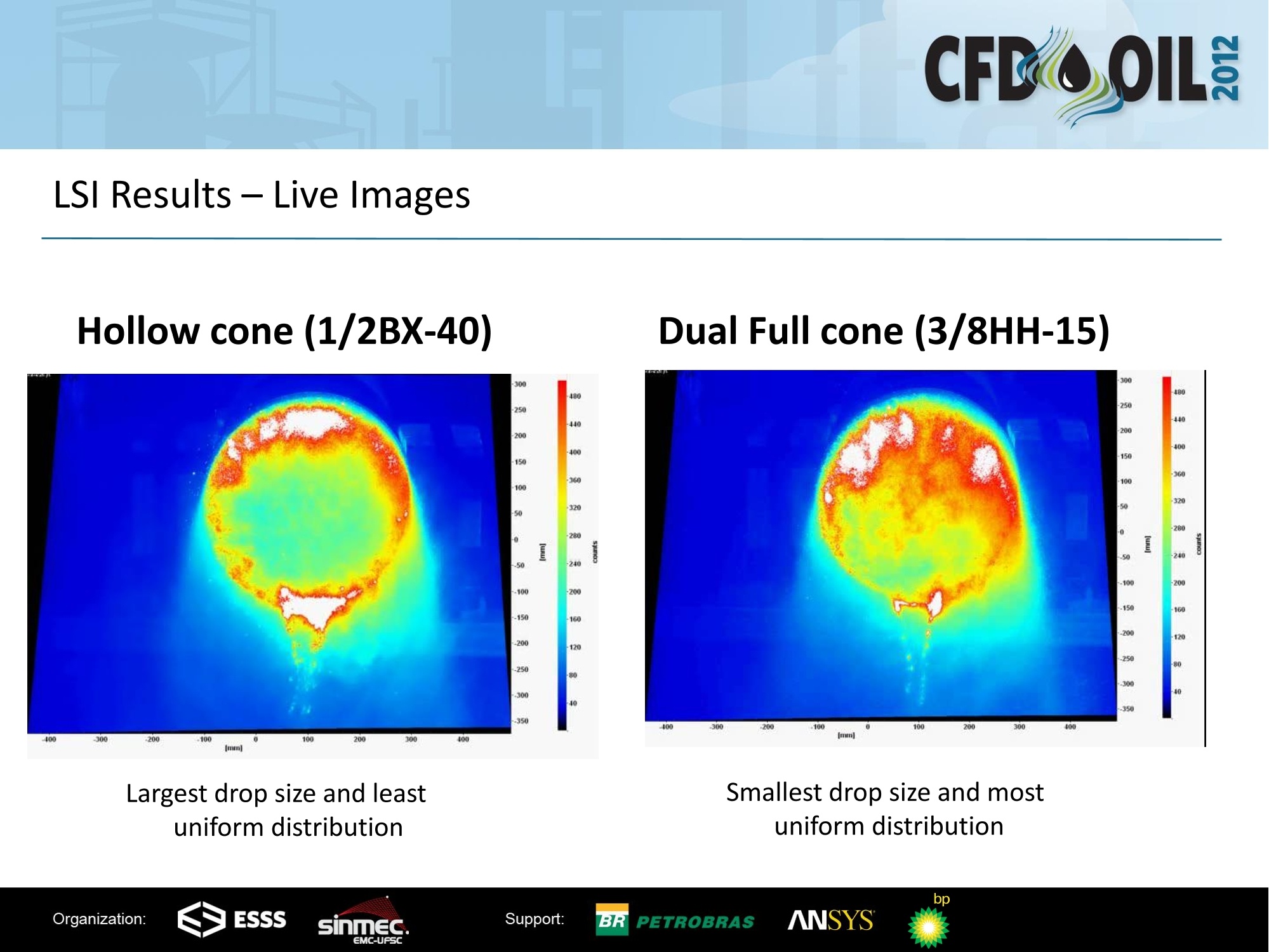

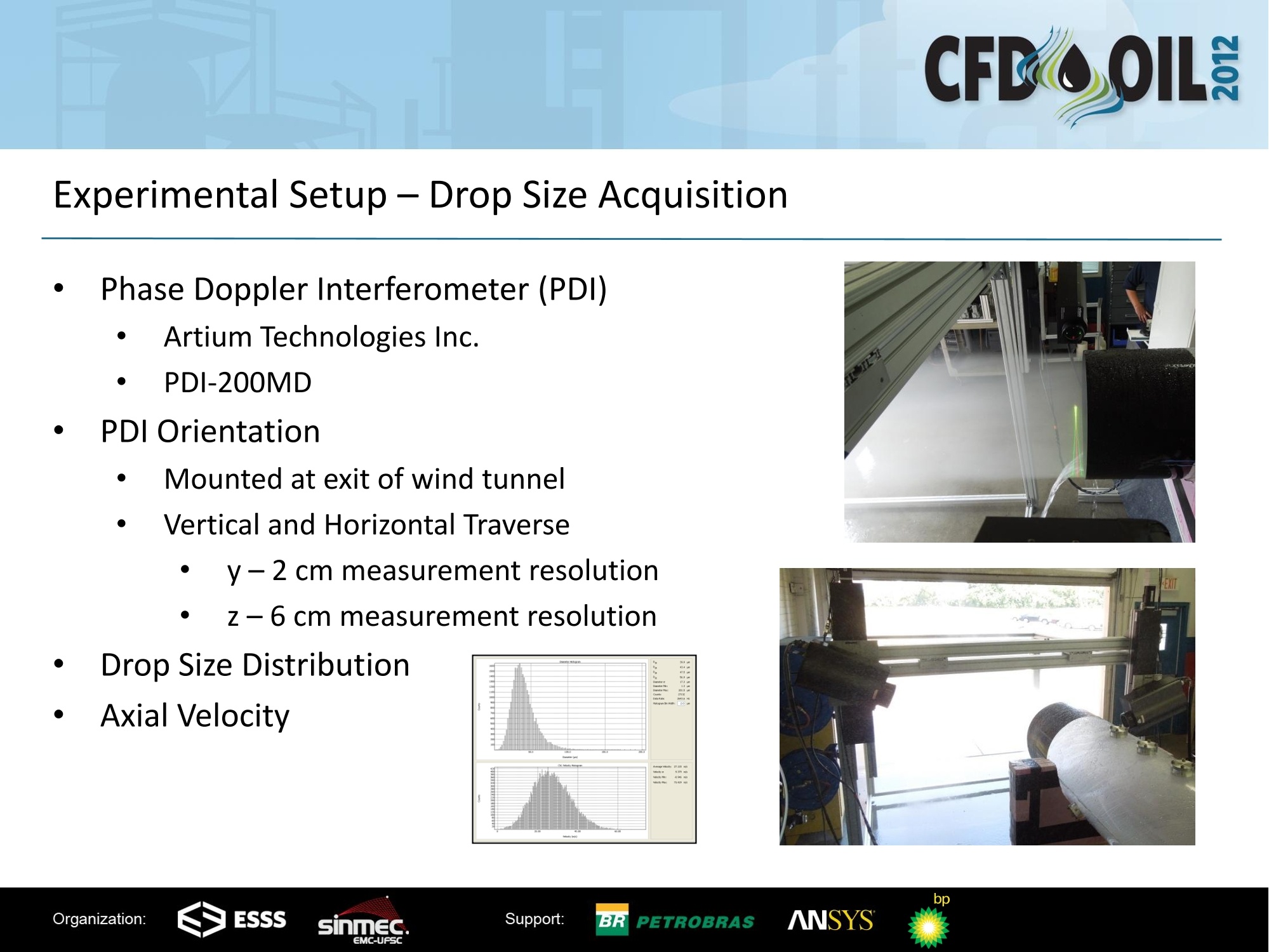

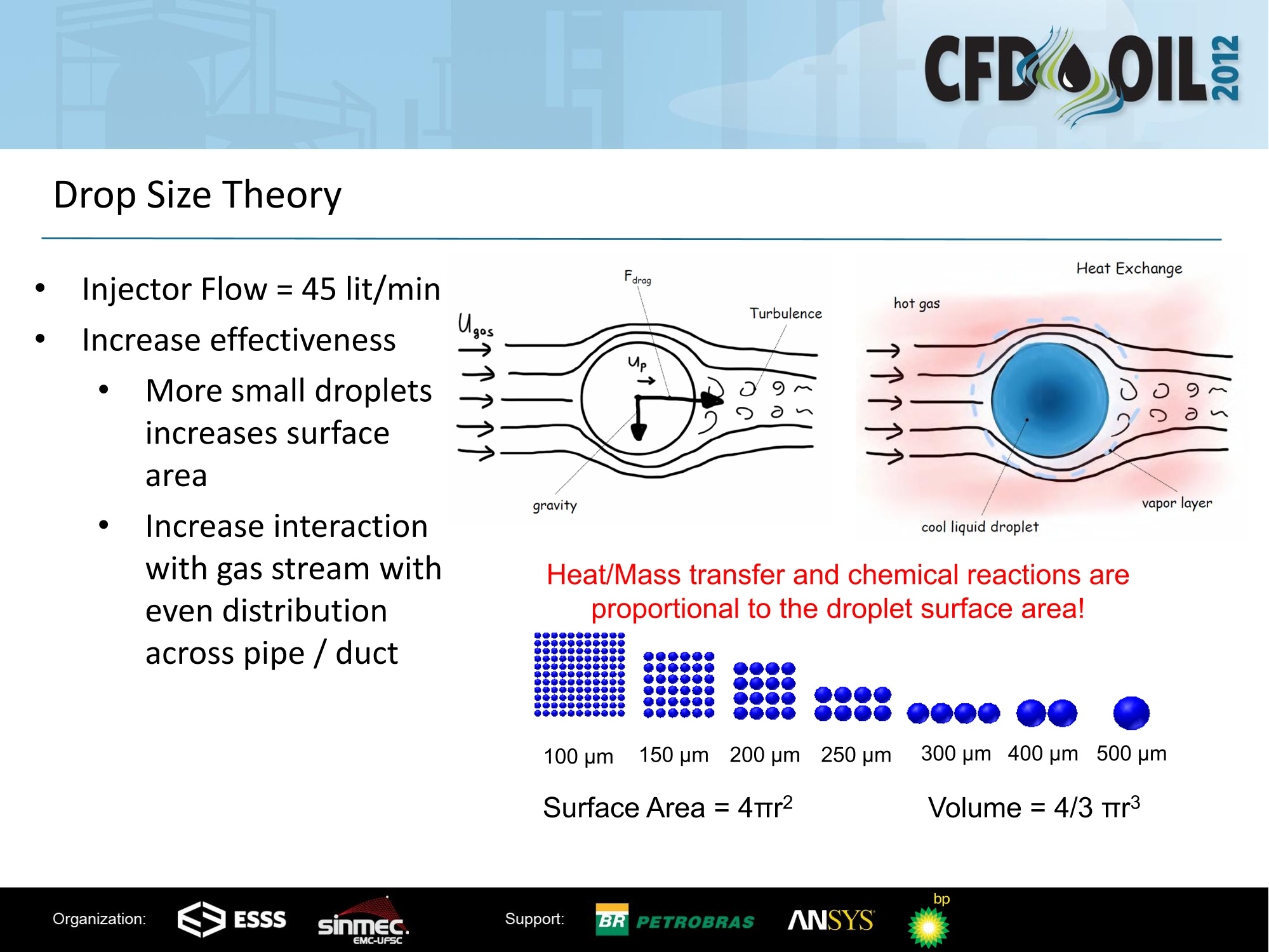

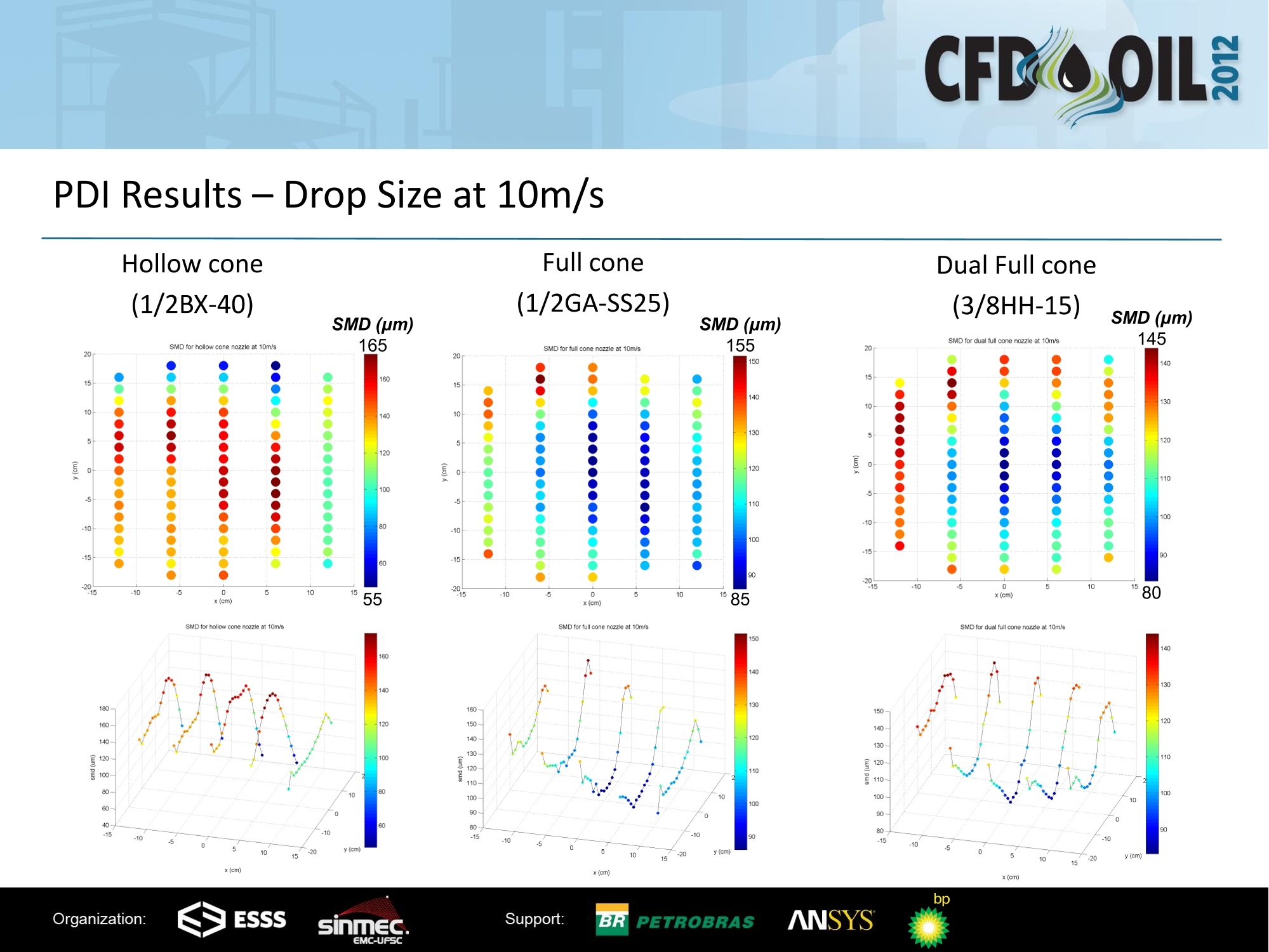

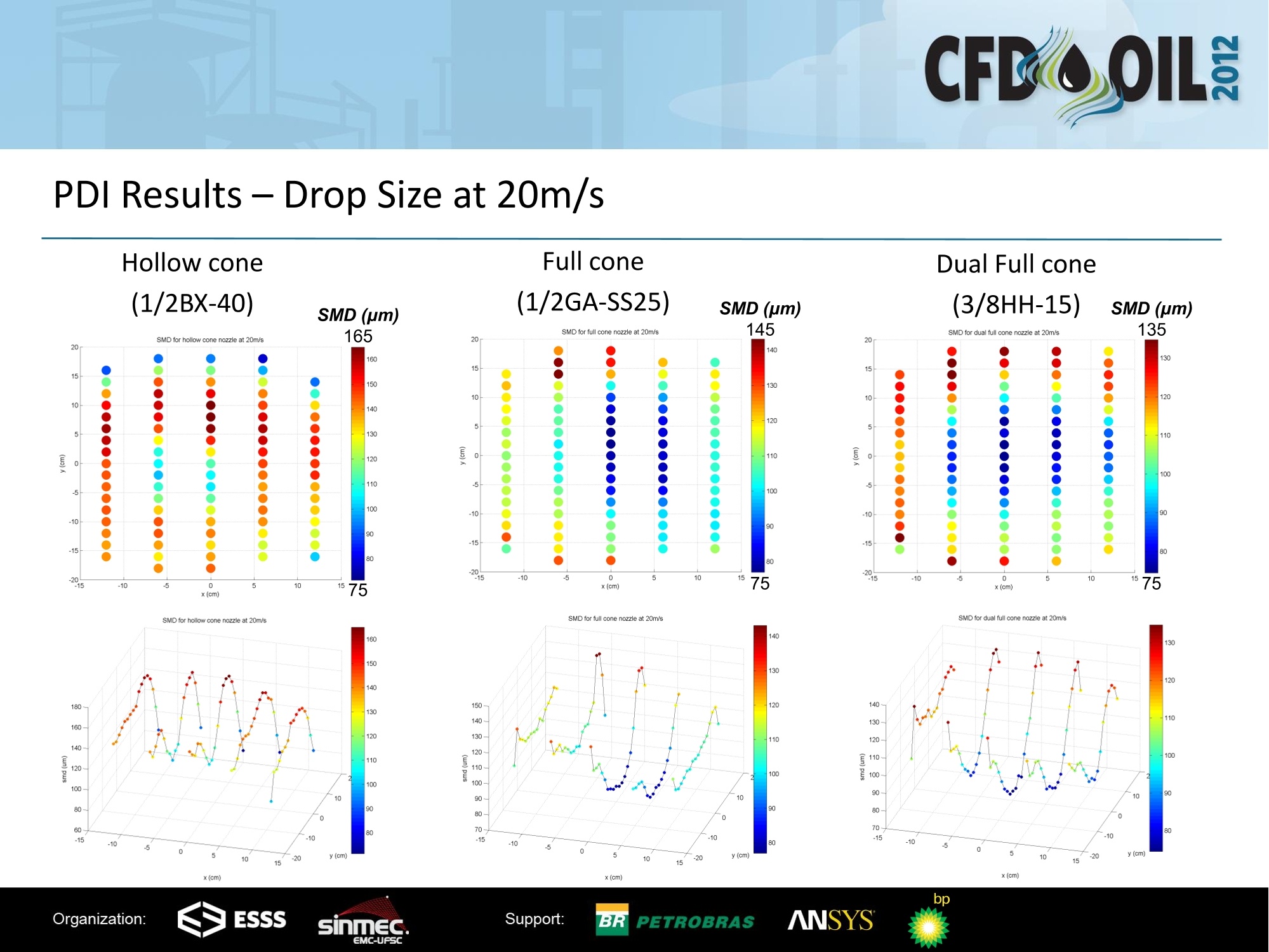

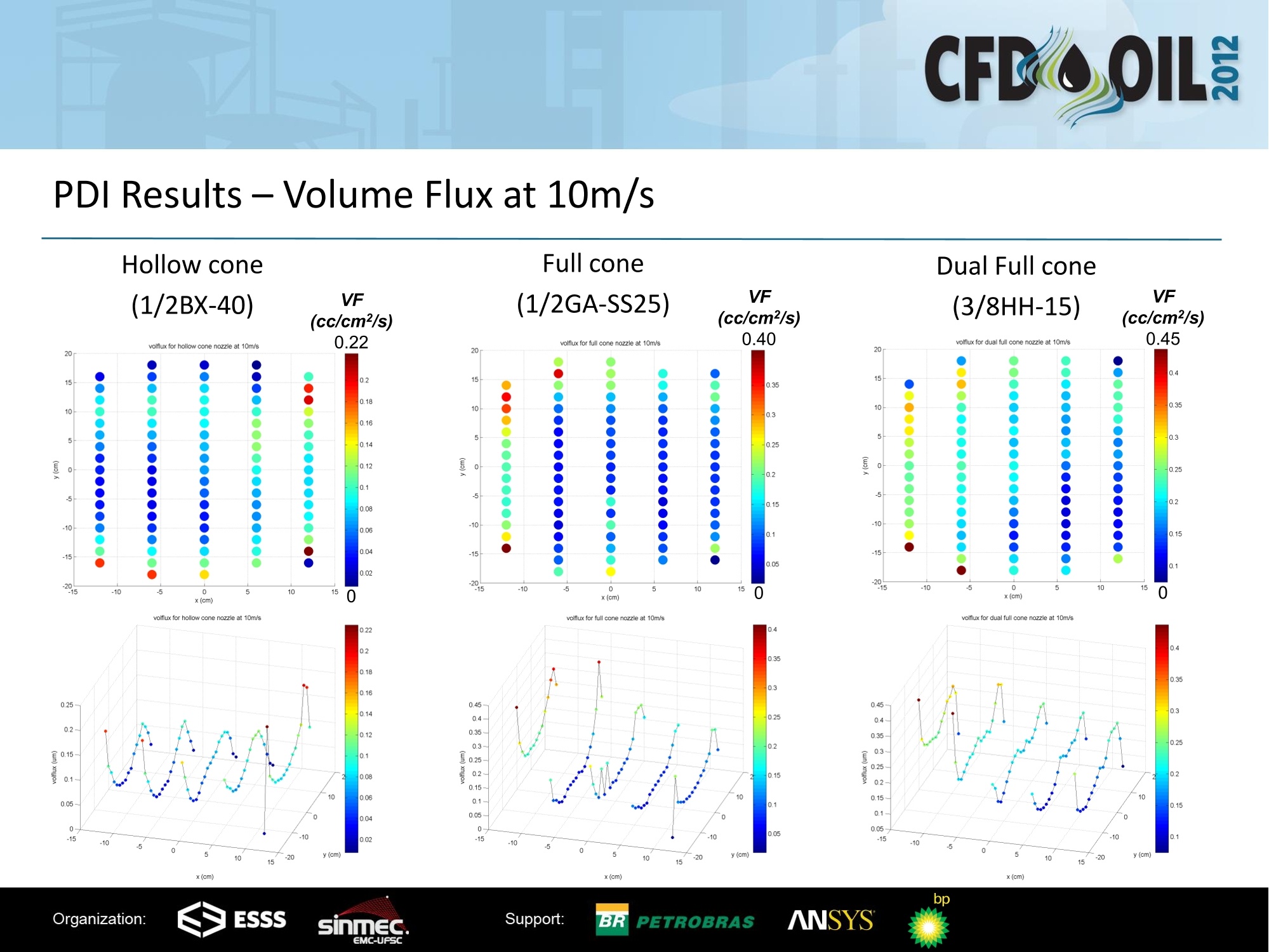

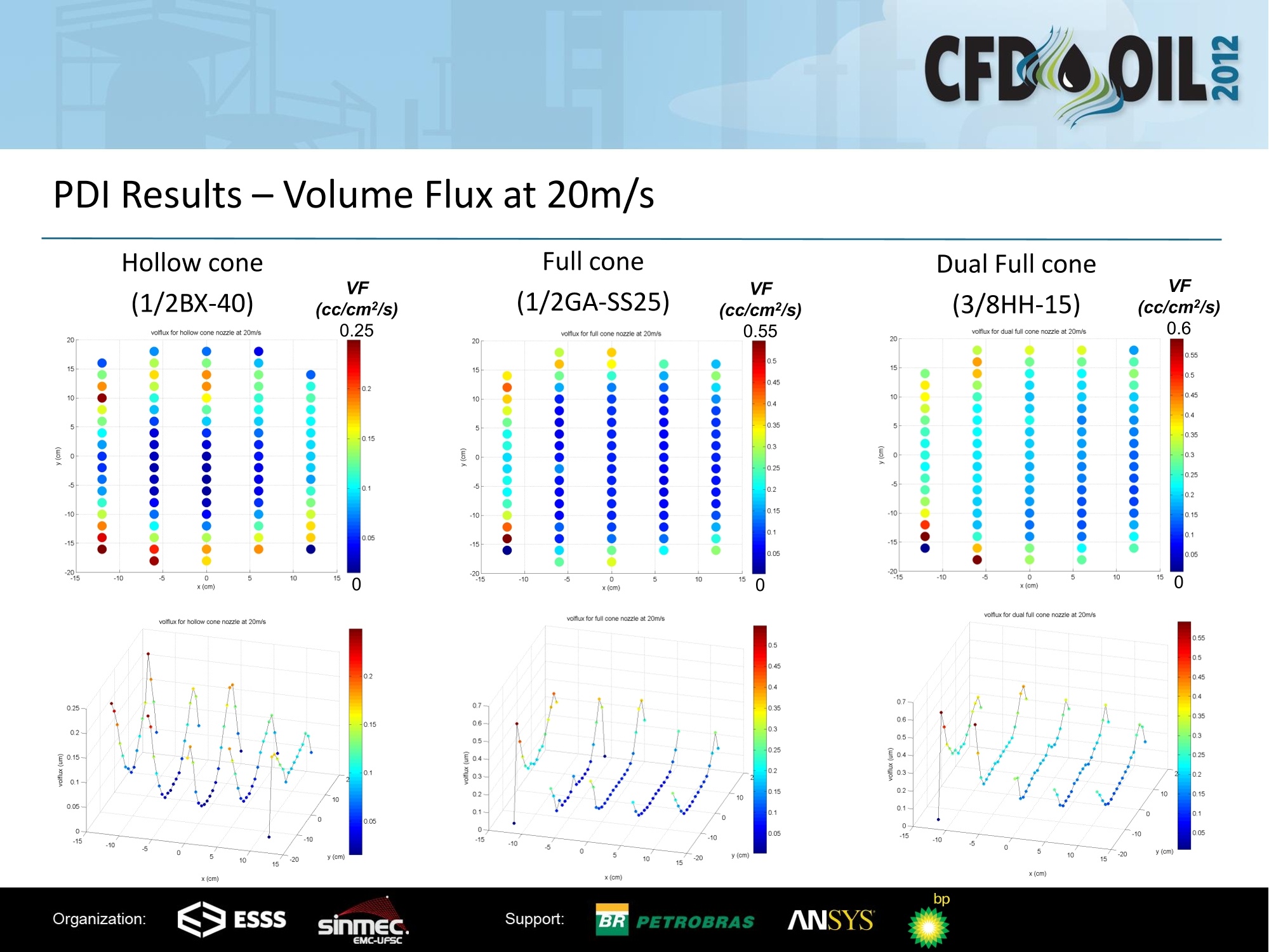

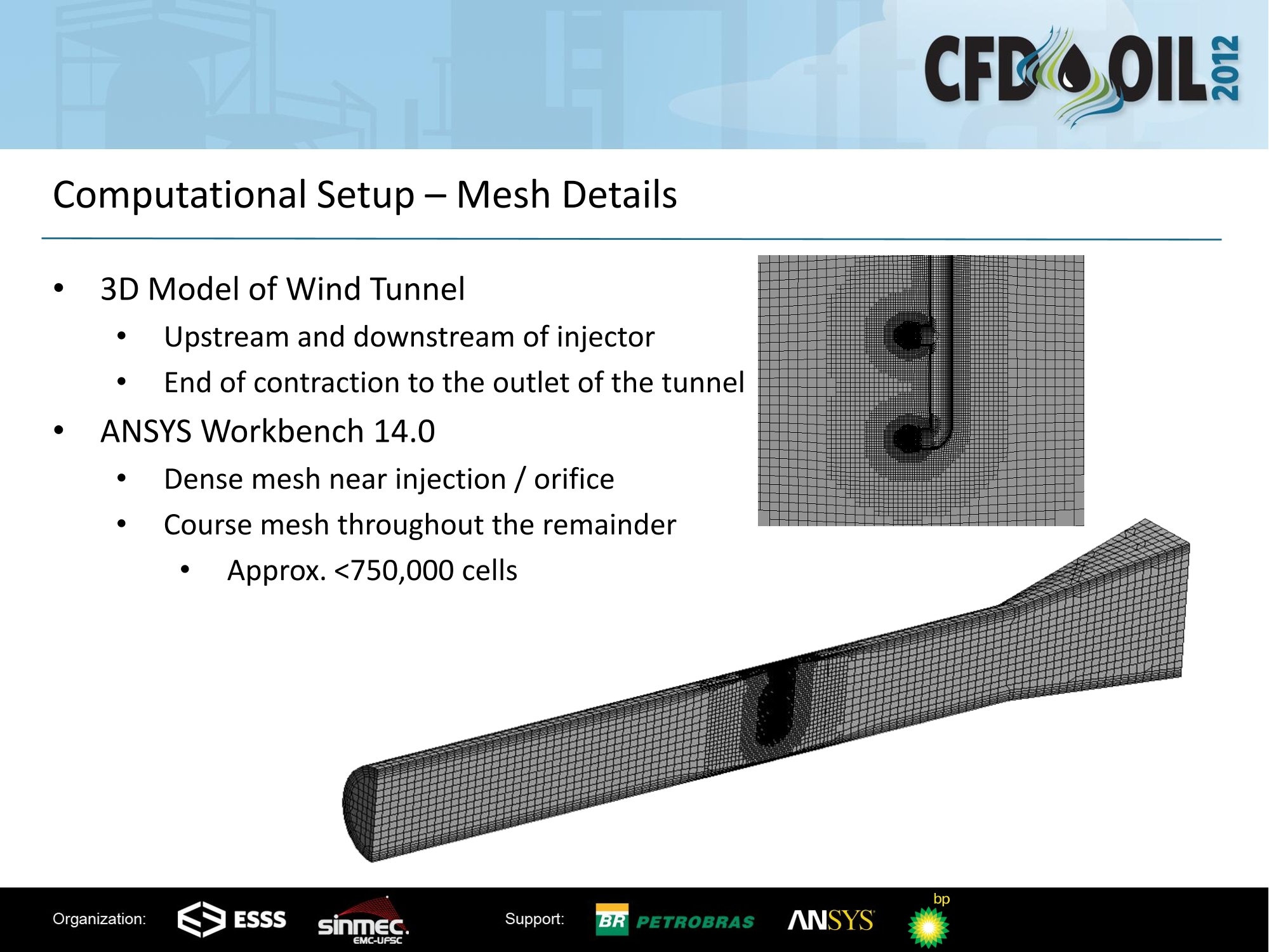

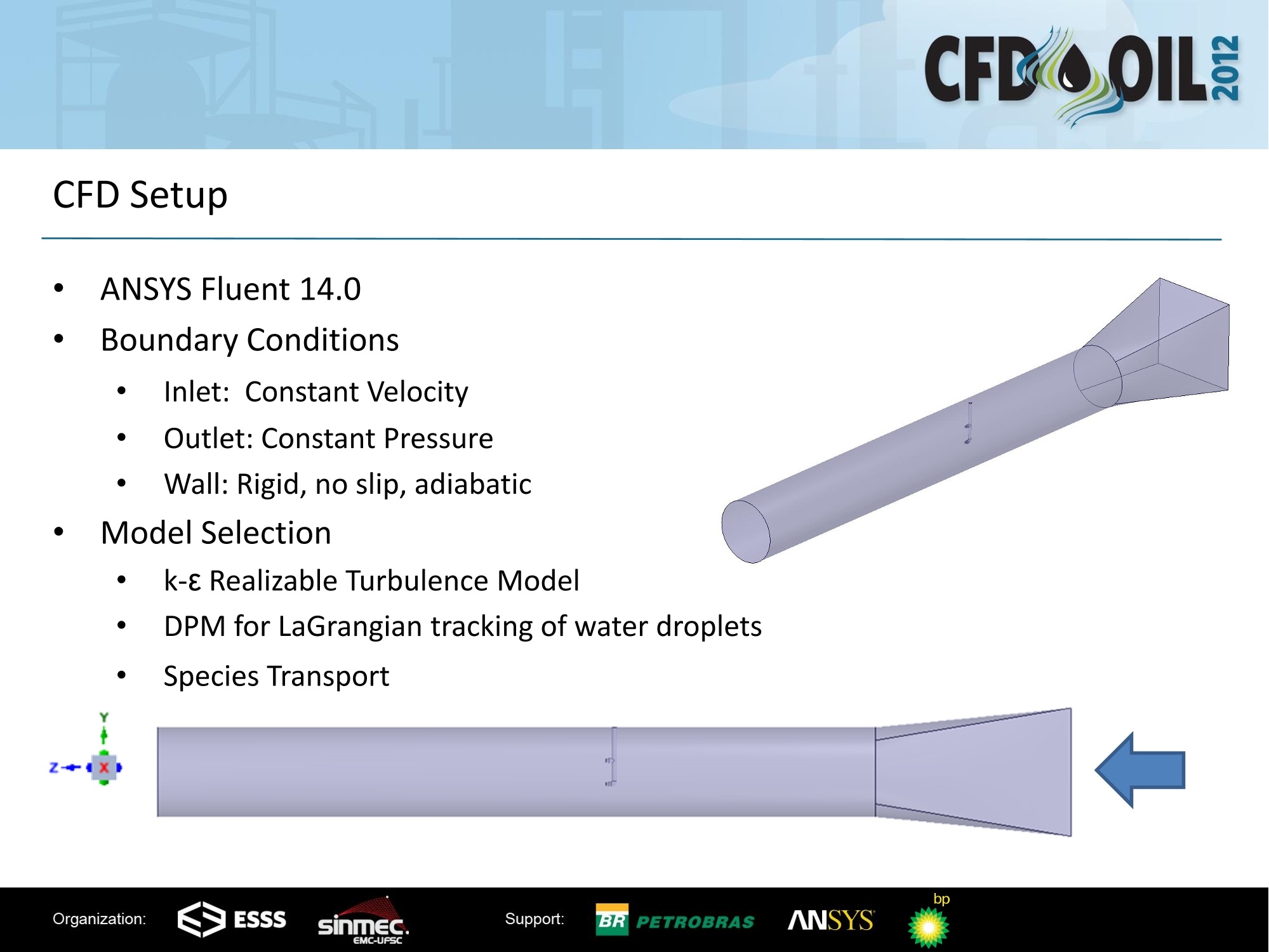

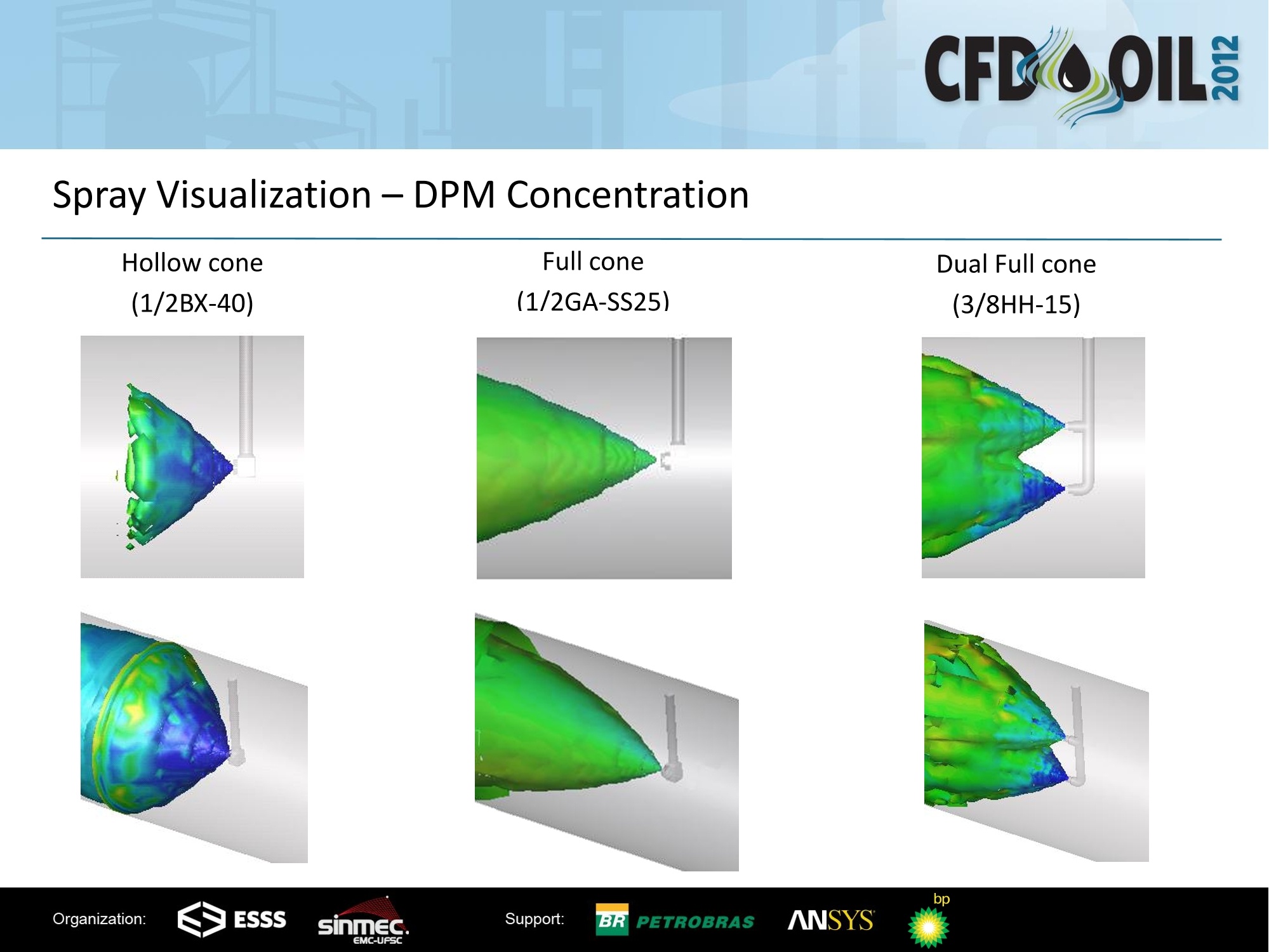

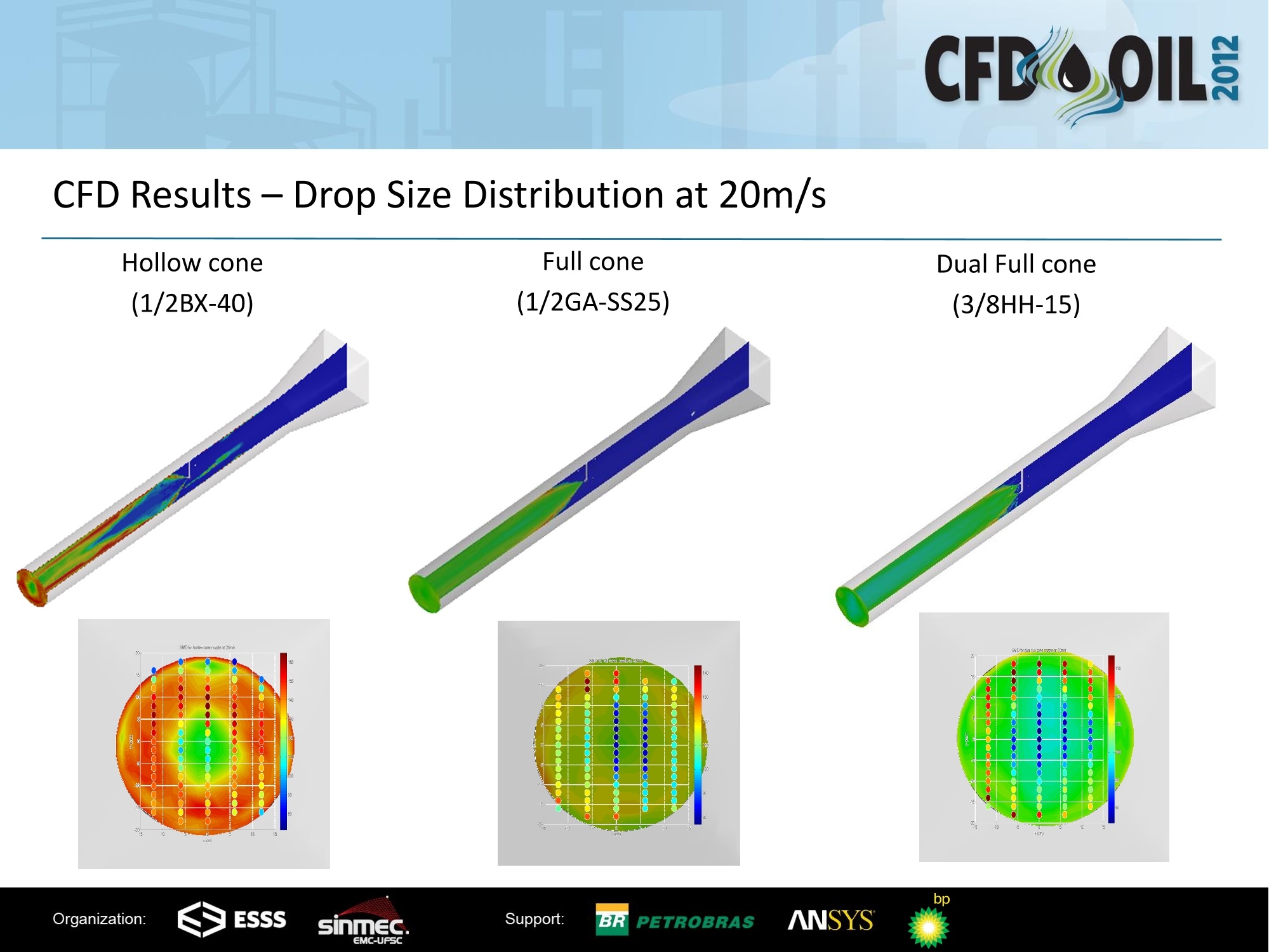

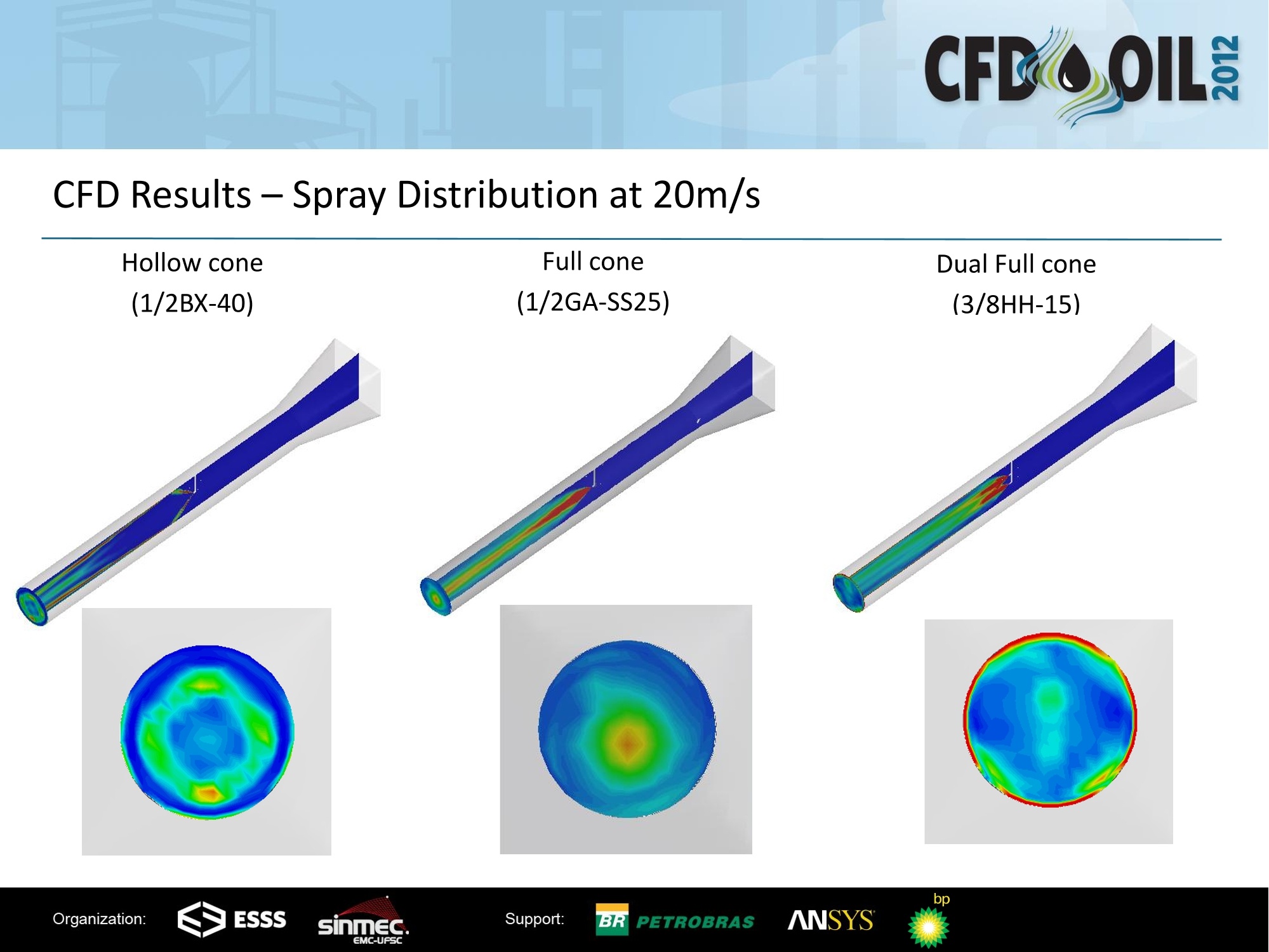

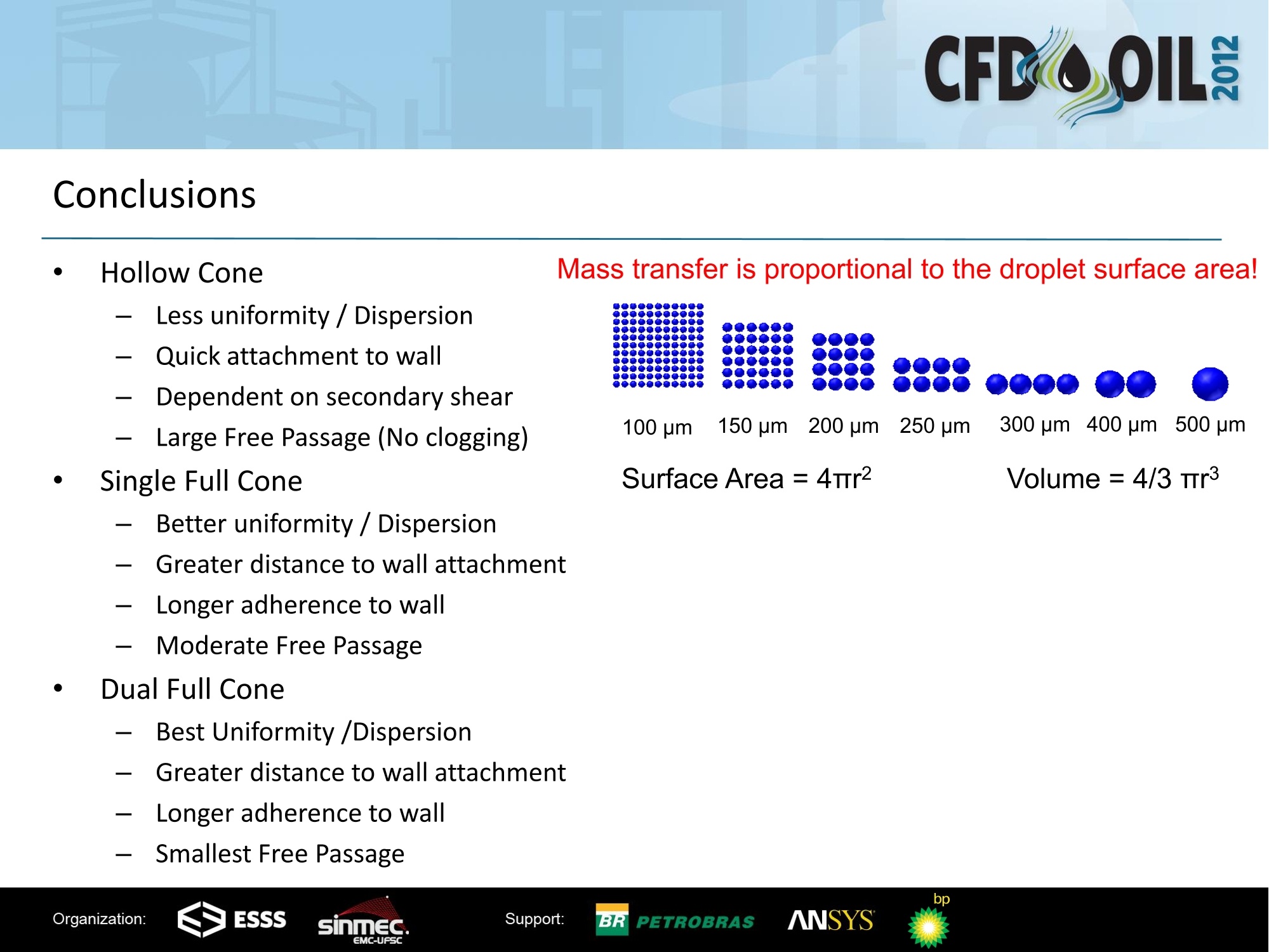

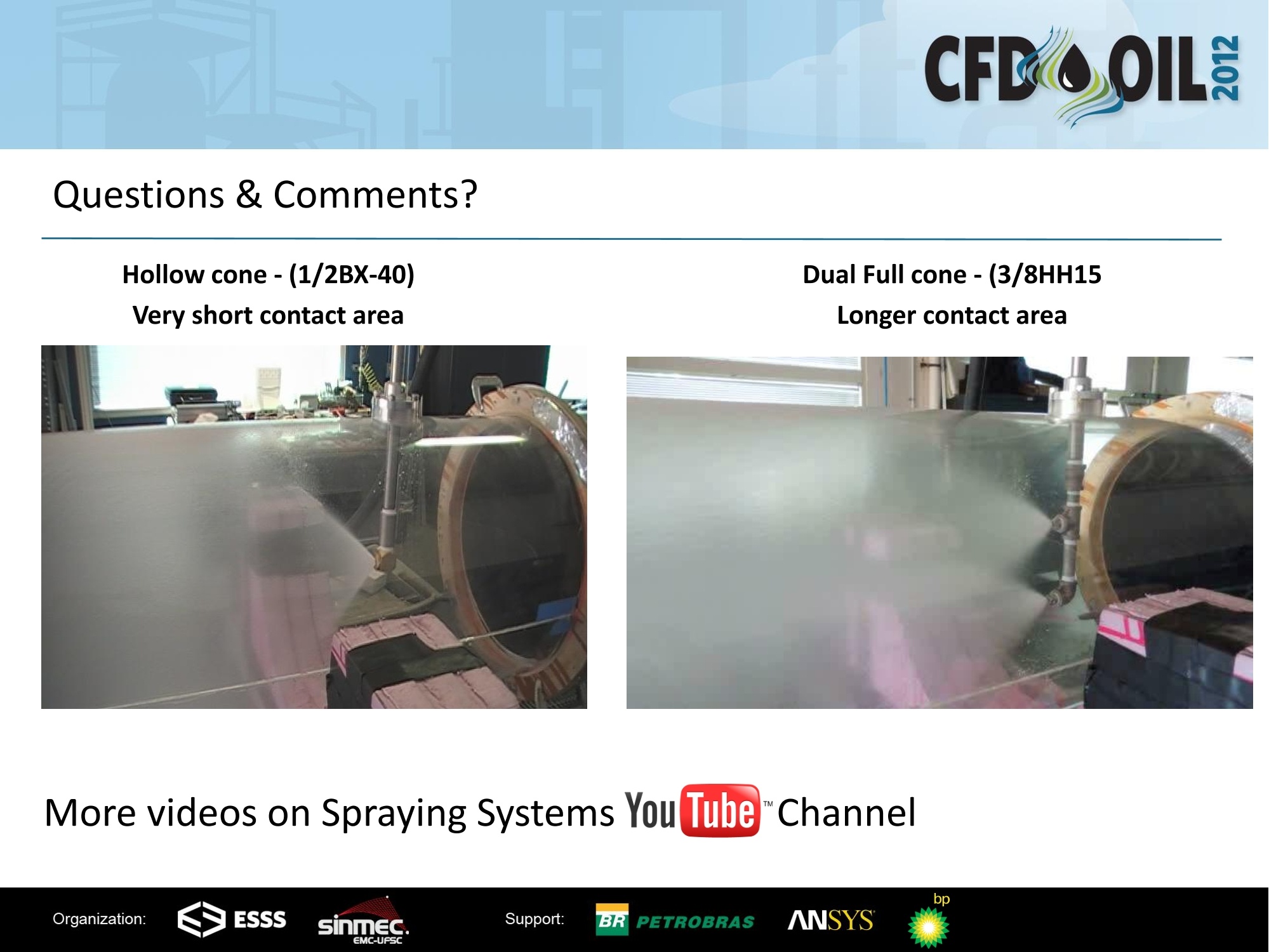

5th Latin American CFD WorkshopApplied to the Oil and Gas IndustryCFKO0LJuly 10-11, 2012Rio de Janeiro-Brazil CFKOILN Experimental and Computational Study of aWater Wash Spray Injection RudolfJ. Schick*, Kathleen J. Brown, Keith L. CronceSpray Analysis and Research Services Spraying Systems Co. - bp Organization: ESSS sinmec. Support: BRPETROBRAS ANSYS Company Overview Problem Description Methodology Results Conclusion and next steps bp ESSS Suppo r t: BRPETROBRA S ANSYS CF&OIL Nozzles Global leader in spray technology ●Globamanufacturing Global sales and support Spray nozzles, headers, injectors, spray controls,research & testing 75 years old SPRAYINGLSYSTIASCO bp sinmec. Support: BRPETROBRAS ANSYS Spray Analysis & Research Services Identify Techniques and Methodology forSpray Applications Proof-of-concept, modeling, prototypes,implementation Educational andConsulting Services Customer's knowledge of spraytechnology and applications Optimization of SprayPerformanceIncrease efficiencies, validateperformance, reduce risk bp Supp or t: BRPETROBRAS ANSYS Problem Description- Wash Water Injection Processing of crude oil creates various salts which can lead to corrosion or plugging at variousstages in the equipment. Water wash is used to scrub the salts from the process stream and to mitigate corrosion risks. Even distribution of water wash increases the effectiveness of a water-wash system. The interaction of a spray plume within a confined cross-flow environment controls the level ofliquid gas mixing and absorption effectiveness. CFD is used in environments that are difficult to access, validation is necessary to be sure injectorrecommendations are accurate and optimized. Process Stream Flow bp Organization: ESSS sinmEC. Support: BRPETROBRAS ANSYS Empirical Setup Wind Tunnel Large capacity Ambient air Modified Test Section 040cm x300cm Optical access Nominally Uniform Airflow 2-50m/s capability Operated at 10m/s and 20m/s Injectors Hollow cone-1/2BX-40 Full cone-1/2GA-SS25 Dual Full cone-3/8HH-15 bp ESSS sinmEC . Support: BRPETROB RAS ANSYS EMC-UFSC Experimental Setup- Spray Uniformity Acquisition Laser Sheet Imaging (LSI) LaVision GmbH LSIOrientation Mounted at exit of wind tunnel Vertical and Horizontal 2D measurement of spray pattern Time dependant fluctuations Light Intensity - Spray uniformity Mie Scattering bp BRPETROB RAS ANSYS LSI Results -10m/s wind speed Hollow cone(1/2BX-40) Full cone(1/2GA-SS25) Dual Full cone(3/8HH-15) bp Support: BRPETROBRA S ANSYS LSI Results -20m/s wind speed Hollow coneFull cone(1/2BX-40)(1/2GA-SS25) Dual Full cone(3/8HH-15) bp Suppo r t: BRPETROBRA S ANSYS LSI Results -Live Images Hollow cone (1/2BX-40) Dual Full cone (3/8HH-15) 480 440 400 320 80 240 200 160 120 80 Largest drop size and leastuniform distribution Smallest drop size and mostuniform distribution bp BRPETROBRAS ANSYS Experimental Setup- Drop Size Acquisition Phase Doppler Interferometer (PDI) Artium Technologies Inc. PDI-200MD PDI Orientation Mounted at exit of wind tunne| Vertical and Horizontal Traverse ● y-2 cm measurement resolution z-6cm measurement resolution Drop Size Distribution Axial Velocitv bp Suppor t : BRPETROBR AS ANSYS Drop Size Theory Injector Flow = 45 lit/min ncrease effectiveness More small dropletsincreases surfacearea Increase interactionwith gas stream witheven distributionacross pipe / duct Heat/Mass transfer and chemical reactions areproportional to the droplet surface area! 100 um 150 um200 um250 pm 300 pm 400 pm 500 unJm Surface Area = 4Trr2 Volume=4/3 TTr3 bp Organization: ESSS Support: BRPETROBRAS ANSYS Hollow cone(1/2BX-40) Full cone Dual Full cone (1/2GA-SS25) (3/8HH-15) SMD (um) SMD (um) SMD (um) SMD for full cone nozzle at 20m/s 145 SMD for dual full cone nozzle at 20m/s 135 SMD for hollow cone nozzle at 20m/s 165 20r 20 20 140 130 160 15- 15 15 150 130 10- 10- 120 10 140 120 5- 5 130 110 120 一E0 110 0 100 110 -5- -5 -5 100 100 90 -10 -10 -10 90 90 -15 -15F 80 80 30 -15 -1D -5 5 10 -15 -10 -5 0 5 10 -5 15- -10 10 15 75 x(cm) 1575 x(cm) 775 x(cm) SMD for full cone nozzle at 20m/s SMD for dual full cone nozzle at 20m/s SMD for hollow cone nozzle at 20m/s 160 140 130 150 130 120 140 1500- 120 140~ 180- 130 110 140- 130- 160- 120 130- 110 120- 140- 120~ 110 110- 100 120- E己110-E E 三100 E1090- 100 100- 10 90- 90 1( 90 10 10 80- 90 90 80 80- 0 0 80 70- 80 -19 -15 -1d -10 80 -10 -10 -10 -5 -5 -5 0 0 0 y(cm) -20 y(cm) 10 -20 Y(cm) 10 -20 10 15 15 15 x (cm) x(cm) x(cm) bp Organization: ESSS sinmec.EMC-UFSC Support: BRPETROBRA S ANSYS Hollow cone (cc/cm2/s) 0.45 0.25 20- volflux for dual full cone nozzle at 10m/s 151 10- 5 0 -5- -10- -15 -10 0 0.25 0.15- 0.05 y (cm) x(cm) bp Organization: ESSS sinmec.EMC-UFSC Support: BRPETROBRAS ANSYS Hollow cone Full cone Dual Full cone VF VF (1/2BX-40) (cc/cm2/s) (1/2GA-SS25) (cc/cm2/s) volflux for hollow cone nozzle at 20m/s 0.25 v olflux for full cone nozzle at 20m/s 0.55 20 20- 0.5 15 15 0.45 0.2 10 10- 0.4 5B 0.35 0.15 0.3 0 0 0.25 -5- 0.1 -5- 0.2 -10 0.15 -10 0.1 -15 0.05 -15 0.05 -20 -1D -5 5 10 15-100 -5 5 10 15 x(cm) Xx(cm) 0 volflux for hollow cone nozzle at 20m/s volflux for full cone nozzle at 20m/s 0.5 0.45 0.2 04 0.25 0.7- 0.35 -0.15 0.6- 022- 03 0.5- 0.25 0.15 E 0.4- 0.1 二> 0.2 0.33- 0. 0.2- 0.15 10 10 0.05 0.1- 0.1 0 0 0.05 -.1C 0.05 -10 -10 -10 -5 -5 0 5 -20 y(cm) 10 -20 y(cm) 10 15 15 x(cm) x(cm) x (cm) bp Organization: ESSS sinmec.EMC-UFSC Support: BRPETROBRAS ANSYS Computational Setup - Mesh Details 3D Model of Wind Tunnel Upstream and downstream of injectorEnd of contraction to the outlet of the tunnel ANSYS Workbench 14.0 Dense mesh near injection/ orifice Course mesh throughout the remainderApprox.<750,000 cells bp Support: BRPETROBRA S ANSYS ANSYS Fluent 14.0 Boundary Conditions Inlet:Constant Velocity Outlet: Constant Pressure Wall: Rigid, no slip, adiabatic ModelSelection k-e Realizable Turbulence Model DPM for LaGrangian tracking of water droplets Species Transport Z bp sinmec. Support: BRPETROBRASA N SYS Spray Visualization - DPM Concentration Hollow cone(1/2BX-40) Full cone (1/2GA-SS25) Dual Full cone(3/8HH-15) Organization: ESSS sinmec. Support: BRPETROBRAS ANSYS CFD Results - Drop Size Distribution at 20m/s Hollow cone(1/2BX-40) Full cone(1/2GA-SS25) Dual Fullcone(3/8HH-15) 8NDbholowa 20m 000 00 Organization: ESSS sinmEC. Suppor t : BRPETROBR AS ANSYS CFD Results - Spray Distribution at 20m/s Hollow cone Dual Full cone (1/2BX-40) Full cone(1/2GA-SS25) (3/8HH-15) Organization: ESSS sinmec. S upport: BRPETROBRA S ANSYS Conclusions Hollow Cone Mass transfer is proportional to the droplet surface area!- Less uniformity/Dispersion CQuick attachment to wall -DDependent on secondary shear 100 um 150 pm200 pm250 um 300 um 400 um :500 pm - Large Free Passage (No clogging) Single Full Cone Surface Area = 4Trr2 Volume =4/3 TTr3 Better uniformity / Dispersion Greater distance to wall attachment Longer adherence to wall 一NModerate Free Passage Dual Full Cone Best Uniformity /Dispersion Greater distance to wall attachment -LLonger adherence to wall Smallest Free Passage Secondary breakup estimation with & without transient CFDAdditional measurement locations (from injector) VOF of internal near orifice for better estimation of exit velocity Walinterference studies User feedback 一From customers case studies Corrosion and de-salting effectiveness bp ESSS BRPETROBRA S ANSYS Hollow cone-(1/2BX-40)Very short contact area Dual Full cone-(3/8HH15Longer contact area More videos on Spraying Systems YoulTubewcwChannel bp ESSS BRPETROBRAS ANSYS Thank You END bp Suppor t : BRPETROBR AS ANSYS Organization: Organization: ESSS

确定

还剩23页未读,是否继续阅读?

北京欧兰科技发展有限公司为您提供《水液滴中液滴直径,液滴速度检测方案(气溶胶)》,该方案主要用于其他中液滴直径,液滴速度检测,参考标准--,《水液滴中液滴直径,液滴速度检测方案(气溶胶)》用到的仪器有Artium PDI-FP 双量程可机载飞行探头、激光相位多普勒干涉仪LDV,PDI,PDPA,PDA、激光诱导白炽光(LII)烟气分析仪

推荐专场

相关方案

更多

该厂商其他方案

更多