方案详情

文

原油是生活中不可或缺的能源但其储备有限,提高原油采集率尤为重要。为优化表面活性剂驱油技术,KRUSS设计了高温高压下测量界面张力的仪器。

方案详情

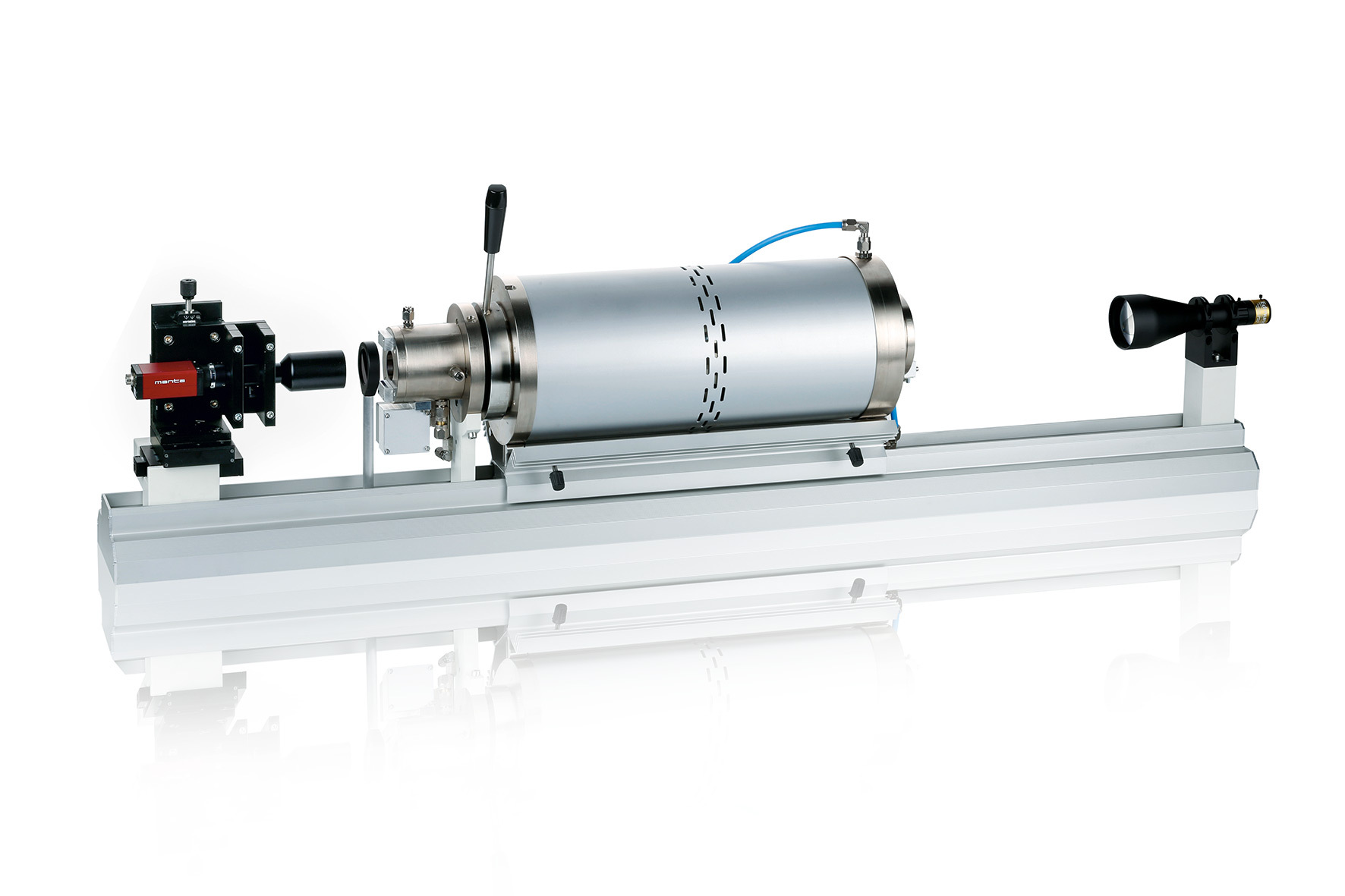

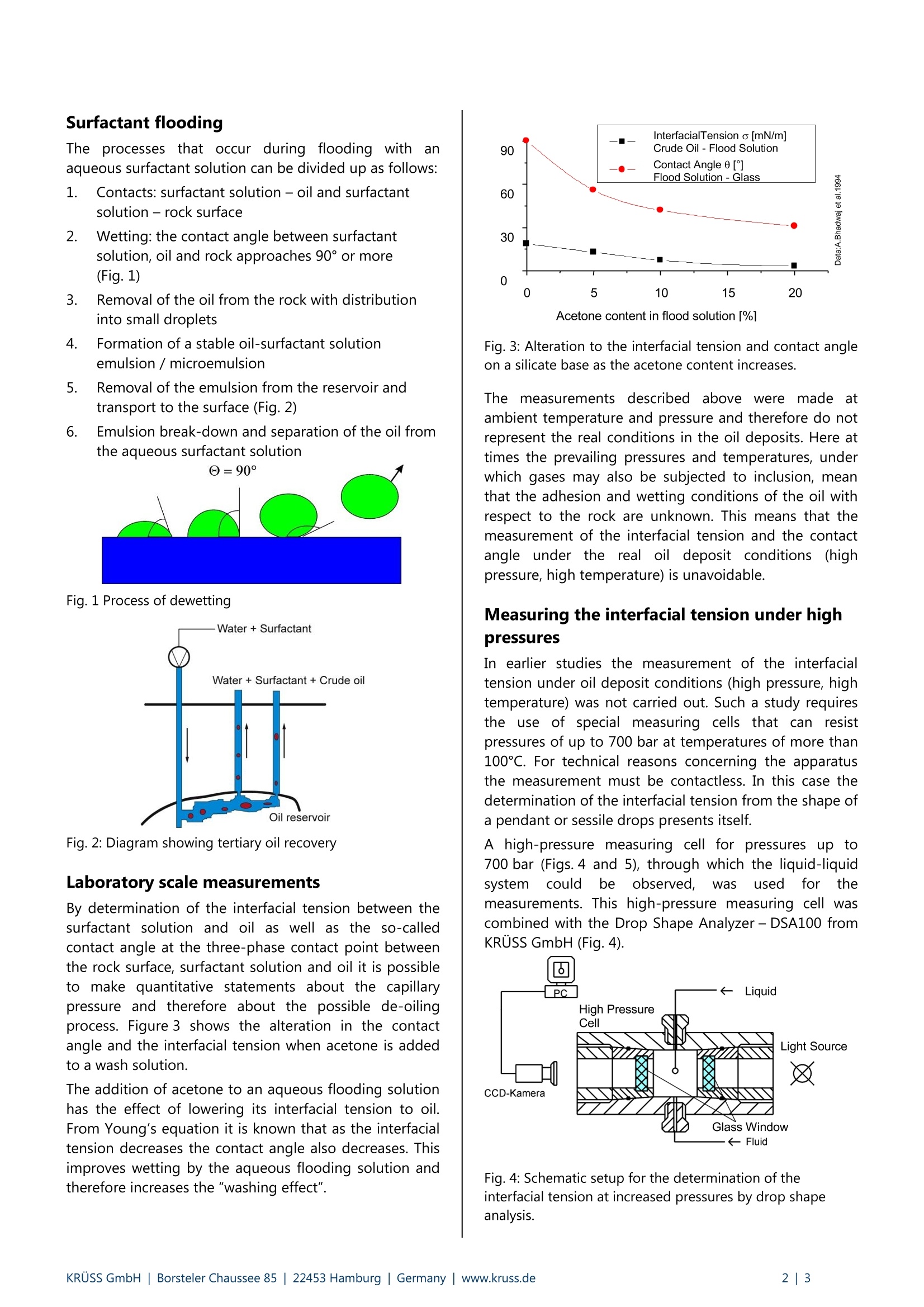

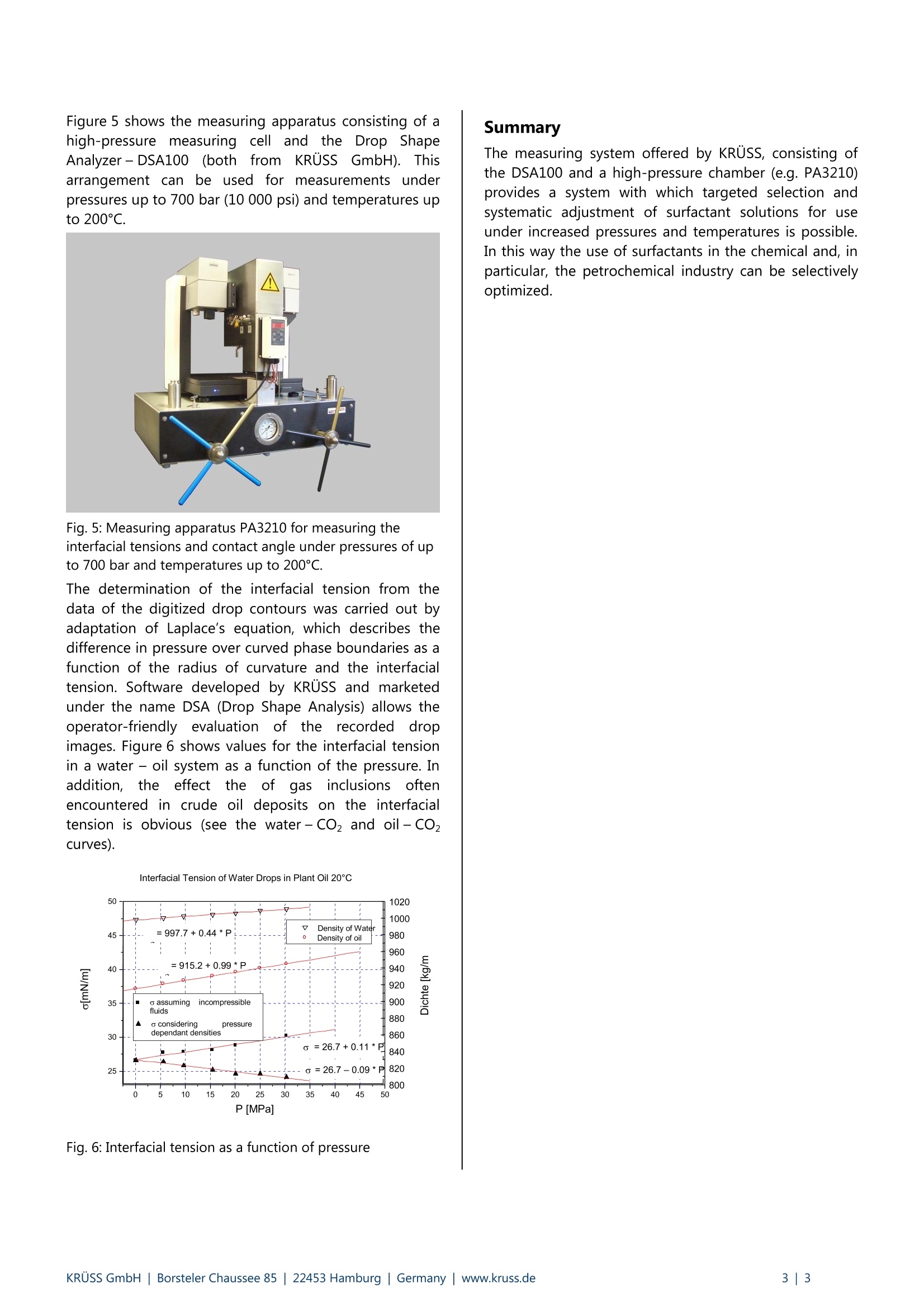

KRUSS Application Report Enhanced Oil Recovery Application report: AR227e Industry section: Petroleum, Gas Author: Dr. P. Jager, Dr. A. Pietsch, Dr. P. Rendtel Date: 04/2002 Method: Drop UShape An alyze r- DSA100HP Keywords: EOR, surfactant flooding, pendant drop, interfacial tension, high pressure, crude oil Phase boundaries under pressure Abstract Get up in the morning and turn the heating on, have a hot shower and put the coffee break sandwiches into a plastic bagand then off to work in the car... Without crude oil all these pleasant things we take for granted in our daily lives would either not exist, or be much moreexpensive. Crude oil is one of the fossil fuels, formed several hundred million years ago.Reserves are not unlimited, andthe discovery of huge new stocks of crude oil is becoming less and less frequent today, and is accompanied by everincreasing costs. This is the reason why the interest in increasing the yield of the existing crude oil reservoirs is rising.After the exploitation of crude oil deposits with primary and secondary methods, tertiary oil recovery methods aredeliberately targeted at the forces that retain the crude oil in the carrier beds with the aim of increasing the mobility ofthe residual oil stock and achieving a total yield of considerably more than 60%. The surfactant flooding technique that isused and the optimization of this method by measuring the interfacial tension at high temperatures and pressures usinga special pressure chamber developed by KRUSS is described below. Surfactant flooding Theprocesses that occur during flooding withanaqueous surfactant solution can be divided up as follows: 1. Contacts: surfactant solution-oil and surfactantsolution - rock surface 2. Wetting: the contact angle between surfactantsolution, oil and rock approaches 90°or more(Fig.1) 3. Removal of the oil from the rock with distributioninto small droplets 4. Formation of a stable oil-surfactant solutionemulsion / microemulsion 5. Removal of the emulsion from the reservoir andtransport to the surface (Fig.2) 6. Emulsion break-down and separation of the oil fromthe aqueous surfactant solution Fig.1 Process of dewetting -Water+ Surfactant Fiq.2: Diagram showing tertiary oil recovery Laboratory scale measurements By determination of the interfacial tension between thesurfactant solution and oil as well as the so-calledcontact angle at the three-phase contact point betweenthe rock surface, surfactant solution and oil it is possibleto make quantitative statements about the capillarypressure and therefore about the possible de-oilingprocess. Figure 3 shows the alteration in the contactangle and the interfacial tension when acetone is addedto a wash solution. The addition of acetone to an aqueous flooding solutionhas the effect of lowering its interfacial tension to oil.From Young’s equation it is known that as the interfacialtension decreases the contact angle also decreases. Thisimproves wetting by the aqueous flooding solution andtherefore increases the "washing effect". Acetone content in flood solution[%] Fig.3: Alteration to the interfacial tension and contact angleon a silicate base as the acetone content increases. The measurements described above were made atambient temperature and pressure and therefore do notrepresent the real conditions in the oil deposits. Here attimes the prevailing pressures and temperatures, underwhich gases may also be subjected to inclusion, meanthat the adhesion and wetting conditions of the oil withrespect to the rock are unknown. This means that themeasurement of the interfacial tension and the contactangle under the real oil deposit condition1sS((highpressure, high temperature) is unavoidable. Measuring the interfacial tension under highpressures In earlier studies the measurement of the interfacialtension under oil deposit conditions (high pressure, hightemperature) was not carried out. Such a study requirestheuse of specialmeasuring cells that can resistpressures of up to 700 bar at temperatures of more than100℃. For technical reasons concerning the apparatusthe measurement must be contactless. In this case thedetermination of the interfacial tension from the shape ofa pendant or sessile drops presents itself. Ahigh-pressure measuring cell for pressures up to700 bar (Figs. 4 and 5), through which the liquid-liquidsystemcould beecobserved, was usedfor themeasurements. This high-pressure measuring cell wascombined with the Drop Shape Analyzer- DSA100 fromKRUSS GmbH (Fig.4). Fig. 4: Schematic setup for the determination of theinterfacial tension at increased pressures by drop shapeanalysis. Figure 5 shows the measuring apparatus consisting of ahigh-pressure measuring cell and the Drop ShapeAnalyzer-DSA100 (bothhfrom KKRUSS GmbH).).Thisarrangement can be used for measurements underpressures up to 700 bar (10 000 psi) and temperatures upto 200°C. Fig. 5: Measuring apparatus PA3210 for measuring theinterfacial tensions and contact angle under pressures of upto 700 bar and temperatures up to 200℃. The determination of the interfacial tension from thedata of the digitized drop contours was carried out byadaptation of Laplace's equation, which describes thedifference in pressure over curved phase boundaries as afunction of the radius of curvature and the interfacialtension. Software developed by KRUSS and marketedunder the name DSA (Drop Shape Analysis) allows theoperator-friendly evaluation of the recorded dropimages. Figure 6 shows values for the interfacial tensionin a water- oil system as a function of the pressure. Inaddition, the effect the ofgas inclusions oftftenencountered in crude oil deposits on the interfacialtension is obvious (see the water-CO, and oil-CO,curves). Interfacial Tension of Water Drops in Plant Oil 20°℃ Fig.6: Interfacial tension as a function of pressure Summary The measuring system offered by KRUSS, consisting ofthe DSA100 and a high-pressure chamber (e.g. PA3210)provides a system with which targeted selection andsystematic adjustment of surfactant solutions for useunder increased pressures and temperatures is possible.In this way the use of surfactants in the chemical and, inparticular, the petrochemical industry can be selectivelyoptimized. KRUSS GmbH |IBorsteler Chaussee Hamburg|Germany |www.kruss.de|

确定

还剩1页未读,是否继续阅读?

克吕士科学仪器(上海)有限公司为您提供《原油中提高石油采收率检测方案(接触角测量仪)》,该方案主要用于原油中提高石油采收率检测,参考标准--,《原油中提高石油采收率检测方案(接触角测量仪)》用到的仪器有KRUSS DSAHT型高温接触角测量仪

推荐专场

相关方案

更多

该厂商其他方案

更多