方案详情

文

肉食杜泊绵羊不同蛋白质水平的全混合日粮(TMR)的成本效益Cost-effectiveness of Total Mixed Ration with Varying Crude Protein Levels for Feeding Dorper Lambs for Human Consumption

方案详情

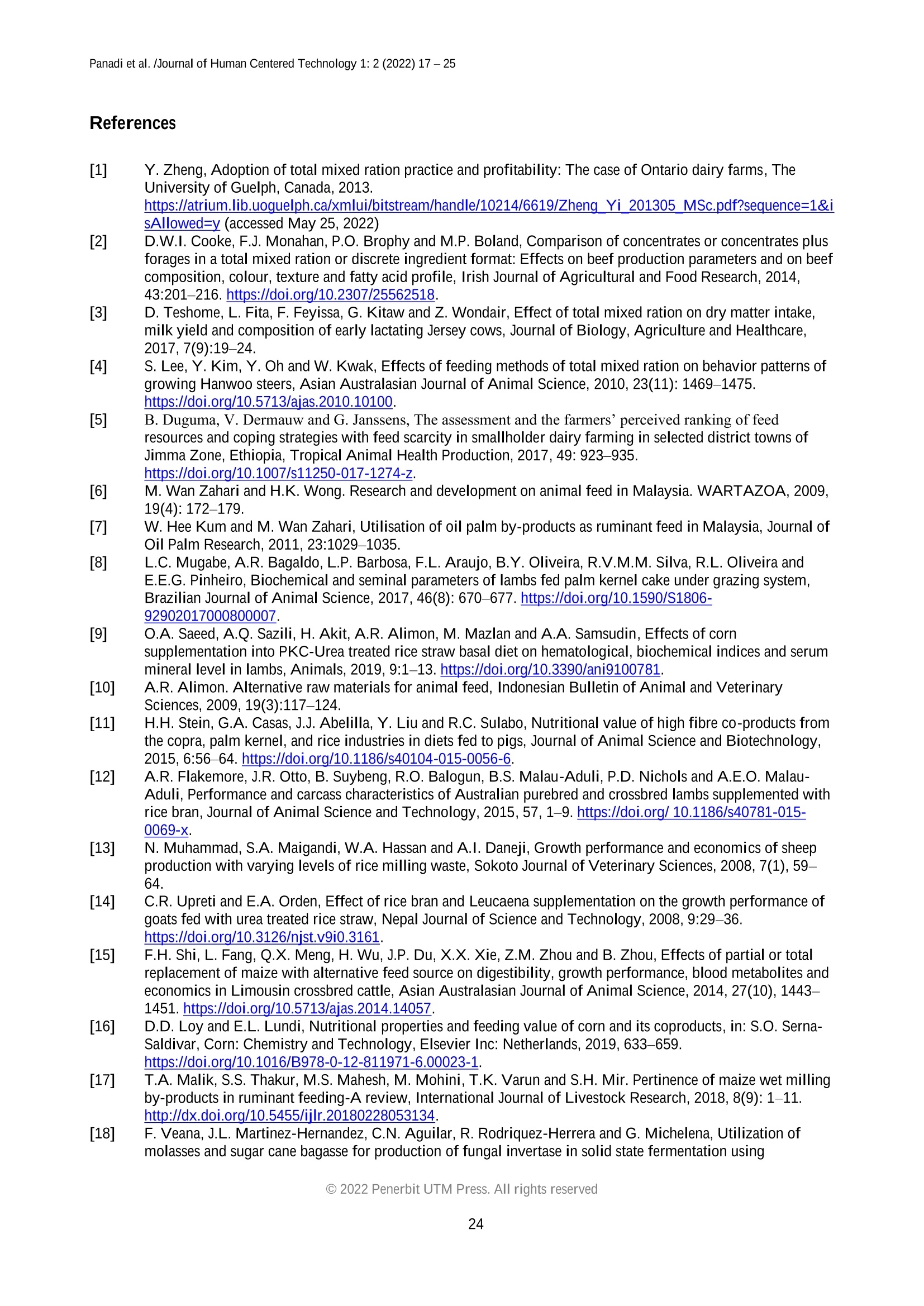

肉食杜泊绵羊不同蛋白质水平的全混合日粮(TMR)的成本效益Cost-effectiveness of Total Mixed Ration with Varying Crude Protein Levels for Feeding Dorper Lambs for Human ConsumptionJournal of Human Centered Technology Vol. 1: No.2 (2022)17-25Journal of Human Centered TechnologyE-ISSN: 2821-3467https://humentech.utm.my Panadi et al. /Journal of Human Centered Technology 1: 2 (2022)17-25 二=: 三二: 三三三 三三三三 肉食杜泊绵羊不同蛋白质水平的全混合日粮(TMR)的成本效益 Cost-effectiveness of Total Mixed Ration with Varyi n g Crude Protein Levels for Feeding Dorper Lambs for Human Consum pt ion Mira Panadil.*, Khairiyah Mat, Nor Dini Rusli,Nur Fadilah Darmansahl Department of Clinical Science and Spor t Technology, School of Biomedical Engineer i ng and Health Sciences,Faculty of Engineering, Universiti Teknologi Malaysia, 81310 Johor Bahru, Johor, Malaysia "Pre-clinical Department, Faculty of Veterinary Medicine, Universiti Malaysia Kelantan, 16100 Kota Bharu,Kelantan, Malaysia Faculty of Agro-Based Industry, Universiti Malaysia Kelantan, 17600 Je l i, Kelantan, Malaysia *Corresponding Author mirapanadi@utm.my Received 22 February 2022; Accepted 25 May 2022; Avai l able online 06 August 2022https://doi.org/10.11113/humentech.v1n2.16 Abstract: The demand for food consumption had increased by 60% due to the increase of human population, resulting i n an increasing demand for sheep meat. High cost of imported feed had restricted the growth of the sheep industry. Hence,the objective of this study was to evaluate the cost-effectiveness of feeding total mixed ration (TMR) in the form of creep feed (CF) and growing ration (GR) to Dorper lambs compared to the control (CON) group fed with farm routine diet consisted of Napier grass and commercial pellet. Two (2) experimental phases were conducted, i .e., Phase I (CF)and Phase II (GR), which consisted of twenty (20) Dorper lambs with five (5) lambs in each group. The CF and GR consisted of constant metabol i ze energy (ME) (11 MJ/kg DM ME). The crude protein (CP) (%) in CF was varied at 14, 16,18 and 20 for CON 14, CF 16, CF 18 and CF 20 respectively, whereas the CP (%) in GR was varied at 11,14,16 and 18 for CON 11, GR 14, GR 16 and GR 18 respectively. The cost of feed/kg gain (RM/kg) of CON 14(1.63) and CF 18 (1.97) was significantly lowered (p<0.05) than CF 20 (3.35) whereas, GR 16 (8.94) was signi f icantly lowered (p<0.05) than CON 11 (22.92) and GR 18 (23.99). This finding revealed that feeding local feed ingredients in TMR form, resulting in low feeding cost and subsequently higher economic returns. It can be concluded that feeding 18% CP (CF 18) and 16% CP (GR 16) were efficient to enhance the growth performance of pre-and post-weaning Dorper lambs respectively. Keywords: Creep feed; Dorper lambs; Growing ration; Total mixed ration 1. Introduction A total mixed ration (TMR), also known as a complete ration, is produced by combining feed ingredients at particular weights to produce a nutritionally balanced ration that provides adequate nutrients for optimum performance and anima l demands. The TMR feeding provides animals with the same feeding mixture [1]. It i s also a feeding solution that uti l izes feed components l ike forages, cereals, and nutritional supplements [2]. The TMR-fed animals consumed a predetermined amount of forage and concentrate needed for produc t ion and health. Furthermore, selective feed consumption is reduced as the TMR consisted of a combination of forages and grains where the animals consumed together instead of separate feeding of forage and grains [3]. The TMR feeding i s also cost-effective as it uses a variety of agro-industr i al by-products and farm-grown forages [4]. Pasture, crop residues, forage crops, agro-industrial by-products, and non-tradit i onal feeds are t he e m m o o s st t common feed resources for sheep [5]. The availabili t y of agro-industria l by-products and crop residues, part i cularly from the oil palm and rice industries wil l influence local feed resources. Thus, increasing domestic feed production will result i n Malaysia's more sustainable ruminant industry [6]. The palm kernel cake (PKC) is a by-product of palm kernel oil extraction via solvent (hexane) extraction of ground palm kernels [7]. It serves as a source of fatty acids such as lauric, myristic, oleic, palmitic, stearic, and l inoleic, raising gonadotropin-releasing hormone (GnRH) pulses and improving reproductive performance [8]. It i s a l so a low-cost source of high-quality ruminant feed that contains 16-20% protein [9]. Copra meal is a cake made from coconut oil extracted from t he coconut f lesh using t he expeller method [10]. The difference in nutrient composition of copra meal is due to variations in residual oil concentration. A common i ssue with copra meal i s i ts quality as i t can be contaminated with a f latoxin, which can cause rancidity, thus lowering feed intake and efficiency [11]. Rice bran is a high-energy, protein -rich source of minerals and vitamins. Rice bran was composed of bran and polishing and the embryo, endosperm, inner and outer bran layers [12]. Rice bran contains 11.5% crude protein (CP),2100 kcal metabolize energy (ME), calcium (Ca) and phosphorus (P) which are necessary for growth [13]. Overall , rice bran provides rumen with a low-cost energy source for efficient nutrient util i sation and microbial protein synthesis [14].Maize is also a significant energy source i n livestock diets [15]. In comparison to other feeds, maize has a low protein content . I t also contains essential minerals and vitamins for animals [16]. Wet milling of maize grain yields a variety of maize by-products such as maize gluten meal , maize gluten feed, maize germ meal, and condensed fermented maize extractives [17]. Molasses are viscous, dark liquids formed by repeated crystallisation from the sugar preparation technique. It contains 60-63% sucrose, 3-5% reducing sugars, and 3-5% trace minerals [18]. It also has a high energy and protein of about 5%. It i s highly palatable and beneficial in stimulating bacteria multiplication in the rumen, which aids in the digestion of f ibrous feed. When mixed with chopped grass, hay, or straws, the recommended inclusion level of molasses in the diet is 2% [19]. Feeding creep feed (CF) and growing ration (GR) are essential for meeting the nutritional needs of pre-and post-weaning animals. Creep feeding i s supplementing nutrition to improve offspring performance during the pre-weaning period. The approach entai l s supplementing offspring's diets [20]. In contrast, the GR in TMR form will ensure nutrient demands are met, resulting in an optimum performance at growing stages to achieve the desired production level [21]. Due to high feeding costs as feed i ngredients are i mported, this has recently become a signi f icant concern. Despite the fact that natura l pastures and crop residues were abundantly produced, their use for livestock feeding has been hampered by economic i ssues. The primary i ngredients i n the commercially prepared feed are i mported feed grains such as maize, soybeans, sorghum, oats, and barley. As a result, most feed ingredients must be imported, resulting in year-round unsustainable meat production. Malaysia imports more than 70% of the raw materials used in the animal feed industry each year, including 2000 tonnes of corn and 1000 tonnes of soybean meal. Malaysian i mports of animal feed are estimated to be worth RM 6.7 billion [22]. In Malaysia, the sheep population i ncreased by 19% between 2010 and 2015, rising f rom 123 475 to 147 033 heads However, the population fell to 138 479 heads (5.8%) and 137 872 heads (0.4%) in 2016 and 2017, respectively. The sheep population increased by 0.17% in 2018 to 138 111 heads [23]. More than 7000 tonnes of sheep meat were produced during this period. In 2050, the globa l human population i s expected to reach 9.1 bil l ion. As a result, food demand will rise by 60%, resulting in i ncreased demand for sheep meat [24]. As a result, Dorper sheep were imported from South Africa to meet 30% of the country's meat production demand.In 2009 and 2011, 3000 and 4680 heads of Dorper sheep were imported, respectively, to produce a high-value Dorper breed that is well-suited to the local environmental conditions [25]. Developing practical and cost-effective feeds becomes a concern when using local forages, crop res i dues, and agricultural by-products as ruminant feeds [26]. Various studies have been conducted to improve the feeding value of local ingredients in feed rations, including availabi li ty,nutritional value, the opt i mum level of inclusion, and t reatment methods [6]. However, there has been l i tt l e research in Malaysia on optimising local ingredients in the form of TMR for feeding sheep. Furthermore, current sheep feeding practices in Malaysia adhere to the international feeding standards established by the United States (National Research Council ) and the United Kingdom (Agriculture and Food Research Counci l ). Due to di f ferences in feed ingredients and nutritional quality, environmental conditions (tropical vs temperate), animal breeds, and genetics, international feeding standards are not always appropriate for use locally [27]. As a result, nutritional requirements, particularly crude prote i n (CP) of Dorper sheep raised in Malaysia may differ f rom t he established feeding standard. Hence, i t is critical to determine the CP requirement of Dorper sheep by utilising local feed resources to produce cost-effective feeding methods to i mprove weaning and growth performance. The aims of this study were to determine the cost-effectiveness of feeding total mixed ration (TMR) to Dorper l ambs i n the form of creep feed (CF ) and growing ration (GR) with varying CP levels. 2. Materials and Methods 2.1 Ethics statements The study protocols , procedures and consent form were approved by the Institutional Animal Care and Use Committee of Universit i Malaysia Kelantan (UMK/FPV/ACUE/PG/2/2019). 2.2 Study area and experimental animals This study was conducted at Agropolitan Besut-Setiu, located in Terengganu. There were two phases conducted i n this study. Phase I consisted of twenty (20) pre-weaning Dorper lambs at 7 days old with a mean initial body weight of 2.91±0.07 kg. Phase I was conducted from day 7 to day 84 of the feeding trial . Phase I I was a continuation of Phase I which was conducted from day 85 to day 180 of the feeding t rial. Figure 1 shows t he Dorper lambs during the feeding trial. Figure 1. Dorper lambs 2.3 Experimental design Al l animals were randomly a l located i nto four (4) groups, with five (5) animals i n each group based on the i nitial body weight, according to t he Randomized Complete Block Design (RCBD). The lambs were penned individually in pens measuring 1.2 m x 1.5 m with their dams in separate pens. The lambs had access to the mother milk during the pre-weaning period. 2.4 Experimental diets and treatments In Phase, I, lambs at pre-weaning stages (day 7 to day 84) in the control (CON) group were fed wi t h Napier grass and commercial creep pellet (CON 14) while the t reatments consisted of creep feed (CF), i .e., CF 16, CF 18 and CF 20.In Phase II , lambs at post-weaning stages (day 85 to day 180) were fed Napier grass and a commercial grower pellet (CON 11). In contrast , the treatment groups were fed with growing ration (GR), i.e., GR 14, GR 16 and GR 18. 2.5 Preparation of creep feed and growing ration The TMR was made up of forage (Napier grass) and grains (PKC, soybean meal, soyhull , corn meal, molasses,mineral premix and salt ). The TMR was mixed using a cement mixer. The ingredients were weighed in accordance with the formulation shown in Table 1. Table 1. Formulation of creep feed and growing ration Ingredients Formulation (%) CON 14 CF 16 CF 18 CF 20 CON 11 GR 14 GR 16 GR 18 Napier grass 40 40 40 40 60 60 60 60 Copra cake 0 20.5 18.4 18.4 0 13.7 6.8 10.5 PKC 0 0 0 0 0 3.7 3.7 0 Soybean meal 0 10.5 16.9 23.5 0 9.9 16.8 23.3 Corn meal 0 0 0 0 0 5.5 5.5 4 Soya hull 0 17.8 16.8 12.9 0 5 5 0 Rice bran 0 9 5.6 2 0 0 0 0 Molasses 0 2 2.1 3 0 0 0 0 Mineral premix 0 0.1 0.1 0.1 0 2 2 2 Salt 0 0.1 0.1 0.1 0 0.1 0.1 0.1 Creep pellet 60 0 0 0 0 0.1 0.1 0.1 Grower pellet 0 0 0 0 40 0 0 0 The f irst mixing step involves combining forage with mineral premix and salt (Figure 2). The forages were chopped before being added to the mixer. The ingredients were thoroughly combined. Other grains, such as soybean meal, soy hull, copra cake, rice bran, and PKC, were added. Finally, molasses liquid feed was added to the mixture. To ensure homogeneous mixing, the mixture was allowed to mix for 5 minutes. (a) (b) (c) Figure 2. (a) Chopping of Napier grass using chopper, (b) Mixing of TMR using cement mixer and (c) Well mixed forage and concentrate 2.6 Chemical analysis of diets The feed ingredients, control and formulated diet were analyzed for dry matter (DM), crude protein (CP), crude fibre (CF), ether extract (EE) and ash according to AOAC (1997) [28]. The DM was determined by drying the sample in a forced-air oven for 24 hours at 105℃, whereas ash was determined by incinerating the sample at 600℃ for 4 hours in a furnace. The Kjeldah l method determined the CP, which involves sample digestion in concentrated sulphuric acid at 400℃, followed by distillation wi t h sodium hydroxide solution and titration against the hydrochloric acid. The EE was determined by extracting the sample with petroleum ether. The CF was determined by washing the sample with sulphuric acid and sodium hydroxide in the Gerhardt Fibretherm system. 2.7 Calculation of feeding cost and cost analysis The feeding cost was calculated based on the total DMI , at which t he total dry matter i ntake (DMI ) t hroughout the feeding trial ti mes with the cost of 1 kg feed, as shown in Equat i on 1. The cost analysis was determined as cost/kg gain (RM/kg) and calculated, as shown in Equation 2. The cost analysis excludes the cost of labour , electricity and other related equipment and utensils. 2.8 Data analysis The data of cost analysis of control and f ormulated diet were analyzed by one-way Analysis of Var i ance (ANOVA)using Statist i cal Package of Social Science (SPSS) version 25 (I nc., Chicago, IL, USA). I f there were significant differences (p<0.05) between different diets, the Duncan Multiple Range Test further analysed the data. 3. Results and Discussion Table 2 shows the chemical composition of the feed ingredients and the diets. The DM of Napier grass (19%) was the lowest followed by molasses (72%). Other feed ingredients contained >85% DM. The ash of Napier grass, PKC,soyhull , copra cake, molasses and soybean meal ranged from 4% to 9%. However, the ash content of salt , mineral premix and rice bran was the highest which at 98%, 73% and 11% respectively. Besides, the CP in soybean meal was the highest at 47%, followed by copra cake (17%), soyhull (16%), PKC (16%) and rice bran (12%). Napier grass and corn meal has a low CP ranged from 7% to 8%. The EE contained in copra cake was the highest at 9%, whereas EE i n other feedstuffs ranged between 1% to 7%, except for molasses, mineral premix and sal t with 0% EE. For the CF, the highest content was found in Napier grass (39%), followed by soyhull and copra cake, which contained 27% CF. Rice bran (12%) and soybean meal (5%) contained low CF, meanwhile CF was not present in molasses, mineral premix and salt . The DM, ash and EE of formulated CF showed a small difference. The formulated CF also contained 61-62% DM, 6-8% ash and 5-6% EE.For GR, t he ash and EE content in formulated GR were 4-5% and 2-3%, respectively. Besides, CF was ranged between 27-30%. Table 2. Chemical composition of feed ingredients and diets Feed DM(%) Ash(%) CP(%) EE(%) CF(%) Feed ingredients Napier grass 18.80±0.15 5.38±0.09 8.06±0.11 1.95±0.02 39.01±1.02 Rice bran 90.09±0.04 11.14±0.05 12.13±0.07 6.56±0.17 12.17±0.43 PKC 90.33±0.03 4.36±0.05 15.57±0.05 1.37±0.01 39.05±0.55 Corn meal 87.37±0.02 1.38±0.02 6.98±0.04 4.31±0.08 2.52±0.22 Soybean meal 89.47±0.03 7.35±0.30 45.68±0.08 2.20±0.40 4.81±0.13 Soyhull 90.16±0.02 9.44±0.07 16.07±0.45 6.09±0.05 26.89±0.85 Copra cake 92.34±0.01 6.85±0.03 16.89±0.38 9.31±0.14 26.51±0.14 Molasses 72.03±0.09 3.70±0.01 4.49±0.14 0 0 Mineral premix 94.29±0.04 72.63±1.66 0 0 0 Salt 98.78±0.04 97.98±0.11 0 0 0 Control diet Creep pellet 87.68±0.03 4.54±0.01 18.26±0.27 2.84±0.09 21.88±0.51 Grower pellet 90.65±0.04 4.74±0.07 15.78±0.08 5.67±0.11 20.99±1.13 Formulated diet CF 16 61.63±0.55 7.81±0.15 16.17±0.51 6.76±2.24 24.54±0.15 CF 18 61.53±0.87 7.43±0.19 18.17±0.15 4.87±0.12 20.63±0.45 CF 20 61.32±0.36 6.39±0.37 20.12±0.62 3.94±0.26 21.05±1.05 GR 14 47.08±0.40 5.12±0.01 13.53±0.38 3.04±0.05 30.44±0.14 GR 16 46.88±0.56 4.65±0.02 15.51±0.20 2.40±0.13 28.95±0.20 GR 18 46.95±0.20 4.25±0.01 17.62±0.08 2.32±0.10 27.41±0.21 As shown i n Table 3, the production costs of the control diet and creep feed for CON 14, CF 16, CF 18, and CF 20were RM 0.79, 0.73, RM 0.83, and RM 0.93, respectively. The lowest cos t formulation is CF 16, which has a lower inclusion of soybean meal than other formulations as soybean meal is an expensive protein source. Creep feed with increased i nclusion of protein sources in its formulation contr i buted to i ts higher pr i ce. However, due to t he high cost of commercial creep pellet, the control diet was more expensive than CF 16. Besides, CON 11, GR 14, GR 16, and GR 18had the lowest production costs (RM) at 0.50,0.57,0.67, and 0.77, respectively. Table 3. Production cost of a control diet , creep feed (CF) and growing ration (GR) Ingredients Cost CON CF CF CF CON GR GR GR (RM/ 14 16 18 20 11 14 16 18 kg) Napier grass 0.10 0.04 0.04 0.04 0.04 0.06 0.06 0.06 0.06 Rice bran 0.70 一 0.06 0.04 0.01 PKC 0.60 一 一 一 一 一 0.02 0.02 Corn meal 0.95 一 一 一 一 一 0.05 0.05 0.04 Soybean 2.30 一 0.24 0.39 0.54 一 0.23 0.39 0.54 meal Soy hull 0.95 一 0.17 0.16 0.12 一 0.05 0.05 Copra cake 0.90 一 0.18 0.17 0.17 一 0.12 0.06 0.09 Molasses 1.30 一 0.03 0.03 0.04 一 0.03 0.03 0.03 Mineral 6.85 0.007 0.007 0.007 0.00 0.007 0.007 vitamin 7 premix Salt 0.65 一 0.001 0.001 0.001 0.00 0.001 0.001 1 Creep pellet 1.25 0.75 一 一 Grower 一 一 一 0.44 一 一 pellet Total cost* 一 0.79 0.73 0.83 0.93 0.50 0.57 0.67 0.77 Table 4 depicts the cost analysis in Phase I and I I . T he total DM consumed, feed cost , total weight gain, and feed cost/kg gain i ncreased l inearly (p<0.05) as the CP level in the diet increased. The total DM consumed (kg) increased linearly (p<0.05) with increasing CP levels in the diet i n the following order: CF 20 (82.67)> CF 16 (67.61)> CF 18(53.07)> CON 14 (41.51). The cost of f eeding lambs (RM) in CF 20 (76.89) was significantly higher (p<0.05) than in CON 14 (29.19), CF 16 (49.36), and CF 18 (44.05), but there was no significant difference (p>0.05) between CON 14,CF 16, and CF 18. Total weight gain (kg) in CF 16 (19.70) was also signi f icantly lower (p<0.05) t han i n CF 20, but not signi f icantly different (p>0.05) from CON 14 and CF 18. Total weight ga i n i ncreased linearly with increased CP l evels in the diet (p<0.05). In general, the cost of feed/kg gain of pre-weaning Dorper lambs in Trial I was statistically signi f icant (p<0.05)between groups. The CON 14 (1.63) and CF 18 (1.97) had significantly lower feed/kg gain (RM/kg) costs (p<0.05) than CF 20. (3.35). The cost of feed/kg gain between CON 14 and CF 16(2.51), on the other hand, did not differ signif i cantly (p>0.05). It was also discovered that i ncreasing the l evel of CP i n the diet caused a linear i ncrease i n feed cost/kg gain (p<0.05). One of the most important factors in a farmer’s ability to maintain economic viability when raising meat sheep is how quickly and efficiently their lambs grow. High growth rates and efficiency reduced t he time it takes l ambs to reach market weight, lowering l abour and feed costs [29]. Concentrate feed, on t he other hand, may result in high lamb growth rates, but it also has a higher production cost, and the benef it does not alway s outweigh t he costs [30]. The current finding was consistent with a study conducted by [31], which discovered that different protein l evels had a significant effect on feed to gain ratio. According to a study published in [32], increasing the CP level i mproves feed effi ies. In Phase I I , the total DM consumed, cost of feeding lambs, total weight gain, and cost of feed/kg gain were all statist i cally significant (p<0.05). The total DMI (kg) of GR 18 (160.92) was significantly higher (p<0.05) than CON 11(114.30) and GR 16 (114.30). However, there were no significant differences (p>0.05) in total DMI between GR 18 and GR 14. (131.66). Furthermore, as the CP level in the diet increased, total DM consumed increased l inearly (p<0.05). Furthermore, the cost of feeding l ambs (RM) was significantly higher (p<0.05) i n GR 18 (123.91), followed by GR 16 (80.54), GR 14 (75.05), and CON 11. (72.04). However, there was no statist i cally significant difference (p>0.05) in the cost of feeding lambs between CON 11, GR 14, and GR 16. Increased CP level i n diet had a linear and quadrat i c effect (p<0.05) on l amb feeding cost. In terms of total weight gain (kg), GR 16 (9.00) had a significantly higher (p<0.05) total weight gain than CON 11.(3.67). However, there was no statistically signi f icant difference (p>0.05) in total weight gain between GR 14 (6.20), GR 16(9.00), and GR 18 (5.90). When total weight gain was considered, the most prof i table feed was GR 16. Higher economic returns result from higher total weight gain and lower feeding costs. The cost of feed for a 1 kg increase i n body weight was RM 8.94 for GR 16, RM 12.13 for GR 14, RM 22.92 for CON 11, and RM 23.99 for GR 18. Table 4. Cost analysis (Mean±SE) of control and formulated diet in Tria l I and Trial II Trial I - Creep feed Parameters CON 14 CF 16 CF 18 CF 20 p-value Linear Quadratic Trial I - Creep feed Total DM consumed (kg) -Napier 19.73±1.61 一 一 一 - Creep pellet 21.77±1.63 一 一 一 -Creep feed 一 一 - 一 - Total 41.51±3.22a 67.61±4.65ab 53.07±2.72a 82.67±5.64 0.020 0.850 Feeding cost (RM) 29.19±2.20a 49.36±3.40a 44.05±7.20a 76.89±5.25 0.002 0.419 Total weight gain 17.83±0.60a 19.70±1.07ab 22.17±0.83bc 22.9±0.64° 0.001 0.545 (kg) Feed cost/kg gain 1.63±0.07a 2.51±0.16ab 1.97±0.30a 3.35±0.18 0.006 0.446 (RM/kg) Trial II - Growing ration Parameters CON 11 GR 14 GR 16 GR 18 p-value Linear Quadratic Total DM consumed Napier 34.26±2.26 一 一 一 一 一 Creep pellet 51.15±3.47 一 - 一 一 一 Creep feed 一 一 一 一 Total 114.30±2.37 131.66±9.71 120.21±2.16 160.92±7.14 0.025 0.317 a ab a Feed cost (RM) 72.04±1.61a 75.05±5.54a 80.54±4.18a 123.91±5.49b 0.000 0.018 Total weight gain 3.67±0.88a 6.20±0.49b 9.00±1.53 5.90±1.12ab 0.064 0.019 (kg) Feed cost/kg gain 22.92±6.99b 12.13±0.30ab 8.94±0.57a 23.99±4.07 0.999 0.005 (RM/kg) means in the same row with different superscripts are significantly different (p<0.05) 4.(Conclusion In conclusion, feeding lambs in CF 18 and CON 14 i n Tria l I i s more profitable than the other groups. The control diet results were attributed to low DMI, which reduced the cost of feeding lambs, whereas, in Trial II , the most profitable feed i n terms of cost and benefit in terms of weight gain was those feds with 16% CP, who had the lowest feed cost/kg g a in. Acknowledgment This study was funded by the Ministry of Higher Education Malaysia under the Fundamental Research Grant Scheme (FRGS): R/FRGS/A06.00/00534A/007/2017/000439. Author would also l ike to thank Agropolitan Besut Setiu Terengganu for providing the research facilities and the experimental animals during the research. References [11 Y. Zheng, Adoption of total mixed ration pract i ce and prof it ability: The case of Ontario dairy farms, The University of Guelph, Canada, 2013.h ttps://atrium.l ib.uoguelph.ca/xmlui/bitstream/handle/10214/6619/Zheng Yi 201305 MSc.pdf?sequence=1&i sAllowed=y (accessed May 25, 2022) 2 D.W.I. Cooke, F.J. Monahan, P.O. Brophy and M.P. Boland, Comparison of concentrates or concentrates plus forages in a total mixed ration or discrete ingredient format: Effects on beef production parameters and on beef composition, colour, texture and fatty acid profile, Irish Journa l of Agricultural and Food Research, 2014,43:201-216.https://do i.o rg /10.2307/25562518. [3] D. Teshome, L. Fita, F . Feyissa, G. Kitaw and Z. Wondair, Effect of total mixed ration on dry matter intake,milk yield and composition o f early l actating Jersey cows, Journal of Biology, Agriculture and Healthcare,2017,7(9):19-24. [4] S. Lee, Y. Kim, Y. Oh and W. Kwak, Effects of feeding methods of tota l mixed ration on behavior patterns of growing Hanwoo steers, Asian Australasian Journal of Animal Science, 2010,23(11):1469-1475.https ://doi.org/10.5713/ajas.2010.10100. [5 B. Duguma, V. Dermauw and G. Janssens, The assessment and t he f armers'perceived ranking of feed resources and coping strategies with feed scarcity in smallholder dairy farming in selected district towns of J i mma Zone, Ethiopia, Tropical Animal Health Production, 2017,49:923-935.htt ps://doi.org/10.1007/s11250-017-1274-Z . [6] M. Wan Zahari and H.K. Wong. Research and development on animal feed in Malaysia. WARTAZOA, 2009,19(4):172-179. [71 W. Hee Kum and M. Wan Zahari , Utilisation of oi l palm by-products as ruminant f eed i n Malaysia, Journal of Oi l Palm Research, 2011,23:1029-1035. [8] L.C . Mugabe, A.R. Bagaldo, L.P. Barbosa, F.L. Araujo, B.Y. Oliveira, R.V.M.M. Silva, R.L. Oliveira and E.E.G. Pinheiro, Biochemical and seminal parameters of lambs fed palm kernel cake under grazing system,Brazilian Journal of Animal Science, 2017, 46(8): 670-677. https://doi.org/10.1590/S1806-92902017000800007. [91 O.A. Saeed, A.Q. Sazili, H. Akit, A.R. Alimon, M. Mazlan and A.A. Samsudin, Effects of corn supplementation i nto PKC-Urea t reated rice straw basal diet on hematological , biochemical i ndices and serum mineral level in lambs, Animals, 2019, 9:1-13. h ttps://do i .org/10.3390/ani9100781. [10] A.R. Al i mon. Alternative raw materials for animal feed, Indonesian Bulletin of Animal and Veterinary Sciences,2009,19(3):117-124. [111 H.H. Stein, G.A. Casas, J.J. Abelilla, Y. Liu and R.C. Sulabo, Nutritional value of high f ibre co-products from the copra, palm kernel , and rice i ndustries in diets fed to pigs, Journal of Animal Science and Biotechnology,2015, 6:56-64. https://doi.org/10.1186/s40104-015-0056-6. [12] A.R. Flakemore, J.R. Otto, B. Suybeng, R.O. Balogun, B.S.Malau-Aduli, P.D. Nichols and A.E.O. Malau-Adul i , Performance and carcass character i stics of Australian purebred and crossbred l ambs supplemented with rice bran, Journal of Animal Science and Technology,2015,57, 1-9. h ttps://doi.org/10.1186/s40781-015-0069-x . [131 N. Muhammad, S.A. Maigandi, W.A. Hassan and A.I . Daneji , Growth performance and economics of sheep production with varying levels of rice milling waste, Sokoto J ournal of Veterinary Sc i ences, 2008, 7(1),59-64. [18] F. Veana, J.L. Martinez-Hernandez, C.N. Aguilar, R. Rodriquez-Herrera and G. Michelena, Utilization of molasses and sugar cane bagasse f or production of f ungal i nvertase i n sol i d state fermentation using Aspergillus niger GH1, Brazilian Journal of Microbiology, 2014, 45(2):373-377.https://doi.o r g/10.1590/S1517-83822014000200002. [191 D.A.D. Costa, C.L.D. Souza, E.D.O.S. Saliba and J.D.C. Carneiro, By-products of sugar cane i ndustry in ruminant nutrition. International Journal of Advance Agricultural Research,2015,3(1):1-9.https://doi.org/10.33500/ijaar.2015.03.001. 20 E.G. Hayes, R.V . Lourencon and J. Richard Browning, Effects of creep feed i ng and its i nteractions with other factors on the performance of meat goat kids and dams when managed on pasture, Translational Animal Science, 2019,3(4):1466-1474. https://do i.org/10.1093/t a s/txz122. [211 A. Perez-Ruchel, J .L. Repetto and C . Cajarville, Supplementing high-quality fresh forage to growing l ambs fed a total mixed ration diet led to higher intake without altering nutrient utilization. Animal, 2017,11(12):2175-2183.https://doi .org/10.1017/S1751731117000933. 122 FAO, The Future of Food and Agriculture : Trend and Challenges, Rome: Food and Agriculture Organization,2017. https ://www.f ao.org /3/i6583e/i 6583e.p d f . 123 FAOSTAT, Food and Agriculture Organization Statistics Database, Rome: Food and Agriculture Organization, 2020. h ttp://www.fao.org/faostat/en/#home. [241 G.F.D. Brito, E.N. Ponnampalam and D.L. Hopkins, The effect of extensive feeding systems on growth rate,carcass traits, and meat quality of f inishing l ambs, Inst i tute of Food Technologies, 2016,16,23-38.https ://do i.o r g /10.1111/1541-4337.12230. [251 East Coast Economic Region Development Council, Annual Report , 2012.https://ww w.ecerdc.com.my/media-room/publications/15110-2/ 26 M.M. Abdelrahman, R.S. Aljumaah, A.H. Alyemni, M. Ayadi , H. Metwally, and M.Y. Al-Saiady, Effect of palm kernel cake and trace minerals on the performance of growing Naemi lambs, Research Opinions i n Animal & Veterinary Sciences, 2014,4(5):268-272. [271 A. Jayanegara, M. Ridla, D.A. Astuti, K.G. Wiryawan, E.B. Laconi and Nahrowi, Determination of energy and protein requirements of sheep in I ndonesia using a meta-analytica l approach, Media Peternakan, 2017,40(2):118-127.htt ps://doi.org/10.5398/medpet.2017.40.2.118. 128 AOAC, Official methods of analysis, 1997, USA: Association of Official Analytical Chemists. [291 L.B. Harthan and D.J.R. Cherney, Okara as a protein supplement affects feed intake and milk composition of ewes and growth performance of l ambs, Animal Nutrition, 2017,3:171-174.https://doi.org/10.1016/j.aninu.2017.04.001. [301 S. Ates, G. Keles, Y.A. Tigezu, U. Demirci, S. Dogan, S. I sik and M. Sahin, Bio-economic efficiency of creep supplementation of forage legumes or concentrate i n pasture-based lamb production system, Grass and Forage Science, 2017, 72(4):1-15.ht tps://doi.org/10.1111/gfs.12291. [311 J.I. Sultan, A. Javaid and M. Aslam, Nutrient digestibility and feedlot performance of l ambs fed diets vary i ng protein and energy contents, Tropica l Anima l Health Production , 2010, 42:941-946.htt ps://do i .org/10.1007/s11250-009-9511-8. 32 N. Dabiri, Effects of different dietary energy and protein l evels at f ixed slaughter weight on performance and carcass characteristics of Arabi f attening l ambs, Journal of Fisheries & Livestock Production, 2016,4(4):1-4.h ttps://doi.org/10.4172/2332-2608.1000201

确定

还剩7页未读,是否继续阅读?

中国格哈特为您提供《肉食杜泊绵羊不同蛋白质水平的全混合日粮(TMR)中蛋白质、脂肪、纤维含量的检测》,该方案主要用于饲料中营养成分检测,参考标准--,《肉食杜泊绵羊不同蛋白质水平的全混合日粮(TMR)中蛋白质、脂肪、纤维含量的检测》用到的仪器有格哈特全自动型纤维分析仪FT12、格哈特全自动超级总脂肪测定系统HT6+SOX416、格哈特凯氏消化系统KT8S、格哈特维克松废气实验室废物处理系统涤气VS、格哈特带自动进样器凯氏定氮仪VAP500C、德国加液器MM、滤纸筒

相关方案

更多

该厂商其他方案

更多