γ-氨基丁酸(GABA)富集对黑巧克力营养,物理,保质期和感官特性的影响The Effects of Gamma-Aminobuytric Acid (GABA) Enrichment on Nutritional, Physical, Shelf-Life, and Sensorial Properties of Dark Chocolate

方案详情

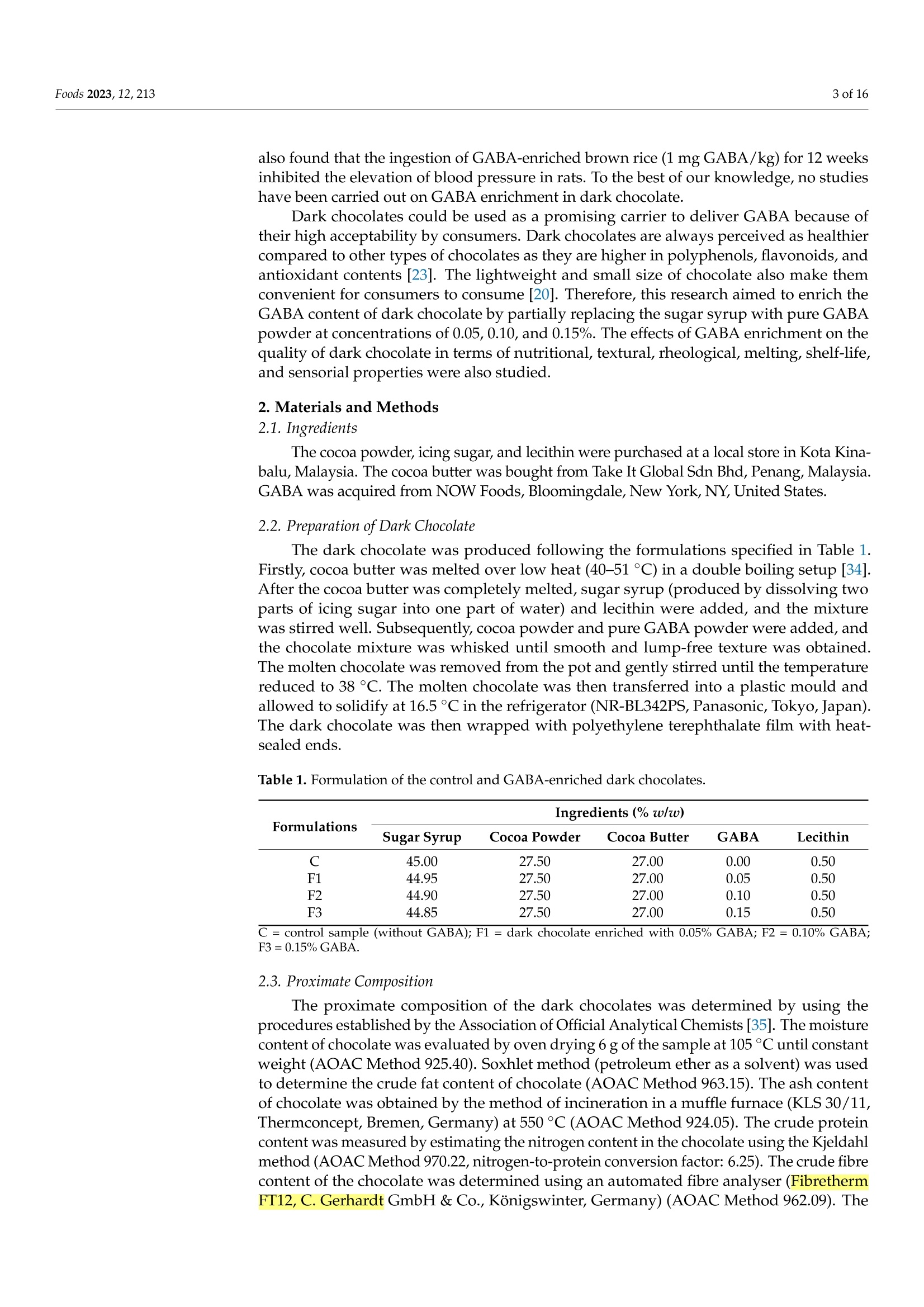

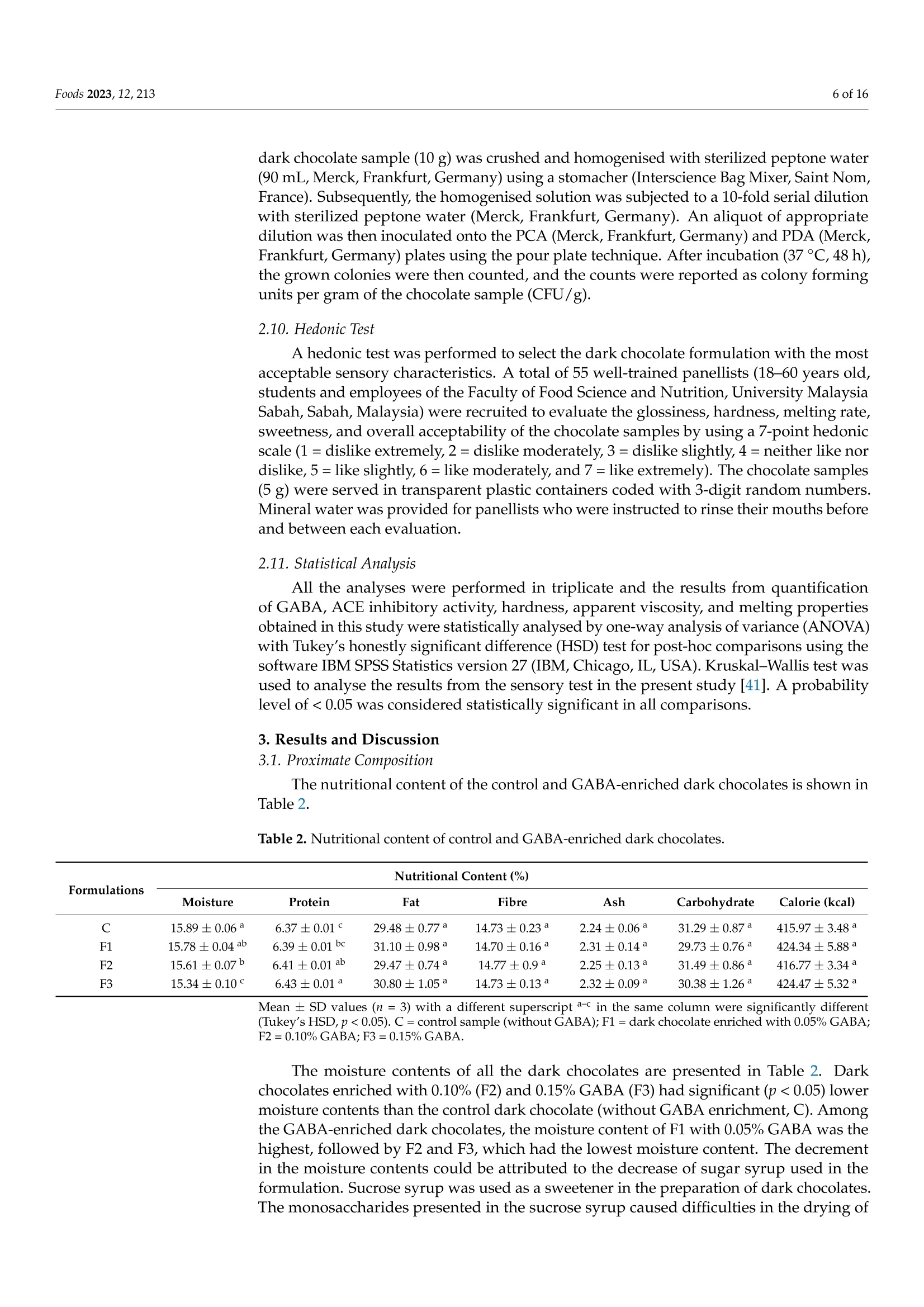

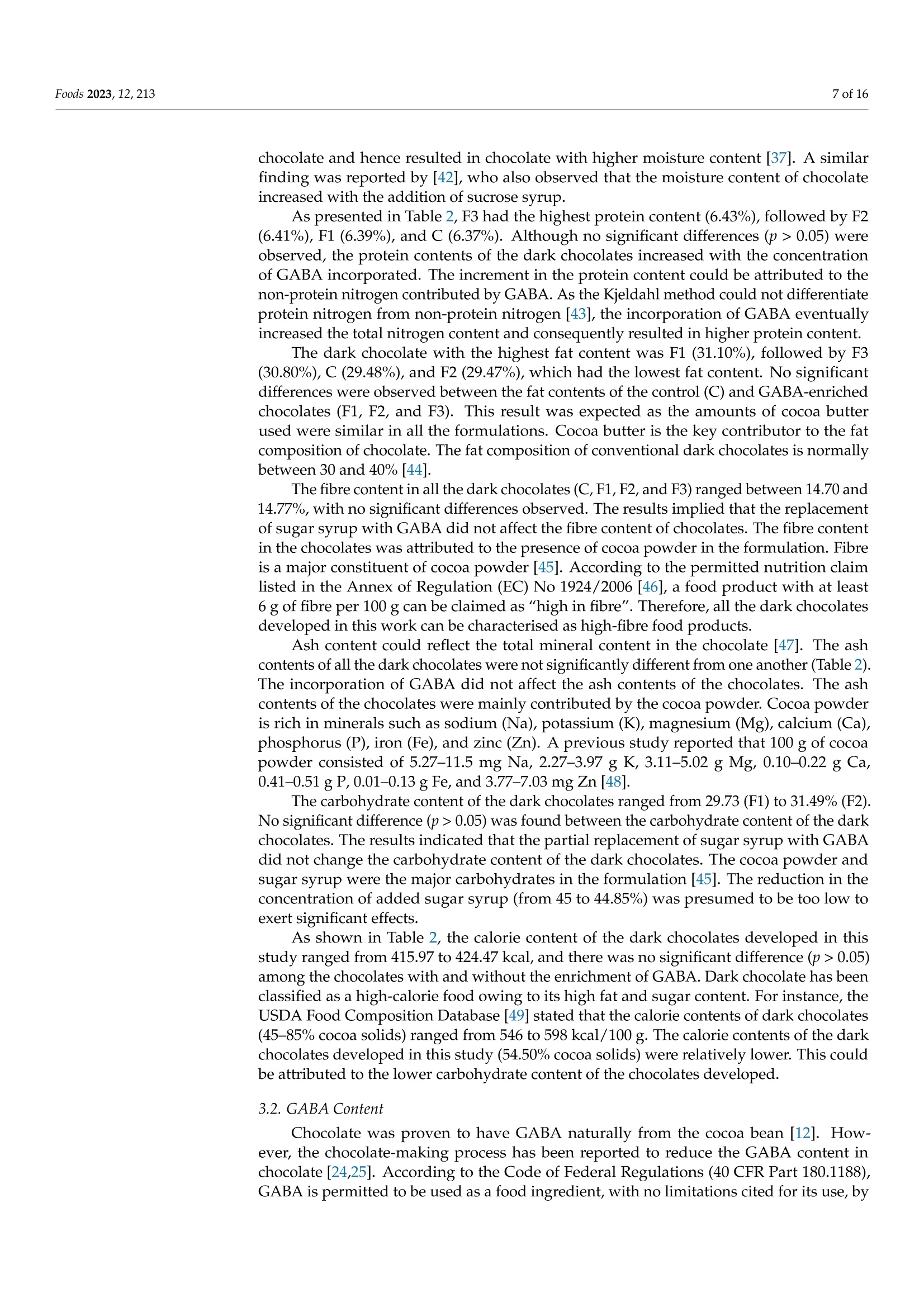

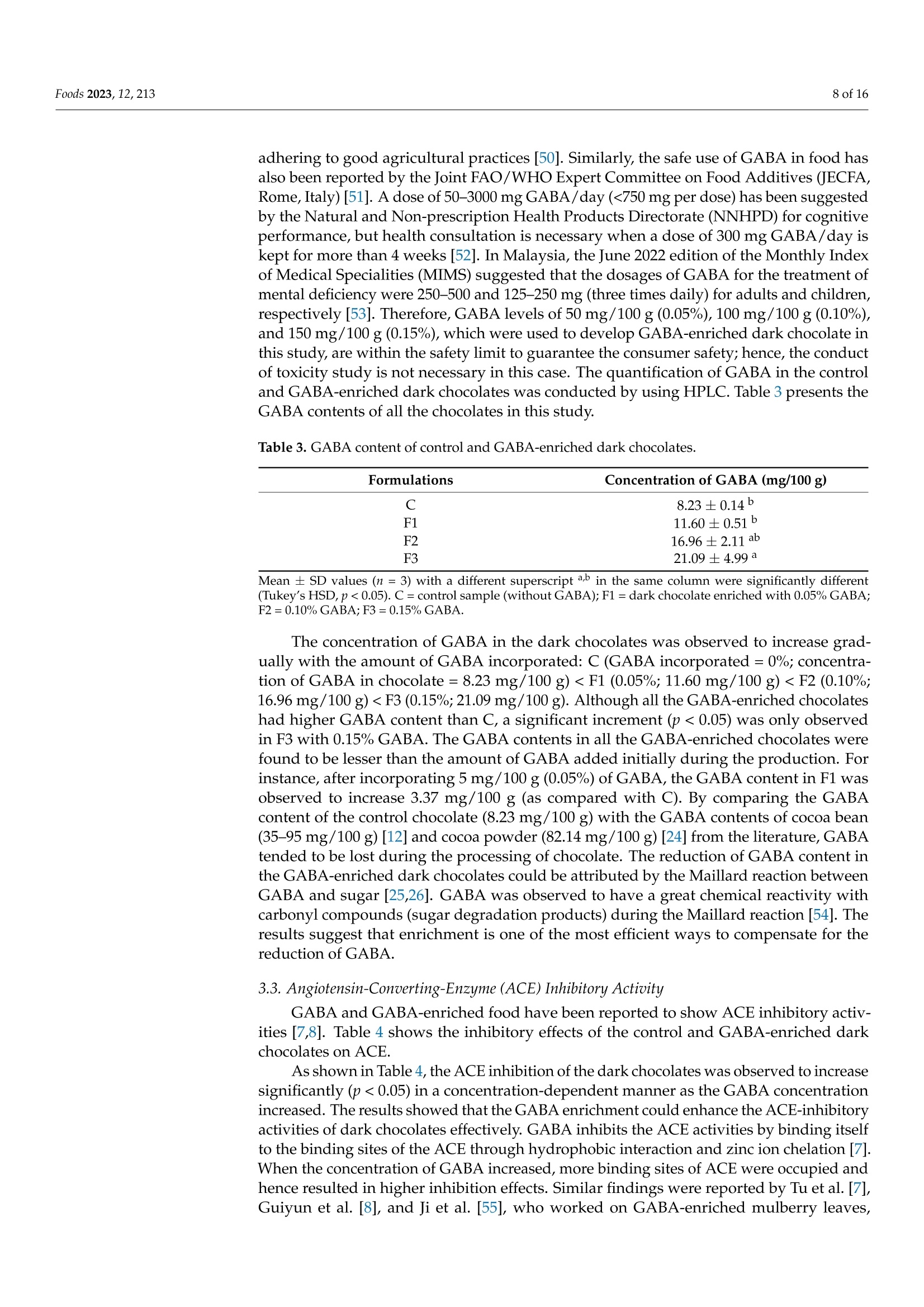

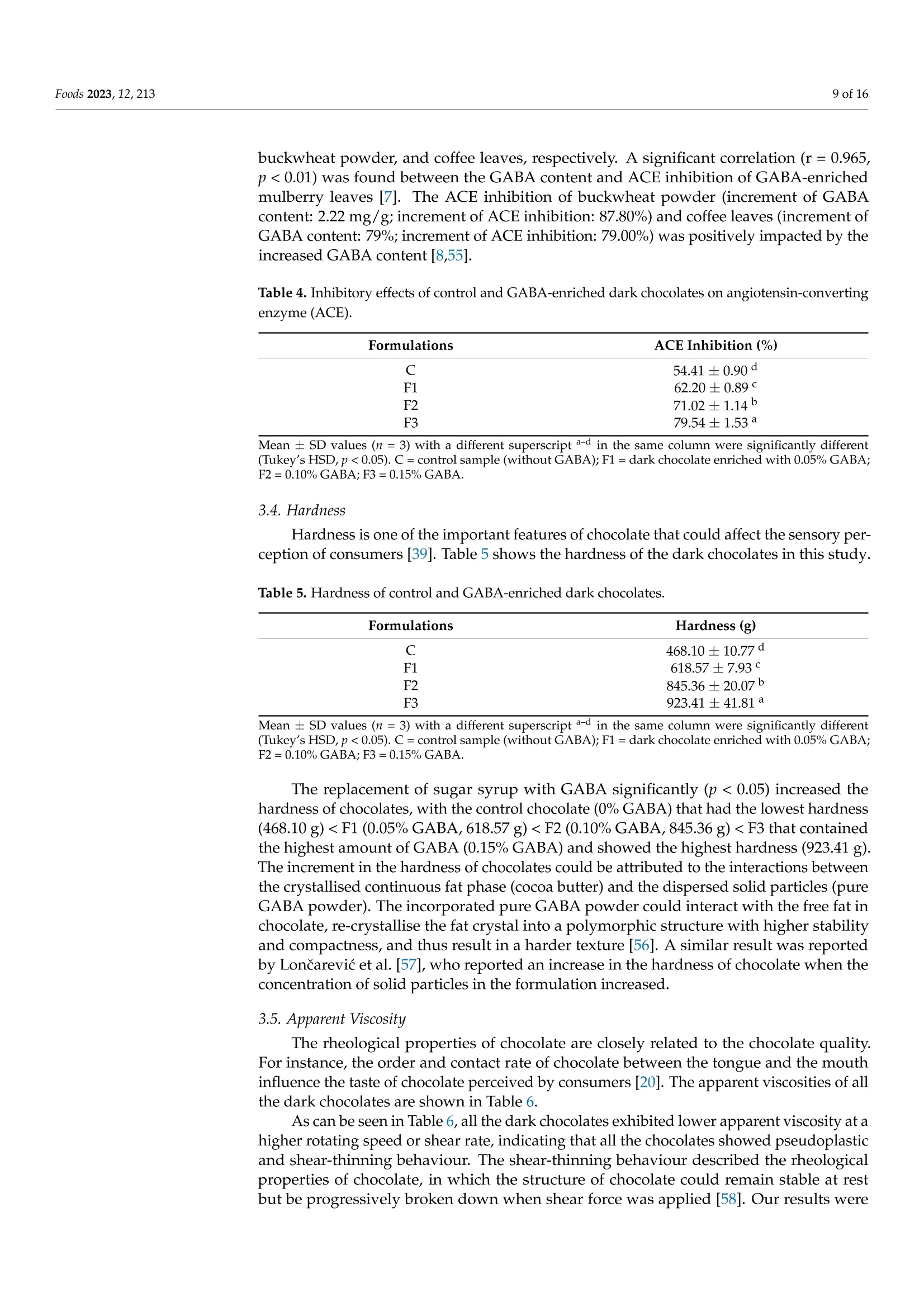

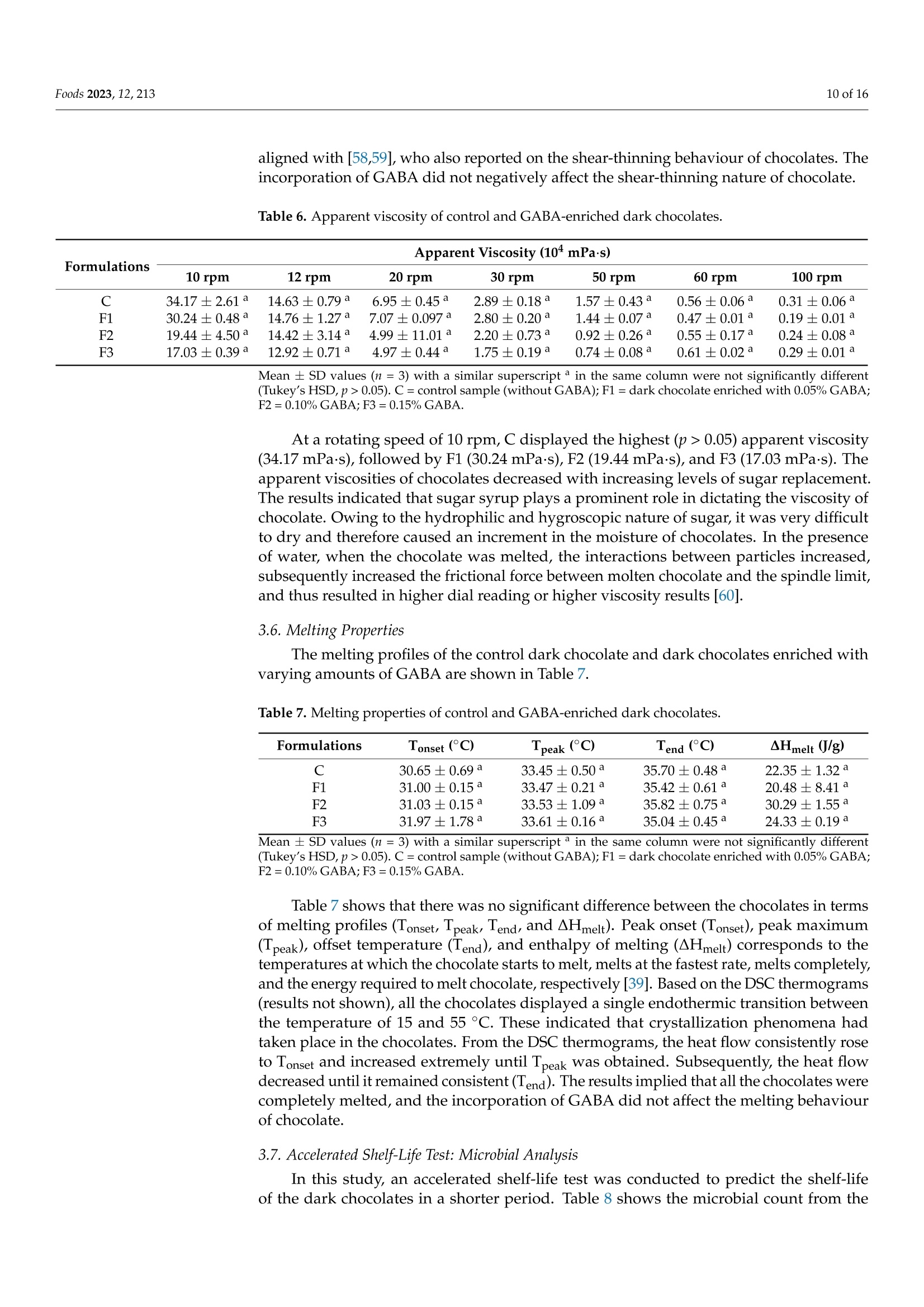

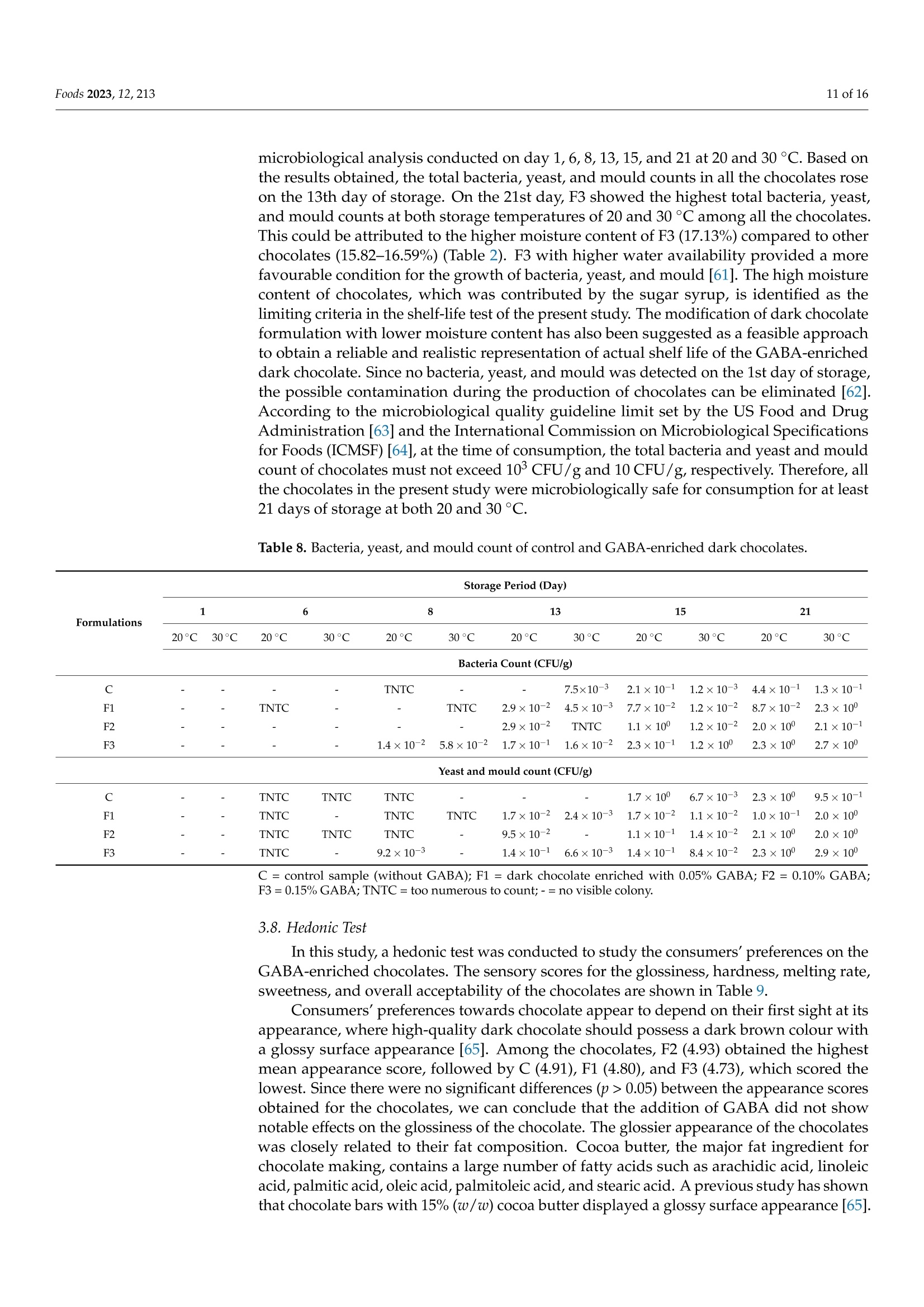

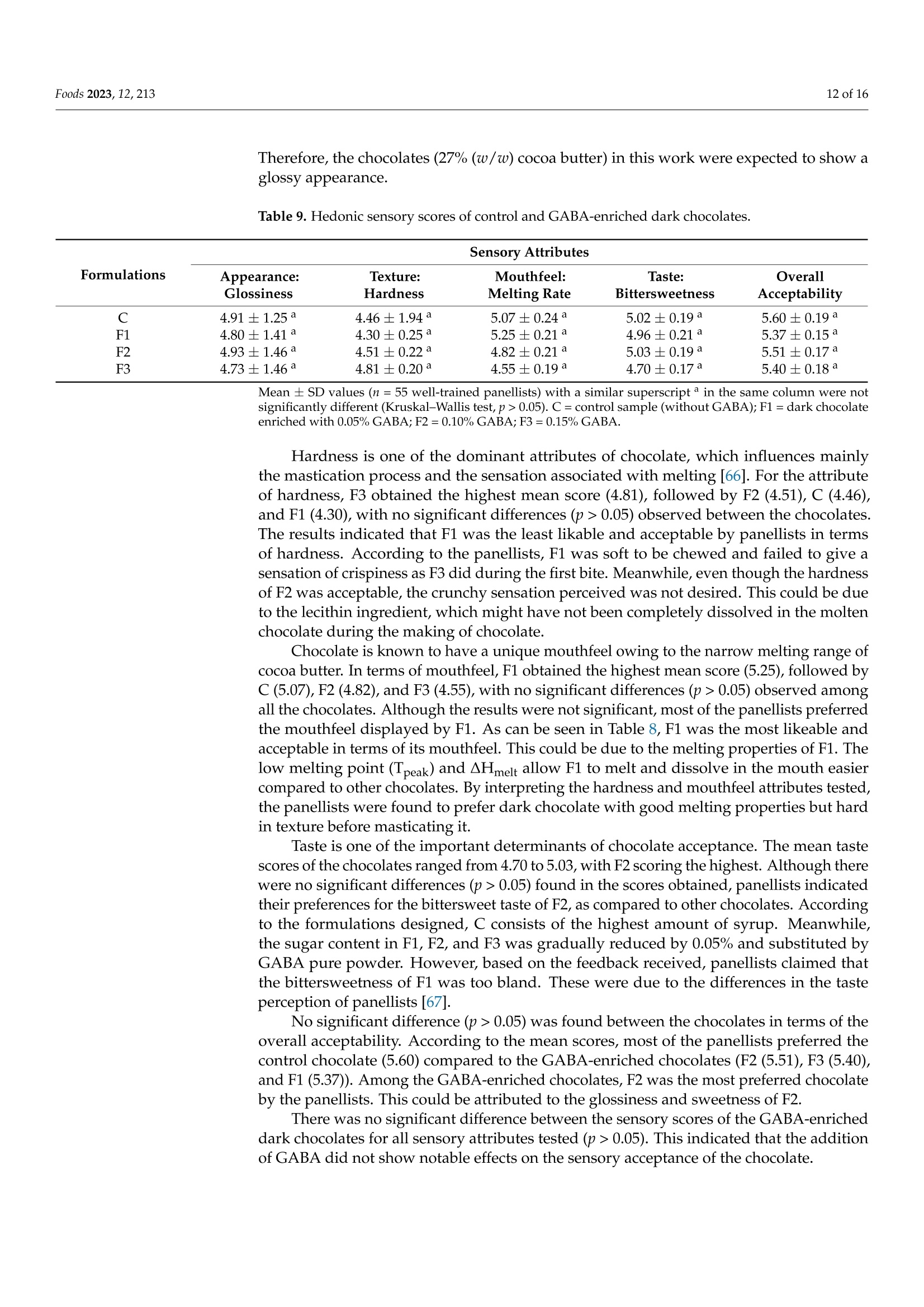

γ-氨基丁酸(GABA)富集对黑巧克力营养,物理,保质期和感官特性的影响The Effects of Gamma-Aminobuytric Acid (GABA) Enrichment on Nutritional, Physical, Shelf-Life, and Sensorial Properties of Dark ChocolateOlfoodsMDPI Foods 2023, 12,2132 of 16 Citation: Koh, W.Y.; Lim, X.X.; Teoh,E.S.W.; Kobun, R.; Rasti, B. TheEffects of Gamma-AminobuytricAcid (GABA) Enrichment onNutritional, Physical, Shelf-Life, andSensorial Properties of DarkChocolate. Foods 2023, 12,213https://doi.org/10.3390/ foods12010213 Academic Editors: Arshad Mehmood Abbasi, Xinbo Guo and Yongsheng Chen Received: 9 November 2022 Revised: 28 December 2022 Accepted: 29 December 2022 Published: 3 January 2023 Copyright: @ 2023 by the authors.Licensee MDPI, Basel, Switzerland.This article is an open access articledistributed under the terms andconditions of the Creative CommonsAttribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/) The Effects of Gamma-Aminobuytric Acid (GABA) Enrichmenton Nutritional, Physical, Shelf-Life, and Sensorial Properties ofDark Chocolate Wee Yin Koh 1*D, Xiao Xian Lim ²D, Eva Sheue Wen Teoh 1D, Rovina Kobun 11 ipDand Babak Rasti’ 1 Faculty of Food Science and Nutrition, Universiti Malaysia Sabah, Kota Kinabalu 88400, Sabah, Malaysia2 Food Technology Division, School of Industrial Technology, Universiti Sains Malaysia,Minden 11800, Pulau Pinang, Malaysia3 Australasian Nanoscience and Nanotechnology Initiative, 8054 Monash University LPO,Clayton, VIC 3168, Australia Correspondence: weeyin@ums.edu.my Abstract: Hypertension is the leading cause of cardiovascular disease and premature death world-wide. Gamma-aminobutyric acid (GABA) has potential in regulating hypertension. Cocoa beans arerich in GABA, but GABA is being destroyed during roasting of cocoa beans and chocolate production.This study aimed to develop GABA-enriched dark chocolate by partially replacing sugar syrupwith pure GABA powder at concentrations of 0.05 (F1), 0.10 (F2), and 0.15% (F3). The chocolatesamples were incorporated with GABA after the heating and melting process of cocoa butter tomaintain the viability and functionality of the GABA in the final product. The effects of GABAenrichment on the quality of chocolate in terms of nutritional, physical, shelf-life, and sensorialproperties were studied. The inclusion of 0.15% GABA significantly increased the GABA content andangiotensin-converting-enzyme (ACE) inhibitory effect of chocolate. The nutritional compositions ofthe control and GABA-enriched chocolates were almost similar. The addition of GABA significantlyincreased the hardness but did not affect the apparent viscosity and melting properties of chocolate.Accelerated shelf-life test results showed that all the chocolates stored at 20 and 30°C were microbio-logically safe for consumption for at least 21 days. Among the GABA-enriched chocolates, panellistspreferred F2 the most followed by F3 and F1, owing to the glossiness and sweetness of F2. F3 withthe highest GABA content (21.09 mg/100 g) and ACE inhibitory effect (79.54%) was identified as thebest GABA-enriched dark chocolate. Keywords: amino acid; functional food; chocolate; gamma-aminobutyric acid; enrichment 1. Introduction The World Health Organization defines hypertension as the chronic elevation ofarterial blood pressure with the systolic blood pressure equal to or above 140 mm Hgand/or diastolic blood pressure equal to or above 90 mm Hg [1]. Hypertension is a leadingcause of death globally as it is a major risk factor for stroke, cardiovascular disease, andkidney failure [2,3]. Based on the latest World Hypertension Report [4],approximately1.13 billion people worldwide suffered from hypertension in 2019 and it is estimated toincrease to 1.56 billion by 2025 [5]. The renin-angiotensin-aldosterone system is one of the main humoral regulators of thecardiovascular system that plays a significant role in regulating blood pressure. In the renin-angiotensin-aldosterone system, renin stimulates the generation of angiotensin I, which isconverted to angiotensin II by zinc-dependent dicarboxypeptidase, namely angiotensin-converting enzyme (ACE), to regulate the electrolyte balance in humans. However, an-giotensin II tends to narrow the blood vessels and secrete aldosterone, thus resulting in anincreased blood pressure [6,7]. Several studies have reported that gamma-aminobutyric acid (GABA) could inhibit ACE through the blockade of angiotensin II formation and ispromising in decreasing blood pressure [7,8]. Gamma-aminobutyric acid (GABA) is a non-proteinogenic amino acid with potentbioactive functions that occurs naturally in animals, plants, and microorganisms. GABA issynthesised in presynaptic neuron through the action of glutamic acid decarboxylase inthe presence of glutamate as a precursor [9,10]. In the human central nervous system, asthe principal inhibitory neurotransmitter, GABA plays a significant role in the regulationof brain metabolism and has shown physiological functions such as anti-hypertensive,anti-depressant, anti-oxidative, hypotensive, and insomnia-curing effects [7,11,12]. How-ever, the ability of the human brain to synthesise GABA is gradually decreased withincreasing age [13]. Several human studies have shown that orally administered GABA(10-20 mg/day) could decrease the blood pressure of hypertensive patients [14-16]. Som-nipathy and depression of patients have been shown to improve through a daily intake of26.4 mg GABA [17]. GABA can be found naturally in cocoa beans [12]. Cocoa beans are the seeds retrieved from the mature fruits of the cocoa tree knownbotanically as Theobroma cacao L. Cocoa beans are known to contain GABA naturally.Based on the study conducted by Ramos-Ruiz et al. [12], GABA content in cocoa beansoriginating from Africa was 35 to 93.9 mg/100 g, America 31.7 to 101.2 mg/100 g, Asia47 to 95 mg/100 g, and Oceania 45 to 68 mg/100 g. Cocoa beans are the basic raw materialfor chocolate production. Chocolate is one of the most consumed and desired confectioneryproducts across the world (2022: revenue generated from the chocolate confectionerymarket reached USD 1.03 trillion worldwide and is expected to increase to USD 1.12 trillionin 2027 [18]) owing to its pleasant sensory properties. Chocolate is a semi-solid suspensionof fine solid particles (cocoa powder) dispersed in a continuous fat phase (cocoa butter) [19].Chocolate can be classified into plain chocolate (dark chocolate), milk chocolate, and whitechocolate, depending on its composition [20]. For instance, dark chocolate contains at least35% of cocoa solids in total, including not less than 18% cocoa butter and 14% non-fat cocoasolids, respectively [21]. Dark chocolate, with a relatively higher cocoa content, is generally considered a goodsource of GABA and its consumption has been linked to a number of health benefits,including mitigation of cardiovascular disease [22], reduction of blood pressure, andimprovement in cognitive health [23]. However, GABA content in dark chocolate was foundto be lower than that in cocoa beans. The manufacturing of chocolate has been reported tocause the loss of GABA, such as during the fermentation of cocoa beans [24] and throughthe Maillard reaction during the roasting of cocoa beans [25,26]. Dark chocolate alsocontains other active compounds that could cause side effects. For instance,theobrominecould cause headaches [27]; caffeine could cause sleep and cardiovascular problems [28];methylxanthines could increase the risk of atrial fibrillation [29]; and histamine couldcontribute to migraines, heart problems, immunological sensitivity, and inflammation-like stimuli [25]. Therefore, GABA content in dark chocolate should be increased toexert beneficial health effects on consumers. Enrichment is one of the effective ways tocompensate for the loss of GABA. GABA-enriched foods have attracted considerable attention in the field of food andmedicine as GABA concentration in natural animal and plant food products is too lowto deliver potential health benefits to consumers. Numerous studies have examined theeffects of GABA-enriched foods on hypertension in humans and experimental animals. Theingestion of GABA-enriched fermented milk (10-12 mg GABA/100 mL/day) over 12 weekshas resulted in a significant decrease in systolic blood pressure (reduced by 17.4 mm Hg)and diastolic blood pressure of 39 patients with mild hypertension (reduced by 7.2 mmHg) [30]. Nishimura et al. [31] found that the 8-week consumption of GABA-enriched rice(150 g GABA-enriched rice/day or 16.8 mg GABA/day) has improved the blood pressureof mildly hypertensive adults. The systolic blood pressure of spontaneously hypertensiverats has been reduced from 189 mm Hg to 150 mm Hg after being fed with GABA-enrichedfermented savoury rice cake (1 mg GABA/rat/day) for 10 weeks [32]. Kawakami et al. [33] also found that the ingestion of GABA-enriched brown rice (1 mg GABA/kg) for 12 weeksinhibited the elevation of blood pressure in rats. To the best of our knowledge, no studieshave been carried out on GABA enrichment in dark chocolate. Dark chocolates could be used as a promising carrier to deliver GABA because oftheir high acceptability by consumers. Dark chocolates are always perceived as healthiercompared to other types of chocolates as they are higher in polyphenols, flavonoids,andantioxidant contents [23]. The lightweight and small size of chocolate also make themconvenient for consumers to consume [20]. Therefore, this research aimed to enrich theGABA content of dark chocolate by partially replacing the sugar syrup with pure GABApowder at concentrations of 0.05, 0.10, and 0.15%. The effects of GABA enrichment on thequality of dark chocolate in terms of nutritional, textural, rheological, melting, shelf-life,and sensorial properties were also studied. 2. Materials and Methods 2.1. Ingredients The cocoa powder, icing sugar, and lecithin were purchased at a local store in Kota Kina-balu, Malaysia. The cocoa butter was bought from Take It Global Sdn Bhd, Penang, Malaysia.GABA was acquired from NOW Foods, Bloomingdale, New York, NY, United States. 2.2. Preparation of Dark Chocolate The dark chocolate was produced following the formulations specified in Table 1.Firstly, cocoa butter was melted over low heat (40-51C) in a double boiling setup [34].After the cocoa butter was completely melted, sugar syrup (produced by dissolving twoparts of icing sugar into one part of water) and lecithin were added, and the mixturewas stirred well. Subsequently, cocoa powder and pure GABA powder were added, andthe chocolate mixture was whisked until smooth and lump-free texture was obtained.The molten chocolate was removed from the pot and gently stirred until the temperaturereduced to 38 °C. The molten chocolate was then transferred into a plastic mould andallowed to solidify at 16.5 °℃ in the refrigerator (NR-BL342PS, Panasonic, Tokyo,Japan).The dark chocolate was then wrapped with polyethylene terephthalate film with heat-sealed ends. Table 1. Formulation of the control and GABA-enriched dark chocolates. Formulations Ingredients (% w/w) Sugar Syrup Cocoa Powder Cocoa Butter GABA Lecithin C 45.00 27.50 27.00 0.00 0.50 F1 44.95 27.50 27.00 0.05 0.50 F2 44.90 27.50 27.00 0.10 0.50 F3 44.85 27.50 27.00 0.15 0.50 C = control sample (without GABA); F1 = dark chocolate enriched with 0.05% GABA; F2= 0.10% GABA;F3=0.15% GABA. 2.3. Proximate Composition The proximate composition of the dark chocolates was determined by using theprocedures established by the Association of Official Analytical Chemists [35]. The moisturecontent of chocolate was evaluated by oven drying 6 g of the sample at 105°C until constantweight (AOAC Method 925.40). Soxhlet method (petroleum ether as a solvent) was usedto determine the crude fat content of chocolate (AOAC Method 963.15). The ash contentof chocolate was obtained by the method of incineration in a muffle furnace (KLS 30/11,Thermconcept, Bremen, Germany) at 550 ℃(AOAC Method 924.05). The crude proteincontent was measured by estimating the nitrogen content in the chocolate using the Kjeldahlmethod (AOAC Method 970.22, nitrogen-to-protein conversion factor: 6.25). The crude fibrecontent of the chocolate was determined using an automated fibre analyser (FibrethermFT12, C. Gerhardt GmbH & Co., Konigswinter, Germany) (AOAC Method 962.09). The carbohydrate content was calculated by subtracting the total values of moisture, crudeprotein, fat, ash, and fibre of the sample from 100 (Equation (1)). The energy contentprovided by the chocolate was calculated by adding up the calories provided by the protein,carbohydrate, and fat (Equation (2)). Carbohydrate (%)=100 - (Moisture +Crude protein + Total fat + Ash + Total dietary fibre) (1) where 4 is the energy conversion factor for protein and carbohydrate, and 9 is the energyconversion factor for fat. 2.4. Quantification of GABA in Dark Chocolate Using HPLC The GABA content of the dark chocolates was measured according to the methodproposed by Dala-Paula et al. [25]. To extract GABA from the dark chocolate, the preparedchocolate (5g) was grounded and homogenised with trichloroacetic acid (TCA, 20 mL,6% w/v, R&M Chemicals, Selangor, Malaysia) for 3 min. After being subjected to centrifu-gation (7000× g, 10 min,4°C), the supernatant was filtered (Whatman, No. 2, Maidstone,UK) and the final volume of the filtrate was brought up to 25 mL with TCA. Both thestandard and extract (diluted filtrate) solutions were then subjected to the benzoylationprocess. The standard (50 pL) and extract solution (2 mL) were mixed with sodium hydrox-ide (NaOH, 2 mL, 2 M, R&M Chemicals, Selangor, Malaysia) followed by benzoyl chloride(10 uL, Sigma-Aldrich, St. Louis, MO, USA). After being kept at room temperature (25°C)for 20 min, the benzoylation processes of GABA were stopped by the addition of saturatedsodium chloride (NaCl, 2 mL, Merck, Frankfurt, Germany). Subsequently, diethyl ether(4 mL, R&M Chemicals, Selangor, Malaysia) was added and the solutions were subjected tocentrifugation (7000× g,10 min,4°C). The upper layer, post-centrifugation, was transferredto a universal bottle, dried under a laminar flow (Model AHC-4A1-ESCO, Changi, Singa-pore), and dissolved in methanol (500 pL, HPLC grade, JT Baker, Phillipsburg, NJ, UnitedStates) for semi-preparative high-performance liquid chromatography with diode arraydetection (Shimadzu LC-6AD instrument, Kyoto, Japan). Chromatographic separation wascarried out on a C18 analytical column (15.9 ×4.6 mm, Thermo Scientific Hypersil Gold,Shimazdu, Kyoto, Japan) maintained at 35 C and a gradient elution consisting of water(A) and methanol (B) (at 0.00-2.00,4.00,5.50,10.00,12.00, 15.50,15.51-19.00, and 19.01 min,with solvent A at 89, 83, 69, 67.5,53.5, 45,0, and 89%, respectively) with a flow rate of0.4 mL/min. The sample injection volume was 1 uL and the detection wavelength was setat 230 nm. The concentration of GABA in the dark chocolate was then quantified by fittingthe peak areas obtained into the linear regression equation of the GABA standard curveprepared from known concentrations of GABA. 2.5. Angiotensin-Converting-Enzyme (ACE) Inhibitory Activity The ACE inhibitory activity of the dark chocolates was determined using the method-ology proposed by Chen et al. [36]. HHL and ACE solution were prepared by dissolvingthe hippuryl-L-histidyl-L-leucine (HHL, Sigma-Aldrich, St. Louis, MO, USA) and rabbitlung acetone powder (HHL, Sigma-Aldrich, St. Louis, MO, USA) in borate suffered saline(100 mM sodium borate buffer (0.5 M, pH 8.5, Thermo Scientific, Calsbad, CA, USA),300 mM NaCl (Merck, Frankfurt, Germany),pH 8.3), respectively. Melted dark chocolate(50 uL) was pre-incubated in HHL solution (50 pL, 10 mM) at 37 °C for 2 min. Subsequently,ACE (50 uL, 0.010U/mL) solution was added, and the mixture was further incubated at37 °C for 30 min. After the reaction was terminated by heating the mixture in a water bathat 85°C for 10 min, the mixture (20 uL) was diluted with deionized water (150 uL). Theresulting mixture was then analysed by using a high-performance liquid chromatography(Shimadzu LC-6AD instrument, Kyoto, Japan) equipped with a C18 analytical column(15.9×4.6 mm, Thermo Scientific Hypersil Gold,Shimazdu, Kyoto,Japan). The temper-ature of the column was maintained at 30 °C. Elution was isocraticed with acetonitrile (≥99.9%, Sigma-Aldrich, St. Louis, MO, USA)/water (75:25, v/v) containing 0.1% TCA ata constant flow rate of 1.5 mL/min. The eluent was monitored at 228 nm and the ACEinhibitory activity was calculated using Equation (3) below: where C, S, and A are the chromatography peak area of borate suffered saline (control),tested sample, and ACE solution, respectively. 2.6. Textural Properties: Hardness The hardness values of the dark chocolates were determined by using the penetrationtest method proposed by McGill and Hartel [37], with slight modification. A textureanalyser (TA. XT Plus, Stable Micro Systems Ltd., Surrey, UK) equipped with a 500 N loadcell and needle geometry was used to measure the hardness values of the chocolates. Thehardness was reported as the maximum penetrating force (N) required for the needle topenetrate through the chocolate (35 mm ×6 mm, depth 15 mm) at 20 °C, over a distance of5 mm at a pre-test speed of 2 mm/s, test speed of 2 mm/s, and post-test speed of 10 mm/s. 2.7. Rheological Measurements: Apparent Viscosity The rheological properties of the dark chocolates were determined using the methodproposed by Cahyani et al. [38]. Before the analysis, chocolates (15 g) were placed in aplastic test tube and melted in a water bath (Memmert WB 14, Schwabach, Germany)at 40 °C. The viscosity of the molten chocolate was then measured by using a viscome-ter (DV-E, Brookfield, Middleborough, MA, USA) with spindle number 7 at a rotatingspeed of 10, 12, 20,30,50,60, and 100 rpm. The shear stress (t) and shear rate (y) of themolten chocolate were calculated from the viscometric data (dial reading) obtained usingthe Mitschka methodology (Equations (4)-(5)). The apparent viscosity (n) of the moltenchocolate was then obtained by dividing shear stress with shear rate (Equation (6)): where 8.4 is the conversion factor for spindle number 7, Kny is the shear rate consistencyobtained by matching the spindle number with the flow behaviour index value (n), and nis the linear slope in the plot of the ln t versus ln rpm. 2.8. Melting Properties The melting properties of the dark chocolates were studied using differential scanningcalorimetry (DSC 1, Mettler Toledo, Schwerzenbach, Switzerland) equipped with a datastation. The dark chocolate sample (5 mg) was loaded into a hermetically sealed aluminiumpan and heated from 15 to 55 °℃ (expected range for melting profile of chocolate) in anitrogen stream at 5°C/min, using an empty pan as reference [39]. The onset temperature(Tonset), end temperature (Tend), peak temperature (Tpeak), and melting enthalpy (AHmelt)were computed by the software. 2.9. Accelerated Shelf-Life Test: Microbial Analysis The accelerated shelf-life test of dark chocolates was designed based on [40]. Freshlyproduced chocolates were heat-sealed in polyethylene bags and kept in two differentincubators (Binder BD-53, Binder GmbH, Tuttlingen, Germany) maintained at 20 and 30°℃with a relative humidity level of 80% f1e1or 3 weeks. The microbial analysis was performedon the chocolates on days 1, 6, 8, 13, 15, and 21 of storage. Plate count agar (PCA, Merck,Frankfurt, Germany) and potato dextrose agar (PDA, Merck, Frankfurt, Germany) wereused to enumerate the total viable count and yeast and mould count,respectively. The dark chocolate sample (10 g) was crushed and homogenised with sterilized peptone water(90 mL, Merck, Frankfurt, Germany) using a stomacher (Interscience Bag Mixer, Saint Nom,France). Subsequently, the homogenised solution was subjected to a 10-fold serial dilutionwith sterilized peptone water (Merck, Frankfurt, Germany). An aliquot of appropriatedilution was then inoculated onto the PCA (Merck, Frankfurt, Germany) and PDA (Merck,Frankfurt, Germany) plates using the pour plate technique. After incubation (37°℃,48 h),the grown colonies were then counted, and the counts were reported as colony formingunits per gram of the chocolate sample (CFU/g). 2.10. Hedonic Test A hedonic test was performed to select the dark chocolate formulation with the mostacceptable sensory characteristics. A total of 55 well-trained panellists (18-60 years old,students and employees of the Faculty of Food Science and Nutrition, University MalaysiaSabah, Sabah, Malaysia) were recruited to evaluate the glossiness, hardness, melting rate,sweetness, and overall acceptability of the chocolate samples by using a 7-point hedonicscale (1= dislike extremely, 2 = dislike moderately, 3=dislike slightly, 4= neither like nordislike, 5 =like slightly, 6 = like moderately, and 7=like extremely). The chocolate samples(5 g) were served in transparent plastic containers coded with 3-digit random numbers.Mineral water was provided for panellists who were instructed to rinse their mouths beforeand between each evaluation. 2.11. Statistical Analysis All the analyses were performed in triplicate and the results from quantificationof GABA, ACE inhibitory activity, hardness, apparent viscosity, and melting propertiesobtained in this study were statistically analysed by one-way analysis of variance (ANOVA)with Tukey’s honestly significant difference (HSD) test for post-hoc comparisons using thesoftware IBM SPSS Statistics version 27 (IBM, Chicago, IL, USA). Kruskal-Wallis test wasused to analyse the results from the sensory test in the present study [41]. A probabilitylevel of < 0.05 was considered statistically significant in all comparisons. 3. Results and Discussion 3.1. Proximate Composition The nutritional content of the control and GABA-enriched dark chocolates is shown inTable 2. Table 2. Nutritional content of control and GABA-enriched dark chocolates. Formulations Nutritional Content(%) Moisture Protein Fat Fibre Ash Carbohydrate Calorie (kcal) C 15.89±0.06a 6.37±0.01℃ 29.48±0.77a 14.73±0.23a 2.24±0.06a 31.29±0.87a 415.97±3.48a F1 15.78±0.04ab 6.39±0.01bc 31.10±0.98a 14.70±0.16a 2.31±0.14a 29.73±0.76a 424.34±5.88a F2 15.61±0.07D 6.41±0.01ab 29.47±0.74a 14.77±0.9a 2.25±0.13a 31.49±0.86a 416.77±3.34a F3 15.34±0.10° 6.43±0.01a 30.80±1.05a 14.73±0.13a 2.32±0.09a 30.38±1.26a 424.47±5.32a Mean ± SD values (n =3) with a different superscript a- in the same column were significantly different(Tukey's HSD, p<0.05). C=control sample (without GABA); F1=dark chocolate enriched with 0.05% GABA;F2=0.10% GABA;F3=0.15%GABA. The moisture contents of all the dark chocolates are presented in Table 2. Darkchocolates enriched with 0.10% (F2) and 0.15% GABA (F3) had significant (p<0.05) lowermoisture contents than the control dark chocolate (without GABA enrichment,C). Amongthe GABA-enriched dark chocolates, the moisture content of F1 with 0.05% GABA was thehighest, followed by F2 and F3, which had the lowest moisture content. The decrementin the moisture contents could be attributed to the decrease of sugar syrup used in theformulation. Sucrose syrup was used as a sweetener in the preparation of dark chocolates.The monosaccharides presented in the sucrose syrup caused difficulties in the drying of chocolate and hence resulted in chocolate with higher moisture content [37]. A similarfinding was reported by [42], who also observed that the moisture content of chocolateincreased with the addition of sucrose syrup. As presented in Table 2, F3 had the highest protein content (6.43%), followed by F2(6.41%), F1 (6.39%), and C (6.37%). Although no significant differences (p > 0.05) wereobserved, the protein contents of the dark chocolates increased with the concentrationof GABA incorporated. The increment in the protein content could be attributed to thenon-protein nitrogen contributed by GABA. As the Kjeldahl method could not differentiateprotein nitrogen from non-protein nitrogen [43], the incorporation of GABA eventuallyincreased the total nitrogen content and consequently resulted in higher protein content. The dark chocolate with the highest fat content was F1 (31.10%), followed by F3(30.80%), C (29.48%), and F2 (29.47%), which had the lowest fat content. No significantdifferences were observed between the fat contents of the control (C) and GABA-enrichedchocolates (F1, F2, and F3). This result was expected as the amounts of cocoa butterused were similar in all the formulations. Cocoa butter is the key contributor to the fatcomposition of chocolate. The fat composition of conventional dark chocolates is normallybetween 30 and 40%[44]. The fibre content in all the dark chocolates (C, F1,F2, and F3) ranged between 14.70 and14.77%, with no significant differences observed. The results implied that the replacementof sugar syrup with GABA did not affect the fibre content of chocolates. The fibre contentin the chocolates was attributed to the presence of cocoa powder in the formulation. Fibreis a major constituent of cocoa powder [45]. According to the permitted nutrition claimlisted in the Annex of Regulation (EC) No 1924/2006 [46], a food product with at least6 g of fibre per 100 g can be claimed as "high in fibre". Therefore, all the dark chocolatesdeveloped in this work can be characterised as high-fibre food products. Ash content could reflect the total mineral content in the chocolate [47]. The ashcontents of all the dark chocolates were not significantly different from one another (Table 2).The incorporation of GABA did not affect the ash contents of the chocolates. The ashcontents of the chocolates were mainly contributed by the cocoa powder. Cocoa powderis rich in minerals such as sodium (Na), potassium (K), magnesium (Mg), calcium (Ca),phosphorus (P), iron (Fe), and zinc (Zn). A previous study reported that 100 g of cocoapowder consisted of 5.27-11.5 mg Na, 2.27-3.97 g K, 3.11-5.02 g Mg, 0.10-0.22 g Ca,0.41-0.51gP, 0.01-0.13 g Fe, and 3.77-7.03 mg Zn [48]. The carbohydrate content of the dark chocolates ranged from 29.73 (F1) to 31.49% (F2).No significant difference (p>0.05) was found between the carbohydrate content of the darkchocolates. The results indicated that the partial replacement of sugar syrup with GABAdid not change the carbohydrate content of the dark chocolates. The cocoa powder andsugar syrup were the major carbohydrates in the formulation [45]. The reduction in theconcentration of added sugar syrup (from 45 to 44.85%) was presumed to be too low toexert significant effects. As shown in Table 2, the calorie content of the dark chocolates developed in thisstudy ranged from 415.97 to 424.47 kcal, and there was no significant difference (p>0.05)among the chocolates with and without the enrichment of GABA. Dark chocolate has beenclassified as a high-calorie food owing to its high fat and sugar content. For instance, theUSDA Food Composition Database [49] stated that the calorie contents of dark chocolates(45-85% cocoa solids) ranged from 546 to 598 kcal/100 g. The calorie contents of the darkchocolates developed in this study (54.50% cocoa solids) were relatively lower. This couldbe attributed to the lower carbohydrate content of the chocolates developed. 3.2. GABA Content Table 3. GABA content of control and GABA-enriched dark chocolates. Formulations Concentration of GABA (mg/100g) C 8.23±0.14D F1 11.60±0.51D F2 16.96±2.11ab F3 21.09±4.99a Mean ± SD values (n =3) with a different superscript ab in the same column were significantly different(Tukey's HSD, p <0.05). C= control sample (without GABA); F1 = dark chocolate enriched with 0.05% GABA;F2=0.10%GABA;F3=0.15%GABA. The concentration of GABA in the dark chocolates was observed to increase grad-ually with the amount of GABA incorporated: C (GABA incorporated =0%; concentra-tion of GABA in chocolate =8.23 mg/100 g)0.05). C= control sample (without GABA); F1 = dark chocolate enriched with 0.05% GABA;F2=0.10%GABA;F3=0.15%GABA. At a rotating speed of 10 rpm, C displayed the highest (p >0.05) apparent viscosity(34.17 mPas), followed by F1 (30.24 mPas), F2 (19.44 mPas), and F3 (17.03 mPa.s). Theapparent viscosities of chocolates decreased with increasing levels of sugar replacement.The results indicated that sugar syrup plays a prominent role in dictating the viscosity ofchocolate. Owing to the hydrophilic and hygroscopic nature of sugar, it was very difficultto dry and therefore caused an increment in the moisture of chocolates. In the presenceof water, when the chocolate was melted, the interactions between particles increased,subsequently increased the frictional force between molten chocolate and the spindle limit,and thus resulted in higher dial reading or higher viscosity results [60]. 3.6. Melting Properties The melting profiles of the control dark chocolate and dark chocolates enriched withvarying amounts of GABA are shown in Table 7. Table 7. Melting properties of control and GABA-enriched dark chocolates. Formulations Tonset (C) Tpeak (C) Tend (C) AHmelt (J/g) C 30.65±0.69a 33.45±0.50a 35.70±0.48a 22.35±1.32a F1 31.00±0.15a 33.47±0.21a 35.42±0.61a 20.48±8.41a F2 31.03±0.15a 33.53±1.09a 35.82±0.75a 30.29±1.55a F3 31.97±1.78a 33.61±0.16a 35.04±0.45a 24.33±0.19a Mean ± SD values (n =3) with a similar superscript in the same column were not significantly different(Tukey's HSD,p>0.05). C= control sample (without GABA); F1 = dark chocolate enriched with 0.05% GABA;F2=0.10% GABA; F3=0.15%GABA. Table 7 shows that there was no significant difference between the chocolates in termsof melting profiles (Tonsets Tpeak Tend and AHmelt). Peak onset (Tonset), peak maximum(Tpeak), offset temperature (Tend), and enthalpy of melting (AHmelt) corresponds to thetemperatures at which the chocolate starts to melt, melts at the fastest rate, melts completely,and the energy required to melt chocolate, respectively [39]. Based on the DSC thermograms(results not shown), all the chocolates displayed a single endothermic transition betweenthe temperature of 15 and 55°C. These indicated that crystallization phenomena hadtaken place in the chocolates. From the DSC thermograms, the heat flow consistently roseto Tonset and increased extremely until Tpeak was obtained. Subsequently, the heat flowdecreased until it remained consistent (Tend). The results implied that all the chocolates werecompletely melted, and the incorporation of GABA did not affect the melting behaviourof chocolate. 3.7. Accelerated Shelf-Life Test: Microbial Analysis In this study, an accelerated shelf-life test was conducted to predict the shelf-lifeof the dark chocolates in a shorter period. Table 8 shows the microbial count from the Table 8. Bacteria, yeast, and mould count of control and GABA-enriched dark chocolates. Formulations Storage Period (Day) 1 6 8 13 15 21 20°C 30°C 20°C 30°C 20°C 30°C 20°C 30°C 20°C 30°C 20°C 30°C Bacteria Count (CFU/g) C 一 一 一 TNTC 一 一 7.5×10- 2.1×10厂1 1.2×10-3 4.4×10-1 1.3×10厂1 F1 一 TNTC 一 TNTC 2.9×10-2 4.5×10厂3 7.7×10-- 1.2×10-2 8.7×10-2 2.3×10° F2 一 一 一 - 一 2.9×10-2 TNTC 1.1×10 1.2×10-2 2.0×10 2.1×10厂1 F3 一 一 1.4×10一2 5.8×10-2 1.7×10-1 1.6×10-2 2.3×10二1 1.2×10% 2.3×10 2.7×10 Yeast and mould count (CFU/g) C 一 一 TNTC TNTC TNTC 一 一 - 1.7×10° 6.7×10-3 2.3×10° 9.5×10-1 F1 一 TNTC TNTC TNTC 1.7×10-2 2.4×10厂3 1.7×10-2 1.1×10-2 1.0×10-1 2.0×10° F2 TNTC TNTC TNTC 9.5×10-2 1.1x10-1 1.4×10-2 2.1×10 2.0×10 F3 一 TNTC - 9.2×10厂3 一 1.4×10一1 6.6×10-3 1.4×10厂1 8.4×10-2 2.3×10 2.9×10 C = control sample (without GABA); F1= dark chocolate enriched with 0.05% GABA; F2=0.10% GABA;F3=0.15%GABA;TNTC= too numerous to count;-= no visible colony. 3.8. Hedonic Test In this study, a hedonic test was conducted to study the consumers' preferences on theGABA-enriched chocolates. The sensory scores for the glossiness, hardness, melting rate,sweetness, and overall acceptability of the chocolates are shown in Table 9. Consumers' preferences towards chocolate appear to depend on their first sight at itsappearance, where high-quality dark chocolate should possess a dark brown colour witha glossy surface appearance [65]. Among the chocolates, F2 (4.93) obtained the highestmean appearance score, followed by C (4.91), F1 (4.80), and F3 (4.73), which scored thelowest. Since there were no significant differences (p >0.05) between the appearance scoresobtained for the chocolates, we can conclude that the addition of GABA did not shownotable effects on the glossiness of the chocolate. The glossier appearance of the chocolateswas closely related to their fat composition. Cocoa butter, the major fat ingredient forchocolate making, contains a large number of fatty acids such as arachidic acid, linoleicacid, palmitic acid, oleic acid, palmitoleic acid, and stearic acid. A previous study has shownthat chocolate bars with 15%(w/w) cocoa butter displayed a glossy surface appearance [65]. Therefore, the chocolates (27%(w/w) cocoa butter) in this work were expected to show aglossy appearance. Table 9. Hedonic sensory scores of control and GABA-enriched dark chocolates. Formulations Sensory Attributes Appearance: Glossiness Texture: Hardness Mouthfeel: Melting Rate Taste: Bittersweetness Overall Acceptability C 4.91±1.25a 4.46±1.94a 5.07±0.24a 5.02±0.19a 5.60±0.19a F1 4.80±1.41a 4.30±0.25a 5.25±0.21a 4.96±0.21a 5.37±0.15a F2 4.93±1.46a 4.51±0.22a 4.82±0.21a 5.03±0.19a 5.51±0.17a F3 4.73±1.46a 4.81±0.20a 4.55±0.19a 4.70±0.17a 5.40±0.18a Mean ± SD values (n =55 well-trained panellists) with a similar superscript in the same column were notsignificantly different (Kruskal-Wallis test, p> 0.05). C= control sample (without GABA); F1 = dark chocolateenriched with 0.05% GABA; F2=0.10% GABA;F3=0.15%GABA. Hardness is one of the dominant attributes of chocolate, which influences mainlythe mastication process and the sensation associated with melting [66]. For the attributeof hardness, F3 obtained the highest mean score (4.81), followed by F2 (4.51), C (4.46),and F1 (4.30), with no significant differences (p > 0.05) observed between the chocolates.The results indicated that F1 was the least likable and acceptable by panellists in termsof hardness. According to the panellists, F1 was soft to be chewed and failed to give asensation of crispiness as F3 did during the first bite. Meanwhile, even though the hardnessof F2 was acceptable, the crunchy sensation perceived was not desired. This could be dueto the lecithin ingredient, which might have not been completely dissolved in the moltenchocolate during the making of chocolate. Chocolate is known to have a unique mouthfeel owing to the narrow melting range ofcocoa butter. In terms of mouthfeel, F1 obtained the highest mean score (5.25), followed byC (5.07), F2 (4.82), and F3 (4.55), with no significant differences (p >0.05) observed amongall the chocolates. Although the results were not significant, most of the panellists preferredthe mouthfeel displayed by F1. As can be seen in Table 8, F1 was the most likeable andacceptable in terms of its mouthfeel. This could be due to the melting properties of F1. Thelow melting point (Tpeak) and AHmelt allow F1 to melt and dissolve in the mouth easiercompared to other chocolates. By interpreting the hardness and mouthfeel attributes tested,the panellists were found to prefer dark chocolate with good melting properties but hardin texture before masticating it. Taste is one of the important determinants of chocolate acceptance. The mean tastescores of the chocolates ranged from 4.70 to 5.03, with F2 scoring the highest. Although therewere no significant differences (p >0.05) found in the scores obtained, panellists indicatedtheir preferences for the bittersweet taste of F2, as compared to other chocolates. Accordingto the formulations designed, C consists of the highest amount of syrup. Meanwhile,the sugar content in F1, F2, and F3 was gradually reduced by 0.05% and substituted byGABA pure powder. However, based on the feedback received, panellists claimed thatthe bittersweetness of F1 was too bland. These were due to the differences in the tasteperception of panellists [67]. No significant difference (p > 0.05) was found between the chocolates in terms of theoverall acceptability. According to the mean scores, most of the panellists preferred thecontrol chocolate (5.60) compared to the GABA-enriched chocolates (F2 (5.51), F3 (5.40),and F1 (5.37)). Among the GABA-enriched chocolates, F2 was the most preferred chocolateby the panellists. This could be attributed to the glossiness and sweetness of F2. There was no significant difference between the sensory scores of the GABA-enricheddark chocolates for all sensory attributes tested (p>0.05). This indicated that the additionof GABA did not show notable effects on the sensory acceptance of the chocolate. 4. Conclusions The present work demonstrated the enrichment of dark chocolate with pure GABApowder at concentrations of 0.05, 0.10, and 0.15%. The incorporation of GABA did notshow any significant effects on the rheological, melting, shelf-life, and sensorial propertiesbut caused an increment in the moisture, protein content, and hardness of dark chocolate.The GABA content and ACE inhibitory activity of the dark chocolate were significantlyenhanced with the incorporation of 0.15% GABA. Overall, F3 is the best GABA-enricheddark chocolate in this study, owing to its highest GABA content (21.09 mg/100 g) andACE inhibitory effect (79.54%). The chocolate production process significantly reducesthe content of GABA and the only way to tackle this issue is by enriching the productwith 0.15% of GABA after the double boiling process of cocoa butter to achieve 2.5 timeshigher amount of GABA as compared to the control. Therefore, 0.15% of GABA enrichmentin chocolate product after the cocoa butter melting step was deemed to be an effectivemethod to compensate the loss of GABA throughout the chocolate production. GABAenrichment could improve the blood pressure regulating effect of dark chocolate. From theeconomic point of view, the formulated and value-added GABA-enriched dark chocolatecould diversify the functional food market. Author Contributions: Project administration, resources, funding acquisition, supervision, investi-gation, methodology, and visualization, W.Y.K.; data curation, writing-original draft, and formalanalysis, X.X.L. and E.S.W.T.; writing-review and editing, W.Y.K., X.X.L., E.S.W.T., R.K. and B.R. Allauthors have read and agreed to the published version of the manuscript. Funding: This research was supported by SPLB grant (SLB2228) provided by Universiti MalaysiaSabah (UMS), Malaysia. Institutional Review Board Statement: Not applicable Informed Consent Statement: All sensory panelists were informed of the procedure and consentwas taken from the sensory panelists for their participation before the start of the sensory test. Data Availability Statement: Data is contained within the article. Conflicts of Interest: The authors declare no conflict of interest. References 1. World Health Organization. A Global Brief on Hypertension. 2013. Available online: https://www.WHO/DCO/WHD/2013.2(accessed on 28 October 2022). 2 Tablado, M.; Angel, M. Accuracy in the diagnosis of hypertension and CKD is key to determine their possible association.Endocrine 2022,78,642-643.[CrossRef] [PubMed] 6. Phan, T.T.V.; Heo, S.-Y.; Jung, W.-K.; Yi, M. Spontaneous hinge-bending motions of angiotensin i converting enzyme: Role inactivation and inhibition. Molecules 2020, 25, 1288. [CrossRef] [PubMed] 7. Tu, J.; Liu, G.; Jin, Y.; Tang, C.; Yao, T.; Zhuo,J.;Li, Q.; Liu, L.; Wang,J. Enrichment of y-aminobutyric acid in mulberry leaves andthe inhibitory effects of the water extract on ACE and o-glucosidase activity. Ind. Crops Prod. 2022,177,114485.[CrossRef] 8. Guiyun, C.; Yushan, W.; Mingyue, Z.; Wanxing, M.; Xixian, X.; Ye, C. Cold atmospheric plasma treatment improves the y-aminobutyric acid content of buckwheat seeds providing a new anti-hypertensive functional ingredient. Food Chem. 2022,388,133064. [CrossRef] [PubMed] 9. Chen, C.; Zhou, X.; He,J; Xie, Z.;Xia, S.; Lu, G. The roles of GABA in ischemia-reperfusion injury in the central nervous systemand peripheral organs. Oxid. Med. Cell. Longev. 2019,2019,1-19. [CrossRef] 10. Murala, S.; Yelam, A.; Ismail, M.M.; Bollu, P.C. History of GABA. In Neurochemistry in Clinical Practice; Springer:Berlin/Heidelberg, Germany, 2022;pp. 73-89. 11. Luo, H.; Liu, Z.; Xie, F; Bilal, M.; Liu, L.; Yang, R.; Wang, Z. Microbial production of gamma-aminobutyric acid: Applications,state-of-the-art achievements, and future perspectives. Crit. Rev. Biotechnol. 2021,41,491-512. [CrossRef] 12. Ramos-Ruiz, R.; Poirot, E.; Flores-Mosquera, M. GABA, a non-protein amino acid ubiquitous in food matrices. Cogent Food Agric.2018,4,1534323.[CrossRef] 13. Marenco, S.; Meyer, C.; van der Veen, J.W.;Zhang, Y.; Kelly, R.; Shen,J; Weinberger, D.R.; Dickinson, D.; Berman, K.F. Role ofgamma-amino-butyric acid in the dorsal anterior cingulate in age-associated changes in cognition. Neuropsychopharmacology 2018,43,2285-2291.[CrossRef] [PubMed] 14. Galli, V.; Venturi, M.; Mari, E.; Guerrini, S.; Granchi, L. Gamma-aminobutyric acid (GABA) production in fermented milk bylactic acid bacteria isolated from spontaneous raw milk fermentation. Int. Dairy J. 2022, 127,105284. [CrossRef] 15. Sahab,N.R.; Subroto, E.; Balia, R.L.; Utama, G.L. y-Aminobutyric acid found in fermented foods and beverages: Current trends.Heliyon 2020, 6, e05526. [CrossRef] [PubMed] 16. Pandey, P.; Mishra, H.N. Co-microencapsulation of y-aminobutyric acid (GABA) and probiotic bacteria in thermostable andbiocompatible exopolysaccharides matrix. LWT 2021, 136,110293. [CrossRef] 17. Pu, Y.; Sinclair, A.J; Zhong, J.; Liu, D.; Song, L. Determination of Y-aminobutyric acid (GABA) in jujube fruit (Ziziphus jujubaMill.). CyTA 2019,17,158-162.[CrossRef] 18. Statista. Size of the chocolate confectionery market worldwide from 2016 to 2027. Available online: https://www.statista.com/forecasts/983554/global-chocolate-confectionery-market-size (accessed on 28 October 2022). 19. Fibrianto, K.; Azhar, L.O.M.F; Widyotomo, S.; Harijono, H. Effect of cocoa bean origin and conching time on the physicochemical and microstructural properties of Indonesian dark chocolate. Braz. J. Food Technol. 2021,24, e2019249.[CrossRef]20. Faccinetto-Beltran, P.; Gomez-Fernandez, A.R.; Santacruz, A.; Jacobo-Velazquez,D.A. Chocolate as Carrier to Deliver Bioactive Ingredients: Current Advances and Future Perspectives. Foods 2021,10,2065. [CrossRef] 21. Codex Alimentarius, FAO/WHO. Standard for Chocolate and Chocolate Products; CODEX STAN 87-1981; Codex AlimentariusCommission: Rome, Italy, 2003. 22. Fanton,S.; Cardozo, L.F; Combet, E.; Shiels, P.G.; Stenvinkel, P.; Vieira, I.O.;Narciso, H.R.; Schmitz, J.; Mafra, D. The sweet sideof dark chocolate for chronic kidney disease patients. Clin. Nutr. 2021, 40, 15-26. [CrossRef] 23 Patel, N.; Jayswal, S.; Maitreya, B.B. Dark Chocolate: Consumption for human health. J. Pharmacogn. Phytochem. 2019, 8,2887-2890. 24. Hue, C.; Gunata, Z.; Breysse, A.; Davrieux, F; Boulanger, R.; Sauvage,F.-X. Impact of fermentation on nitrogenous compounds ofcocoa beans (Theobroma cacao L.) from various origins. Food Chem. 2016, 192,958-964. [CrossRef] 25. Dala-Paula,B.M.; Deus, V.L.; Tavano, O.L.; Gloria, M.B.A. In vitro bioaccessibility of amino acids and bioactive amines in 70%cocoa dark chocolate: What you eat and what you get. Food Chem. 2021, 343, 128397.[CrossRef] [PubMed] 26. Le, P.H.; Le, T.T.; Raes, K. Effects of pH and heat treatment on the stability of y-aminobutyric acid (GABA) in germinated soymilk.J. Food Process. Presero. 2020, 44,e14301.[CrossRef] 27. Ward, J. From South America to Willy Wonka-a brief outline of the production and composition of chocolate. Chem. N. Z. 2018,82,71-73. 28. Chandio, Z.A.; Sidiqua, A.; Khaskheli, M.I.; Waghani, A.; Metlo, W.A. Review effect of caffeine overdose. RADS J. Biol. Res. Appl.Sci. 2020, 11,154-158.CrossRef 29. Gammone, M.A.; D'Orazio, N. Cocoa overconsumption and cardiac rhythm: Potential arrhythmogenic trigger or beneficialpleasure? Curr. Res. Nutr. Food Sci. 2021, 9,40-51. [CrossRef] 30. Inoue,K.; Shirai, T.; Ochiai,H.; Kasao,M.; Hayakawa, K.;Kimura, M.;Sansawa, H. Blood-pressure-lowering effect of a novelfermented milk containing gamma-aminobutyric acid (GABA) in mild hypertensives. Eur. J. Clin. Nutr. 2003, 57, 490-495.[CrossRef][PubMed] 33. Kawakami, K.; Yamada, K.; Yamada, T.;Nabika, T.; Nomura, M. Antihypertensive effect of y-aminobutyric acid-enriched brownrice on spontaneously hypertensive rats. J. Nutr. Sci. Vitaminol. 2018, 64,56-62. [CrossRef] 34. Ibrahim, S.F.; Dalek, N.E.M.; Raffie, Q.F.M.; Ain, M.F. Quantification of physicochemical and microstructure properties of darkchocolate incorporated with palm sugar and dates as alternative sweetener. Mater. Today Proc. 2020, 31, 366-371. [CrossRef AOAC. Official Methods of Analysis, 17th ed.; The Association of Official Analytical C3hemists: Gaithersburg, MD, USA, 2000. Chen, Y.; Liu, W.; Xue, J; Yang, J.; Chen, X.; Shao, Y.; Kwok, L.-y; Bilige, M.; Mang, L.; Zhang, H. Angiotensin-convertingenzyme inhibitory activity of Lactobacillus helveticus strains from traditional fermented dairy foods and antihypertensive effect offermented milk of strain H9. J. Dairy Sci. 2014,97,6680-6692. [CrossRef] [PubMed] 37. McGill, J.; Hartel, R.W. Water relations in confections. In Water Activity in Foods: Fundamentals and Applications; Wiley:New York, NY, USA, 2020; pp. 483-500. 38. Cahyani, A.; Kurniasari,J.; Nafingah, R.; Rahayoe, S.; Harmayani, E.; Saputro, A.D. Determining casson yield value, cassonviscosity and thixotropy of molten chocolate using viscometer. IOP Conf. Ser. Earth Environ. Sci. 2019,355,012041. [CrossRef] 39. Goktas, H.; Konar, N.; Sagdic, O.; Toker, O.S. Investigation effects of inulin degree of polymerization on compound chocolatequality. J. Food Process. Presero. 2021,45,e15766.[CrossRef] 40. Phimolsiripol, Y.; Suppakul, P. Techniques in shelf-life evaluation of food products. In Reference Module in Food Science; Elsevier:Amsterdam, The Netherlands, 2016;pp. 1-8. 41. Ramdany, R.; Rachmawati, Y.; Supu, L.; Mallongi, A. The effect of substitution of purple sweet potato flour and tempeh onorganoleptic quality of MP-ASI biscuit. Syst. Rev. Pharm. 2020, 11, 957-961. 42. Pero, M.; Borhani, B.; Parvian, S.K.; Rashidi, R.; Jafari Asl, M. Substitution of sucrose with HFCS-55 in the formulation of chocolatesyrup: Effects on the physicochemical and sensorial properties. J. Food Process. Presero. 2022,46,e16422.[CrossRef] 43. Kuswari, M.; Gifari, N.; Nuzrina, R.; Justickarin, S.; Fathiya, A.; Hutasuhut, F. Analysis of protein content on commercial proteinsupplement in Indonesia. JUARA J. Olahraga 2021,6,207-212.[CrossRef] 44. Joseph, C.; Batra, R.; Selvasekaran, P.; Chidambaram, R. Low calorie cocoa-based products: A short review. JFST 2021, 59,2931-2939.[CrossRef 45. Kim, S.M.; Woo, J.H.; Kim, H.W.; Park, H.J. Formulation and evaluation of cold-extruded chocolate ganache for three-dimensionalfood printing. J. Food Eng. 2022, 314,110785. [CrossRef] 46. EC (European Commission). Commission Regulation (EC) No 1924/2006 of 20 December 2006 on Nutrition and Health ClaimsMade on Foods. Available online: http://data.europa.eu/eli/reg/2006/1924/oj (accessed on 28 October 2022). 47. Melo, C.W.B.d.; Bandeira, M.d.J.; Maciel, L.F.; Bispo, E.d.S.; Souza, C.O.d.; Soares, S.E. Chemical composition and fatty acidsprofile of chocolates produced with different cocoa (Theobroma cacao L.) cultivars. Food Sci.Technol. 2020, 40, 326-333.[CrossRef] 48. Kruszewski, B.; Obiedzinski, M.W. Multivariate analysis of essential elements in raw cocoa and processed chocolate massmaterials from three different manufacturers. LWT 2018,98,113-123. [CrossRef] 49. United States Department of Agriculture (USDA). Available online: https://fdc.nal.usda.gov/fdc-app.html#/?query=dark%20chocolate (accessed on 28 October 2022). 50. U.S. Code of Federal Regulations. Title 40, Parts 180. Available online: https://www.ecfr.gov/current/title-40/chapter-I/subchapter-E/part-180/subpart-D/section-180.1188 (accessed on 28 October 2022). 51. JECFA (Joint FAO/WHO Expert Committee on Food Additives World Health Organization). Evaluation of Certain Food Additivesand Contaminants: Sixty-First Report of the Joint FAO/WHO Expert Committee on Food Additives; World Health Organization: Geneva,Switzerland, 2004; Volume 61. 52. Natural and Non-Prescription Health Products Directorate (NNHPD). Natural Health Products Ingredients Database.4-Aminobutanoic Acid. Group 7: Ingredients with Relaxation Action. 2021. Available online: http://webprod.hc-sc.gc.ca/nhpid-bdipsn/atReq.do?atid=fonc.cognitive.func&lang=eng (accessed on 28 October 2022). 53. Monthly Index of Medical Specialities (MIMS). Aminobutyric Acid. Available online: https://www.mims.com/malaysia/drug/info/aminobutyric%20acid?mtype=generic (accessed on 28 October 2022). 54. Bruhns, P.; Kanzler, C.; Degenhardt, A.G.; Koch, T.J.; Kroh, L.W. Basic structure of melanoidins formed in the Maillard reaction of3-deoxyglucosone and y-aminobutyric acid. J. Agric. Food Chem. 2019, 67,5197-5203. [CrossRef] [PubMed] 55. Ji, D.; Ma, H.; Chen, X. Ultrasonication increases y-aminobutyric acid accumulation in coffee leaves and affects total phenoliccontent and angiotensin-converting enzyme inhibitory activity. J. Food Process. Presero. 2021, 45, e15777. [CrossRef] 56. Suri, T.; Basu, S. Heat resistant chocolate development for subtropical and tropical climates: A review. Crit. Rev. Food Sci. Nutr.2022, 62,5603-5622. [CrossRef] [PubMed] 57. Loncarevic, I.; Pajin, B.; Fistes, A.; Saponjac, V.T.; Petrovic,J.; Jovanovic, P; Vulic, J; Zaric, D. Enrichment of white chocolatewith blackberry juice encapsulate: Impact on physical properties, sensory characteristics and polyphenol content. LWT 2018, 92,458-464. [CrossRef 58. Toker, O.S.; Konar, N.; Pirouzian, H.R.; Oba, S.; Polat, D.G.; Palabiyik, I.; Poyrazoglu, E.S.; Sagdic, O. Developing functional whitechocolate by incorporating different forms of EPA and DHA-Effects on product quality. LWT 2018, 87, 177-185. [CrossRef] 59. Sun, P; Xia, B.; Ni, Z.-J.; Wang, Y.; Elam, E.;Thakur, K.; Ma, Y.-L.; Wei, Z.-J. Characterization of functional chocolate formulatedusing oleogels derived from B-sitosterol with y-oryzanol/lecithin/stearic acid. Food Chem. 2021, 360,130017.[CrossRef] 60. Saglio, A.; Bourgeay,J.; Socrate, R.; Canette, A.; Cuvelier, G. Understanding the structure of ganache: Link between compositionand texture. Int. J. Gastron. Food Sci. 2018, 13,29-37. [CrossRef] 61. Ozturk, B.; Elvan, M.;Ozer, M.; Harsa, S.T. Effect of different microencapsulating materials on the viability of S. thermophilusCCM4757 incorporated into dark and milk chocolates. Food Biosci. 2021, 44,101413.[CrossRef] 62. Gadhiya, D.; Shah, N.; Patel, A.; Prajapati, J. Preparation and shelf-life study of probiotic chocolate manufactured usingLactobacillus helveticus MTCC 5463. Acta Aliment. 2018, 47,350-358.[CrossRef] 63. Food and Drug Administration (FDA). Revised Guidelines for the Assessment of Microbiological Quality of Processed FoodsNo. 2013-010; 2013.Available online: https://www.fda.gov.ph/wp-content/uploads/2021/03/FDA-Circular-No.-2013-010.pdf(accessed on 27 December 2022). 64. International Commission on Microbiological Specifications for Foods (ICMSF). Microorganisms in Foods 5: MicrobiologicalSpecifications of Pathogens; Blackie Academic & Professional: London, UK, 1996; pp. 141-182. 65. Halim, H.S.a.A.; Selamat,J; Mirhosseini, S.H.; Hussain, N. Sensory preference and bloom stability of chocolate containing cocoabutter substitute from coconut oil. J. Saudi Soc. Agric. Sci. 2019,18,443-448. 66. Sethupathy, P.; Priyadarshini, S.; Moses, J.A.; Anandharamakrishnan, C. Matrix-dependent oral processing, oro-sensory percep-tion, and glycemic index of chocolate bars. J. Food Process. Presero. 2021, 45, e16067. [CrossRef] Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individualauthor(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury topeople or property resulting from any ideas, methods, instructions or products referred to in the content.

确定

还剩14页未读,是否继续阅读?

中国格哈特为您提供《黑巧克力蛋白质、脂肪、纤维含量的检测》,该方案主要用于巧克力及制品中营养成分检测,参考标准--,《黑巧克力蛋白质、脂肪、纤维含量的检测》用到的仪器有格哈特全自动超级总脂肪测定系统HT6+SOX416、格哈特凯氏消化系统KT8S、格哈特维克松废气实验室废物处理系统涤气VS、格哈特全自动型纤维分析仪FT12、格哈特带自动进样器凯氏定氮仪VAP500C、德国加液器MM

该厂商其他方案

更多