Ferroalloys are alloys of iron that contain a high level of one or more other primary elements. The principle ferroalloys consist of silicon, manganese, and chromium that are used as vehicles to introduce the alloying element into the molten metal when making steel or cast iron. For example, silicon is used to deoxidize steel and as an alloying element in cast iron. Manganese is used as an alloying element and mitigates the harmful effects of sulfur in cast iron and steel. Chromium increases corrosion resistance in stainless steels. Since carbon is the most important alloying constituent in steel and cast iron production, and sulfur is a harmful contaminant that negatively affects the mechanical properties of steel and cast iron, the determination of carbon and sulfur levels in the ferroalloy feed stock is a critical quality control parameter.

方案详情

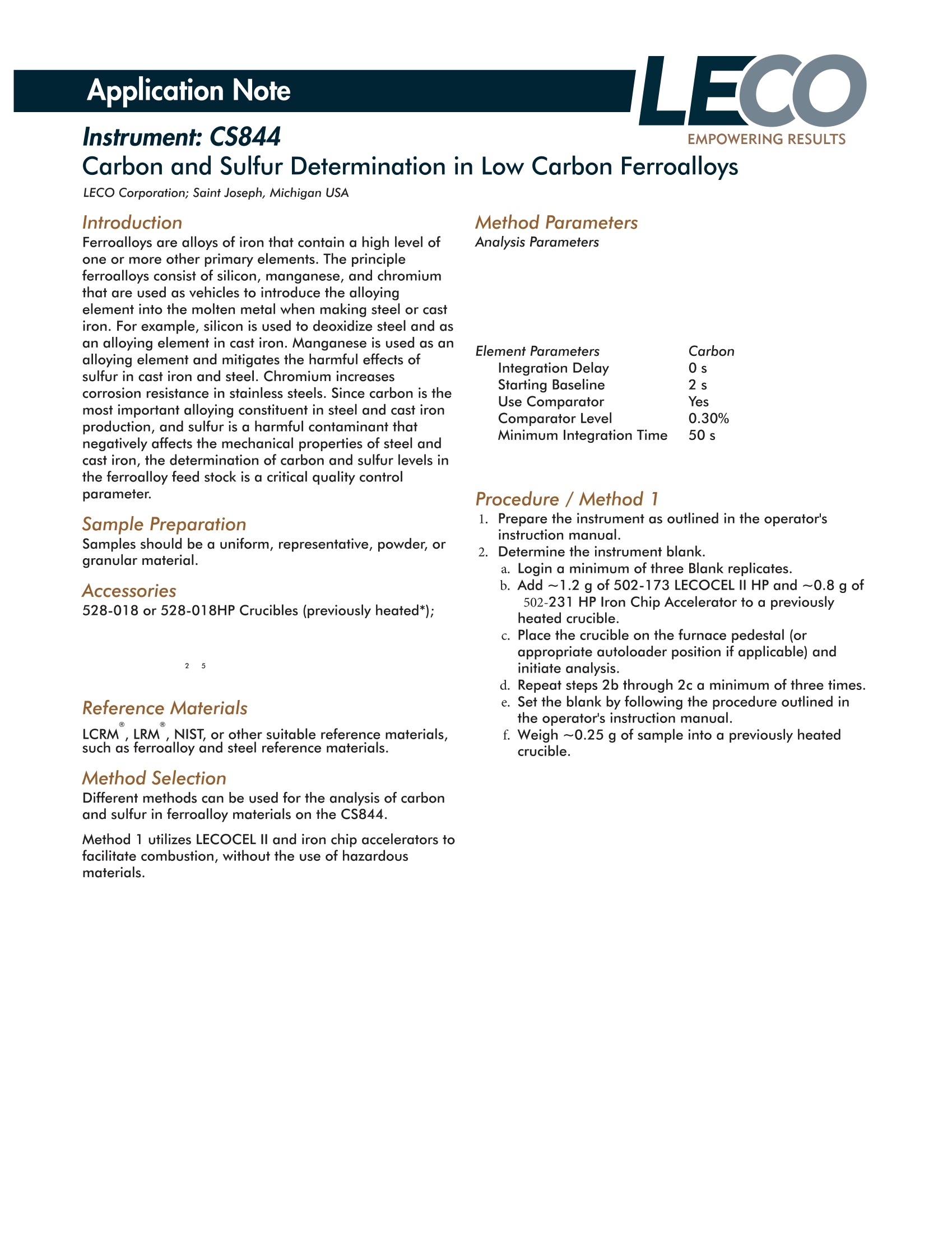

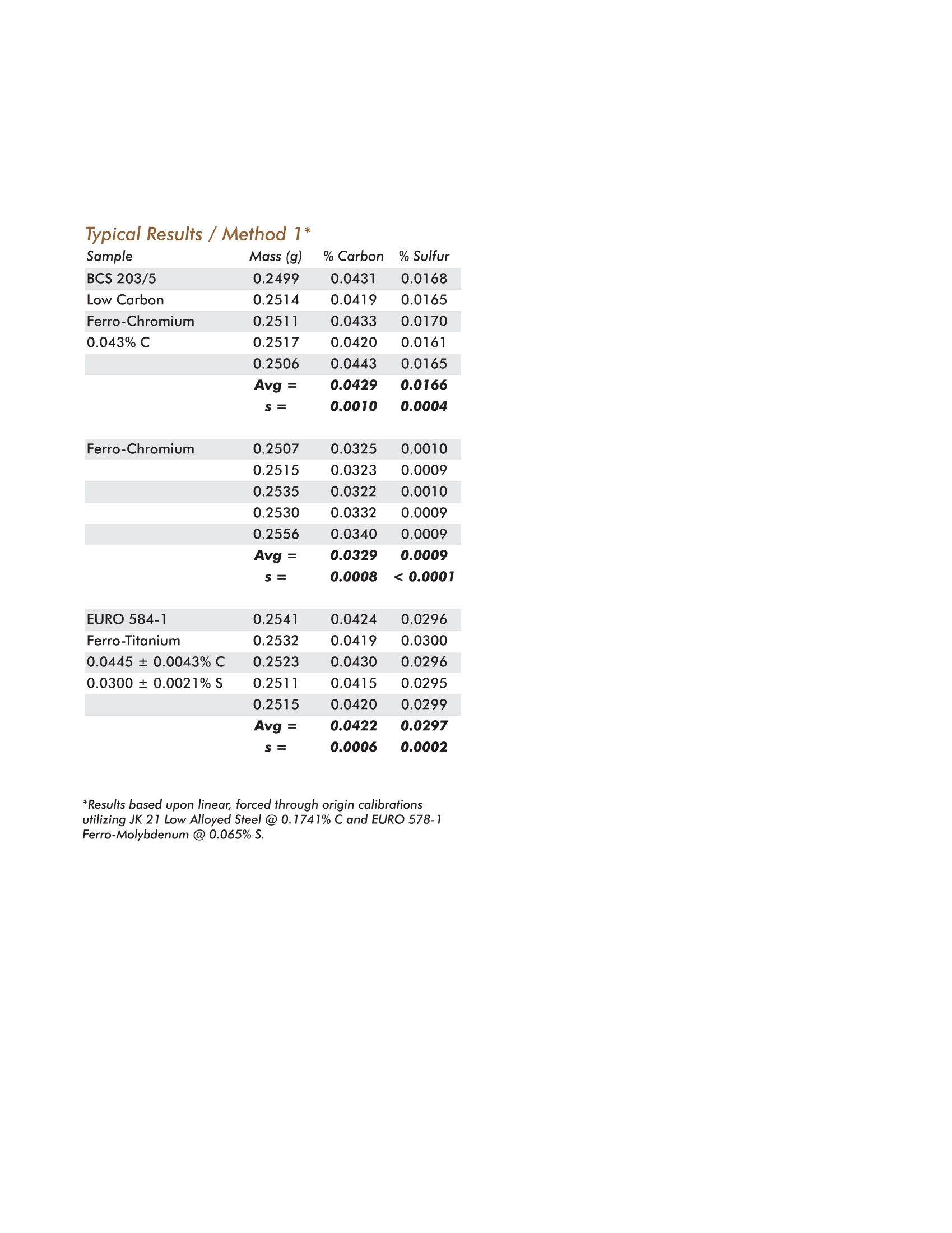

Application NoteEMPOWERING RESULTSLECO Corporation| 3000 Lakeview Avenue| St. Joseph, Ml 49085| Phone:800-292-6141|269-985-5496info@leco.com·www.leco.com|ISO-9001:2015 Q-994|LECO is a registered trademark of LECO Corporation.LCRM = LECO Certified Reference Material; LRM = LECO Reference Material and are registered trademarks of LECO Corporation.7/19-REV0Form No. 203-821-588C 2019 LECO Corporation Instrument: CS844 Carbon and Sulfur Determination in Low Carbon Ferroalloys LECO Corporation; Saint Joseph, Michigan USA IntroductionFerroalloys are alloys of iron that contain a high level ofone or more other primary elements. The principleferroalloys consist of silicon, manganese, and chromiumthat are used as vehicles to introduce the alloyingelement into the molten metal when making steel or castiron.For example, silicon is used to deoxidize steel and asan alloying element in cast iron. Manganese is used as analloying element and mitigates the harmful effects ofsulfur in cast iron and steel. Chromium increasescorrosion resistance in stainless steels. Since carbon is themost important alloying constituent in steel and cast ironproduction, and sulfur is a harmful contaminant thatnegatively affects the mechanical properties of steel andcast iron, the determination of carbon and sulfur levels inthe ferroalloy feed stock is a critical quality controlparameter. Sample Preparation Samples should be a uniform, representative, powder, orgranular material. Accessories 528-018 or 528-018HP Crucibles (previously heated*); 2 5 Reference Materials LCRM , LRM , NIST, or other suitable reference materials,such as ferroalloy and steel reference materials. Method Selection Different methods can be used for the analysis of carbonand sulfur in ferroalloy materials on the CS844. Method 1 utilizes LECOCEL II and iron chip accelerators tofacilitate combustion, without the use of hazardousmaterials. Analysis Parameters Element Parameters Carbon Procedure /Method 1 1. Prepare the instrument as outlined in the operator'sinstruction manual. 2. Determine the instrument blank. a. Login a minimum of three Blank replicates. b. Add ~1.2 g of 502-173 LECOCEL II HP and~0.8g of502-231 HP Iron Chip Accelerator to a previouslyheated crucible. c. Place the crucible on the furnace pedestal (orappropriate autoloader position if applicable) andinitiate analysis. d. Repeat steps 2b through 2c a minimum of three times. e. Set the blank by following the procedure outlined inthe operator's instruction manual. f. Weigh ~0.25 g of sample into a previously heatedcrucible. Typical Results / Method 1* Sample Mass (g) % Carbon % Sulfur BCS 203/5 0.2499 0.0431 0.0168 Low Carbon 0.2514 0.0419 0.0165 Ferro-Chromium 0.2511 0.0433 0.0170 0.043%C 0.2517 0.0420 0.0161 0.2506 0.0443 0.0165 Avg= 0.0429 0.0166 s= 0.0010 0.0004 Ferro-Chromium 0.2507 0.0325 0.0010 0.2515 0.0323 0.0009 0.2535 0.0322 0.0010 0.2530 0.0332 0.0009 0.2556 0.0340 0.0009 Avg= 0.0329 0.0009 S= 0.0008 <0.0001 EURO 584-1 0.2541 0.0424 0.0296 Ferro-Titanium 0.2532 0.0419 0.0300 0.0445±0.0043% C 0.2523 0.0430 0.0296 0.0300±0.0021% S 0.2511 0.0415 0.0295 0.2515 0.0420 0.0299 Avg= 0.0422 0.0297 S= 0.0006 0.0002 *Results based upon linear, forced through origin calibrationsutilizing JK 21 Low Alloyed Steel @0.1741% C and EURO 578-1Ferro-Molybdenum @ 0.065% S. Typical Results / Method 2* Sample Mass (g) % Carbon % Sulfur BCS 203/5 0.2514 0.0421 0.0162 Low Carbon 0.2563 0.0427 0.0164 Ferro-Chromium 0.2542 0.0447 0.0164 0.043% C 0.2625 0.0428 0.0160 0.2567 0.0437 0.0163 Avg = 0.0432 0.0163 s= 0.0010 0.0002 Ferro-Chromium 0.2544 0.0337 0.0008 0.2547 0.0328 0.0008 0.2524 0.0349 0.0008 0.2540 0.0341 0.0008 0.2521 0.0335 0.0008 Avg= 0.0338 0.0008 S= 0.0008 <0.0001 EURO 584-1 0.2512 0.0423 0.0292 Ferro-Titanium 0.2506 0.0432 0.0294 0.0445±0.0043%C 0.2512 0.0426 0.0291 0.0300±0.0021%S 0.2538 0.0437 0.0295 0.2534 0.0421 0.0301 Avg = 0.0428 0.0294 S= 0.0006 0.0004 *Results based upon linear, forced through origin calibrationsutilizing JK 21 Low Alloyed Steel @ 0.1741% C and EURO 578-1Ferro-Molybdenum @0.065% S. 采用力可公司 LECO CS844碳硫分析仪分析铁合金中的低碳和低硫含量,获得满意的结果

确定

还剩1页未读,是否继续阅读?

美国力可公司为您提供《铁合金中碳硫含量检测方案(红外碳硫仪)》,该方案主要用于铁中含量分析检测,参考标准--,《铁合金中碳硫含量检测方案(红外碳硫仪)》用到的仪器有力可LECO CS844碳硫分析仪

推荐专场

相关方案

更多