方案详情

文

激光诱导击穿光谱技术(Laser-induced breakdown spectroscopy 简称 LIBS)是一种快速兴起的分析技术。LIBS 技术在过去的几年里得到了多种工业行业的越来越多的关注。在矿产业,相较与上文提到的传统分析方法,LIBS 具有很多有吸引力的分析优势。LIBS 可以检测从 H 到 Pu 的多种元素,包括如 H、N、F 和 O 等其它分析方法很难或不可能检测的非金属元素。此外,与 XRF 相比,LIBS 对于轻元素(如 B、Li、C、K、Ca、Mg、Al、Si 等)有更高的灵敏度,而这些轻元素的检测对于许多矿产应用都很关键。本案例中,非洲矿产标准(AMIS)标准参考物质(CRMs)被用于分析,以证明 LIBS 技术对于矿产业是一种有效的分析方法。

方案详情

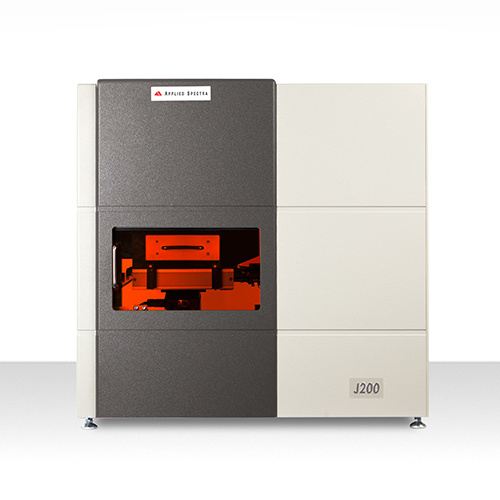

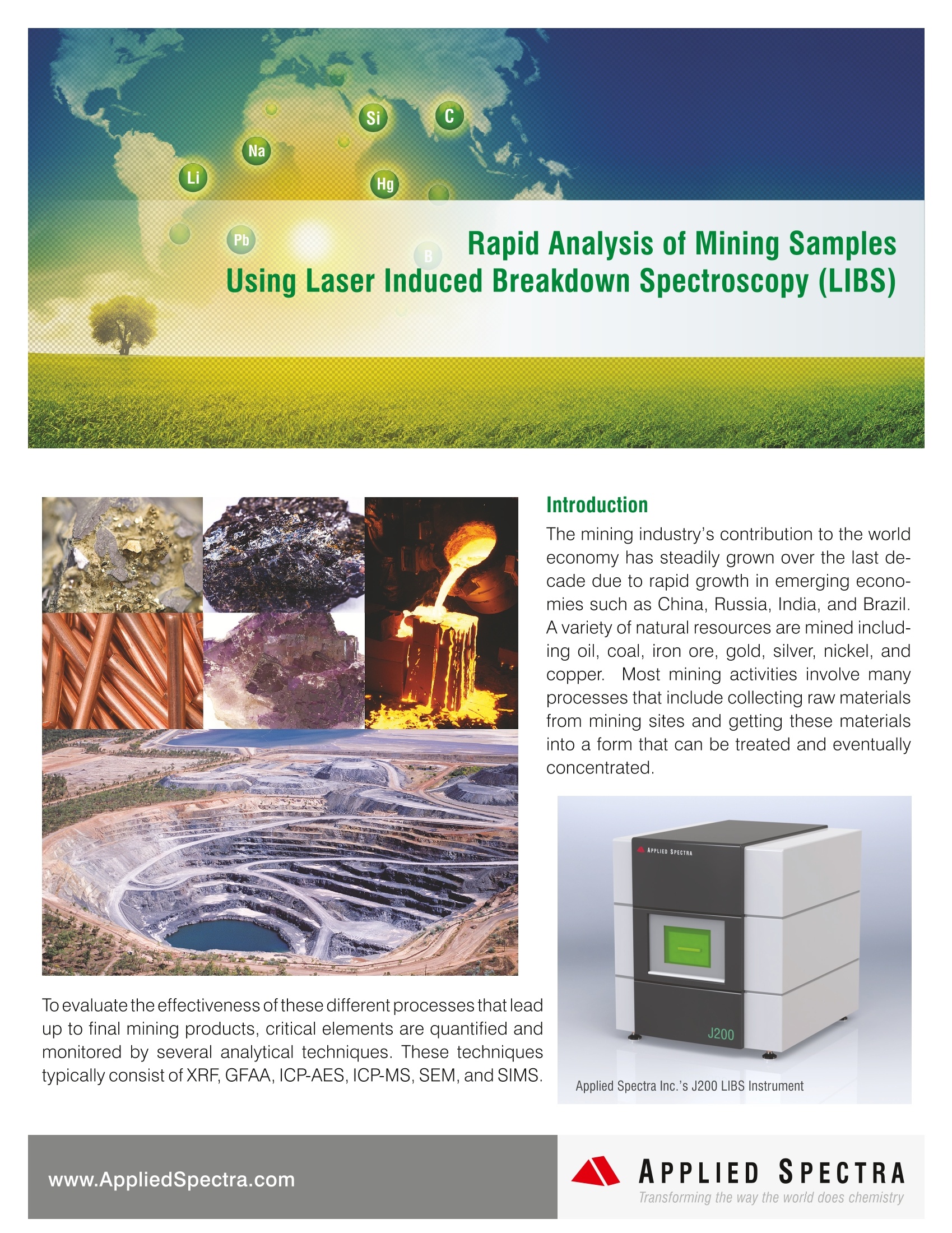

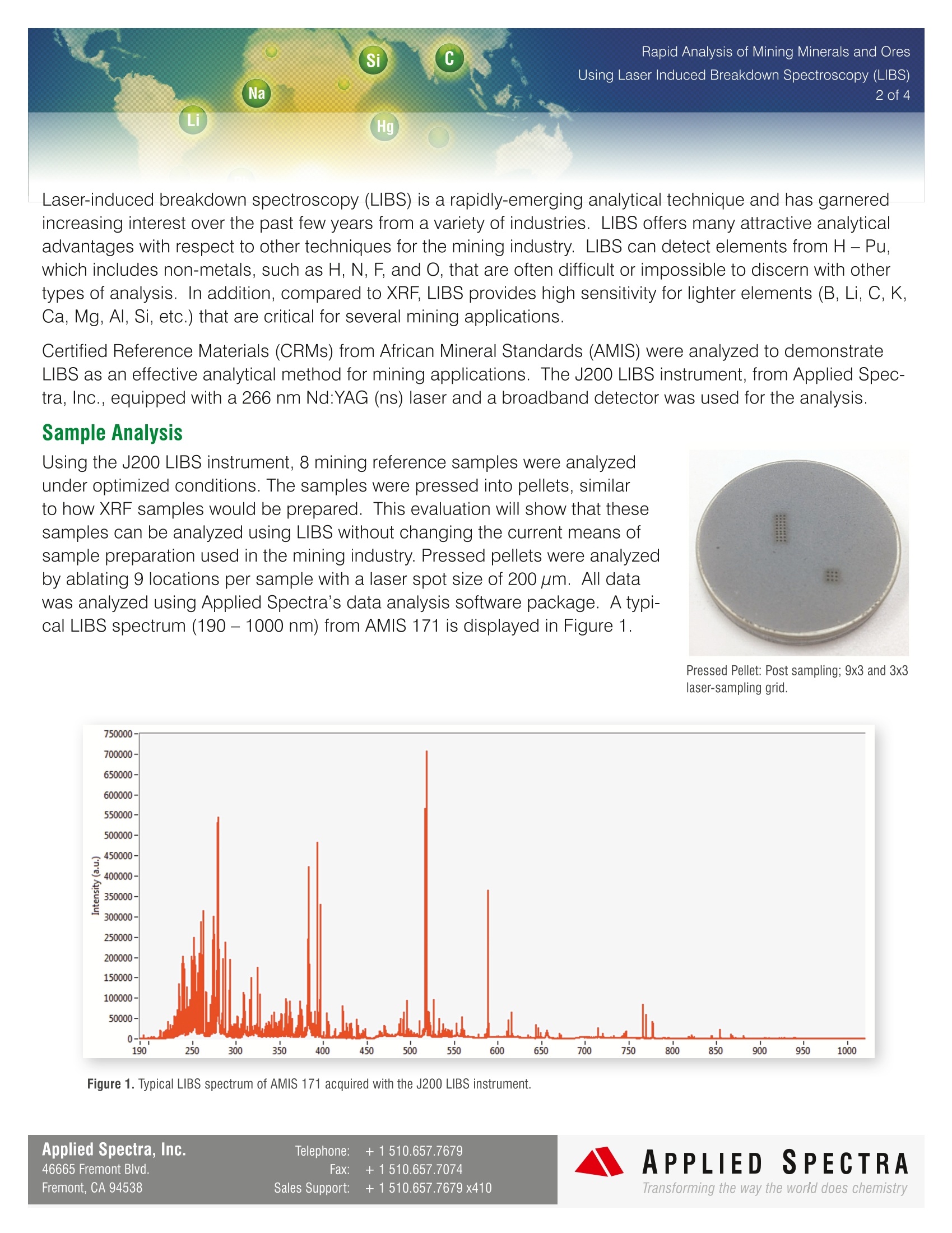

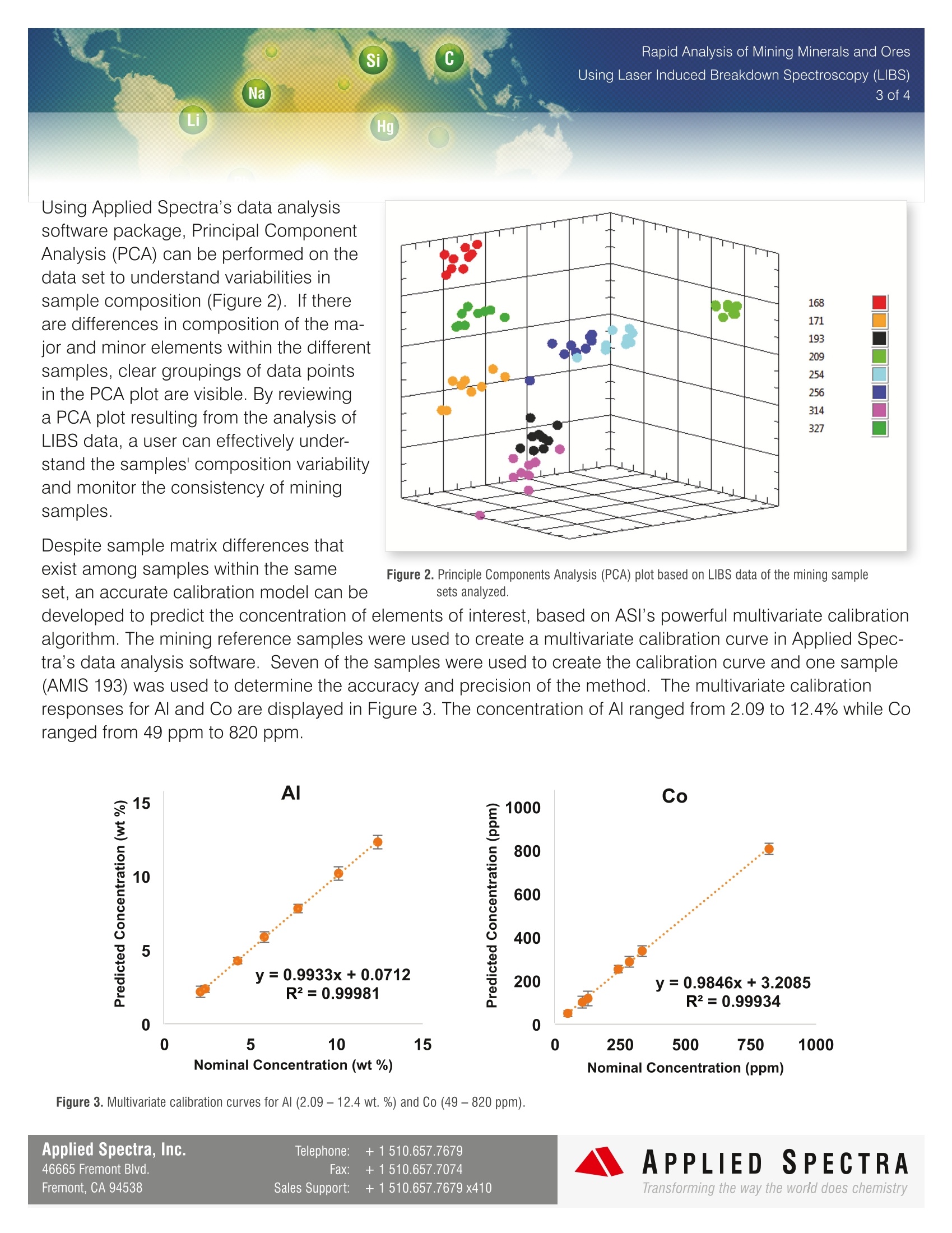

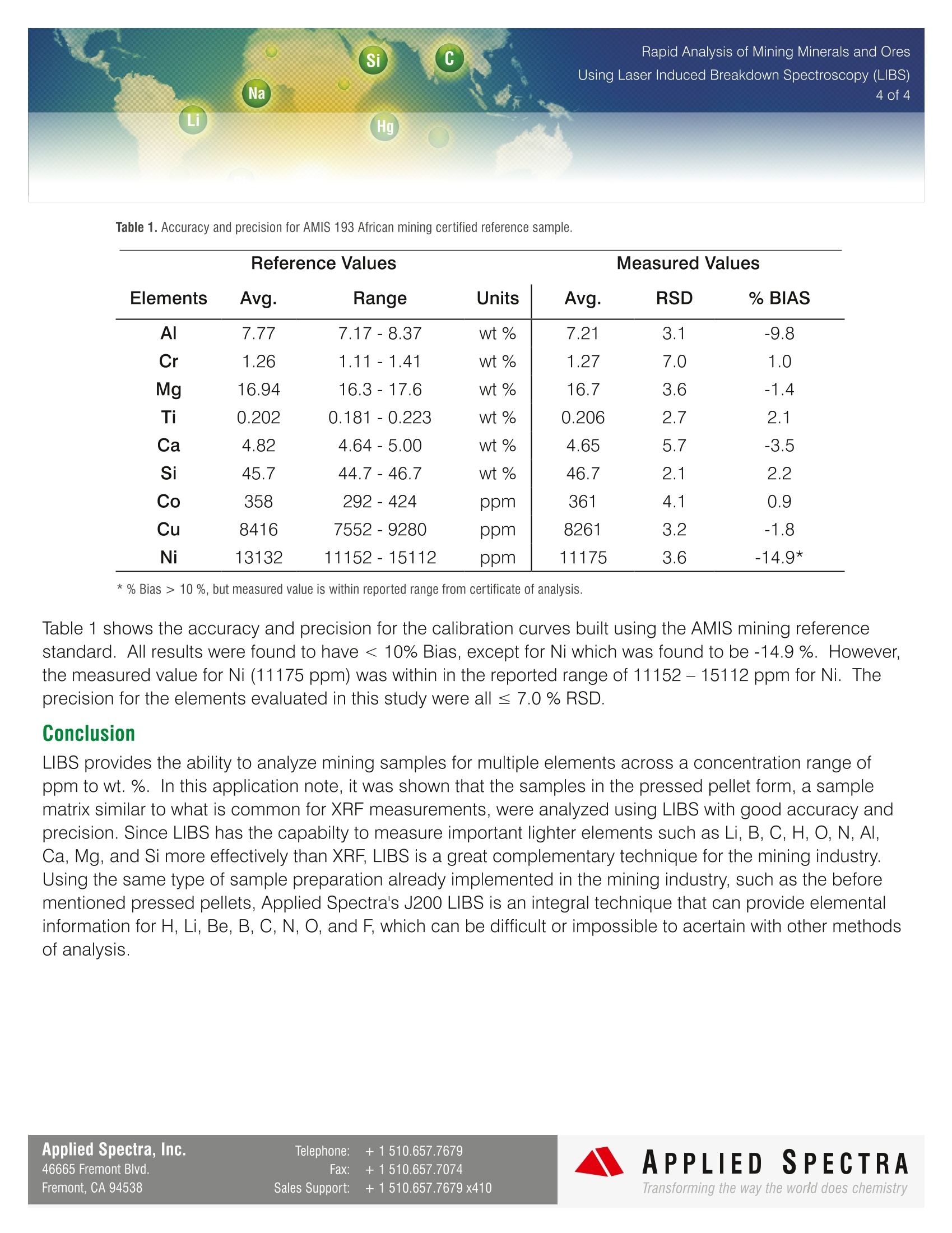

Rapid Analysis of Mining Minerals and OresUsing Laser Induced Breakdown Spectroscopy (LIBS)4 of 4Table 1. Accuracy and precision for AMIS 193 African mining certified reference sample. Si Na Li Hg Pb Rapid Analysis of Mining SamplesUsing Laser Induced Breakdown Spectroscopy (LIBS) To evaluate the effectiveness of these different processes thatleadup to final mining products, critical elements are quantified andmonitored by several analytical techniques. These techniquestypically consist of XRF, GFAA, ICP-AES, ICP-MS, SEM, and SIMS. Introduction The mining industry's contribution to the worldeconomy has steadily grown over the last de-cade due to rapid growth in emerging econo-mies such as China, Russia,India, and Brazil.A variety of natural resources are mined includ-ing oil, coal, iron ore, gold, silver, nickel, andcopper.Most mining activities involve manyprocesses that include collecting raw materialsfrom mining sites and getting these materialsinto a form that can be treated and eventuallyconcentrated. Applied Spectra Inc.'s J200 LIBS Instrument Laser-induced breakdown spectroscopy (LIBS) is a rapidly-emerging analytical technique and has garneredincreasing interest over the past few years from a variety of industries. LIBS offers many attractive analyticaladvantages with respect to other techniques for the mining industry. LIBS can detect elements from H-Pu,which includes non-metals, such as H, N, F, and O, that are often difficult or impossible to discern with othertypes of analysis. In addition, compared to XRF, LIBS provides high sensitivity for lighter elements (B, Li, C, K,Ca, Mg, Al, Si, etc.) that are critical for several mining applications. Certified Reference Materials (CRMs) from African Mineral Standards (AMIS) were analyzed to demonstrateLIBS as an effective analytical method for mining applications. The J200 LIBS instrument, from Applied Spec-tra, Inc., equipped with a 266 nm Nd:YAG (ns) laser and a broadband detector was used for the analysis. Sample Analysis Using the J200 LIBS instrument, 8 mining reference samples were analyzedunder optimized conditions. The samples were pressed into pellets, similarto how XRF samples would be prepared. This evaluation will show that thesesamples can be analyzed using LIBS without changing the current means ofsample preparation used in the mining industry. Pressed pellets were analyzedby ablating 9 locations per sample with a laser spot size of 200 um. All datawas analyzed using Applied Spectra's data analysis software package. A typi-cal LIBS spectrum (190-1000 nm) from AMIS 171 is displayed in Figure 1. Pressed Pellet: Post sampling; 9x3 and 3x3laser-sampling grid. Figure 1. Typical LIBS spectrum of AMIS 171 acquired with the J200 LIBS instrument. Applied Spectra, Inc. Telephone: +1510.657.7679 Fax: + 1 510.657.7074 Fremont, CA 94538 Using Applied Spectra's data analysissoftware package, Principal ComponentAnalysis (PCA) can be performed on thedata set to understand variabilities insample composition (Figure 2). If thereare differences in composition of the ma-ior and minor elements within the differentsamples, clear groupings of data pointsin the PCA plot are visible. By reviewinga PCA plot resulting from the analysis ofLIBS data, a user can effectively under-stand the samples' composition variabilityand monitor the consistency of miningsamples. Despite sample matrix differences thatexist among samples within the sameset, an accurate calibration model can be Figure 2. Principle Components Analysis (PCA) plot based on LIBS data of the mining samplesets analyzed. developed to predict the concentration of elements of interest, based on ASI’s powerful multivariate calibrationalgorithm. The mining reference samples were used to create a multivariate calibration curve in Applied Spec-tra’s data analysis software. Seven of the samples were used to create the calibration curve and one sample(AMIS 193) was used to determine the accuracy and precision of the method. The multivariate calibrationresponses for Al and Co are displayed in Figure 3. The concentration of Al ranged from 2.09 to 12.4% while Coranged from 49 ppm to 820 ppm. Al Nominal Concentration (ppm) Figure 3. Multivariate calibration curves for Al (2.09-12.4 wt. %) and Co (49-820ppm). Reference Values Measured Values Elements Avg. Range Units Avg. RSD %BIAS AI 7.77 7.17-8.37 wt % 7.21 3.1 -9.8 Cr 1.26 1.11-1.41 wt% 1.27 7.0 1.0 Mg 16.94 16.3-17.6 wt% 16.7 3.6 -1.4 Ti 0.202 0.181-0.223 wt% 0.206 2.7 2.1 Ca 4.82 4.64-5.00 wt % 4.65 5.7 -3.5 Si 45.7 44.7-46.7 wt % 46.7 2.1 2.2 Co 358 292-424 ppm 361 4.1 0.9 Cu 8416 7552-9280 ppm 8261 3.2 -1.8 Ni 13132 11152-15112 ppm 11175 3.6 -14.9* * % Bias > 10 %, but measured value is within reported range from certificate of analysis. Table 1 shows the accuracy and precision for the calibration curves built using the AMIS mining referencestandard. All results were found to have <10% Bias, except for Ni which was found to be-14.9%. However,the measured value for Ni (11175 ppm) was within in the reported range of 11152 - 15112 ppm for Ni. Theprecision for the elements evaluated in this study were all ≤ 7.0% RSD. Conclusion LIBS provides the ability to analyze mining samples for multiple elements across a concentration range ofppm to wt.%. In this application note, it was shown that the samples in the pressed pellet form, a samplematrix similar to what is common for XRF measurements, were analyzed using LIBS with good accuracy andprecision. Since LIBS has the capabilty to measure important lighter elements such as Li, B, C, H,O, N, Al,Ca, Mg, and Si more effectively than XRF, LIBS is a great complementary technique for the mining industry.Using the same type of sample preparation already implemented in the mining industry, such as the beforementioned pressed pellets, Applied Spectra's J200 LIBS is an integral technique that can provide elementalinformation for H, Li, Be, B, C,N,O,and F, which can be difficult or impossible to acertain with other methodsof analysis. APPLIEDSPECTRAwww.AppliedSpectra.comTransforming the way the world does chemistry APPLIEDSPECTRAFremont Blvd.Sales Support: +xransforming the way the world does chemistry 表 1 为通过 AMIS 矿石标准样品建立的标准曲线检测待测样品(AMIS 193)结果的准确度和精度。 其中除了 Ni 的偏差为-14.9%,其余的样品偏差均<10%。然而测量结果的 Ni 元素的含量为的 11175ppm, 在参考范围(11152-15112ppm)之内;且待测样品的其它元素测量值与参考值相比,RSD 均小于 7.0%。LIBS 技术提供了一种同时检测矿石样品多种元素的快速分析方法,检测范围从 ppm~wt%。在此案 例中,通过压片进行前处理的样品(样品的基体效应与常规的 XRF 分析方法相同),通过 LIBS 分析得 到较好的准确度和精度。因为 LIBS 具有能检测重要的轻元素,如 Li、B、C、H、O、N、Al、Ca、Mg、 Si 等,同 XRF 相比,LIBS 技术更为高效。LIBS 技术将成为矿产业有力的技术手段。采用矿产业已经 建立的样品前处理方法(如前文提到的压片),ASI 的 J200 就能得到 H、Li、Be、B、C、N、O、F 等 其它分析方法很难或不可能得到的元素信息。

确定

还剩2页未读,是否继续阅读?

北京富尔邦科技发展有限责任公司为您提供《矿物中多元素检测方案(激光诱导击穿)》,该方案主要用于其他中多元素检测,参考标准--,《矿物中多元素检测方案(激光诱导击穿)》用到的仪器有美国ASI 激光诱导击穿光谱仪(LIBS)

推荐专场

相关方案

更多

该厂商其他方案

更多