方案详情

文

煮鹰嘴豆和平菇结合的素肉块理化特性和感觉特性Physicochemical and Sensory Characteristics of Meatless Nuggets of Boiled Chickpea and in Combination with Oyster Mushroom

方案详情

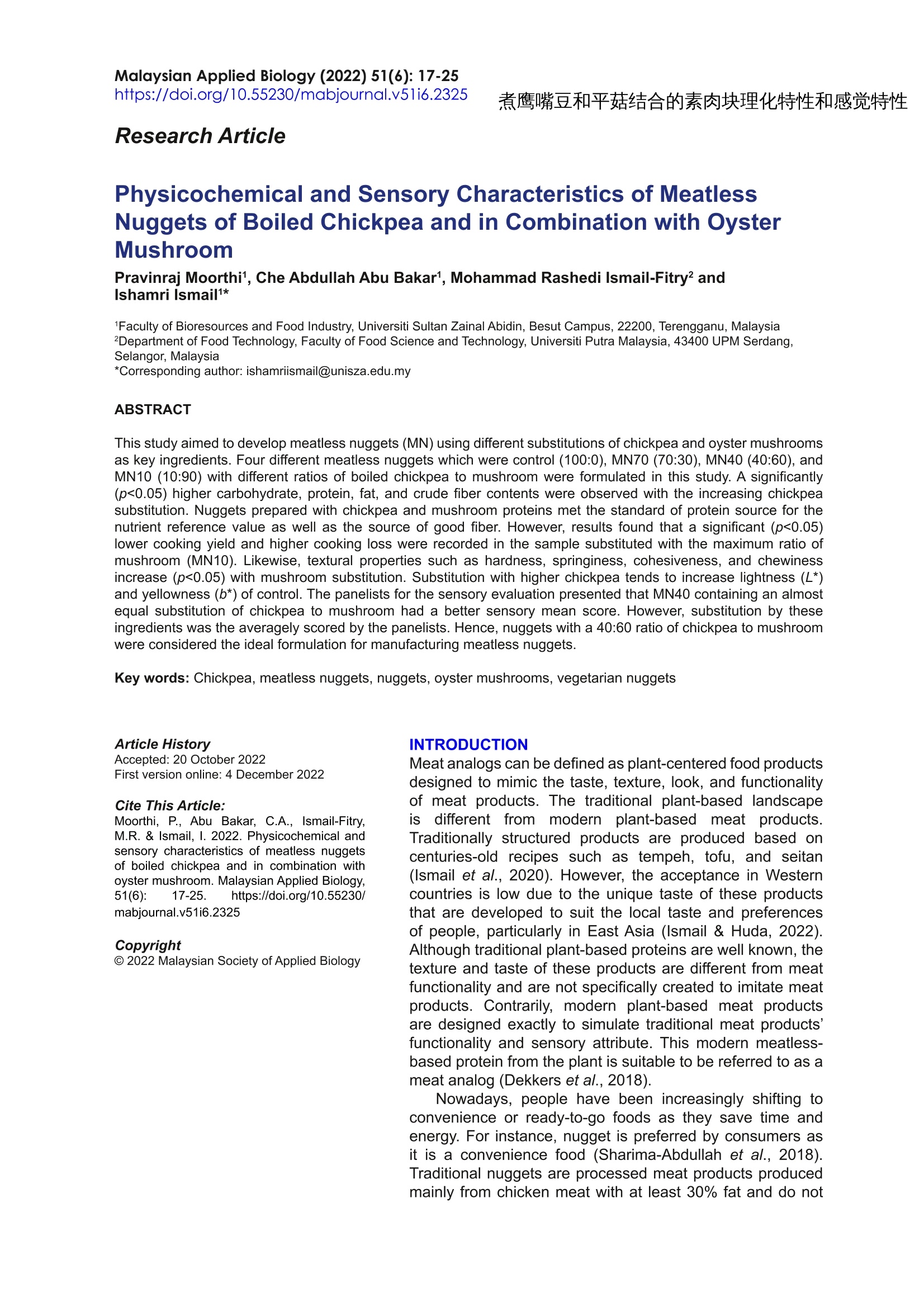

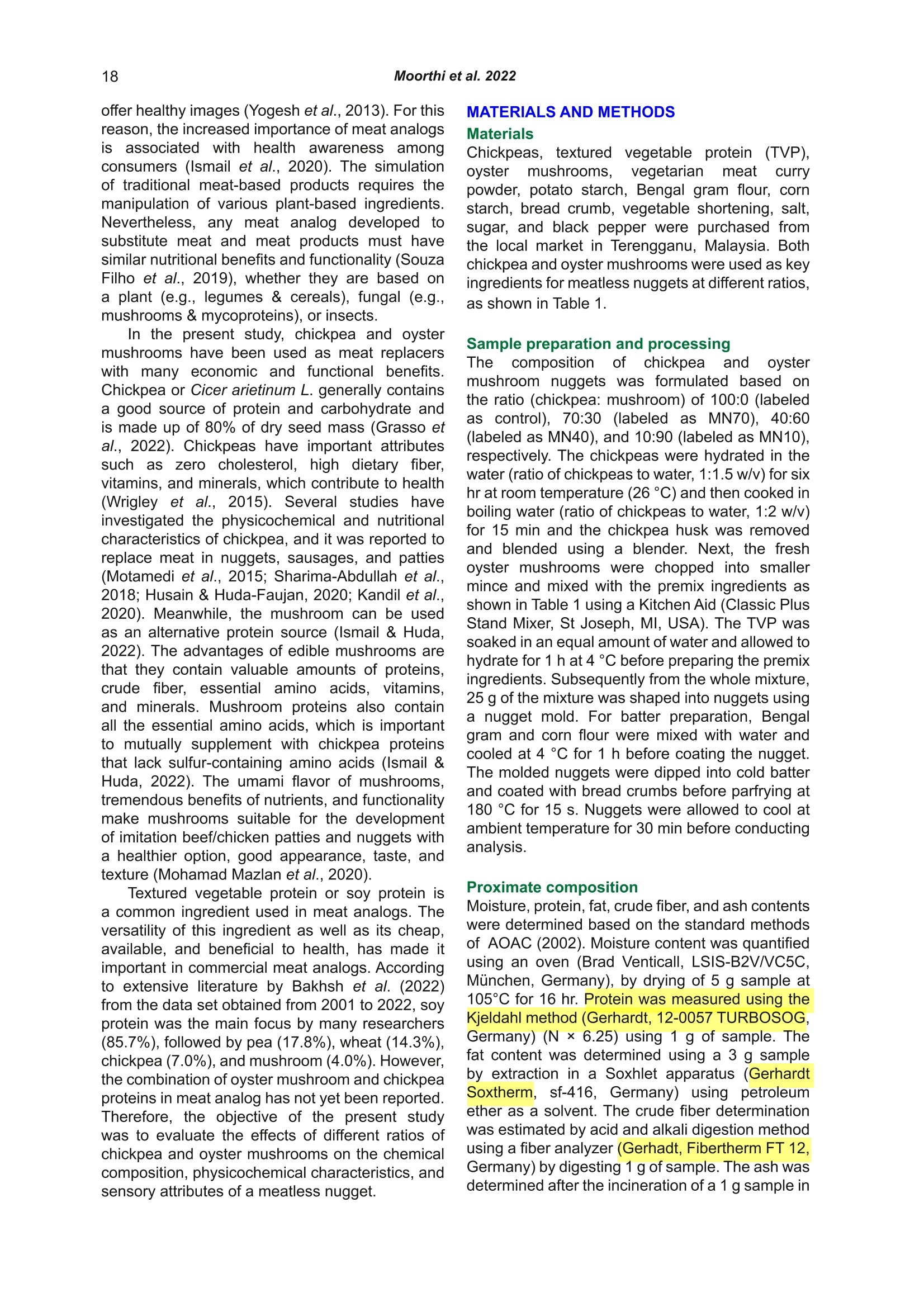

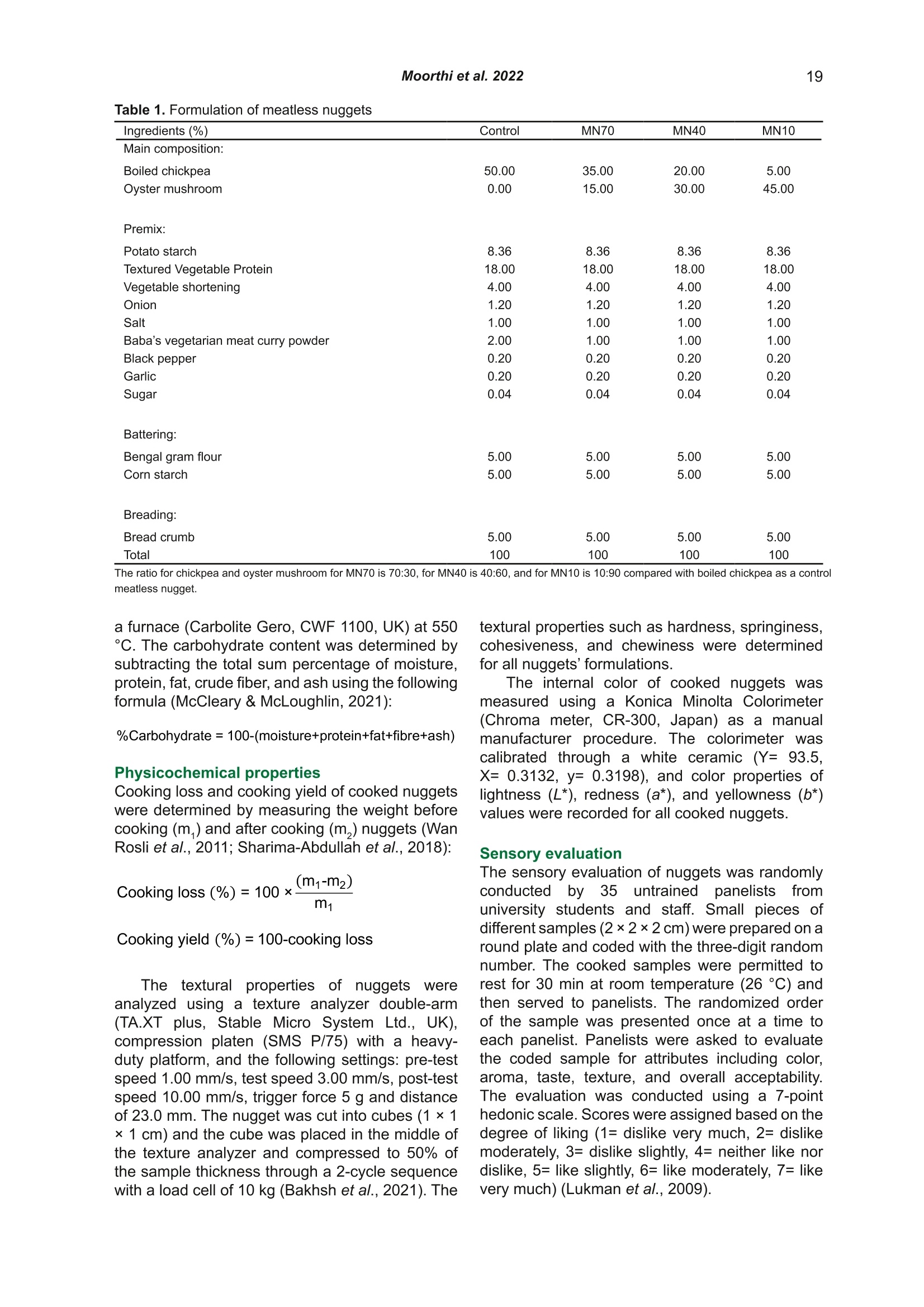

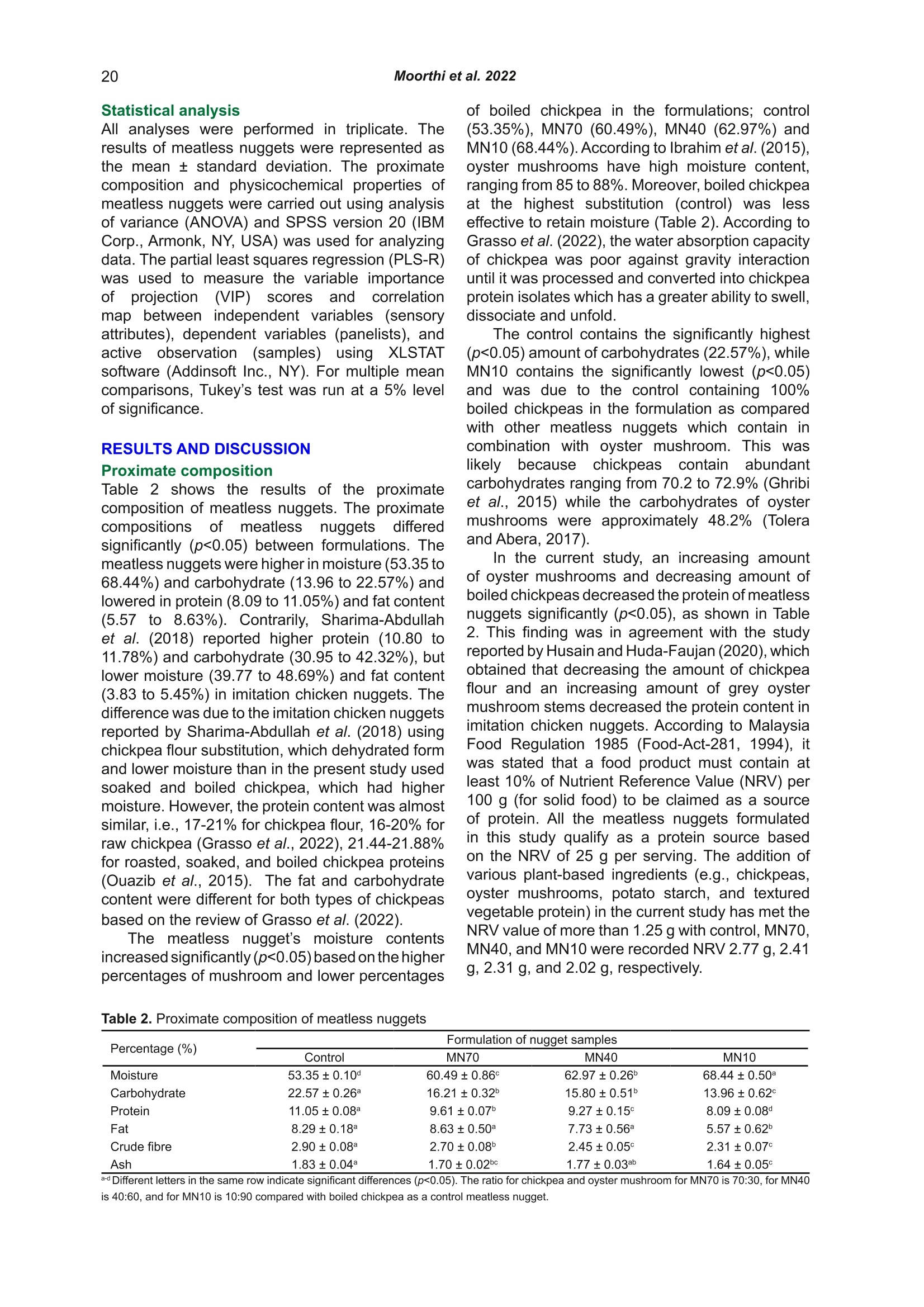

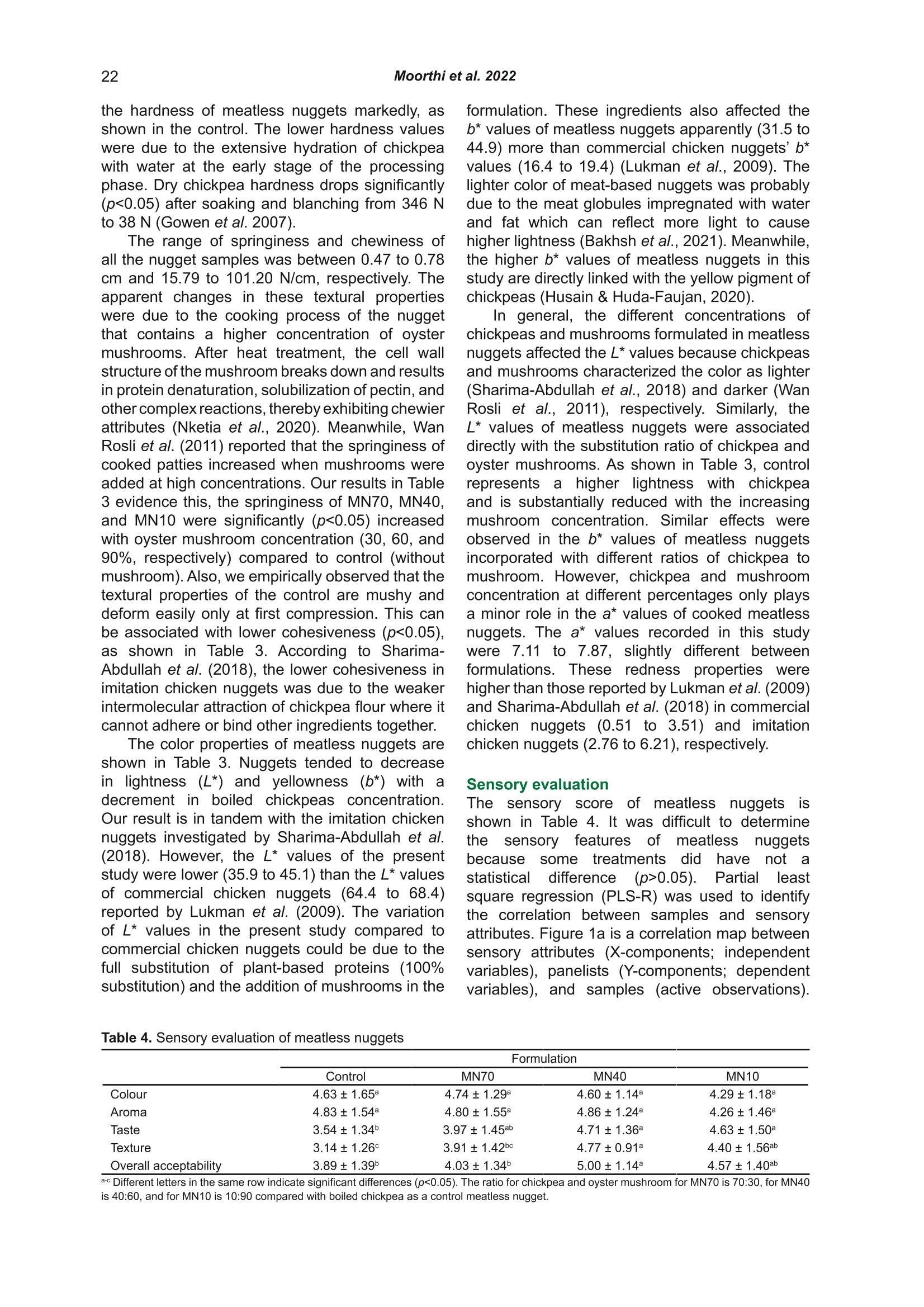

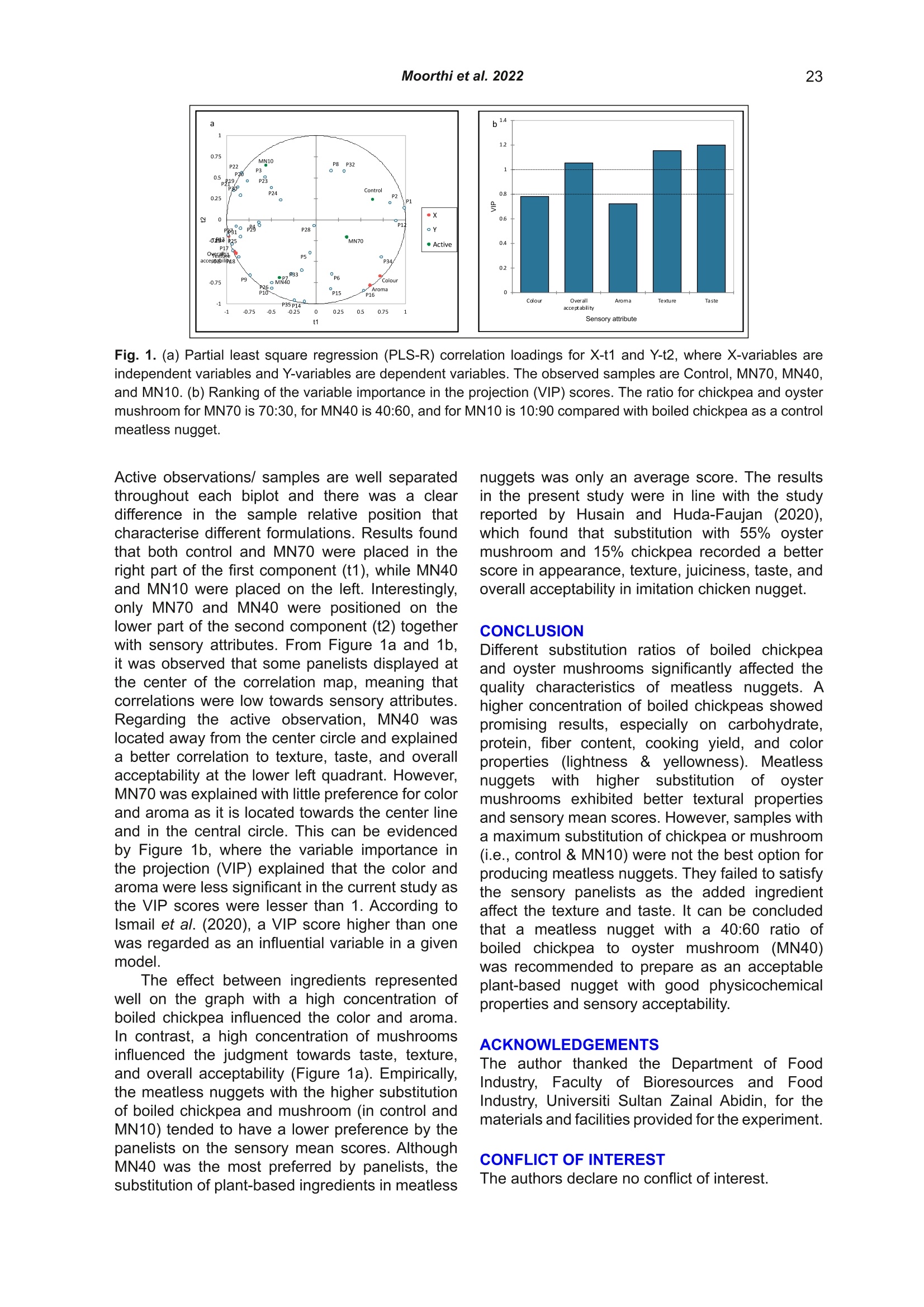

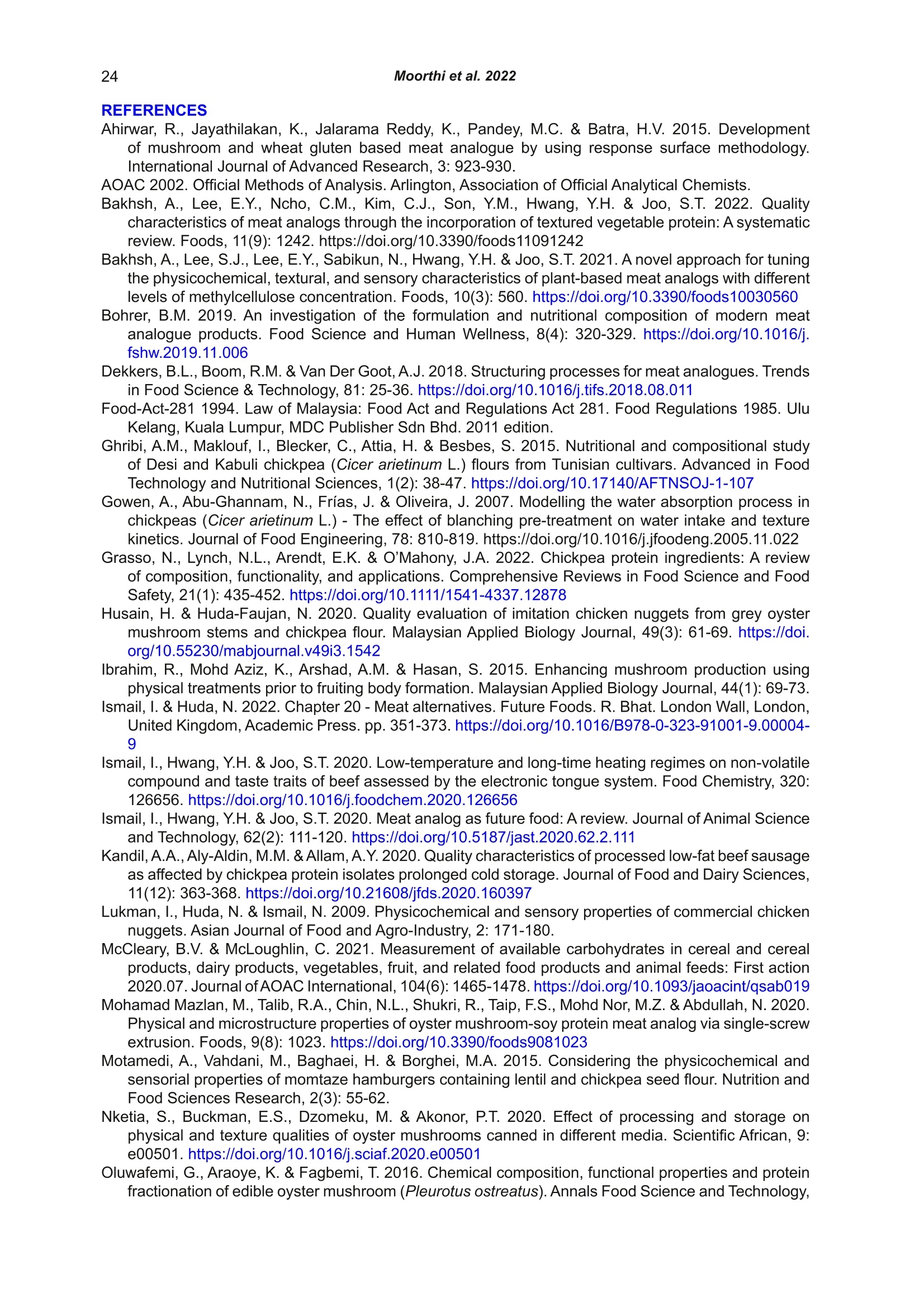

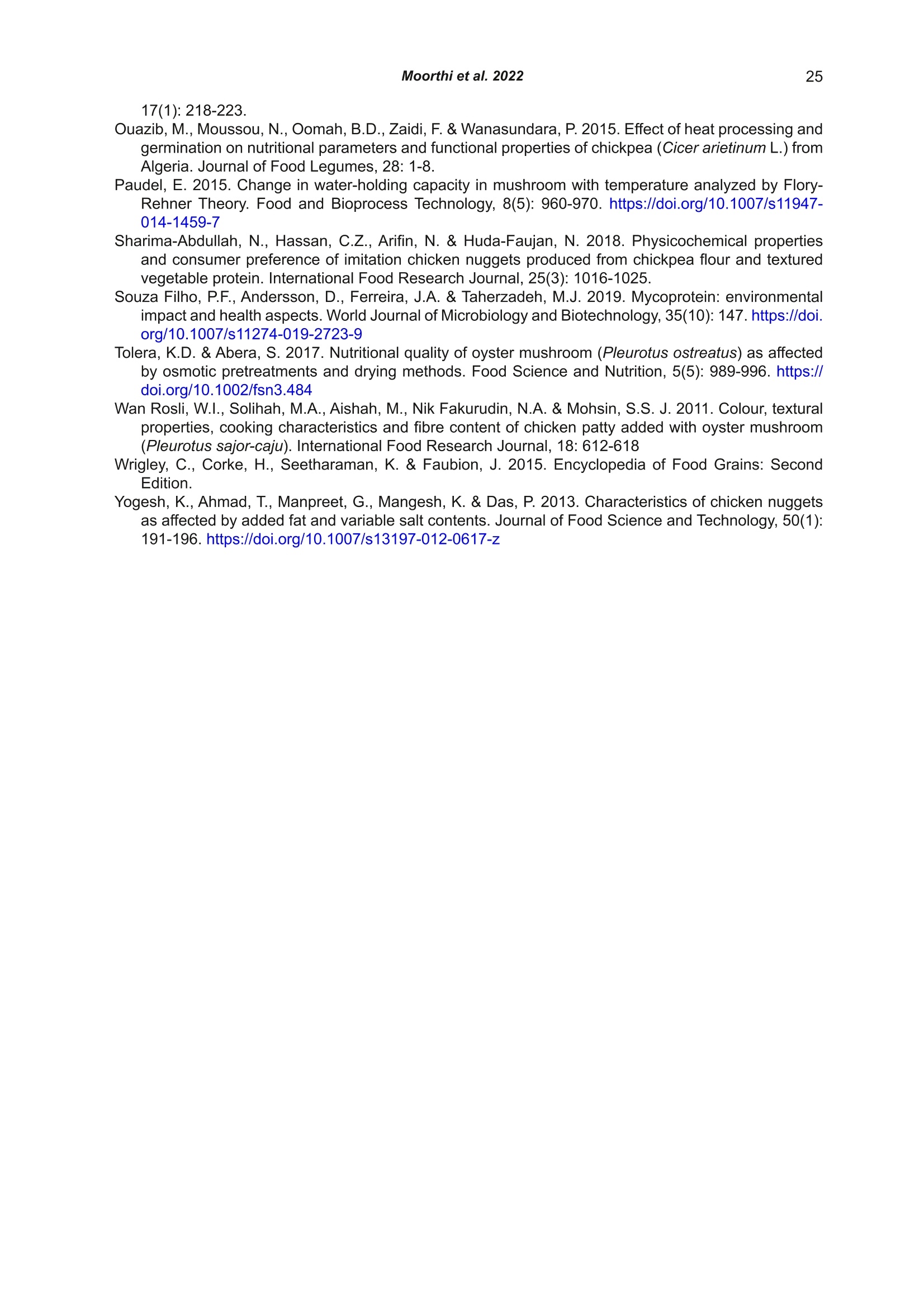

煮鹰嘴豆和平菇结合的素肉块理化特性和感觉特性Physicochemical and Sensory Characteristics of Meatless Nuggets of Boiled Chickpea and in Combination with Oyster MushroomMalaysian Applied Biology (2022)51(6):17-25https://doi.org/10.55230/mabjournal.v51i6.2325Research Article 18Moorthi et al. 2022 煮鹰嘴豆和平菇结合的素肉块理化特性和感觉特性 Physicochemical and Sensory Characteristics of Meatless Nu gg ets of Boiled Chickpea and in Combination with O yst e r Mushroom Pravinraj Moorthi1, Che Abdullah Abu Bakar, Mohammad Rashedi Ismail-Fitry²and Ishamri Ismail1* 1Faculty of Bioresources and Food Industry, Universiti Sultan Zainal Abidin, Besut Campus, 22200, Terengganu, Malaysia 2Department of Food Technology, Faculty of Food Science and Technology, Universiti Putra Malaysia , 43400 UPM Serdang,Selangor, Malaysia *Corresponding author: i shamriismail@unisza.edu.my ABSTRACT This study aimed to develop meatless nuggets (MN) using different substitutions of chickpea and oyster mushrooms as key i ngredients . Four different meatless nuggets which were control (100:0), MN70 (70:30), MN40 (40:60), and MN10 (10:90) with different ratios of boiled chickpea to mushroom were formulated in this study. A signif i cantly (p<0.05) higher carbohydrate, protein , fat, and crude fiber contents were observed with the increasing chickpea substitut i on. Nuggets prepared with chickpea and mushroom proteins met the standard of protein source for the nutrient reference value as well as t he source of good fiber. However, results found that a significant (p<0.05)lower cooking yield and higher cooking loss were recorded i n the sample substituted with the maximum ratio of mushroom (MN10). Likewise, textural properties such as hardness, springiness, cohesiveness, and chewiness increase (p<0.05) with mushroom substitution. Substitution with higher chickpea tends to increase lightness (L*)and yellowness (b*) of control. The panelists for the sensory evaluation presented that MN40 containing an almost equal substitution of chickpea to mushroom had a better sensory mean score. However, substitution by these ingredients was the averagely scored by the panelists. Hence, nuggets with a 40:60 ratio of chickpea to mushroom were considered the ideal formulation for manufacturing meatless nuggets. Key words: Chickpea, meatless nuggets, nuggets, oyster mushrooms, vegetarian nuggets Accepted: 20 October 2022 First version online: 4 December 2022 Cite This Article: Moorthi, P., Abu Bakar, C .A., Ismail-Fitry,M.R. & I smail, 1. 2022. Physicochemical and sensory characteristics of meatless nuggets of boiled chickpea and in combination with oyster mushroom. Malaysian Applied Biology,51(6): 17-25. https://doi.org/10.55230/mabjournal .v51i6.2325 Copyright INTRODUCTION Meat analogs can be defined as plant-centered food products designed to mimic the taste, texture, look, and functionality of meat products. The traditional plant-based landscape is different f rom modern plant-based meatproducts.Traditionally structured products are produced based on centuries-old recipes such as tempeh, tofu, and seitan (Ismail et al., 2020). However, the acceptance in Western countries is low due to the unique taste of these products that are developed to suit the local taste and preferences of people, particularly in East Asia (Ismail & Huda, 2022).Although traditional plant-based proteins are well known, the texture and taste of these products are different f rom meat functionality and are not specifically created to imitate meat products. Contrarily, modern plant-based meat products are designed exactly to simulate traditional meat products functionality and sensory attribute. This modern meatless-based protein from the plant is suitable to be referred to as a meat analog (Dekkers et al., 2018). Nowadays, people have been increasingly shifting to convenience or ready-to-go foods as they save time and energy. For instance, nugget is preferred by consumers as it is a convenience food (Sharima-Abdullah et al., 2018).Traditional nuggets are processed meat products produced mainly from chicken meat with at least 30% fat and do not offer healthy images (Yogesh et al., 2013). For this reason, the increased importance of meat analogs is associated with health 1 awareness among consumers (Ismail et al., 2020). The simulation of traditional meat-based products requires the manipulation of various plant-based i ngredients.Nevertheless, any meat analog developed to substitute meat and meat products must have similar nutritional benefits and functionality (Souza Filho et al., 2019), whether they are based on a plant (e.g., legumes & cereals), fungal (e.g.,mushrooms & mycoproteins), or insects. In the present study, chickpea and oyster mushrooms have been used as meat replacers with many economic and functional benefits.Chickpea or Cicer arietinum L. generally contains a good source of protein and carbohydrate and is made up of 80% of dry seed mass (Grasso et al ., 2022). Chickpeas have important attributes such;as zero cholesterol , high dietary fiber,vitamins, and minerals, which contribute to health (Wrigley et al ., 2015). Several studies have investigated the physicochemical and nutritional characteristics of chickpea, and i t was reported to replace meat in nuggets, sausages, and patties (Motamedi et al., 2015; Sharima-Abdullah et al.,2018; Husain & Huda-Faujan, 2020; Kandil et al.,2020). Meanwhile, the mushroom can be used as an alternative protein source (Ismail & Huda,2022). The advantages of edible mushrooms are that they contain valuable amounts of proteins,crude fiber, essential amino acids, vitamins,and minerals. Mushroom proteins also contain all the essential amino acids, which is important to mutually supplement with chickpea proteins that lack sulfur-containing amino acids (Ismail &Huda, 2022). The umami flavor of mushrooms,tremendous benefits of nutrients, and functionality make mushrooms suitable for the development of imitation beef/chicken patties and nuggets with a healthier option, good appearance, taste, and texture (Mohamad Mazlan et al.,2020). Textured vegetable protein or soy protein is a common ingredient used in meat analogs. The versatility of t his ingredient as well as its cheap,available, and beneficial to health, has made it important i n commercial meat analogs. According to extensive literature by Bakhsh et al. (2022)from the data set obtained from 2001 to 2022, Soy protein was the main focus by many researchers (85.7%), followed by pea (17.8%), wheat (14.3%),chickpea (7.0%), and mushroom (4.0%). However,the combination of oyster mushroom and chickpea proteins in meat analog has not yet been reported.Therefore, the objective of the present study was to evaluate the effects of different ratios of chickpea and oyster mushrooms on the chemical composition, physicochemical characteristics, and sensory attributes of a meatless nugget. MATERIALS AND METHODS Materials Chickpeas,textured vegetable protein ((TVP),oystermushrooms,vegetarian meat curry powder , potato starch, Bengal gram flour, corn starch, bread crumb, vegetable shortening, salt,sugar, and black pepper were purchased from the local market in Terengganu, Malaysia. Both chickpea and oyster mushrooms were used as key ingredients for meatless nuggets at different ratios,as shown in Table 1. Sample preparation and processing The e (composition (of chickpea 2and d oyster mushroom nuggets was formulated based on the ratio (chickpea : mushroom) of 100:0 (labeled as control), 70:30 (labeled as MN70), 40:60(labeled as MN40), and 10:90 (labeled as MN10),respectively. The chickpeas were hydrated in the water (ratio of chickpeas to water, 1:1.5 w/v) for six hr at room temperature (26°C) and then cooked in boiling water (ratio of chickpeas to water, 1:2 w/v)for 15 min and the chickpea husk was removed and blended using a blender. Next, the fresh oyster mushrooms were chopped into smaller mince and mixed with the premix ingredients as shown in Table 1 using a Kitchen Aid (Classic Plus Stand Mixer, St Joseph, MI , USA). The TVP was soaked in an equal amount of water and allowed to hydrate for 1 h at 4°C before prepar i ng the premix ingredients. Subsequently from the whole mixture,25 g of the mixture was shaped i nto nuggets using a nugget mold . For batter preparation, Bengal qram and corn flour were mixed with water and cooled at 4 °℃ for 1 h before coating the nugget.The molded nuggets were dipped into cold batter and coated with bread crumbs before parfrying at 180 °℃ for 15 s. Nuggets were allowed to cool at ambient temperature for 30 min before conducting analysis. Proximate composition Table 1. Formulation of meatless nuggets Ingredients (%) Control MN70 MN40 MN10 Main composition: Boiled chickpea 50.00 35.00 20.00 5.00 Oyster mushroom 0.00 15.00 30.00 45.00 Premix: Potato starch 8.36 8.36 8.36 8.36 Textured Vegetable Protein 18.00 18.00 18.00 18.00 Vegetable shortening 4.00 4.00 4.00 4.00 Onion 1.20 1.20 1.20 1.20 Salt 1.00 1.00 1.00 1.00 Baba's vegetarian meat curry powder 2.00 1.00 1.00 1.00 Black pepper 0.20 0.20 0.20 0.20 Garlic 0.20 0.20 0.20 0.20 Sugar 0.04 0.04 0.04 0.04 Battering: Bengal gram flour 5.00 5.00 5.00 5.00 Corn starch 5.00 5.00 5.00 5.00 Breading: Bread crumb 5.00 5.00 5.00 5.00 Total 100 100 100 100 The r atio f or chickpea and oyster mushroom for MN70 is 70:30, for MN40 is 40:60, and for MN10 is 10:90 compared wi t h boiled chickpea as a control meatless nugget. a furnace (Carbolite Gero, CWF 1100, UK) at 550C. The carbohydrate content was determined by subtracting the total sum percentage of moisture,protein, fat, crude f iber, and ash using the following formula (McCleary & McLoughlin,2021): %Carbohydrate= 100-(moisture+protein+fat+fibre+ash) Physicochemical properties Cooking loss and cooking yield of cooked nuggets were determined by measuring the weig h t before cooking (m,) and after cooking (m,) nuggets (Wan Rosli et al., 2011; Sharima-Abdullah et al., 2018): Cooking yield (%)=100-cooking loss The t t e extural 【properties of nuggets were analyzed using a texture analyzer double-arm (TA.XT plus, Stable Micro System Ltd., UK),compression platen (SMS P/75) with a heavy-duty platform, and the following settings: pre-test speed 1.00 mm/s, test speed 3.00 mm/s, post-test speed 10.00 mm/s, trigger force 5 g and distance of 23.0 mm. The nugget was cut into cubes (1×1x 1 cm) and t he cube was placed in the middle of the texture analyzer and compressed to 50% of the sample thickness through a 2-cycle sequence with a load cell of 10 kg (Bakhsh et al., 2021). The textural properties such as hardness, springiness,cohesiveness, and chewiness were determined for all nuggets' formulations. The internal color of cooked nuggets was measured using a Konica Minolta Colorimeter (Chroma meter, CR-300, Japan) as a manual manufacturer procedure. The colorimeter was calibrated through a white ceramic (Y= 93.5,X= 0.3132, y= 0.3198), and color properties of lightness (L*), redness (a*), and yellowness (b*)values were recorded for all cooked nuggets. Sensory evaluation The sensory evaluation of nuggets was randomly conducted by 35 untrained 【panelists from university students and staff. Small pieces of different samples (2×2×2 cm) were prepared on a round plate and coded with the three-digit random number. The cooked samples were permitted to rest for 30 min at room temperature (26℃) and then served to panelists. The randomized order of the sample was presented once at a time to each panelist. Panelists were asked to evaluate the coded sample for attributes including color,aroma, taste, texture, and overall acceptability.The evaluation was conducted using a 7-point hedonic scale. Scores were assigned based on the degree of liking (1= dislike very much, 2= dislike moderately, 3= dislike slightly, 4= neither like nor dislike, 5= like slightly, 6= like moderately, 7= like very much) (Lukman et al., 2009). Statistical analy si s All analyses were performed in t r iplicate. The results of meatless nuggets were represented as the mean ± standard deviation. The proximate composition and physicochemical properties of meatless nuggets were carried out using analysis of variance (ANOVA) and SPSS version 20 (IBM Corp., Armonk, NY, USA) was used for analyzing data. The partial least squares regression (PLS-R)was used to measure the variable importance of projection (VIP) scores and correlation map between independent variables (sensory attributes), dependent variables (panelists), and active observation (samples)using XLSTAT software (Addinsoft Inc., NY). For multiple mean comparisons, Tukey's test was run at a 5% level of significance. RESULTS AND DISCUSSION Proximate composition Table 2 shows the resu l ts of the proximate composition of meat l ess nuggets. The proximate compositions offmeatlessnuggetsdiffered significantly (p<0.05) between formulations. The meatless nuggets were higher in moisture (53.35to 68.44%) and carbohydrate (13.96 to 22.57%) and lowered in protein (8.09 to 11.05%) and fat content (5.57 to 8.63%). Contrarily, Sharima-Abdullah et al. (2018) reported higher protein (10.80 to 11.78%) and carbohydrate (30.95 to 42.32%), but lower moisture (39.77 to 48.69%) and fat content (3.83 to 5.45%) in imitation chicken nuggets. The difference was due to the imitation chicken nuggets reported by Sharima-Abdullah et al. (2018) using chickpea flour substitution, which dehydrated form and lower moisture than in the present study used soaked and boiled chickpea, which had higher moisture. However, the protein content was almost similar, i.e., 17-21% for chickpea flour, 16-20% for raw chickpea (Grasso et al., 2022),21.44-21.88%for roasted, soaked, and boiled chickpea proteins (Ouazib et al ., 2015). The fat and carbohydrate content were different for both types of chickpeas based on the review of Grasso et al.(2022). The meatless nugget’s moisture contents increased significantly (p<0.05)based on the higher percentages of mushroom and lower percentages of boiled chickpea in the formulations; control (53.35%), MN70 (60.49%), MN40 (62.97%) and MN10 (68.44%).According to Ibrahim et al. (2015),oyster mushrooms have high moisture content,ranging from 85 to 88%. Moreover, boiled chickpea at t he highest substitution (control) was less effective to retain moisture (Table 2). According to Grasso et al.(2022), the water absorption capacity of chickpea was poor against gravity interaction until it was processed and converted into chickpea protein isolates which has a greater ability to swell,d i ssociate and unfold. The control contains the significantly highest (p<0.05) amount of carbohydrates (22.57%), whi汆e MN10 contains the significantly lowest (p<0.05)and was due to the control containing 100%boiled chickpeas in the formulation as compared with other meatless nuggets which contain in combination with oyster mushroom. This was likely becausee chickpeas contain abundant carbohyd r ates ranging from 70.2 to 72.9% (Ghribi et al., 2015) while the carbohydrates of oyster mushrooms were approximately 48.2%(Tolera and Abera, 2017). In the current study, an increasing amount of oyster mushrooms and decreasing amount of boiled chickpeas decreased the protein of meatless nuggets significantly (p<0.05), as shown in Table 2. This f inding was in agreement with the study reported by Husain and Huda-Faujan (2020), which obtained that decreasing the amount of chickpea flour and an increasing amount of grey oyster mushroom stems decreased t he protein content i n imitation chicken nuggets. According to Malaysia Food Regulation 1985 (Food-Act-281, 1994), it was stated that a food product must contain at least 10% of Nutrient Reference Value (NRV) per 100 g (for solid food) to be claimed as a source of protein. All the meatless nuggets formulated in this study qualify as a protein source based on the NRV of 25 g per serving. The addition of various plant-based ingredients (e.g., chickpeas,oyster mushrooms, potato starch, and textured vegetable protein) in the current study has met the NRV value of more than 1.25 g with control, MN70,MN40, and MN10 were recorded NRV 2.77 g,2.41g , 2.31 g, and 2.02 g, respectively. Table 2. Proximate composition of meatless nuggets Percentage (%) Formulation of nugget samples Control MN70 MN40 MN10 Moisture 53.35±0.10d 60.49±0.86° 62.97±0.26 68.44±0.50= Carbohydrate 22.57±0.26a 16.21±0.325 15.80±0.51b 13.96±0.62° Protein 11.05±0.08a 9.61±0.07b 9.27±0.15° 8.09±0.08 Fat 8.29±0.18a 8.63±0.50a 7.73±0.56a 5.57±0.62b Crude fibre 2.90±0.08= 2.70±0.08 2.45±0.05° 2.31±0.07c Ash 1.83±0.04a 1.70±0.02bc 1.77±0.03ab 1.64±0.05° a-d Different letters in the same row i ndicate significant differences (p<0.05). The ratio for ch i ckpea and oyster mushroom for MN70 is 70:30, for MN40is 40:60, and for MN10 is 10:90 compared with boiled chickpea as a control meatless nugget . Consequently, meatless nuggets with different boiled chickpea and oyster mushrooms exhibited no major difference (p>0.05) in fat content and were lower than commercial chicken nuggets (18.1to 20.8% of fat) (Lukman et al., 2009). It has been reported that the fat content of meat alternatives is rationally different from t raditional processed meat products (Bakhsh et al., 2021). The fat content of the present study (5.57 to 8.63%) was less or within the range reported by Bohrer (2019) (5.63to 15.93%). Generally, plant-based meat products are considered low i n fat and protein contents than traditional meat Ahirwar et al.(2015). The fiber contentsfor meatless s nuggets (2.45 to 2.90%) were recorded as higher than traditional nuggets (0.00%) Bohrer (2019), due to the chickpea and mushroom incorporated in the nugget formulations (Table 2). The fiber content of t he control was significantly (p<0.05) higher than other meatless nugget formulations. A similar finding was also found by Husain and Huda-Faujan (2020) i n t heir imitation chicken nuggets. Although mushrooms contributed less fiber (7.5 to 8.1%)(Oluwafemi et al., 2016) than chickpeas (18.7to 21.9%) (Ghribi et al., 2015), both ingredients were believed to enrich the fiber in the meatless nuggets. The added value of fiber in plant-based meat can provide a health benefit to prevent ischaemic heart disease, large bowel disease, and diabetes mellitus than traditional meat products (Bakhsh et al., 2021). Irrespective of the application of different ratios of chickpea and oyster mushrooms, ash content showed a significant difference (p<0.05).The difference in ash content was very marginal between formulations. However, the ash content in the present study (1.64 to 1.83%) was lower than that reported by Sharima-Abdullah et al. (2018)in imitation chicken nuggets (3.11 to 3.36%) but almost similar to commercial chicken nuggets (1.20 to 1.58%) reported by Lukman et al.(2009). Physicochemical properties Table 3 shows the results of cooking loss, cooking yield, textural, and color properties of different formulations of meatless nuggets. I t was found that the cooking loss of MN10 was the highest (p<0.05)(7.11%), while the cooking loss of control was t he lowest (3.03%). An increment of oyster mushroom level in meatless nuggets by up to 90% increased the cooking loss and decreased the cooking yield.These findings contrasted with the result reported by Husain and Huda-Faujan (2020) who found the subst i tution of higher chickpea flour and lower grey oyster mushroom contributed to a higher cooking yield (negative cooking loss). Nevertheless, the current study was similar to Sharima-Abdullah et al . (2018) in the imitation chicken nugget with the lower incorporation of chickpea flour represents a higher cooking loss. The reason could be associated with the biopolymer network of chickpeas (protein and polysaccharides) that is good at retaining water (Jukanti et al., 2012; Wood et al., 2011). Meanwhile, the biopolymer network of mushrooms is unstable and interfered with by temperature. I t loses its integrity of binding water after subject i ng to a temperature above 40℃(Paudel, 2015). Although the moisture content of MN10 (90% oyster mushroom) was the highest before cooking (Table 2), it tends to lose of water through evaporation upon heating and results in a lower yield (Table 3). The textural properties are crucial in meatless nuggets because the products must mimic the appearance and texture of chicken nuggets. Table 3 shows the textural properties, including hardness,springiness, cohesiveness, and chewiness. All of the textural attributes of MN10 were significant l y (p<0.05) the highest compared to all meatless nuggets.The higher hardness in MN10 was expected , t his was due to the higher loss of water.Also, this was evidenced by Sharima-Abdullah et al.(2018) in their i mitation chicken nugget. However,the i ncorporation of a higher proportion of oyster mushrooms in the recipe was not the main factor for the nugget's hardness because Wan Rosli et al. (2011) found chicken patty hardness decreased proportionally with the level of mushroom. An increment in chickpea concentration decreased Table 3. Cooking loss, cooking yield, textural, and color properties of meatless nuggets Formulation Control MN70 MN40 MN10 Cooking loss (%) 3.03±0.15° 4.20±0.21 4.39±0.30 7.11±0.27a Cooking yield (%) 96.97±0.15 95.80±0.21b 95.61±0.30 92.89±0.27c Hardness (N) 100.75±1.65d 143.50±0.34c 150.82±0.64 218.05±0.53a Springiness (cm) 0.47±0.01c 0.65±0.01b 0.73±0.025 0.78±0.03a Cohesiveness (N/cm) 0.35±0.01b 0.51±0.01b 0.57±0.02a 0.59±0.01a Chewiness (N/cm) 15.79±0.61d 47.06±0.25° 55.07±0.61b 101.20±1.24a Lightness (L*) 45.06±0.51a 40.66±0.50 38.08±0.24C 35.86±0.50 Redness (a*) 7.36±0.23ab 7.34±0.04ab 7.87±0.15 7.11±0.34b Yellowness (b*) 44.93±0.64a 41.28±0.44 37.53±0.49° 31.52±0.44d the hardness of meatless nuggets markedly, as shown in the control. The lower hardness values were due to the extensive hydration of chickpea with water at the early stage of the processing phase. Dry chickpea hardness drops significantly (p<0.05) after soaking and blanching from 346 N to 38 N (Gowen et al .2007). The range of springiness and chewiness of all the nugget samples was between 0.47 to 0.78cm and 15.79 to 101.20 N/cm, respectively. The apparent changes in these textural properties were due to the cooking process of the nugget that contains a higher concentration of oyster mushrooms . After heat treatment, the cell wall structure of the mushroom breaks down and results in protein denaturation, solubilization of pectin, and other complex reactions, thereby exhibiting chewier attributes (Nket i a et al., 2020). Meanwhile, Wan Rosli et al. (2011) reported that the springiness of cooked patties increased when mushrooms were added at high concentrations. Our results in Table 3 evidence this, the springiness of MN70, MN40,and MN10 were significantly (p<0.05) increased with oyster mushroom concentration (30, 60, and 90%, respect i vely) compared to control (without mushroom). Also, we empirically observed that the textural properties of the control are mushy and deform easily only at first compression. This can be associated with lower cohesiveness (p<0.05),as shown in Table 3. According to Sharima-Abdullah et al . (2018), the lower cohesiveness in imitation chicken nuggets was due to the weaker intermolecular attraction of chickpea flour where it cannot adhere or bind other ingredients together. The color properties of meatless nuggets are shown in Table 3. Nuggets tended to decrease in lightness S (L*) and yellowness S (b*) with h a decrement in boiled chickpeas concentration.Our result is in tandem with the imitation chicken nuggets investigated by Sharima-Abdullah et al.(2018). However, the L* values of the present study were lower (35.9 to 45.1) than the L* values of commercial chicken nuggets (64.4 to 68.4)reported by Lukman et al. (2009). The variation of L* values in the present study compared to commercial chicken nuggets could be due to the full subst i tution of plant-based proteins (100%substitution) and the addition of mushrooms in the formulation. These ingredients also affected the b* values of meatless nuggets apparently (31.5to 44.9) more than commercial chicken nuggets' b*values (16.4 to 19.4) (Lukman et al., 2009). The lighter color of meat-based nuggets was probably due to the meat globules impregnated with water and fat which can reflect more l i ght to cause higher lightness (Bakhsh et al., 2021). Meanwhile,the higher b* values of meatless nuggets in this study are directly l inked with the yellow pigment of chickpeas (Husain & Huda-Faujan, 2020). In general , the different concentrations of chickpeas and mushrooms formulated in meatless nuggets affected the L* val u es because chickpeas and mushrooms characterized the color as lighter (Sharima-Abdullah et al., 2018) and darker (Wan Rosli et al., 2011), respectively. Similarly, the L* values of meatless nuggets were associated directly with the substitution ratio of chickpea and oyster mushrooms. As shown in Table 3, control representsa 日 higher lightnesswith chickpea and is substantially reduced with the increasing mushroom concentration. Similar effects were observed in the b* values of meatless nuggets incorporated with different ratios of chickpea to mushroom. However, chickpea and mushroom concentration at different percentages only plays a minor role in the a* values of cooked meatless nuggets. The a* values recorded in this study were 7.11I to 7.87, sl i ghtly different between formulations S ..These redness 卜 properties were higher than those reported by Lukman et al. (2009)and Sharima-Abdullah et al.(2018) in commercial chicken nuggets (0.51 to 3.51) and imitation chicken nuggets (2.76 to 6.21), respectively. Sensory evaluation The e sensory score of meatlessSnuggets is shown in Table 4. It was difficult to determine the sensoryfeaturesofmeatlessS 厂 nuggets because some treatments didhave not a statisticaldifference (p>0.05))..Partialleast square regression (PLS-R) was used to identify the correlation between samples and sensory attributes. Figure 1a is a correlation map between sensory attributes (X-components; independent variables), panelists (Y-components; dependent variables), and samples (active observations). Formulation Control MN70 MN40 MN10 Colour 4.63±1.65a 4.74±1.29a 4.60±1.14a 4.29±1.18a Aroma 4.83±1.54a 4.80±1.55a 4.86±1.24a 4.26±1.46a Taste 3.54±1.34b 3.97±1.45ab 4.71±1.36a 4.63±1.50 Texture 3.14±1.26° 3.91±1.42bc 4.77±0.91a 4.40±1.56ab Overall acceptability 3.89±1.39 4.03±1.34 5.00±1.14a 4.57±1.40ab a c Different letters i n the same row indicate signi fi cant differences (p<0.05). The ratio for chickpea and oyster mushroom for MN70 is 70:30, for MN40is 40:60, and f or MN10 is 10:90 compared with boiled chickpea as a control meatless nugge t . Fig. 1. (a) Partial least square regression (PLS-R) correlation loadings for X-t1 and Y-t2, where X-variables are independent variables and Y-variables are dependent variables. The observed samples are Control, MN70, MN40,and MN10. (b) Ranking of the variable importance in the projection (VIP) scores. The ratio for chickpea and oyster mushroom for MN70 i s 70:30, for MN40 is 40:60, and for MN10 is 10:90 compared with boiled chickpea as a control meatless nugget. Active observations/ samples are well separated throughout each biplot and there was a clear difference in the sample relative position that characterise d i fferent formulations. Results found that both control and MN70 were placed in the right part of the first component (t1), while MN40and MN10 were placed on the left. Interest i ngly,only MN70 and MN40 were positioned on the lower part of the second component (t2) together with sensory attr i butes. From Figure 1a and 1b,it was observed that some panelists displayed at the center of the correlation map, meaning that correlations were low towards sensory attributes.Regarding the active observation, MN40 was located away from the center circle and explained a better correlation to texture, taste, and overall acceptability at the lower left quadrant. However,MN70 was explained with little preference for color and aroma as it is located towards the center line and in the central circle. This can be evidenced by Figure 1b, where the variable importance in the projection (VIP) explained that the color and aroma were less significant in the current study as the VIP scores were lesser than 1. According to Ismail et al. (2020), a VIP score higher than one was regarded as an influential variable in a given model. The effect between ingredients represented well on the graph with a high concentration of boiled chickpea influenced the color and aroma.In contrast, a high concentration of mushrooms influenced the judgment towards taste, texture,and overall acceptability (Figure 1a). Empirically,the meatless nuggets with the higher substitution of boiled chickpea and mushroom (in control and MN10) tended to have a lower preference by the panelists on the sensory mean scores. Although MN40 was the most preferred by panelists, the substitution of plant-based ingredients in meatless nuggets was only an average score. The results in the present study were in line with the study reported by Husain and Huda-Faujan (2020),which found that substitution with 55% oyster mushroom and 15% chickpea recorded a better score in appearance, texture, juiciness, taste,and overall acceptability in i mitation chicken nugget . CONCLUSION Different substitution ratios of boiled chickpea and oyster mushrooms significantly affected the quality characteristics of meatless nuggets. A higher concentration of boiled chickpeas showed promising results, especially on carbohydrate,protein, fiber content, cooking yield, and color properties ((lightness &yellowness)).. Meatless nuggets V with higher substitution 1of oyster mushrooms exhibited better textural properties and sensory mean scores. However, samples with a maximum substitution of chickpea or mushroom (i .e., control & MN10) were not the best option for producing meatless nuggets. They failed to satisfy the sensory panelists as the added ingredient affect the texture and taste. It can be concluded that a meatless nugget with a 40:60 ratio of boiled chickpea to oyster mushroom (MN40)was recommended to prepare as an acceptable plant-based nugget with good physicochemical properties and sensory acceptability. ACKNOWLEDGEMENTS The author thanked the Department of Food Industry , Faculty of Bioresources and Food Industry, Universiti Sultan Zainal Abidin, for the materials and facilities provided for the experiment. The authors declare no conflict of interest. REFERENCES Ahirwar, R., Jayathilakan, K., Jalarama Reddy, K., Pandey, M.C. & Batra, H.V. 2015. Development of mushroom and wheat gluten based meat analogue by using response surface methodology.International Journal of Advanced Research,3: 923-930. AOAC 2002. Official Methods of Analysis. Arlington, Association of Official Analytical Chemists. Bakhsh, A., Lee, E.Y., Ncho, C.M., Kim, C.J ., Son, Y.M., Hwang, Y.H. & Joo, S.T. 2022. Quality character i st i cs of meat analogs through the incorporation of textured vegetable protein: A systematic review. Foods, 11(9): 1242. https://doi.org/10.3390/foods11091242 Bakhsh, A.,Lee, S.J., Lee, E.Y. Sabikun, N., Hwang, Y.H. & Joo, S.T. 2021. A novel approach for tuning the physicochemical, textural, and sensory characteristics of plant-based meat analogs with different levels of methylcellulose concentration. Foods, 10(3): 560. https://doi.org/10.3390/foods10030560 Bohrer, B.M. 2019. An investigation of the formulation and nutritional composition of modern meat analogue products. Food Science and Human Wellness, 8(4): 320-329. https://doi.org/10.1016/j.fshw.2019.11.006 Dekkers, B.L., Boom, R.M. & Van Der Goot , A.J. 2018. Structuring processes for meat analogues.Trends in Food Science & Technology, 81: 25-36.https://doi.org/10.1016/j.tifs.2018.08.011 Food-Act-281 1994. Law of Malaysia: Food Act and Regulations Act 281. Food Regulations 1985. Ulu Kelang, Kuala Lumpur, MDC Publisher Sdn Bhd. 2011 edition. Ghribi, A.M ., Maklouf, 1., Blecker , C., Attia, H. & Besbes, S. 2015. Nutritional and compositional study of Desi and Kabuli chickpea (Cicer arietinum L.) flours from Tunisian cultivars. Advanced in Food Technology and Nutritional Sciences, 1(2): 38-47.https://doi.org/10.17140/AFTNSOJ-1-107 Gowen, A., Abu-Ghannam, N., Frias, J. & Oliveira, J. 2007. Modelling the water absorption process in chickpeas (Cicer arietinum L.)- The effect of blanching pre-treatment on water intake and texture kinetics. Journal of Food Engineer i ng, 78: 810-819.ht t ps://doi.org/10.1016/j.j foodeng.2005.11.022 Grasso, N., Lynch, N.L., Arendt, E.K. & O'Mahony, J.A. 2022. Chickpea protein ingredients: A review of composition, f unctionality, and applications. Comprehensive Reviews in Food Science and Food Safety, 21(1): 435-452. https://doi.org/10.1111/1541-4337.12878 Husain, H. & Huda-Faujan, N. 2020. Qual i ty evaluation of imitation chicken nuggets from grey oyster mushroom stems and chickpea flour. Malaysian Applied Biology Journal , 49(3): 61-69. https://doi.org/10.55230/mabjournal.v49i3.1542 Ibrahim, R., Mohd Aziz, K., Arshad, A.M. & Hasan, S. 2015. Enhancing mushroom production using physical treatments prior to fruiting body formation. Malaysian Applied Biology Journal, 44(1):69-73. Ismail ,l . & Huda, N. 2022. Chapter 20-Meat alternatives. Future Foods. R. Bhat. London Wall, London,United Kingdom,Academic Press. pp.351-373.https://doi.org/10.1016/B978-0-323-91001-9.00004-9 Ismail ,1., Hwang, Y.H.& Joo, S.T . 2020. Low-temperature and long-time heating regimes on non-volat i le compound and taste t raits of beef assessed by the electronic tongue system. Food Chemistry, 320:126656. https://doi.org/10.1016/j.foodchem.2020.126656 Ismail,1., Hwang, Y.H. & Joo, S.T. 2020. Meat analog as future food: A review. Journal of Animal Science and Technology, 62(2): 111-120. htt p s://doi.org/10.5187/jast.2020.62.2.111 Kandil,A.A.,Aly-Aldin, M.M. & Allam,A.Y. 2020. Quality characteristics of processed low-fat beef sausage as affected by chickpea protein isolates prolonged cold storage. Journal of Food and Dairy Sciences,11(12): 363-368.https://doi .org/10.21608/jfds.2020.160397 Lukman, I., Huda, N. & Ismail, N. 2009. Physicochemical and sensory properties of commercial chicken nuggets. Asian Journal of Food and Agro-Industry, 2: 171-180. McCleary, B.V. & McLoughlin, C. 2021. Measurement of available carbohydrates in cereal and cereal products, dairy products, vegetables, f ruit, and related food products and animal feeds: First action 2020.07. Journal of AOAC I nternational, 104(6): 1465-1478.https://doi.org/10.1093/jaoacint/qsab019 Mohamad Mazlan, M., Talib, R.A., Chin, N.L., Shukri, R., Taip, F.S., Mohd Nor, M.Z. & Abdullah, N. 2020.Physical and microstructure properties of oyster mushroom-soy protein meat analog via single-screw extrusion. Foods,9(8): 1023. https://doi.org/10.3390/foods9081023 Motamedi, A., Vahdani, M., Baghaei, H. & Borghei, M.A. 2015. Considering the physicochemical and sensorial properties of momtaze hamburgers containing lentil and chickpea seed flour. Nutrition and Food Sciences Research,2(3):55-62. Nketia, S., Buckman, E.S., Dzomeku, M. & Akonor, P.T . 2020. Effect of processing and storage on physical and texture qualities of oyster mushrooms canned in different media. Scient i fic African, 9:e00501. https://doi.org/10.1016/j.sciaf.2020.e00501 Oluwafem i, G., Araoye, K. & Fagbemi, T . 2016. Chemical composition, functional properties and protein fractionation of edible oyster mushroom (Pleurotus ostreatus). Annals Food Science and Technology, 17(1):218-223. Ouazib, M., Moussou,N., Oomah, B.D., Zaidi, F. & Wanasundara, P.2015. Effect of heat processing and germination on nutritional parameters and functional properties of chickpea (Cicer arietinum L.) from Algeria. Journal of Food Legumes, 28: 1-8. Paudel, E. 2015. Change in water-holding capacity in mushroom with temperature analyzed by Flory-Rehner Theory. Food and Bioprocess Technology, 8(5): 960-970. https://doi.org/10.1007/s11947-014-1459-7 Sharima-Abdullah, N., Hassan, C.Z., Arifin, N. & Huda-Faujan, N. 2018. Physicochemical properties and consumer preference of imitation chicken nuggets produced from chickpea flour and textured vegetable protein. International Food Research Journal, 25(3):1016-1025. Souza Filho, P.F., Andersson, D., Ferreira, J.A. & Taherzadeh, M.J. 2019. Mycoprotein: environmental impact and health aspects. World Journal of Microbiology and Biotechnology,35(10): 147. https://doi.or g/10.1007/s11274-019-2723-9 Tolera , K.D. & Abera, S. 2017. Nutritional quality of oyster mushroom (Pleurotus ostreatus) as affected by osmotic pretreatments and drying methods. Food Science and Nutrition, 5(5): 989-996. https://doi .o rg /10.1002/fsn3.484 Wan Rosli, W.l., Solihah, M.A., Aishah, M., Nik Fakurudin, N.A. & Mohsin, S.S. J. 2011. Colour, textural properties, cooking characterist i cs and fibre content of chicken patty added with oyster mushroom (Pleurotus sajor-caju). International Food Research Journal, 18: 612-618 Wrigley, C., Corke, H., Seetharaman, K. & Faubion, J. 2015. Encyclopedia of Food Grains: Second Edition. Yogesh , K., Ahmad, T., Manpreet, G., Mangesh, K. & Das, P. 2013. Characteristics of chicken nuggets as affected by added fat and variable salt contents. Journal of Food Sc i ence and Technology,50(1):191-196. https://doi.o rg/10.1007/s13197-012-0617-Z

确定

还剩8页未读,是否继续阅读?

中国格哈特为您提供《鹰嘴豆和平菇结合的素肉中蛋白质、脂肪、纤维含量的检测》,该方案主要用于豆制品中营养成分检测,参考标准《GB 5009.6 食品中脂肪的测定》,《鹰嘴豆和平菇结合的素肉中蛋白质、脂肪、纤维含量的检测》用到的仪器有格哈特全自动超级总脂肪测定系统HT6+SOX416、格哈特凯氏消化系统KT8S、格哈特维克松废气实验室废物处理系统涤气VS、格哈特全自动型纤维分析仪FT12、格哈特带自动进样器凯氏定氮仪VAP500C、德国加液器MM、滤纸筒

相关方案

更多

该厂商其他方案

更多