方案详情

文

Alpha-phase titanium alloys are

less ductile and have less strength than the beta-phase

alloys, but have higher corrosion resistance and

deformability. Carbon is considered to be an impurity,

commonly introduced during the manufacturing

process, of commercially pure (CP) titanium grades.

方案详情

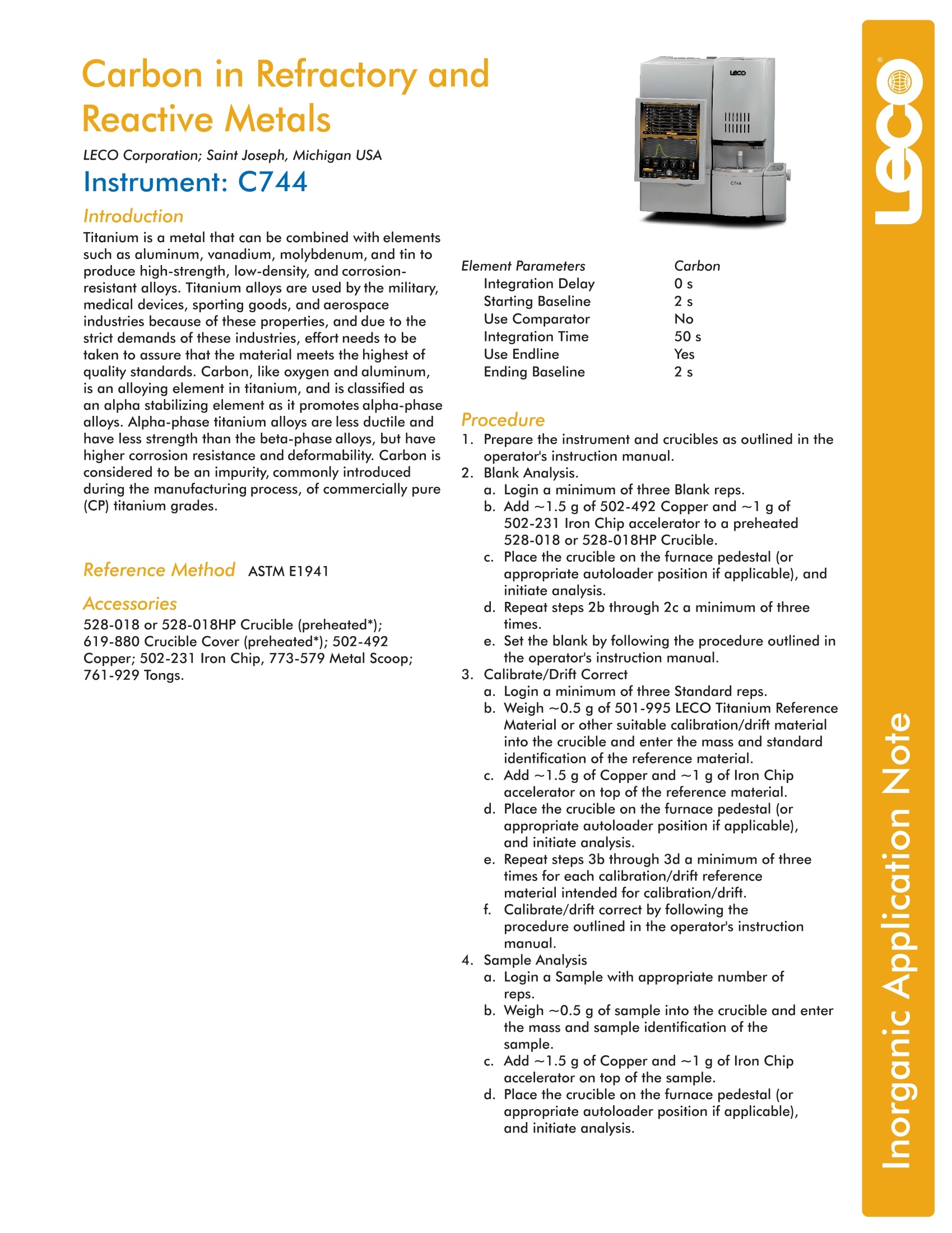

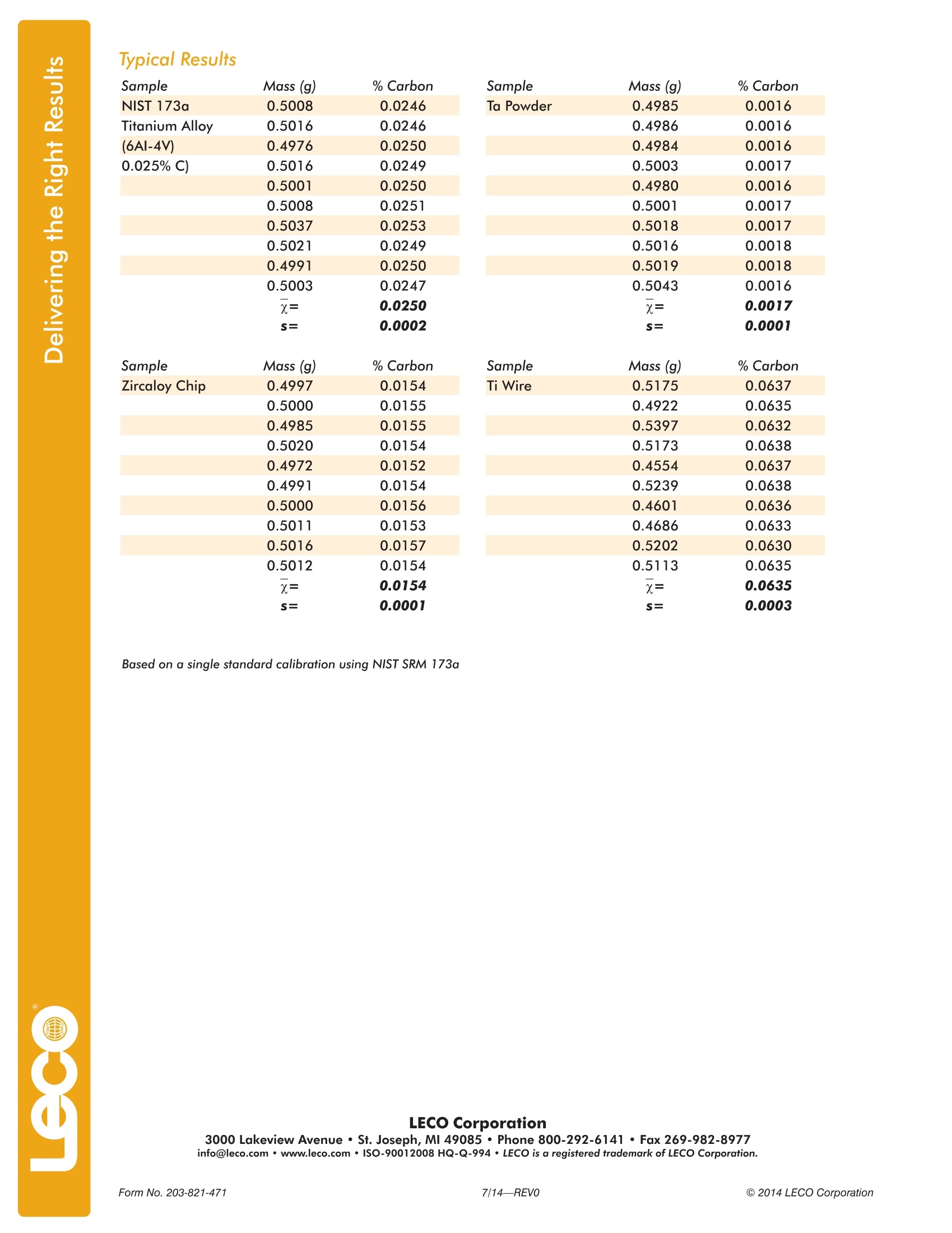

LECO Corporation3000 Lakeview Avenue·St. Joseph,MI 49085· Phone 800-292-6141·Fax 269-982-8977info@leco.com·www.leco.com·ISO-90012008 HQ-Q-994·LECO is a registered trademark of LECO Corporation.Form No. 203-821-4717/14—REV0C 2014 LECO Corporation Introduction Titanium is a metal that can be combined with elementssuch as aluminum, vanadium, molybdenum, and tin toproduce high-strength, low-density, and corrosion-resistant alloys. Titanium alloys are used by the military,medical devices, sporting goods, and aerospaceindustries because of these properties, and due to thestrict demands of these industries, effort needs to betaken to assure that the material meets the highest ofquality standards. Carbon, like oxygen and aluminum,is an alloying element in titanium, and is classified asan alpha stabilizing element as it promotes alpha-phasealloys. Alpha-phase titanium alloys are less ductile andhave less strength than the beta-phase alloys, but havehigher corrosion resistance and deformability. Carbon isconsidered to be an impurity, commonly introducedduring the manufacturing process, of commercially pure(CP) titanium grades.S. Reference MethodAASTME1941 Accessories 528-018 or 528-018HP Crucible (preheated*);619-880 Crucible Cover (preheated*); 502-492Copper; 502-231 Iron Chip, 773-579 Metal Scoop;761-929 Tongs. Element Parameters Carbon Procedure 1. Prepare the instrument and crucibles as outlined in theoperator's instruction manual. 2. 1Blank Analysis. a. Login a minimum of three Blank reps. b. Add ~1.5 g of 502-492 Copper and ~1 g ofana502-231 Iron Chip accelerator to a preheated528-018 or 528-018HP Crucible. c. Place the crucible on the furnace pedestal (orappropriate autoloader position if applicable), andinitiate analysis. d. Repeat steps 2b through 2c a minimum of threetimes. Set the blank by following the procedure outlined inthe operator's instruction manual. 3. Calibrate/Drift Correct a. Login a minimum of three Standard reps. b. Weigh~0.5 g of 501-995 LECO Titanium ReferenceMaterial or other suitable calibration/drift materialinto the crucible and enter the mass and standardidentification of the reference material. c. Add ~1.5 g of Copper and ~1 g of Iron Chipaccelerator on top of the reference material. d. Place the crucible on the furnace pedestal (orappropriate autoloader position if applicable),and initiate analysis. e. Repeat steps 3b through 3d a minimum of three times for each calibration/drift reference material intended for calibration/drift. f. Calibrate/drift correct by following the procedure outlined in the operator's instruction manual. 4.Sample Analysis a. Login a Sample with appropriate number of reps. b. Weigh ~0.5 g of sample into the crucible and enter the mass and sample identification of the sample. c. Add ~1.5 g of Copper and ~1 g of Iron Chipaccelerator on top of the sample. d. Place the crucible on the furnace pedestal (orappropriate autoloader position if applicable),and initiate analysis. Typical Resultso上co Sample Mass (g) % Carbon Sample Mass (g) % Carbon NIST 173a 0.5008 0.0246 Ta Powder 0.4985 0.0016 Titanium Alloy 0.5016 0.0246 0.4986 0.0016 (6AI-4V) 0.4976 0.0250 0.4984 0.0016 0.025%C) 0.5016 0.0249 0.5003 0.0017 0.5001 0.0250 0.4980 0.0016 0.5008 0.0251 0.5001 0.0017 0.5037 0.0253 0.5018 0.0017 0.5021 0.0249 0.5016 0.0018 0.4991 0.0250 0.5019 0.0018 0.5003 0.0247 0.5043 0.0016 X= 0.0250 X= 0.0017 S= 0.0002 S= 0.0001 Sample Mass (g) % Carbon Sample Mass (g) % Carbon Zircaloy Chip 0.4997 0.0154 Ti Wire 0.5175 0.0637 0.5000 0.0155 0.4922 0.0635 0.4985 0.0155 0.5397 0.0632 0.5020 0.0154 0.5173 0.0638 0.4972 0.0152 0.4554 0.0637 0.4991 0.0154 0.5239 0.0638 0.5000 0.0156 0.4601 0.0636 0.5011 0.0153 0.4686 0.0633 0.5016 0.0157 0.5202 0.0630 0.5012 0.0154 0.5113 0.0635 X= 0.0154 X= 0.0635 S= 0.0001 S= 0.0003 Based on a single standard calibration using NIST SRM 173a 利用力可LECO CS744碳硫分析仪分析难熔金属中碳含量,获得如下结果,详细方法见附件:

确定

还剩1页未读,是否继续阅读?

美国力可公司为您提供《难熔金属,高温合金中碳含量检测方案(红外碳硫仪)》,该方案主要用于合金中含量分析检测,参考标准--,《难熔金属,高温合金中碳含量检测方案(红外碳硫仪)》用到的仪器有美国力可LECO CS744碳硫分析仪

推荐专场