Temperature measurements using planar laser-induced fluorescence (PLIF)are most often associated with experimental challenges. In addition, no PLIF technique is generally applicable in all kinds of environment. Especially under sooting conditions problems are prone to arise, which limits the use of these techniques. In this paper the two-line atomic fluorescence (TLAF) technique was investigated in sooting environments. Indium atoms were used as thermometry species and seeded into the combustion region. Data from two-dimensional measurements are often difficult to analyse, because of problems with treating noise. A statistical analysis method for

correction of laser fluctuations was developed to increase the precision of the temperature calculations.

The results show that TLAF holds promise for temperature

measurements in rich combustion, such as diesel engines, where other

techniques have proven to fail. Drawbacks with the TLAF technique are that the probe volume is biased towards the post-flame zone and that seeding is required. The statistical analysis improved the precision considerably and is suitable for evaluation of other two-dimensional thermometry techniques.

This paper also presents a critical review and comparison with alternatives, such as OH and NO thermometry.

方案详情

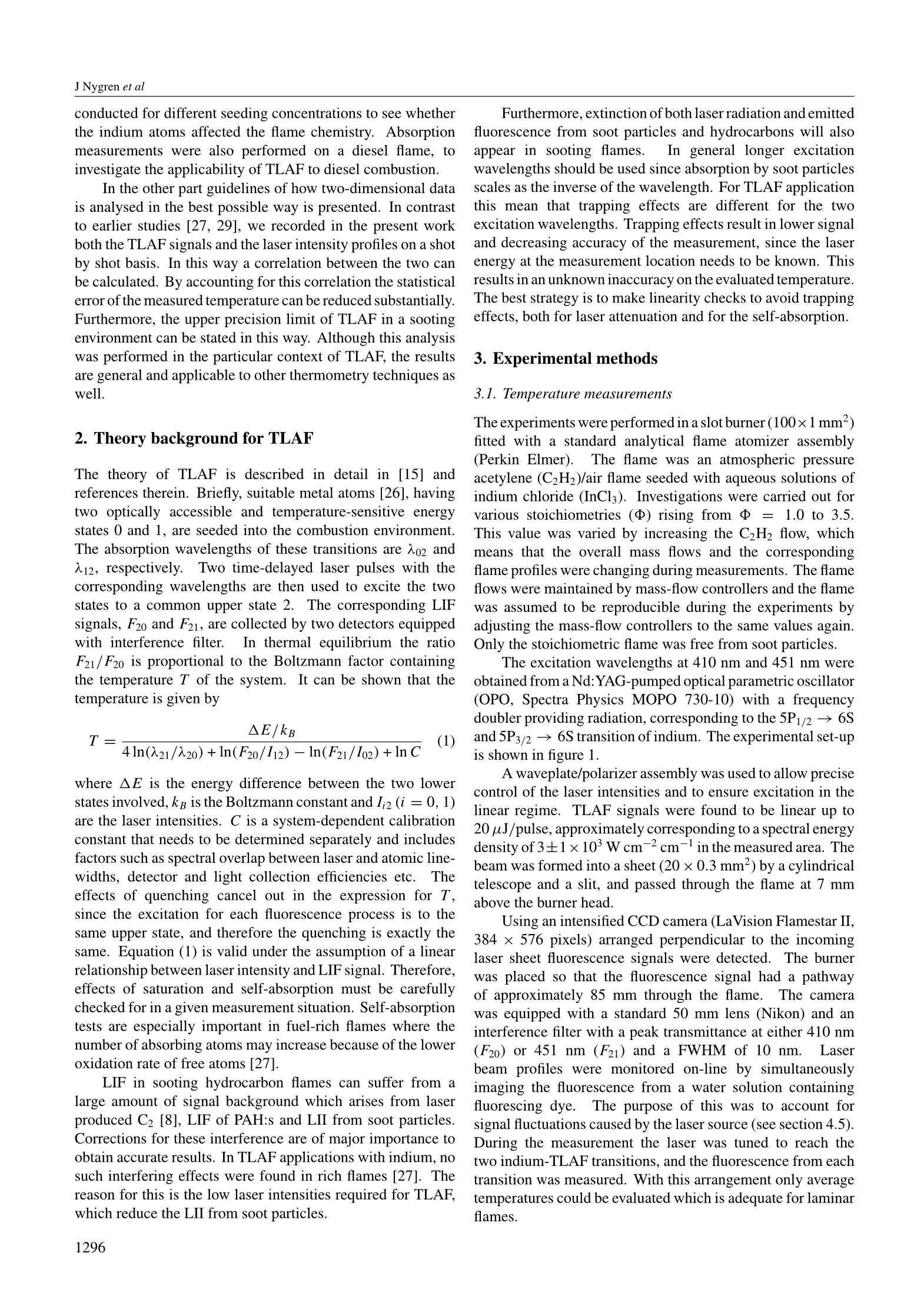

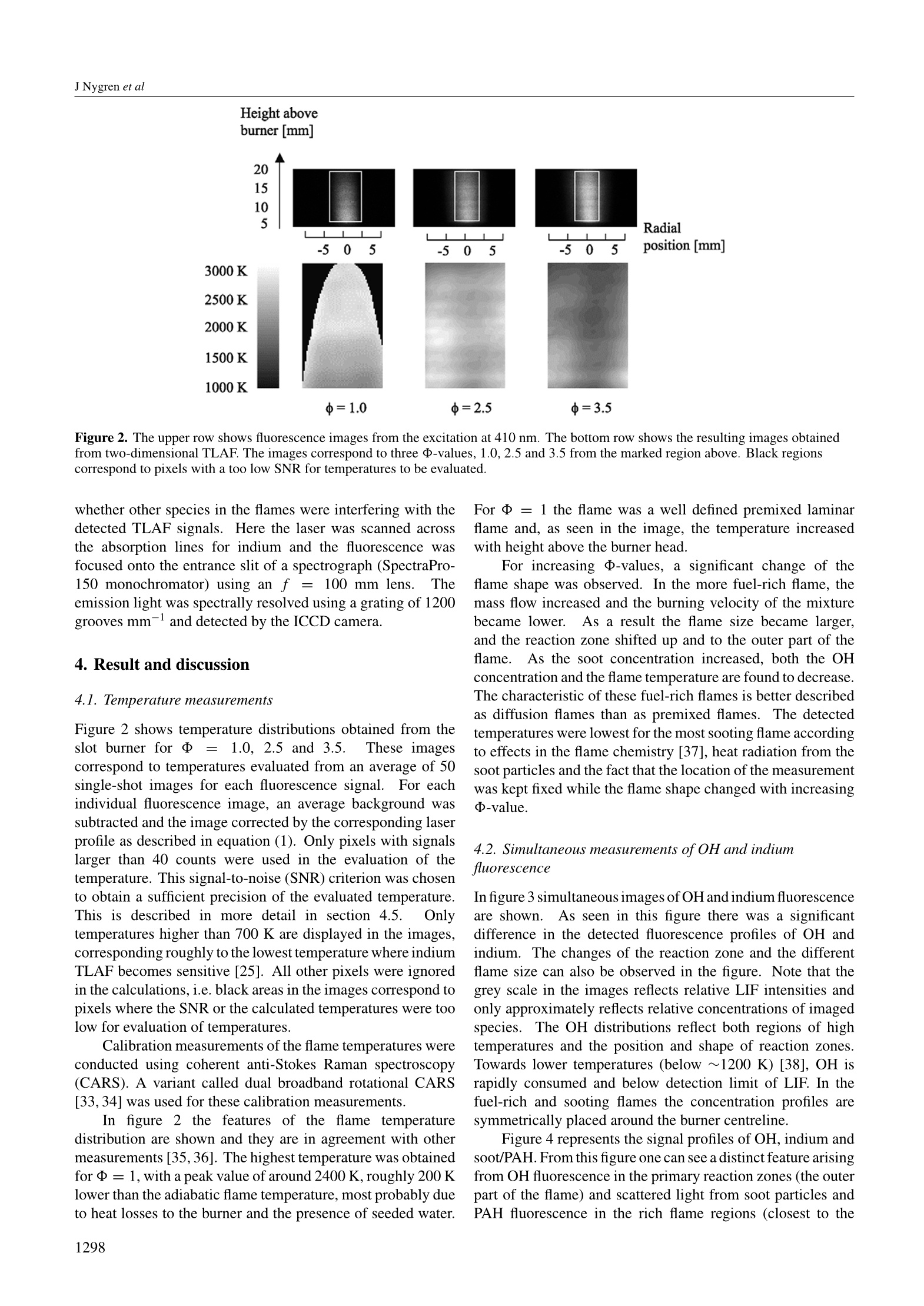

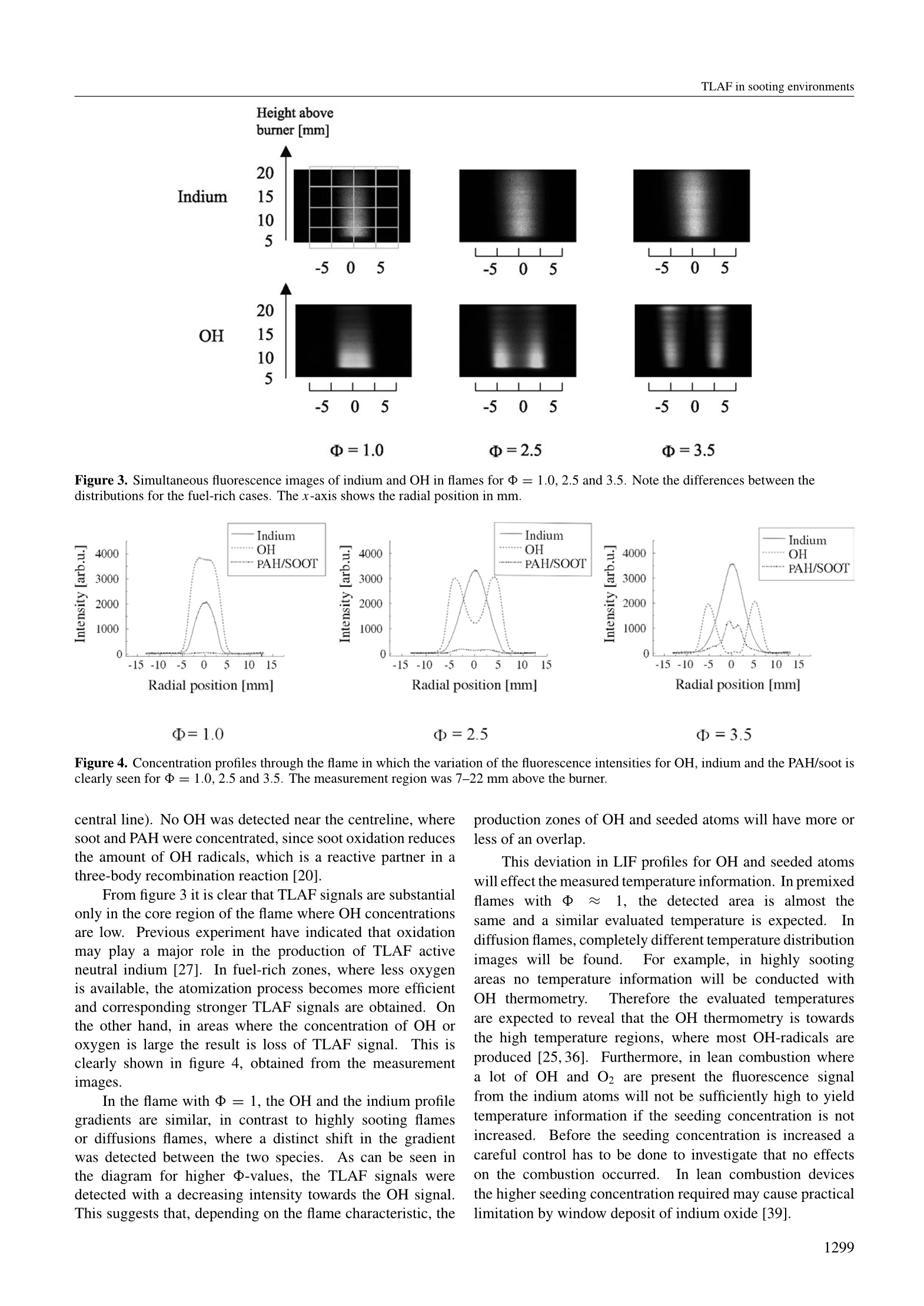

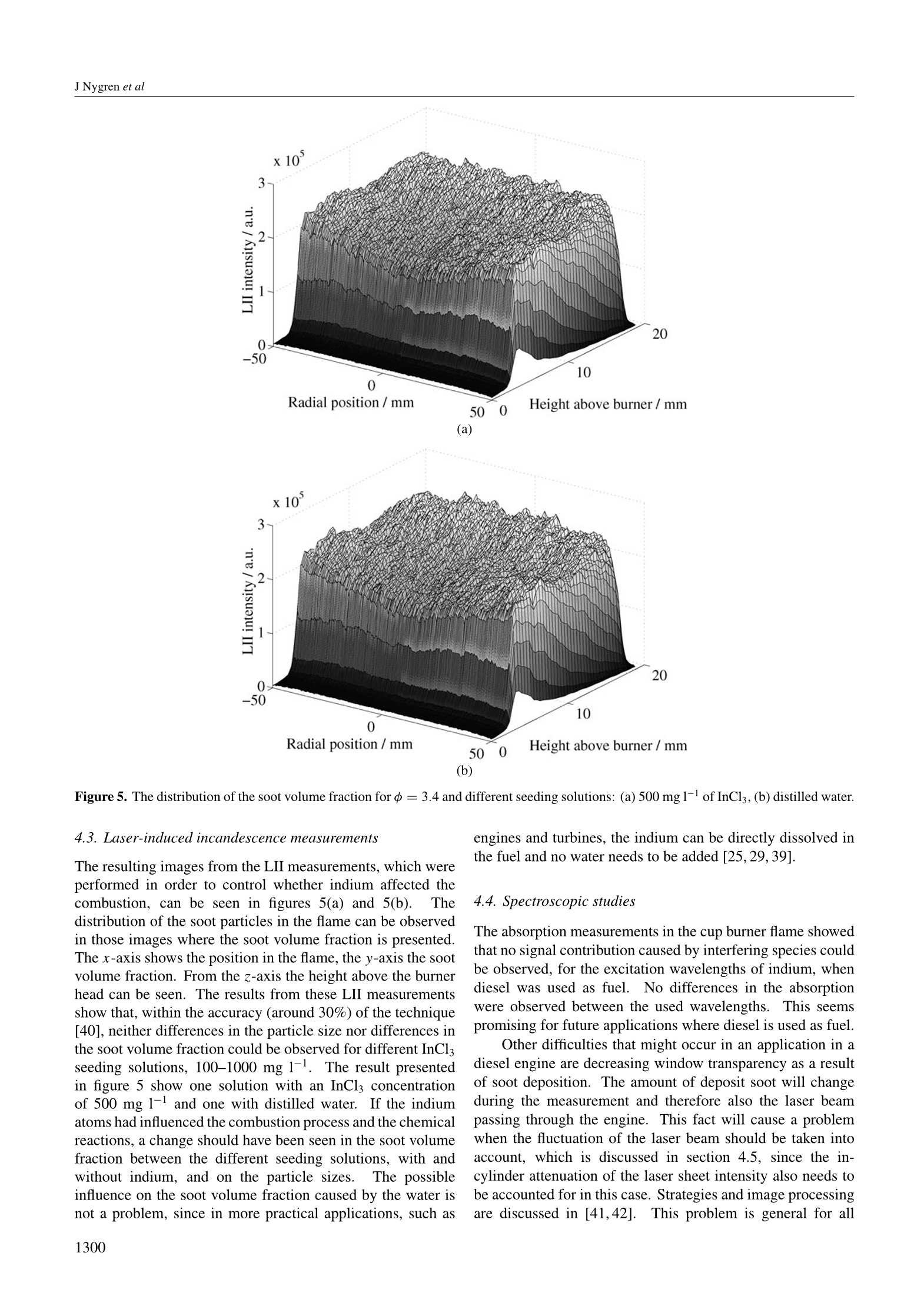

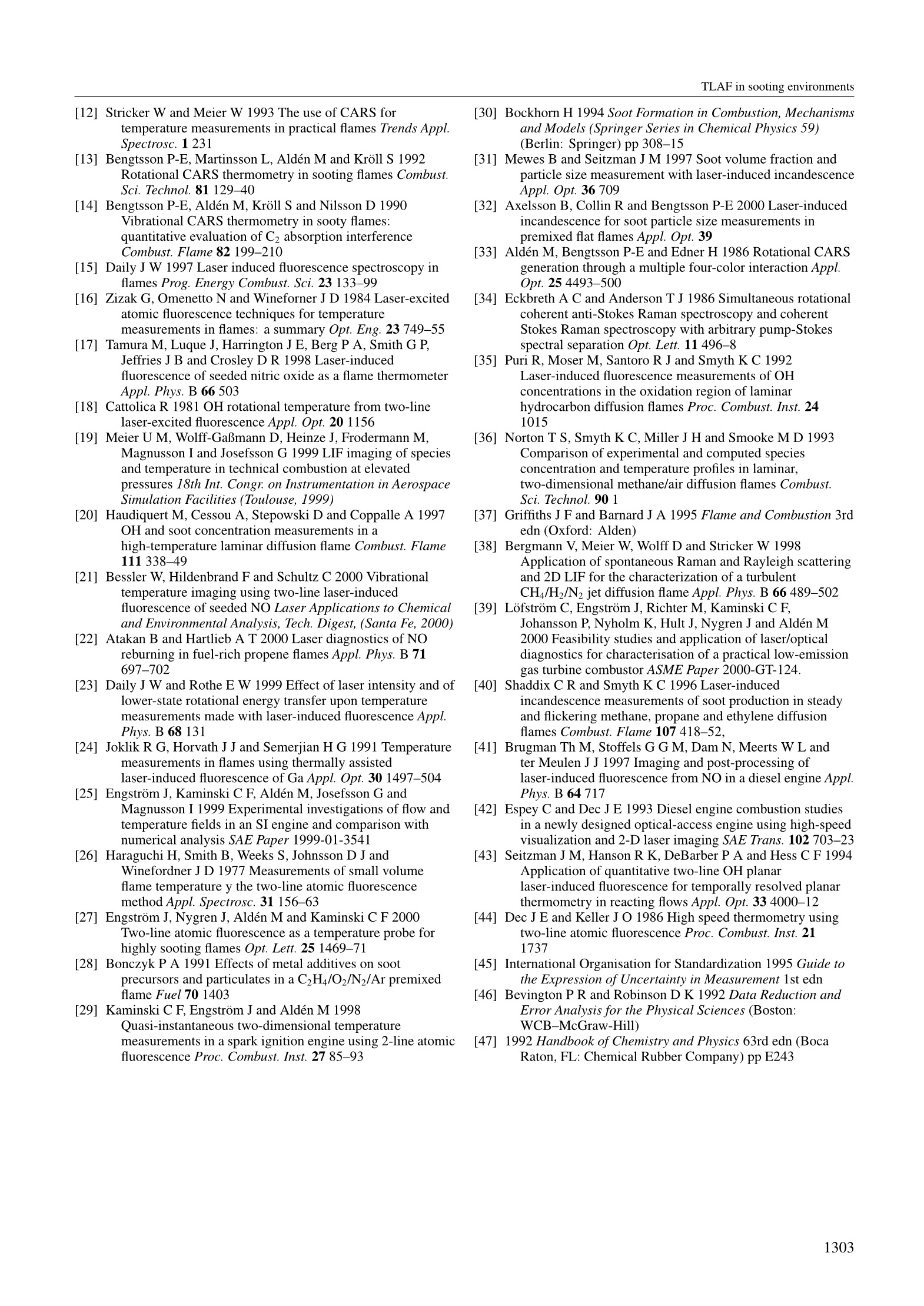

MEASUREMENT SCIENCE AND TECHNOLOGYINSTITUTE OF PHYSICS PUBLISHINGMeas. Sci. Technol. 12 (2001)1294-1303www.iop.org/Journals/mt PII: S0957-0233(01)20788-7 TLAF in sooting environments Applications and evaluation of two-lineatomic LIF thermometry in sootingcombustion environments J Nygren', J Engstrom, J Walewski', C F KaminskiandM Alden' Department of Combustion Physics, Lund Institute of Technology, Box 118, S-22100 Lund,Sweden Department of Chemical Engineering, University of Cambridge, Pembroke Street,Cambridge CB2 3RA, UK E-mail: jenny.nygren@forbrf.lth.se Received 11 January 2001, accepted for publication 19 April 2001 Abstract Temperature measurements using planar laser-induced fluorescence (PLIF)are most often associated with experimental challenges. In addition, no PLIFtechnique is generally applicable in all kinds of environment. Especiallyunder sooting conditions problems are prone to arise, which limits the use ofthese techniques. In this paper the two-line atomic fluorescence (TLAF)technique was investigated in sooting environments. Indium atoms wereused as thermometry species and seeded into the combustion region. Data from two-dimensional measurements are often difficult to analyse,because of problems with treating noise. A statistical analysis method forcorrection of laser fluctuations was developed to increase the precision ofthe temperature calculations. The results show that TLAF holds promise for temperaturemeasurements in rich combustion, such as diesel engines, where othertechniques have proven to fail. Drawbacks with the TLAF technique are thatthe probe volume is biased towards the post-flame zone and that seeding isrequired. The statistical analysis improved the precision considerably and issuitable for evaluation of other two-dimensional thermometry techniques.This paper also presents a critical review and comparison with alternatives,such as OH and NO thermometry. Keywords: 2D-temperature, sooting environments, LIF,combustiondiagnostics, statistical data analysis 1. Introduction Measurements of temperature fieldss are crucial for animproved understanding of combustion processes in industrialdevices. The development of improved accurate thermometrytechniques for diesel engines is an especially importanttask, since diesel engines are becoming increasingly popularbecause of their highly efficient combustion in comparison tospark ignition engines. This high efficiency generally leads tolower emission of CO2 and as a consequence diesel fuel drivenengines tend to contribute less to the greenhouse effect. Unfortunately other forms of pollution from diesel enginesare still comparatively high, especially those resulting from soot and NO, emissions. Soot particles can be reducedby higher combustion temperatures, which lead to strongeroxidation of soot particles. On the other hand, highertemperature increases thermal NOx production. This problemhighlights the importance of temperature information for theoptimization of diesel engines. In general, laser techniques are not easily applied instrongly sooting combustion environments, owing to thestrong absorption,spectral interference from particulatescattering and fluorescence from large molecules. Temporallyresolved temperature measurements in sooting environmentsare however essential for improving the overall understandingof sootformation and oxidation. A development of novel temperature techniques for applications in sootingenvironment is therefore important. Laser-based methods for temperature measurements inreactive and turbulent environments have been the subjectof extensive research [1-3].For turbulent flames, whichfluctuate both in space and in time, instantaneous imagingof temperature distributions are especially desirable.Themajority of such measurements have been performed in leancombustion environments and have not been optimized forapplications under fuel-rich and sooting conditions. In sooting environments, temperature measurementsusing line-of sight emission have recently been performed [4].These experiments were made in order to improve the accuracy. of laser induced incandescence (LII) measurements. Theywere used for the validation of underlying models of coolingand particularly of heat conduction in the vaporization processof soot particles..,However, measurements using emissionspectroscopy must be employed in a very careful manner toavoid systematic error [5]. Since emission from chemicallygenerated species is not usually thermally equilibrated theemission method may bias temperatures to high values.These problems are discussed by Aust [6], where equilibriumtemperature measurements from an SI engine are reported. Filtered Rayleigh [7] and Raman [8,9] scattering tech-niques have been used in sooting flames for both temperatureand species concentration measurements. These techniquesrevealed reliable information in sooting environments, but theaccuracy is limited since knowledge of the collisional cross-sections is required for all involved species [10]. This wouldtend to limit these techniques for thermometry applications inpractical environments with non-homogeneously mixed sys-tems, such as diesel engines, where local effective cross sec-tions are unknown. Furthermore, in realistic engine geometrystrong elastic scattering from surfaces may also causeproblem A thermometry technique that is applicable in sootingenvironments is coherent anti-Stokes Raman spectroscopy(CARS). This is a technique used for point-wise measurementsof temperature and major species concentrations, which isdescribed in [11-14]. Different thermometry applicationss based onlaser-induced fluorescence (LIF) techniques have been reviewed byDaily [15]. In the simplest approach of LIF, the temperatureis deduced from the intensity of a single transition. For suchmeasurements to be precise, however, the variation of molefraction and collisional quenching in the reacting flow must beaccounted for quantitatively. In highly sooting and turbulentflames this task is almost impossible. These problems can beavoided by extracting the temperature from the ratio of twoLIF signals from two temperature transitions and determininga two-line Boltzmann temperature [16]. A disadvantage oftwo-line LIF methods is that they are experimentally complex,since two laser and gated detector systems are required. Aquantitative comparison of the two approaches is found in [17]. LIF thermometry can be based either on seeded speciesor on native molecules in the combustion process. One ofthe most commonly used species is the OH radical [3,18,19],which, however, exhibits low concentrations in fuel-rich andsooting flames due to the low prevailing temperatures and lowlevels of oxidizing species present [20]. Forapplications ofLIFthermometry in such flames, the use of seeded species may be a preferable choice [10]. However, when tracer species areseeded into the combustion process, it is essential that theirinfluence on the combustion process is negligible Recently,Bessler et allhave showntemperaturedistributions in rich flames based on two-line thermometry ofseeded NO [21]. The characteristics of NO molecules as flametemperature markers have been discussed in detail in [17],showing that one advantage of this approach is that it providesinformation about the temperature, in both pre- and post-flamezones. Since NO is a chemically active combustion speciessignificant reduction effects of seeded NO concentrations havebeen observed in flames [22]. This reduction is produced by acombination of reburn chemistry and dilution. The reburningof NO has the largest influence in rich flames where NO reactswith CH producing HCN and O. This reaction will in turnincrease the oxidation of soot particles since more oxygenbecomes available. The effects are exacerbated by the factthat large amounts of NO are required to achieve the signalto noise ratios required for LIF thermometry. Thus carefulchecks have to be carried out to control that seeded NO doesnot interfere with the combustion process. Furthermore, whenmolecular species are employed for thermometry, correctionsfor rotational and vibrational energy transfer processes have tobe performed [23]. In the latter respect, a temperature evaluation from atomicspecies is far easier according to the simpler spectroscopicfeatures of an atom [15].Thermometry measurementshave been performed with thermally assisted fluorescence(THAF) in fuel-rich flames using seeded gallium atoms [24].A disadvantage with this technique is that knowledge ofcollisional cross-sections for all involved species is required.Further, due to low signal levels THAF does not seem to beapplicable for temperature measurements in engines on singleshot basis. Two-line atomic fluorescence (TLAF), on the otherhand, has recently been reported to provide this [25]. TLAFis based on suitable atoms being seeded into the combustionregion and indium has been pointed out to be an attractivecandidate for practical combustion, since it is sensitive over.a wide temperature range (700-3000 K) [26].It has alsobeen shown that indium TLAF holds promise for temperaturemeasurements in highly sooting flames [27]. It has beenshown that the number density of TLAF active indium atomsincreases in fuel-rich flames, with the result that very lowseeding concentrations can be used. However, a limitationof the technique is that only regions behind the flame front areaccessible by the technique, owing to the process by whichindium is produced in flames. The purpose of this paper is twofold. The first part isexperimental, where a two-dimensional approach for TLAF inhighly sooting flames has been performed. The fluorescencesignals were measured and the temperature was evaluated fordifferentequivalenceratios() in an atmospheric acetylene/airflame. Furthermore we simultaneously measured the profilesof indium and OH LIF signals as a function of flamestoichiometry. The results indicate the preferred flame regionin which to perform LIF thermometry approaches on indiumor on OH. In particular it is shown that the OH thermometryis towards high temperature regions and difficult to apply insooting environments. Since adding metallic ions may change the soot production[28],laser induced incandescence (LII) measurements were conducted for different seeding concentrations to see whetherthe indium atoms affected the flame chemistry. Absorptionmeasurements were also performed on a diesel flame, toinvestigate the applicability of TLAF to diesel combustion. In the other part guidelines of how two-dimensional datais analysed in the best possible way is presented. In contrastto earlier studies [27, 29], we recorded in the present workboth the TLAF signals and the laser intensity profiles on a shotby shot basis. In this way a correlation between the two canbe calculated. By accounting for this correlation the statisticalerror of the measured temperature can be reduced substantially.Furthermore, the upper precision limit of TLAF in a sootingenvironment can be stated in this way. Although this analysiswas performed in the particular context of TLAF, the resultsare general and applicable to other thermometry techniques aswell. 2. Theory background for TLAF The theory of TLAF is described in detail in [15] andreferences therein. Briefly, suitable metal atoms [26], havingtwo optically accessible and temperature-sensitive energystates 0 and 1, are seeded into the combustion environment.The absorption wavelengths of these transitions are A02 and入12, respectively.Two time-delayed laser pulses with thecorresponding wavelengths are then used to excite the twostates to a common upper state 2. The corresponding LIFsignals, F20 and F21, are collected by two detectors equippedwith interference filter. In thermal equilibrium the ratio10F21/F20 is proportional to the Boltzmann factor containingthe temperature T of the system. It can be shown that thetemperature is given by where E is the energy difference between the two lowerstates involved, kg is the Boltzmann constant and Ii2 (i=0, 1)are the laser intensities. C is a system-dependent calibrationconstant that needs to be determined separately and includesfactors such as spectral overlap between laser and atomic line-widths, detector and light collection efficiencies etc. Theeffects of quenching cancel out in the expression for T,since the excitation for each fluorescence process is to thesame upper state, and therefore the quenching is exactly thesame. Equation (1) is valid under the assumption of a linearrelationship between laser intensity and LIF signal. Therefore,effects of saturation and self-absorption must be carefullychecked for in a given measurement situation. Self-absorptiontests are especially important in fuel-rich flames where thenumber of absorbing atoms may increase because of the loweroxidation rate of free atoms [27]. LIF in sooting hydrocarbon flames can suffer from alarge amount of signal background which arises from laserproduced C2 [8], LIF of PAH:s and LII from soot particles.Corrections for these interference are of major importance toobtain accurate results. In TLAF applications with indium, nosuch interfering effects were found in rich flames [27]. Thereason for this is the low laser intensities required for TLAF,which reduce the LII from soot particles. Furthermore,extinction of both laser radiation and emittedfluorescence from soot particles and hydrocarbons will alsoappear in sooting flames. In general longer excitationwavelengths should be used since absorption by soot particlesscales as the inverse of the wavelength. For TLAF applicationthis mean that trapping effects are different for the twoexcitation wavelengths. Trapping effects result in lower signaland decreasing accuracy of the measurement, since the laserenergy at the measurement location needs to be known. Thisresults in an unknown inaccuracy on the evaluated temperature.The best strategy is to make linearity checks to avoid trappingeffects, both for laser attenuation and for the self-absorption. 3. Experimental methods 3.1. Temperature measurements The experiments were performed in a slot burner (100×1mm)fitted with a standard analytical flame atomizer assembly(Perkin Elmer). The flame was an atmospheric pressureacetylene (C2H2)/air flame seeded with aqueous solutions ofindium chloride (InCl3). Investigations were carried out forvarious stoichiometries (D) rising from = 1.0 to 3.5.This value was varied by increasing the C2H2 flow, whichmeans that the overall mass flows and the correspondingflame profiles were changing during measurements. The flameflows were maintained by mass-flow controllers and the flamewas assumed to be reproducible during the experiments byadjusting the mass-flow controllers to the same values again.Only the stoichiometric flame was free from soot particles. The excitation wavelengths at 410 nm and 451 nm wereobtained from a Nd:YAG-pumped optical parametric oscillator(OPO, Spectra Physics MOPO 730-10) with a frequencydoubler providing radiation, corresponding to the 5P1/2→6Sand 5P3/2→6S transition of indium. The experimental set-upis shown in figure 1. A waveplate/polarizer assembly was used to allow precisecontrol of the laser intensities and to ensure excitation in thelinear regime. TLAF signals were found to be linear up to20 uJ/pulse, approximately corresponding to a spectral energydensity of3±1×10Wcm-2cm- in the measured area. Thebeam was formed into a sheet (20×0.3 mm²) by a cylindricaltelescope and a slit, and passed through the flame at 7 mmabove the burner head. Using an intensified CCD camera (LaVision Flamestar II,384 × 576 pixels) arranged perpendicular to the incominglaser sheet fluorescence signals were detected. The burnerwas placed so that the fluorescence signal had a pathwayof approximately 85 mm through the flame..The camerawas equipped with a standard 50 mm lens (Nikon) and aninterference filter with a peak transmittance at either 410 nm(F20) or 451 nm (F21) and a FWHM of 10 nm. Laserbeam profiles were monitored on-line by simultaneouslyimaging the fluorescence from a water solution containingfluorescing dye.e.The purpose of this was to account forsignal fluctuations caused by the laser source (see section 4.5).During the measurement the laser was tuned to reach thetwo indium-TLAF transitions, and the fluorescence from eachtransition was measured. With this arrangement only averagetemperatures could be evaluated which is adequate for laminarflames. For turbulent flows, F20 and F21 have to be measured on atime scale which is shorter than turbulence time scales, whichin practice means that two lasers and two detectors have to beused simultaneously as described in [29]. 3.2. Simultaneous indium/OH LIF measurements The deviation of the fluorescence profiles from OH and indiumwas investigated, both in the slot burner and in small pool-flames in a cup burner with different liquid fuels. Since thelatter fluctuated in time,OH and indium measurements hadto be performed simultaneously and two laser and detectorsystems were used. The slot-burner was operated underidentical conditions as described in section 3.1. The cup burnerhad a diameter of 30 mm. Methanol, diesel and JET-A wereexamined. In addition to the OPO (see section 3.1) a standard Nd:YAG/ dye system (Continuum) was used for OH excitation.For the OH measurements, the Qi (8) line in the X2I(u=0)→A²z(u=1) band at 入=283.68 nm was excited usinga pulse energy of approximately 6×107 W cm-2cm-. Thisexcitation line was chosen because its population is the leasttemperature sensitive (varying by less than 5% between 1400and 2100 K [1]). The two laser beams were combined using aspecially coated quartz plate, formed into sheets and carefullyaligned through the flame to ensure excitation in same region asthose in which the temperature measurements were previouslyperformed. Two filtered intensified CCD cameras, arrangedat right angles to each other and aligned on a pixel by pixelbasis, monitored the fluorescence signals, at 309 nm for OHand at 410 nm for indium. The filter in front of the camera thatmonitored the OH signal was an interference filter with a peaktransmittance of around 312 nm and a FWHM of 20 nm. Abeam splitter was used to separate the two fluorescence signals.A similar experimental set-up can be seen in [25]. Background images were recorded for all the LIFmeasurements by tuning the laser slightly off the resonancefrequency for respectively species. The background imageswere then subtracted from the fluorescence signals in orderto eliminate contributions to the signal from soot and PAH.When the laser was tuned off for the OH excitation line, thefluorescence signal from the OH-molecules disappeared, butscattered light from soot particles and LIF from PAH could still be observed. However, since the off-resonance profilewas obtainedjust by changing the laser wavelength by 0.1 nm,no differences in signal strength could be detected, either forthe scattered light from the soot particles or for the PAHfluorescence, when identical laser energies were used. Thus,the pure OH fluorescence signal could be obtained, even inthe presence of soot particles, when the off-resonance imagewas subtracted from the resonance image. No corrections forlaser attenuation (<3%), temperature or trapping effects wasmade. In contrast to the OH imaging, hardly any laser-inducedbackground was detected in the TLAF experiments, even in themost sooting flame. 3.3. Laser-induced incandescence measurements It has been discussed in the literature [30] that adding metalliccomplexes may either decrease soot formation or increase therate of soot oxidation. There are different mechanisms thataffect the soot formation of the seeded metal and it is almostexclusively dependent on temperature, seeding concentrationandionization potential [28]. One mechanism is that metal ionsare expected to increase the nucleation rate and lead to smallerindividual particles for a given carbon yield and therefore tohigher chemical rate oxidation. Therefore LII was used tomeasure the soot volume fraction and the soot particle size asa function of seeded indium concentration. The measurementswere performed in the region 7-22 mm above the burner head.In this experiment the slot burner was arranged so the camerawas placed perpendicular to the slit. Two flames with differentequivalence ratios D=2.5 and 3.5 were investigated and boththe soot volume fraction and the size of the soot particles weremeasured. Each flame measurements were performed with twodifferent seeding solutions, one with a solution of indium anddistilled water and the other with only distilled water. Detailsof the LII technique are found in [31,32]. 3.4. Spectroscopic studies Feasibility spectroscopic studies were also carried out in thecup burner flame for these fuels. First, experiments weremade using a xenon lamp to establish the expected laserbeam attenuation from absorption and extinction for differentwavelengths. Secondly,experiments were made to investigate Height aboveburner [mm] Figure 2. The upper row shows fluorescence images from the excitation at 410 nm. The bottom row shows the resulting images obtainedfrom two-dimensional TLAF. The images correspond to three D-values, 1.0, 2.5 and 3.5 from the marked region above. Black regionscorrespond to pixels with a too low SNR for temperatures to be evaluated. whether other species in the flames were interfering with thedetected TLAF signals. Here the laser was scanned acrossthe absorption lines for indium and the fluorescence wasfocused onto the entrance slit of a spectrograph (SpectraPro-150 monochromator) using an f = 100 mm lens.Theemission light was spectrally resolved using a grating of 1200grooves mm- and detected by the ICCD camera. 4. Result and discussion 4.1. Temperature measurements Figure 2 shows temperature distributions obtained from theslot burner for = 1.0,2.5 and 3.5. These imagescorrespond to temperatures evaluated from an average of 50single-shot images for each fluorescence signal. For eachindividual fluorescence image, an average background wassubtracted and the image corrected by the corresponding laserprofile as described in equation (1). Only pixels with signalslarger than 40 counts were used in the evaluation of thetemperature. This signal-to-noise (SNR) criterion was chosento obtain a sufficient precision of the evaluated temperature.This is described in more detail in section 4.5. Onlytemperatures higher than 700 K are displayed in the images,corresponding roughly to the lowest temperature where indiumTLAF becomes sensitive [25]. All other pixels were ignoredin the calculations, i.e. black areas in the images correspond topixels where the SNR or the calculated temperatures were toolow for evaluation of temperatures. Calibration measurements of the flame temperatures wereconducted using coherent anti-Stokes Raman spectroscopy(CARS). A variant called dual broadband rotational CARS[33,34] was used for these calibration measurements. In figure 2 the features of the flame temperaturedistribution are shown and they are in agreement with othermeasurements [35,36]. The highest temperature was obtainedfor =1, with a peak value of around 2400 K,roughly 200 Klower than the adiabatic flame temperature, most probably dueto heat losses to the burner and the presence of seeded water. For D=1 the flame was a well defined premixed laminarflame and, as seen in the image, the temperature increasedwith height above the burner head. For increasing D-values, a significant change of theflame shape was observed. In the more fuel-rich flame, themass flow increased and the burning velocity of the mixturebecame lower.As a result the flame size became larger,and the reaction zone shifted up and to the outer part of theflame.As the soot concentration increased, both the OHconcentration and the flame temperature are found to decrease.The characteristic of these fuel-rich flames is better describedas diffusion flames than as premixed flames. The detectedtemperatures were lowest for the most sooting flame accordingto effects in the flame chemistry [37], heat radiation from thesoot particles and the fact that the location of the measurementwas kept fixed while the flame shape changed with increasingD-value. 4.2. Simultaneous measurements ofOH and indiumfluorescence In figure 3 simultaneous images ofOH and indium fluorescenceare shown. As seen in this figure there was a significantdifference in the detected fluorescence profiles of OH andindium. The changes of the reaction zone and the differentflame size can also be observed in the figure. Note that thegrey scale in the images reflects relative LIF intensities andonly approximately reflects relative concentrations of imagedspecies. The OH distributions reflect both regions of hightemperatures and the position and shape of reaction zones.Towards lower temperatures (below~1200 K) [38], OH israpidly consumed and below detection limit of LIF. In thefuel-rich and sooting flames the concentration profiles aresymmetrically placed around the burner centreline. Figure 4 represents the signal profiles of OH, indium andsoot/PAH. From this figure one can see a distinct feature arisingfrom OH fluorescence in the primary reaction zones (the outerpart of the flame) and scattered light from soot particles andPAH fluorescence in the rich flame regions (closest to the Height aboveburner [mm] Indium 5 OH巧5 -5 0 5 -5 0 5-5 0 5 ①=1.0 ①=2.5 =3.5 Figure 3. Simultaneous fluorescence images of indium and OH in flames for =1.0, 2.5 and 3.5. Note the differences between thedistributions for the fuel-rich cases. The x-axis shows the radial position in mm. D=1.0 =2.5 叮=3.5 Figure 4. Concentration profiles through the flame in which the variation of the fluorescence intensities for OH, indium and the PAH/soot isclearly seen for 中= 1.0, 2.5 and 3.5. The measurement region was 7-22 mm above the burner. central line). No OH was detected near the centreline, wheresoot and PAH were concentrated, since soot oxidation reducesthe amount of OH radicals, which is a reactive partner in athree-body recombination reaction [20]. From figure 3 it is clear that TLAF signals are substantialonly in the core region of the flame where OH concentrationsare low. Previous experiment have indicated that oxidationmay play a major role in the production of TLAF activeneutral indium [27]. In fuel-rich zones, where less oxygenis available, the atomization process becomes more efficientand corresponding stronger TLAF signals are obtained. Onthe other hand, in areas where the concentration of OH oroxygen is large the result is loss of TLAF signal.This isclearly shown in figure 4, obtained from the measurementimages. In the flame with p= 1, the OH and the indium profilegradients are similar, in contrast to highly sooting flamesor diffusions flames, where a distinct shift in the gradientwas detected between the two species. As can be seen inthe diagram for higher D-values, the TLAF signals weredetected with a decreasing intensity towards the OH signal.This suggests that, depending on the flame characteristic, the production zones of OH and seeded atoms will have more orless of an overlap. This deviation in LIF profiles for OH and seeded atomswill effect the measured temperature information. In premixedflames with 1, the detected area is almost thesame and a similar evaluated temperature is expected.. Indiffusion flames, completely different temperature distributionimages will be found.For example, in highly sootingareas no temperature information will be conducted withOH thermometry. Therefore the evaluated temperaturesare expected to reveal that the OH thermometry is towardsthe high temperature regions, where most OH-radicals areproduced [25,36]. Furthermore, in lean combustion wherea lot of OH and O2 are present the fluorescence signalfrom the indium atoms will not be sufficiently high to yieldtemperature information if the seeding concentration is notincreased. Before the seeding concentration is increased acareful control has to be done to investigate that no effectson the combustion occurred.In lean combustion devicesthe higher seeding concentration required may cause practicallimitation by window deposit of indium oxide [39]. (b) 4.3. Laser-induced incandescence measurements The resulting images from the LII measurements, which wereperformed in order to control whether indium affected thecombustion, can be seen in figures 5(a) and 5(b). Thedistribution of the soot particles in the flame can be observedin those images where the soot volume fraction is presented.The x-axis shows the position in the flame, the y-axis the sootvolume fraction. From the z-axis the height above the burnerhead can be seen. The results from these LII measurementsshow that, within the accuracy (around 30%) of the technique[40], neither differences in the particle size nor differences inthe soot volume fraction could be observed for different InClsseeding solutions, 100-1000 mg 1-. The result presentedin figure 5 show one solution with an InCls concentrationof 500 mg 1-l and one with distilled water. If the indiumatoms had influenced the combustion process and the chemicalreactions, a change should have been seen in the soot volumefraction between the different seeding solutions, with andwithout indium, and on the particle sizes.The possibleinfluence on the soot volume fraction caused by the water isnot a problem, since in more practical applications, such as engines and turbines, the indium can be directly dissolved inthe fuel and no water needs to be added [25,29,39]. 4.4. Spectroscopic studies The absorption measurements in the cup burner flame showedthat no signal contribution caused by interfering species couldbe observed, for the excitation wavelengths of indium, whendiesel was used as fuel. No differences in the absorptionwere observed between the used wavelengths. This seemspromising for future applications where diesel is used as fuel. Other difficulties that might occur in an application in adiesel engine are decreasing window transparency as a resultof soot deposition. The amount of deposit soot will changeduring the measurement and therefore also the laser beampassing through the engine. This fact will cause a problemwhen the fluctuation of the laser beam should be taken intoaccount, which is discussed in section 4.5, since the in-cylinder attenuation of the laser sheet intensity also needs tobe accounted for in this case. Strategies and image processingare discussed in [41,42]. TThis problem is general for all 4.5. Data analysis In a2D application it is important to make corrections for thespatial laser intensity distribution to obtain reliable and correctinformation from the LIF images. It is equally important toinvestigate the impact of laser intensity fluctuations on the LIFsignals. Both should preferably be recorded on a shot-to-shotbasis. In this section a statistical treatment and discussionwill be presented to put this on a quantitative footing.Similar investigations have been reported by Seitzmann et al[43], showing the importance of these corrections. Themeasurements were analysed with respect to the statisticaluncertainty of evaluated temperature, which is introduced bylaser intensity fluctuations. The precision of a technique isdefined as the variability of the measured parameter due tonoise and/or random measurement variations. The associatedmeasurement errors in equation (1) result from an additivecombination of errors from F2o and F21 and the laser intensitiesIo and I12. This is the way in which the error analysis wastreated in earlier publications [27, 29]. In this work TLAFsignals and laser intensities were measured simultaneously,providing a measure for the correlation of signal and laserfluctuations. This allows us to eliminate the contribution oflaser intensity fluctuations to the uncertainty of the calculatedtemperature. The expression for the statistical error and a moredetailed discussion can be found in the appendix. A discussion on errors associated with 2D TLAF is foundin [29]. The reported precision of evaluated temperatures was14%, a figure suggested to improve by on-line intensity profilemeasurements of the laser source. All errors stated here areor/T. Taking laser fluctuations into account the statisticalerror of the temperature was found to decrease by 20-50%in this work. The value depends on the signal strength. Thismeans that at least 20% ofthe statistical error of the temperatureis caused by laser fluctuations, which can be easily correctedfor. For the presented data a precision of at best 8-9% fora single CCD pixel was obtained when corrections for laserfluctuations were made. This value only contains contributionsfrom detector noise and flame fluctuations and presents anupper precision limit for TLAF measurements in this work.One can reduce the detector noise error by averaging pixelswith their neighbours (thereby reducing spatial information).The precision will then improve by a factor of the square rootof the number of pixels. Averaging pixels, 2× 2 or 3 ×3,improving the precision to 3-4% for the present data, which isa value of the same order as reported by Dec and Keller [44]for point measurements in turbulent flames. In any case, it is not always possible to measure the laserintensity profiles on a shot-to-shot basis.B.In this case theprecision can be substantially improved by using more stablelaser sources. Our laser system showed laser fluctuationso/I ≈ 5 and 10% for 451 and 410 nm, respectively.Suggesting available lasers with stability ai/I<2% on therespective excitation wavelength it is possible to reach thesame precision as in this work without correcting for laserfluctuations. The value of the statistical uncertainty itself isoverall depending on the stability of the flame. Indium-TLAF is also favourable in statistical termscompared with OH-thermometry in fuel-rich and sootingflames, since the S/N yields for indium-TLAF signals aremuch higher due to the reductive processes of OH in suchenvironments. Higher signal levels increase the precision ofthe evaluated temperature. 5. Conclusion Two-line atomic fluorescence was demonstrated for two-dimensional temperature measurements in highly sootingenvironments.The experiments were performed in a slotburner with stoichiometries varying between 1.0 and 3.5. LIImeasurements were carried out to investigate whether theseeded indium atoms caused any effect on the flame chemistry.Within the uncertainty limit of the LII technique, no influenceon the soot volume fraction could be observed for differentamount of indium seeded into the flame. We showed that laser fluctuations can lead to a significantbias in the precision of evaluated temperatures. These are notcorrected for by standard error analysis methods, which arecommonly used in this context. The presented treatment ofthe data can improve the precision of the technique within 20-50% for a sufficient S/N ratio if compensation is made forlaser fluctuations. This improvement can be made if an onlinebeam profile is measured for each single-shot fluorescenceimage. This analysis is not restricted to the current methodbut is applicable to all ratiometric measurement techniques. These measurements show promising results for usingthe TLAF technique in future two-dimensional temperatureapplications in diesel engines, since the technique did notappear to be disturbed by soot particles and no detectableattenuation of the laser was seen in diesel combustion. Fromthe spectroscopic studies of the absorption from different fuels,only a small absorption was observed for the used indiumwavelengths 410 and 451 nm. Simultaneous indium and OH fluorescence images weremeasured for different stoichiometries. The results fromthese investigations showed that the regions where the specieswere measured changed with increasing D-values.Thesesimultaneous recorded In/OH images indicate that when usingOH thermometry the measured region is biased towards thehigh temperature side and when using temperatures obtainedwith indium TLAF, the temperature information originatesfrom more fuel-rich and hence colder parts. Acknowledgments We gratefully acknowledge the financial support by theSwedishNNationallEnergyAdministration.1. the SwedishResearch Council for Engineering Science and the Centre ofCompetence: Combustion Processes. The authors also thank Boman Axelsson and RobertCollin for the LII measurements, Joakim Bood and ChristianBrackmann for the CARS measurements and Thomas Metz forfruitful discussions about statistical data analysis. The statistical investigations include an analysis of differentexperimental sources of uncertainty and their influence onthe precision of TLAF. The main aim of the investigation isto improve the precision of the evaluated temperature andto give an upper limit for the precision of the temperature.The questions analysed here are the statistical uncertaintyof evaluated temperatures from different types of sourcelike laser fluctuations and detector noise. The measurementerrors of the temperature evaluated from TLAF when onlyaccounting for linear correction terms can easily be derivedfrom equation (1)[45,46]. where ox/x denotes the relative error in the quantity x andcov(x,y) the covariance of the quantities x and y. The relativeuncertainty of the excitation wavelength is substantially lowerthan that of the variables [47] and therefore 0x21=020=0.ac/C is within 2% according to the accuracy of CARS. Here itis assumed that the laser source has a much broader bandwidththan the absorption lines. Therefore the uncertainty of the lineoverlap is assumed to be zero. Similar expressions for the uncertainty of the temperaturein earlier publications [27,29] did not contain the covarianceterms in equation (A1). Laser fluctuations were suggestedto have a pronounced influence on the uncertainty of theevaluated temperature. Indeed, when taking these fluctuationsinto account according to equation (A1), or was found todecrease between 20 and 50% in this work. The value dependson the signal intensity. Figure A1 shows an example of thedifference in the standard deviation of the temperature T withand without covariance terms in equation (A1). Due to a read-out error for one of the excitationwavelengths, a rectangular gap appeared both in the laserand the LIF profile in the region: height = 10.2-13.8 mm.This introduces an uncertainty on the laser intensity and theLIF signal. Anyhow, both signals were distorted at the sametime, which entails a strong correlation between them. Whencorrecting for this correlation, by calculating the covarianceterms in equation (A1), the uncertainty due to the read-outerror vanishes. As seen in equation (A1) the precision of the determinedtemperature increases with increasing separation between thetwo lower energy levels.The accuracy of the temperaturemeasurements depends on the temperature sensitivity, whichis a function of the energy spacing between these twolevels and their relative population at different temperatures.Furthermore, when the relative statistical errors of themeasured variables are fixed, the relative error of the evaluatedtemperature is inverse proportional to the temperature itself.This is similar for other two-line thermometry methods. Thismeans that the relative precision of the measured temperaturebenefits from lower temperatures. However, the anti-Stokes Figure A1. This figure shows an example of the difference in thestandard deviation of the temperature T with and without covarianceterms in equation (A1) (=2). Notice the strong deviations ofboth curves between 10 and 15 mm height, which are due toread-out error in one of the In LIF images. fluorescence signal F20 decreases with increasing E andincrease with higher temperature.In practice care has tobe taken so that the SNR is maximized in combination withan acceptable precision. It has been suggested [3, 15] thatgood temperature sensitivity in general is obtained if △E/k iscomparable to the maximum temperature of interest. References ( [1 ] Eckbreth A C 1 996 Laser Diagnostics for CombustionTemperature and Species 2nd edn (Amsterdam: Gordon andBreach) ) ( [2] Laurendeau N M 1 988 Temperature measurements bylight-scattering methods Prog. Energy Combust. Sci. 14147-70 ) ( [3] K ohse-Hoinghause K 1994 Laser techniques for the q uantitative detection of reactive intermediates in combustion s ystems Prog. Energy Combust. Sci. 20 203-79 ) ( [4] S chraml S , Dankers S, B a der K, Will S and Leipertz A 2000Soot temperature measurements and implications fortime-resolved laser induced incandescence (TIRE-LII) Combust. Flame 120 439-50 ) ( [5] D e Iuliis S, Barbini M, Benecchi S, Cignoli F and Zizak G 1998 Determination of the soot volume fraction in a n ethylene diffusion f lame by multiwavelength an a lysis of soot radiation Combust. Flame 115 253-61 ) ( [6] Aust V, Zimmermann G, Manz P-W and Hentschel W 1999Crank-angle resolved t emperature i n SI engines measured by emission-absorption spectroscopy SAE Paper 1999-01-3542 ) ( [7] Hofmann D and L e ipertz A 1997 Temperature field measurements in a sooting flame by filtered Rayleigh scattering (FRS) Proc. Comb. Inst. 26 945 ) ( [8] Brockhinke A, Hartlieb A T, Kohse-Hoinghaus K and C rosley DR 1998 Tunable KrF laser-induced fluorescence of C2 in a sooting flame Appl. Phys. B 67 659 ) ( [9] Rabenstein F and Leipertz A 1998 One-dimensional, t ime-resolved Raman m e asurements in a sooting flame made with 355 nm excitation Appl. O p t. 37 4937 ) ( [ 1 0] H artlieb A T, Atakan B and K ohse-Hoinghaus K 2000Temperature measurements in fuel-rich n o n-sootinglow-pressure hydrocarbon flames Appl. Phys. B 70 435 ) ( [ 11 ] G reenhalgh D A 1988 Advances in Non-linear Spectroscopy(New York: W iley) pp 193-250 ) ( [12] Stricker W and Meier W 1 993 The use of CARS for temperature m easurements in practical flames Trends Appl. Spectrosc. 1 231 ) ( [13] Bengtsson P -E, Martinsson L, Alden M and K roll S 1992Rotational CARS thermometry in sooting flames Combust.Sci. Technol. 81 129-40 ) ( [14] B engtsson P-E, Alden M, Kroll S and Nilsson D 1990Vibrational CARS thermometry in s o oty flames: quantitative evaluation of C2 absorption interferenceCombust. Flame 82 199-210 ) ( [15] D aily JW 1997 Laser induced fluorescence spectroscopy in flames Prog. Energy Combust. S c i. 23 133-99 ) ( [16] Z izak G, Omenetto N and Wineforner J D 1984 Laser-excitedatomic fluorescence techniques for temperaturemeasurements in flames: a summary Opt. Eng. 23 749-55 ) ( [ 1 7] T amura M, Luque J, Harrington J E, Berg P A, Smith G P,Jeffries J B and Crosley D R 1 998 Laser-induced fluorescence of seeded nitric oxide as a flam e thermometer Appl. Phys. B 66 503 ) ( [18] Cattolica R 1981 OH rotational temperature from two-line laser-excited fluorescence Appl. Opt. 20 1156 ) ( [19] Meier U M, Wolff-GaBmann D, Heinze J, Frodermann M,Magnusson I and Josefsson G 1999 LIF imaging of speciesand temperature in t echnical combustion a t elevatedpressures 18th Int. Congr. on Instrumentation in Aerospace Simulation F acilities (Toulouse, 1999) ) ( [20] H audiquert M, Cessou A, S tepowski D and Coppalle A 1 997 OH and soot concentration measurements in a high-temperature laminar diffusion flame Combust. Flame111338-49 ) ( [21] B essler W, Hildenbrand F and Schultz C 20 0 0 Vibrational temperature i maging using two-line laser-inducedfluorescence of seeded NO Laser Applications to Chemical and Environmental Analysis, Tech. Digest, (Santa Fe, 2000) [22] Atakan B and H artlieb A T 2000 Laser diagnostics of NO ) ( reburning in fuel-rich propene flames Appl. Phys. B 7 1 697-702 ) ( [23] D aily J W and Rothe E W 1999 Effect of laser intensity and of lower-state rotational energy transfer upon t e mperaturemeasurements m a de with laser-induced f l uorescence Appl.Phys. B 68 131 ) ( [24] Joklik R G, Horvath JJ and Semerjian H G 1991 Temperaturemeasurements in flames us i ng thermally assisted laser-induced fluorescence of Ga Appl. Opt. 30 1497-504 ) ( [25] E ngstrom J, Kaminski C F, Alden M, Josefsson G andMagnusson I 1 9 99 Experimental investigations of flow and temperature fields in an SI engine and comparison withnumerical analysis SAE Paper 1999-01-3541 ) [26] Haraguchi H, Smith B, WeeksS, Johnsson D J andWinefordnerJD 1977 Measurements of small volumeflame temperature y the two-line atomic fluorescencemethod Appl. Spectrosc. 31 156-63 ( [27] E ngstrom J, Nygren J, Alden M and Kaminski C F 2000Two-line atomic f l uorescence as a temperature probe fo r highly sooting flames Opt. Lett. 25 1469-71 ) ( [28] B onczyk P A 19 9 1 Effects of metal ad d itives on sootprecursors and particulate s in a C2H4/O2/N2/Ar premixed flame Fuel 70 1403 ) ( [29] K aminski C F, Engstrom J and Alden M 1 998Quasi-instantaneous two-dimensional temperaturemeasurements in a spark ignition engine using 2-line atomic fluorescence Proc. Combust. Inst. 27 85-93 ) ( [30] Bockhorn H 1 9 94 Soot Formation in Combustion, Mechanismsand Models (Springer Series in C hemical Physics 59)(Berlin: Springer) pp 308-15 ) ( [31] M ewes B and Seitzman J M 19 9 7 Soot volume fraction and particle size measurement with laser-induced incandescence Appl.Opt. 36 709 ) ( [32] A xelsson B, Collin R and Bengtsson P-E 2000 Laser-induced incandescence for s o ot particle size measurements in premixed flat flames Appl. Opt. 39 ) ( [33] Alden M, Bengtsson P-E and Edner H 1986 Rotational CARSgeneration through a multiple four-color interaction A ppl.Opt. 25 4493-500 ) ( [34] E ckbreth A C and A n derson T J 1986 Simultaneous rotationalcoherent anti-Stokes Raman s p ectroscopy and coherentStokes R aman s p ectroscopy with arbitrary pump-Stokesspectral separation Opt. Lett . 11 496-8 ) ( [35] Puri R, Moser M, Santoro R J and Smyth K C 1992 Laser-induced fluorescence measurements of OH concentrations i n the oxidation region of laminar hydrocarbon diffusion flames Proc. Combust. I nst. 24 1015 ) [36] Norton T S, Smyth K C, Miller J H and Smooke M D 1993Comparison of experimental and computed speciesconcentration and temperature profiles in laminar,two-dimensional methane/air diffusion flames Combust.Sci. Technol. 90 1 [37] Griffiths JFand Barnard J A 1995 Flame and Combustion 3rdedn (Oxford: Alden) [38] Bergmann V, Meier W, Wolff D and Stricker W 1998Application of spontaneous Raman and Rayleigh scatteringand 2D LIF for the characterization of a turbulentCH4/H2/N2 jet diffusion flame Appl. Phys. B 66 489-502 ( [39] L ofstrom C , Engstrom J, R i chter M , Kaminski C F,Johansson P, Nyholm K , Hult J, Nygren J and Alden M 2000 Feasibility studies and a pplication o f laser/opticaldiagnostics for characterisation of a practical l ow-emission gas turbine combustor ASME Paper 2000-GT-124. ) ( [40] Shaddix C R and Smyth K C 1 996 Laser-induced incandescence measurements of s o ot production in s teady and f lickering methane, propane and ethylene diffusionflames Combust. Flame 107 418-52, ) ( [41] B rugman T h M, Stoffels G G M, Dam N, Meerts W L a nd ter Meulen JJ 1 997 Imaging and post-processing of laser-induced fluorescence from NO in a diesel engine Appl. Phys. B 64 717 ) ( [42] E spey C and Dec J E 1 9 93 D i esel engine combustion studies in a newly designed optical-access engine using high-speedvisualization and 2-D laser imaging SAE Trans. 102 703-23 ) ( [43] Seitzman J M, Hanson R K, DeBarber P A and Hess C F 1994Application of quantitative two-line OH planarlaser-induced f l uorescence for temporally resolved planar t hermometry in reacting flows Appl. Opt. 33 4000-12 ) ( [44] D ec J E and Keller J O 1986 High speed thermometry usingtwo-line atomic fluorescence Proc. Combust. Inst. 21 1737 ) ( [45] I nternational O rganisation f o r Standardization 1 9 95 Guide tothe Expression ofUncertainty in Measurement 1st edn ) ( [46] Bevington P R and Robinson D K 1 9 92 Data Reduction andError Analysis for the Physical Sciences (Boston:WCB-McGraw-Hill) ) ( [47] 1992 Handbook of Chemistry and Physics 63rd edn (Boca Raton, FL: Chemical Rubber Company) pp E243 ) C IOP Publishing Ltd Printed in the UK

确定

还剩8页未读,是否继续阅读?

北京欧兰科技发展有限公司为您提供《火焰,燃烧,碳烟中温度场检测方案 》,该方案主要用于其他中温度场检测,参考标准--,《火焰,燃烧,碳烟中温度场检测方案 》用到的仪器有PLIF平面激光诱导荧光火焰燃烧检测系统

推荐专场

相关方案

更多

该厂商其他方案

更多