方案详情

文

The determination of the amount of oxygen,

nitrogen, and hydrogen in iron, steel, nickel-, and

cobalt-base alloys represents some of the most

important quality metrics for these materials.

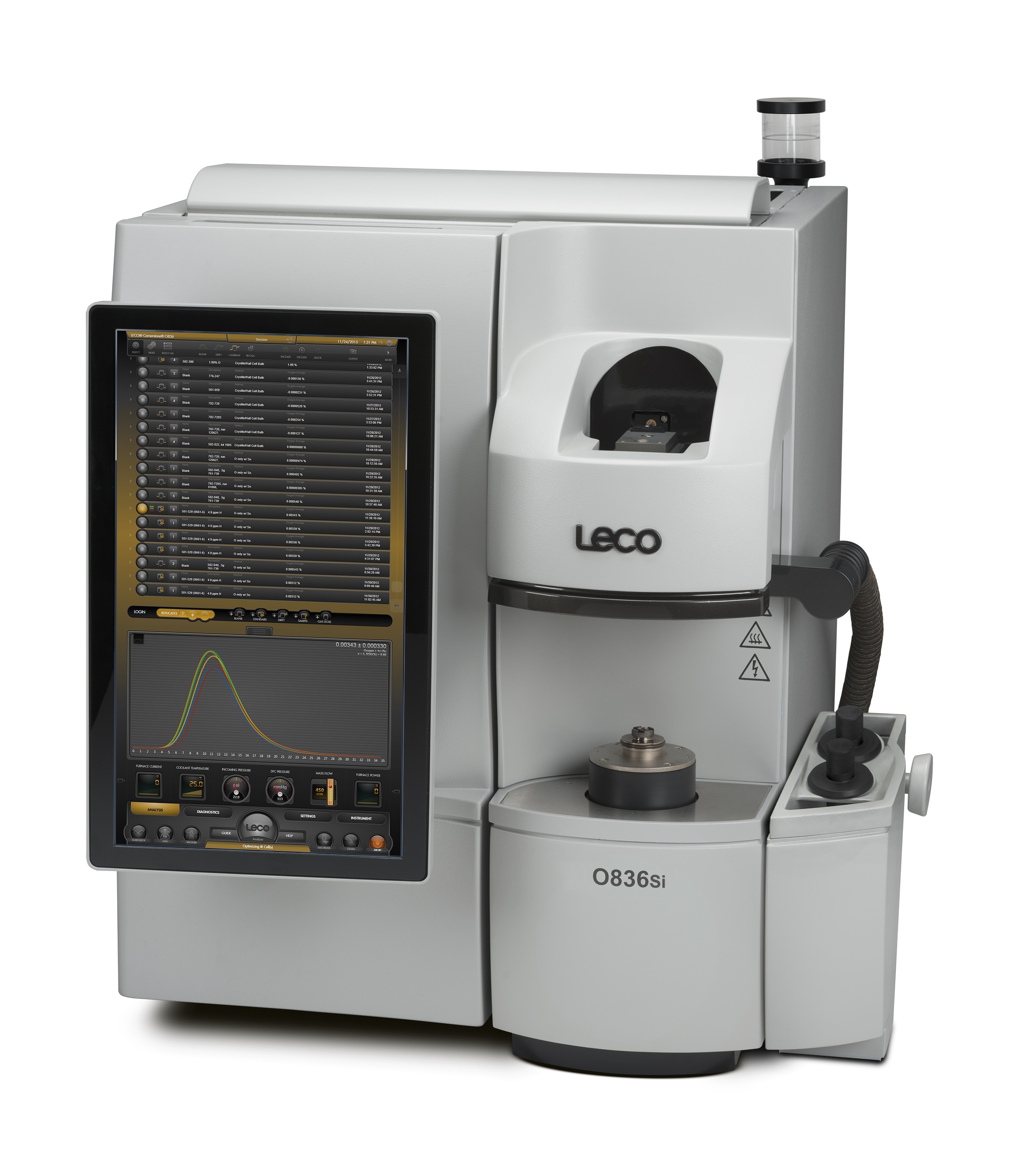

The ONH836 utilizes a high-power

electrode furnace to quickly and efficiently release

the target gases from within the sample, which allows

for a very rapid simultaneous determination of

oxygen, nitrogen, and hydrogen.

方案详情

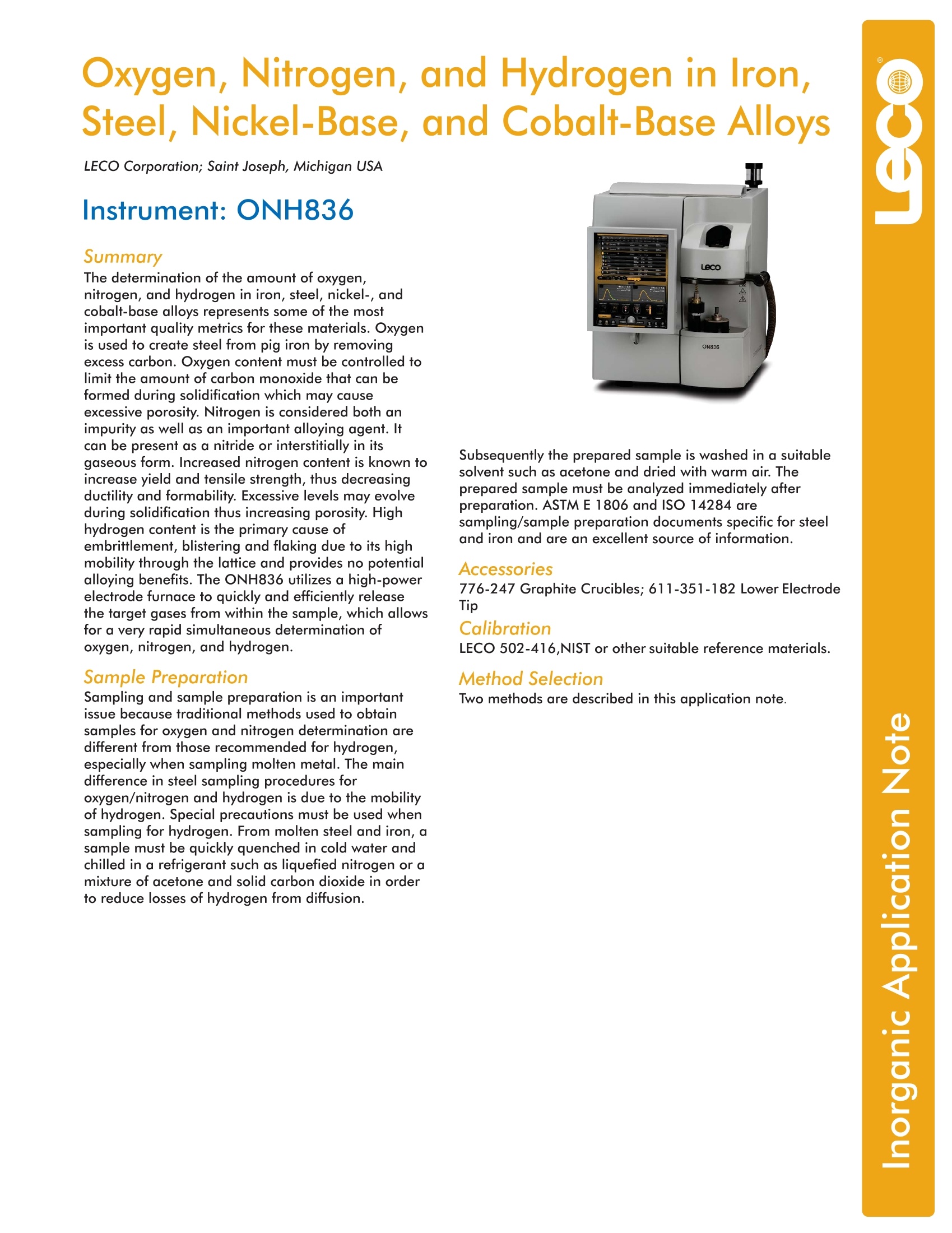

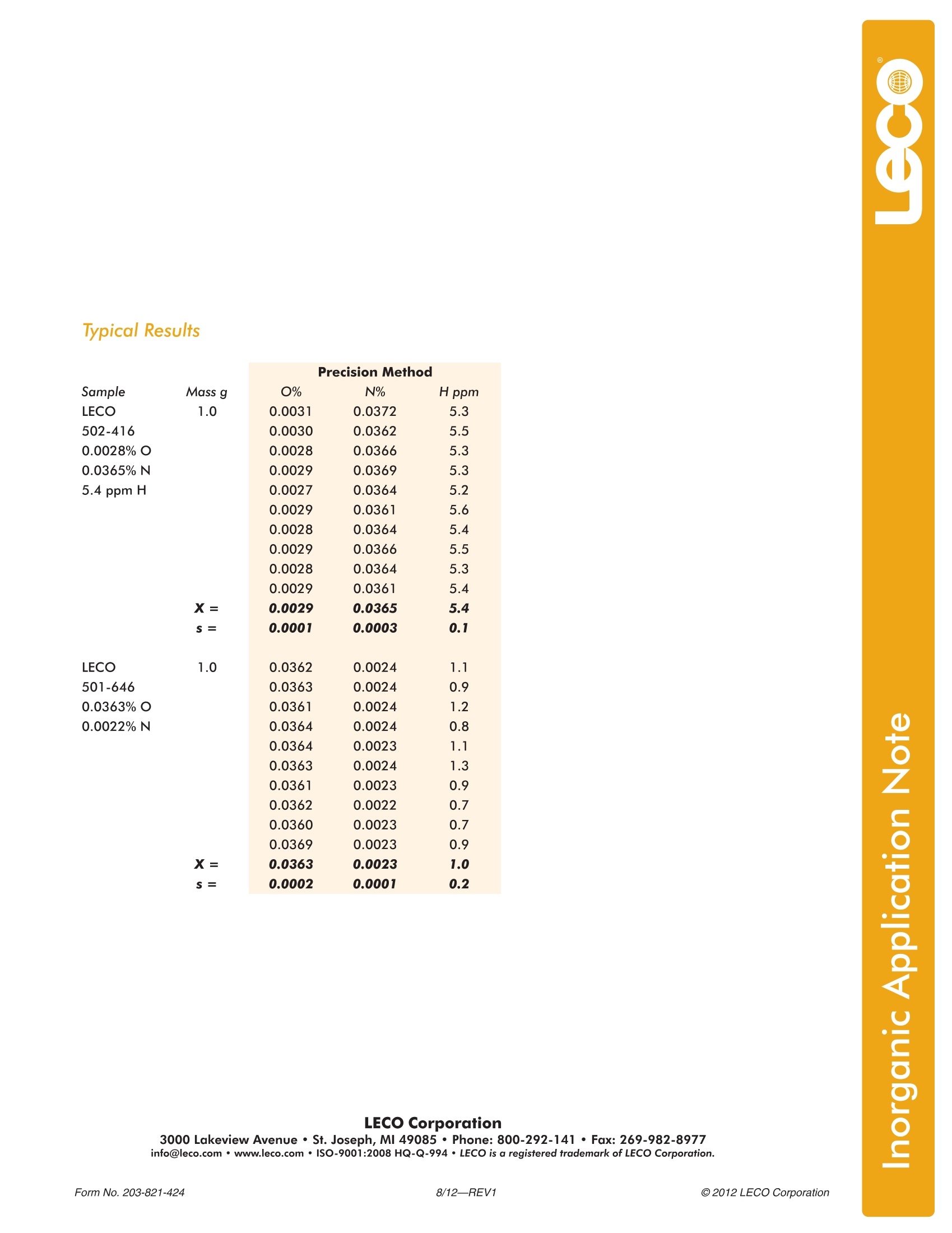

LECO Corporation3000 Lakeview Avenue·St. Joseph,MI 49085· Phone: 800-292-141·Fax: 269-982-8977info@leco.com·www.leco.com·ISO-9001:2008 HQ-Q-994· LECO is a registered trademark of LECO Corporation.Form No. 203-821-4248/12—REV1C 2012 LECO Corporation Oxygen, Nitrogen, and Hydrogen in Iron,Steel,Nickel-Base, and Cobalt-Base Alloys LECO Corporation; Saint Joseph, Michigan USA Instrument: ONH836 Summary The determination of the amount of oxygen,nitrogen, and hydrogen in iron, steel, nickel-, andcobalt-base alloys represents some of the mostimportant quality metrics for these materials. Oxygenis used to create steel from pig iron by removingexcess carbon. Oxygen content must be controlled tolimit the amount of carbon monoxide that can beformed during solidification which may causeexcessive porosity. Nitrogen is considered both animpurity as well as an important alloying agent. Itcan be present as a nitride or interstitially in itsgaseous form. Increased nitrogen content is known toincrease yield and tensile strength, thus decreasingductility and formability. Excessive levels may evolveduring solidification thus increasing porosity. Highhydrogen content is the primary cause ofembrittlement, blistering and flaking due to its highmobility through the lattice and provides no potentialalloying benefits. The ONH836 utilizes a high-powerelectrode furnace to quickly and efficiently releasethe target gases from within the sample, which allowsfor a very rapid simultaneous determination ofoxygen, nitrogen, and hydrogen. Sample Preparation Sampling and sample preparation is an importantissue because traditional methods used to obtainsamples for oxygen and nitrogen determination aredifferent from those recommended for hydrogen,especially when sampling molten metal. The maindifference in steel sampling procedures foroxygen/nitrogen and hydrogen is due to the mobilityof hydrogen. Special precautions must be used whensampling for hydrogen. From molten steel and iron, asample must be quickly quenched in cold water andchilled in a refrigerant such as liquefied nitrogen or amixture of acetone and solid carbon dioxide in orderto reduce losses of hydrogen from diffusion. Subsequently the prepared sample is washed in a suitablesolvent such as acetone and dried with warm air. Theprepared sample must be analyzed immediately afterpreparation. ASTM E 1806 and ISO 14284 are"esampling/sample preparation documents specific for steeland iron and are an excellent source of information. Accessories 776-247 Graphite Crucibles; 611-351-182 Lower ElectrodeTipCalibrationLECO 502-416,NIST or other suitable reference materials. Method Selection Two methods are described in this application note. Method Parameters General Parameters Precision Method cco Sample Introduction Automated Sample Drop Analysis Delay 25s Auto Analyze on Mass Entry No Outgas Before Mass Entry No Wait for User to Load Sample Yes Vacuum On Time 18s Element Parameters Oxygen Nitrogen Hydrogen Integration Delay 5s 15s 10 s Starting Baseline 2s 2s 2s Use Comparator No No No Integration Time 30 s 60s 60 s Use Endline Yes Yes Yes Ending Baseline 2s Range Select Auto Range Lower Limit 800 Range Upper Limit 900 Furnace Parameters Furnace Control Mode Power Outgas Furnace Settings Cycles 2 Power Mode Constant Power 5500* W Time 20 s Cool Time 5 s Surface Oxide Removal Remove Surface Oxides No Analyze Furnace Settings Step 1 Power Mode Constant Power 4800*W Approximate Cycle Time 3.5 Minutes *May vary, depending on line voltage. Level can be adjusted to facilitate recovery and/or reduce crucible burn-through. Automation Parameters (if equipped) General Parameters Auto Cleaner StateEnabledAuto Cleaner ModeDuring AnalysisClean Time8 s Procedure 1. Prepare the instrument as outlined in theoperator's instruction manual. g. Repeat steps 2b through 2f a minimum ofthree times. 2. Determine the instrument blank. a. Login a minimum of 3 Blank replicates. h. Set the blank following the procedureoutlined in the operator's instruction manual. b. Press the Analyze button on the instrumentscreen. After a short delay, the loading headslide-block will open. C. PPress the Analyze button on the instrumentscreen again, the loading head slide-blockwill close and the lower electrode will open. 8 d. Clean the upper and lower electrodemanually, or, if applicable, remove thecrucible and press the analyze button to cleanwith the automatic cleaner. e. Firmly place a graphite crucible on the lowerelectrode tip. f Press the Analyze button on the instrumentscreen, the lower electrode will close and theanalysis sequence will start and endautomatically. Typical Results Precision Method Sample Mass g 0% N% H ppm LECO 1.0 0.0031 0.0372 5.3 502-416 0.0030 0.0362 5.5 0.0028%0 0.0028 0.0366 5.3 0.0365% N 0.0029 0.0369 5.3 5.4 ppm H 0.0027 0.0364 5.2 0.0029 0.0361 5.6 0.0028 0.0364 5.4 0.0029 0.0366 5.5 0.0028 0.0364 5.3 0.0029 0.0361 5.4 X= 0.0029 0.0365 5.4 S = 0.0001 0.0003 0.1 LECO 1.0 0.0362 0.0024 1.1 501-646 0.0363 0.0024 0.9 0.0363%0 0.0361 0.0024 1.2 0.0022%N 0.0364 0.0024 0.8 0.0364 0.0023 0.0363 0.0024 0.0361 0.0023 0.9 0.0362 0.0022 0.7 0.0360 0.0023 0.7 0.0369 0.0023 0.9 X= 0.0363 0.0023 1.0 S = 0.0002 0.0001 0.2

确定

还剩1页未读,是否继续阅读?

美国力可公司为您提供《钢铁及镍钴合金中氧氮氢元素含量检测方案(氧氮分析仪)》,该方案主要用于合金中含量分析检测,参考标准--,《钢铁及镍钴合金中氧氮氢元素含量检测方案(氧氮分析仪)》用到的仪器有力可LECO ONH836氧氮氢分析仪

推荐专场