采用LaVision的DaVis 8.2.2 软件平台,可编程时间控制单元PTU, ImagerIntense高灵敏度低噪声相机,构成一套2D粒子成像测速系统。并利用该系统对纳米流体在湍流自然对流过程中的流动特性进行了实验研究和理论分析。

方案详情

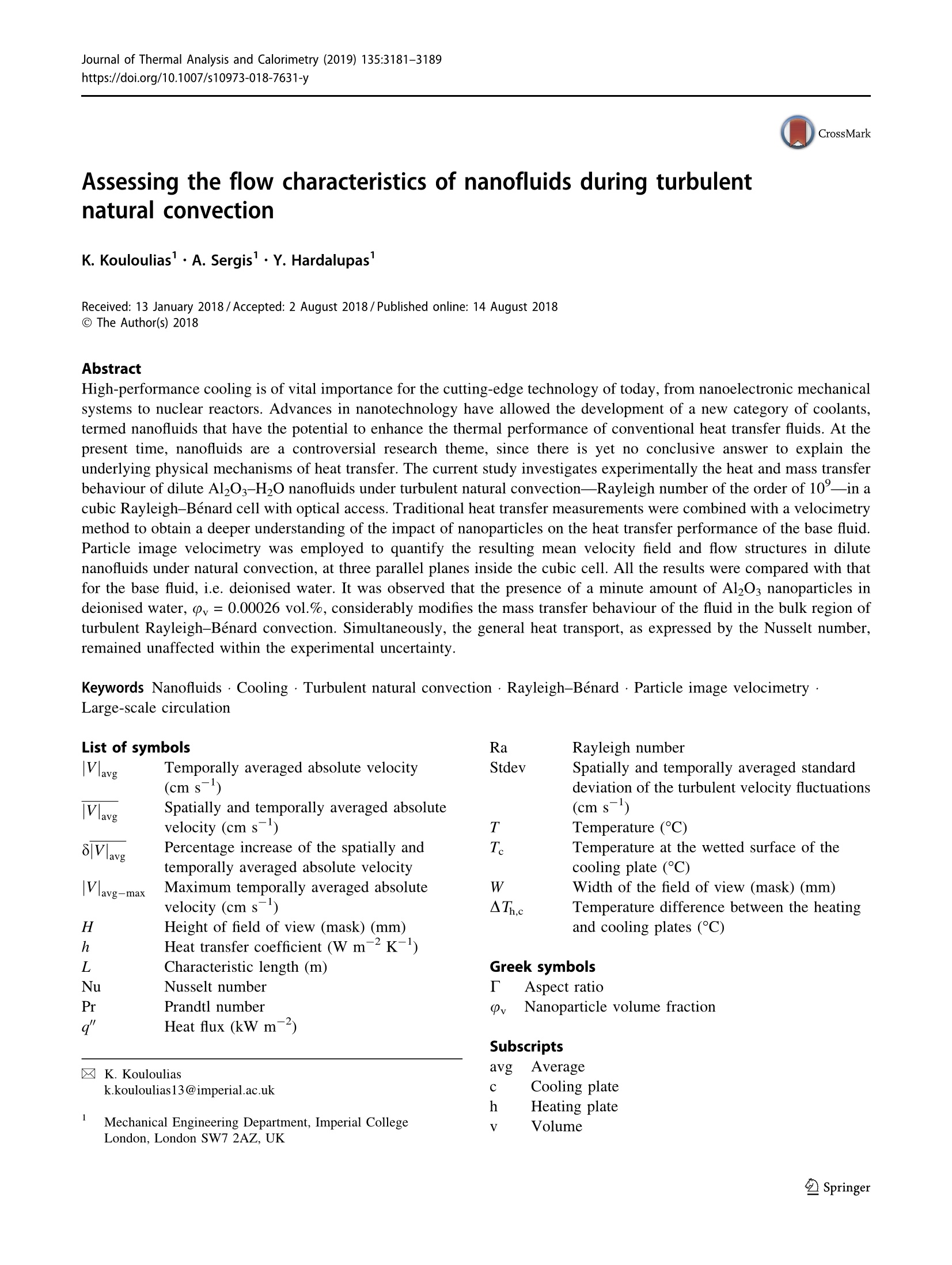

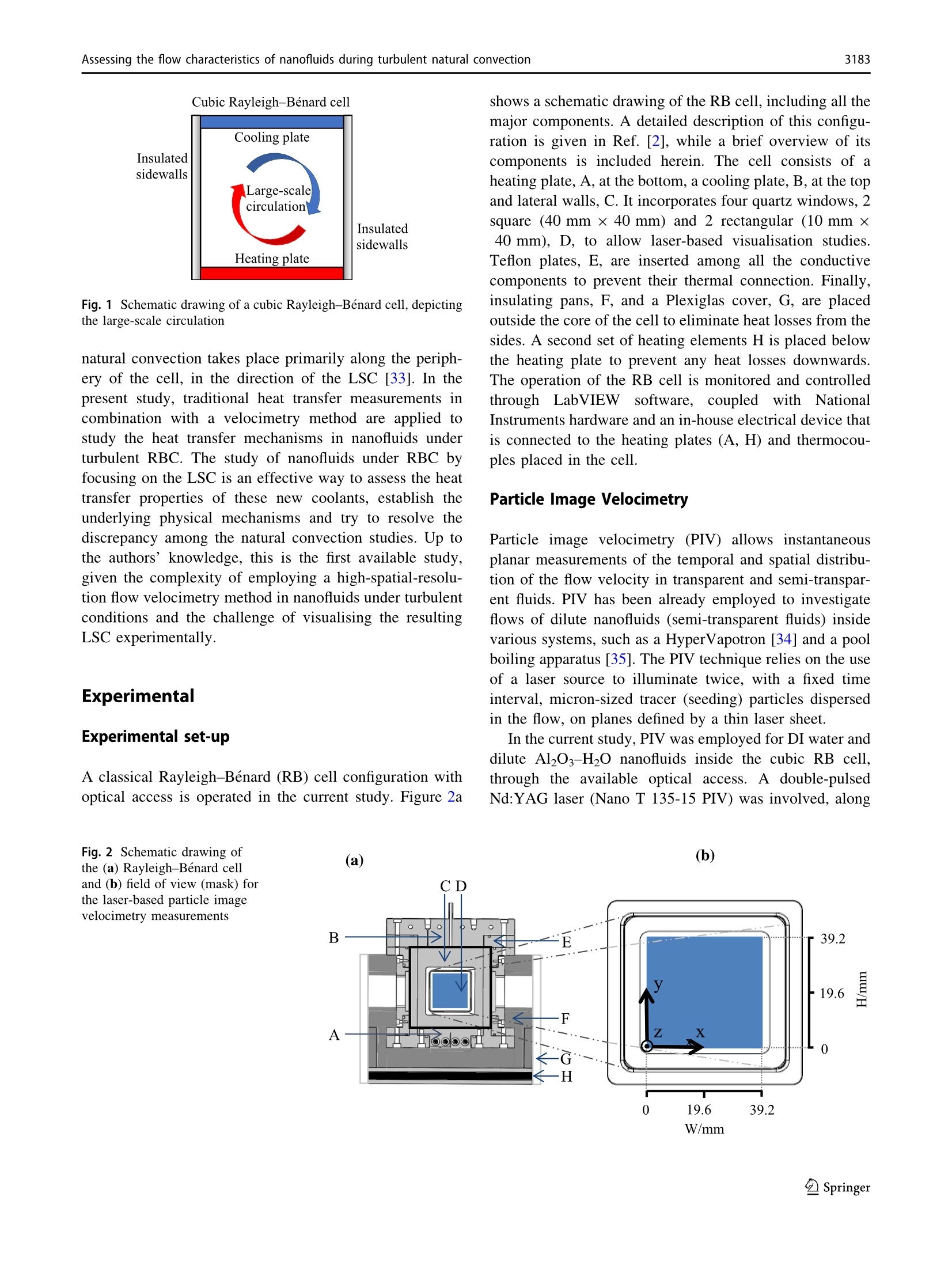

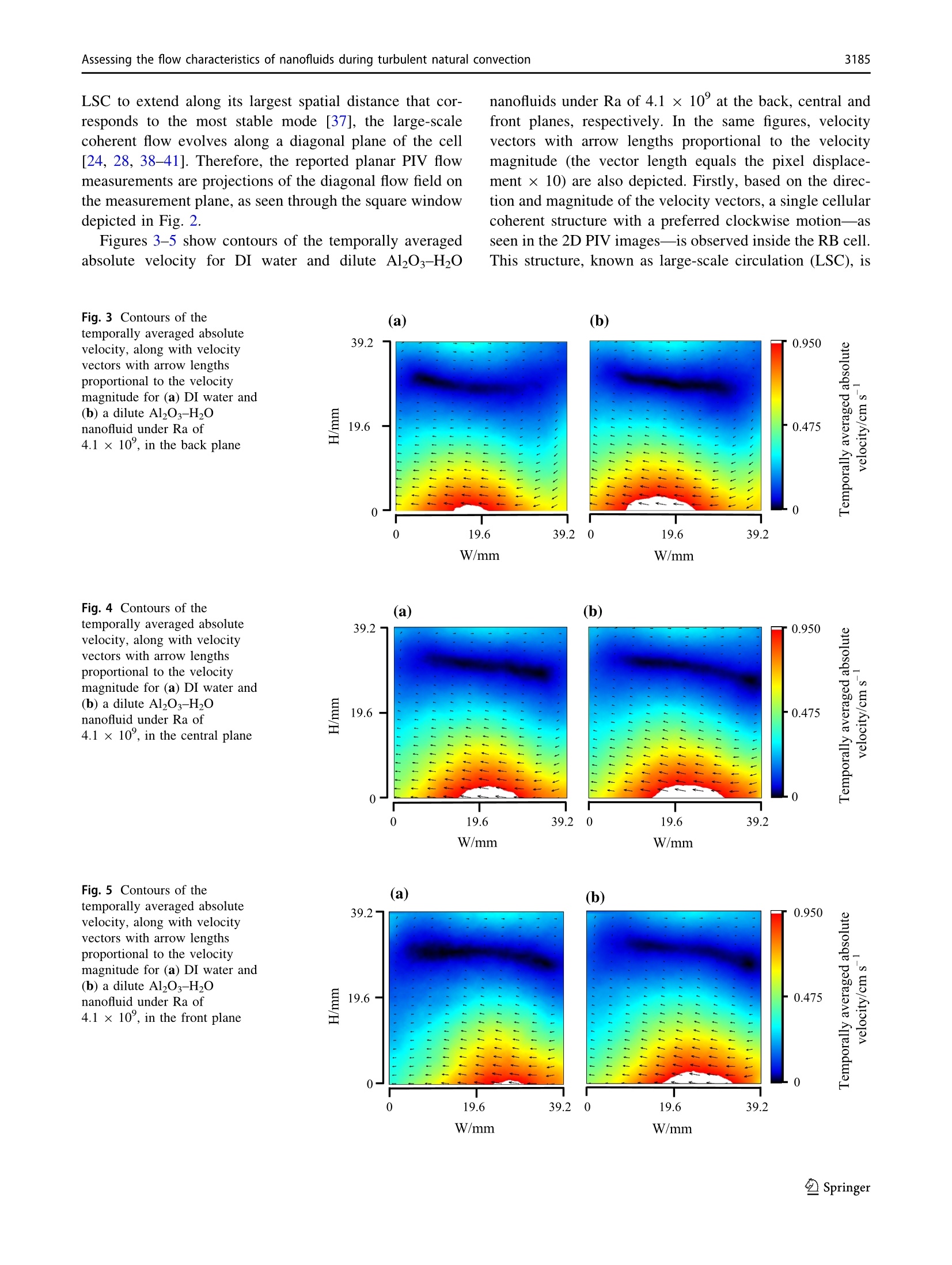

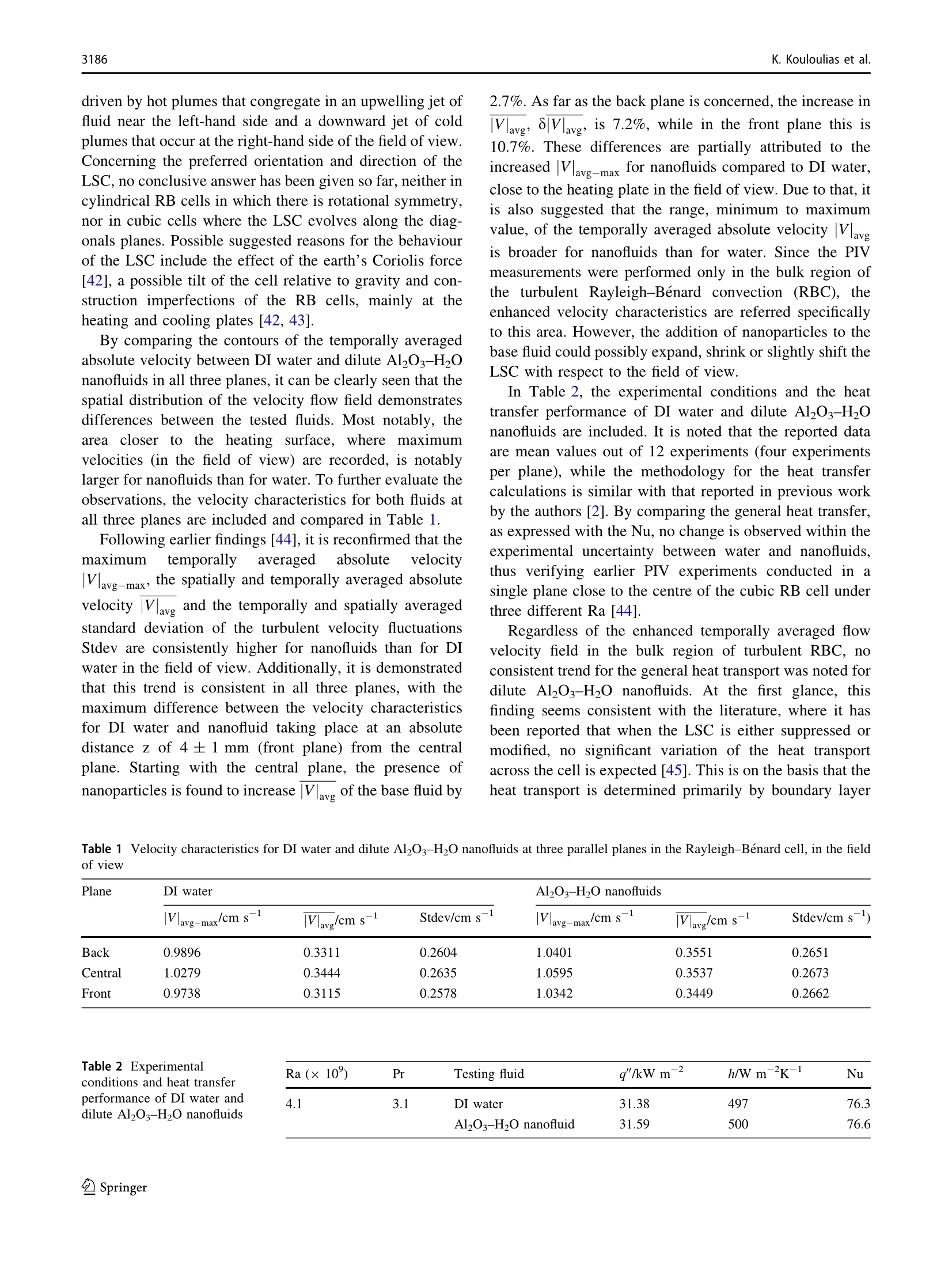

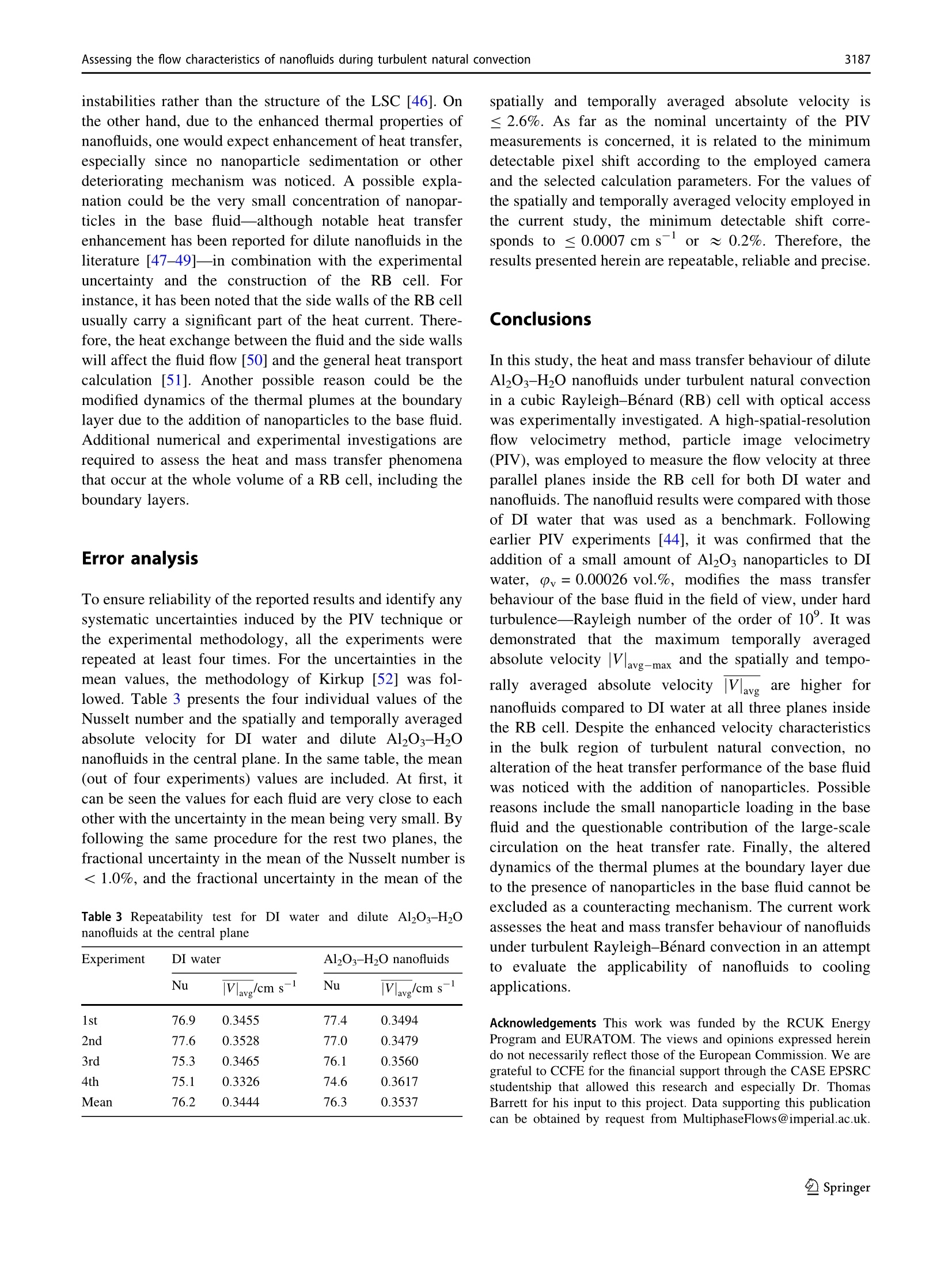

Journal of Thermal Analysis and Calorimetry (2019) 135:3181-3189https://doi.org/10.1007/s10973-018-7631-yCrossMark 3182K. Kouloulias et al. Assessing the flow characteristics of nanofluids during turbulentnatural convection K. Kouloulias· A. Sergis·Y. Hardalupas Received: 13 January 2018/Accepted: 2 August 2018/ Published online: 14 August 2018C The Author(s) 2018 Abstract High-performance cooling is of vital importance for the cutting-edge technology of today, from nanoelectronic mechanicalsystems to nuclear reactors. Advances in nanotechnology have allowed the development of a new category of coolants,termed nanofluids that have the potential to enhance the thermal performance of conventional heat transfer fluids. At thepresent time, nanofluids are a controversial research theme, since there is yet no conclusive answer to explain theunderlying physical mechanisms of heat transfer. The current study investigates experimentally the heat and mass transferbehaviour of dilute Al2O3-H2O nanofluids under turbulent natural convection-Rayleigh number of the order of 10°-in acubic Rayleigh-Benard cell with optical access. Traditional heat transfer measurements were combined with a velocimetrymethod to obtain a deeper understanding of the impact of nanoparticles on the heat transfer performance of the base fluid.Particle image velocimetry was employed to quantify the resulting mean velocity field and flow structures in dilutenanofluids under natural convection, at three parallel planes inside the cubic cell. All the results were compared with thatfor the base fluid, i.e. deionised water. It was observed that the presence of a minute amount of Al2O3 nanoparticles indeionised water, v=0.00026 vol.%, considerably modifies the mass transfer behaviour of the fluid in the bulk region ofturbulent Rayleigh-Benard convection. Simultaneously, the general heat transport, as expressed by the Nusselt number,remained unaffected within the experimental uncertainty. Keywords Nanofluids · Cooling.Turbulent natural convection·Rayleigh-Benard· Particle image velocimetry·Large-scale circulation Mechanical Engineering Department, Imperial CollegeLondon, London SW7 2AZ, UK List of symbolsRa Rayleigh numberlVlavg Temporally averaged absolute velocityStdev Spatially and temporally averaged standard(cms)deviation of the turbulent velocity fluctuationsVI Spatially and temporally averaged absolute(cm s-)iavgvelocity (cm s-)TTemperature (C) 8VlavgPercentage increase of the spatially andTemperature at the wetted surface of thetemporally averaged absolute velocitycooling plate (C)|Vlavg-max Maximum temporally averaged absoluteW Width of the field of view (mask) (mm)velocity (cm s)ATh.c Temperature difference between the heatingH Height of field of view (mask) (mm)and cooling plates (C)h Heat transfer coefficient (Wm-K-l)L Characteristic length (m)Greek symbolsNu Nusselt numberAspect ratioHPrandtl numberNanoparticle volume fraction dHeat flux (kW m)Subscripts区K. Koulouliasavg Averagek.kouloulias13@imperial.ac.ukC Cooling plate h Heating plate V Volume DI Deionised water S Hollow glass spheres LSC Large-scale circulation PIV Particle image velocimetry RB Rayleigh-Benard RBC Rayleigh-Benard convection TEM Transmission electron microscopy Introduction Nanofluids represent a new category of nanotechnology-based fluids engineered by dispersing and stably suspend-ing nanosized particles, fibres or tubes in traditional heattransfer fluids. The employed nanoparticles can be metal-lic, non-metallic or carbon nanotubes and are dispersed inbase fluids, such as water, ethanol, ethylene glycol andengine oil[1-3]. The novelty behind nanofluids is the highsurface-to-volume ratio of nanoparticles that is orders ofmagnitude higher than that of larger particles, such as bymillimetre-and micrometre-sized particles. As a conse-quence, the high surface area of nanoparticles was sug-gested to lead to an enhanced thermal conductivity innanofluids, since more solid surface can take part in heattransfer [4]. Up to the present, nanofluids have attractedsignificant attention [5, 6], due to their intriguing heattransfer properties under various heat transfer modes andtheir potential use in a broad range of applications [7, 8]. An attractive way to assess the heat and mass transportmechanisms in nanofluids is by experimentation underdifferent heat transfer modes that meet extensive applica-bility in nature and engineering systems. One example isnatural convection where only gravitational and buoyantforces are present. Given the controversy among the convection studies in nanofluids, there is an additionalmotivation to exploit the heat and mass transfer propertiesof nanofluids under natural convection that is of primarysignificance for numerous applications in engineering [23],atmospheric and oceanic sciences [24, 25]. Convection is in general the transport of energy due torandom molecular motion (energy diffusion) and bulk, ormacroscopic, motion (advection). It is the progression ofconduction when the temperature variations in a fluid arelarge enough to overcome its resistance to motion. Con-vection can be classified, according to the nature of theflow, to forced convection and free or natural convection.In forced convection, the flow is caused by external means,such as a fan or a pump. In natural convection, the flow isinduced by buoyant forces due to density differences,caused by temperature variations in the fluid. One of themost established models to study buoyancy-driven flowsand the associated heat and mass transport mechanisms isRayleigh-Benard convection (RBC). This involves the useof a relatively simple apparatus, though characterised byincreased controllability, known as Rayleigh-Benard (RB)cell. A typical RB cell is a closed system that contains a fluid,confined between two horizontal parallel plates at a dis-tance L apart. The fluid is heated from the lower plate andcooled from the upper plate, while the insulated side wallscomplete the set-up. For the study of RBC, different RBcells have been employed that vary in aspect ratio T, shape,design and construction materials. Studies of natural con-vection in RB cells have been conducted for low, moderate(~10) and high Rayleigh numbers (> 10) over a broadrange of operating conditions. Based on the resulting flowconditions, two types of natural convection are distin-guished: laminar and turbulent. Turbulent natural convec-tion has mostly attracted the scientific interest, due to thecomplex features associated with turbulence, and theresulting increased heat and mass transfer rates that havebeen reported [26]. In turbulent convection, two discrete states have beenidentified according to the Rayleigh number, Ra, of theflow and the aspect ratio, T, of the employed cell. In cellswith aspect ratios close to unity, a soft turbulent state hasbeen observed for Ra <10’ and hard turbulent state for Rabetween 4 × 10 to 10[27-29], with the difference lyingon the way in which the thermals and plumes develop andtraverse inside. It has been widely reported that, at the hardturbulent state, a large-scale coherent flow exists [30-32],which is self-organised by the hot rising and cold fallingplumes. This flow mode is known as mean wind or large-scale circulation (LSC). Figure 1 illustrates a two-dimen-sional sketch of a typical cubic RB cell, along with theLSC.Up to date, the LSC remains an attractive feature tostudy and further analyse, as the heat transport in turbulent Fig. 1 Schematic drawing of a cubic Rayleigh-Benard cell, depictingthe large-scale circulation natural convection takes place primarily along the periph-ery of the cell, in the direction of the LSC [33]. In thepresent study, traditional heat transfer measurements incombination with a velocimetry method are applied tostudy the heat transfer mechanisms in nanofluids underturbulent RBC. The study of nanofluids under RBC byfocusing on the LSC is an effective way to assess the heattransfer properties of these new coolants, establish theunderlying physical mechanisms and try to resolve thediscrepancy among the natural convection studies. Up tothe authors’knowledge, this is the first available study,given the complexity of employing a high-spatial-resolu-tion flow velocimetry method in nanofluids under turbulentconditions and the challenge of visualising the resultingLSC experimentally. Experimental Experimental set-up A classical Rayleigh-Benard (RB) cell configuration withoptical access is operated in the current study. Figure 2a shows a schematic drawing of the RB cell, including all themajor components. A detailed description of this configu-ration is given in Ref. [2], while a brief overview of itscomponents is included herein. The cell consists of aheating plate, A, at the bottom, a cooling plate, B, at the topand lateral walls, C. It incorporates four quartz windows, 2square (40 mm × 40 mm) and 2 rectangular (10 mm x40 mm), D, to allow laser-based visualisation studies.Teflon plates, E, are inserted among all the conductivecomponents to prevent their thermal connection. Finally,insulating pans, F, and a Plexiglas cover, G, are placedoutside the core of the cell to eliminate heat losses from thesides. A second set of heating elements H is placed belowthe heating plate to prevent any heat losses downwards.The operation of the RB cell is monitored and controlledthrough LabVIEWsoftware, coupled withNationalInstruments hardware and an in-house electrical device thatis connected to the heating plates (A, H) and thermocou-ples placed in the cell. Particle Image Velocimetry Particle image velocimetry (PIV) allows instantaneousplanar measurements of the temporal and spatial distribu-tion of the flow velocity in transparent and semi-transpar-ent fluids. PIV has been already employed to investigateflows of dilute nanofluids (semi-transparent fluids) insidevarious systems, such as a HyperVapotron [34] and a poolboiling apparatus [35]. The PIV technique relies on the useof a laser source to illuminate twice, with a fixed timeinterval, micron-sized tracer (seeding) particles dispersedin the flow, on planes defined by a thin laser sheet. In the current study, PIV was employed for DI water anddilute Al2O3-H2O nanofluids inside the cubic RB cell,through the available optical access. A double-pulsedNd:YAG laser (Nano T 135-15 PIV) was involved, along Fig. 2 Schematic drawing ofthe (a) Rayleigh-Benard celland (b) field of view (mask) forthe laser-based particle imagevelocimetry measurements W/mm with a charge-coupled device (CCD) camera (ImagerIntense, LaVision) that was placed perpendicular to thelaser sheet. The CCD camera has a spatial resolution of1376× 1040 pixel, and it was used to record the dis-placement of the seeding particles between the two laserpulses. A Nikon AF Nikkor 50 mm f/1.4D lens withmanual focus was mounted to the camera. Additionally, abandpass filter (10 nm bandwidth, 532 nm centre wave-length) was attached to the lens to provide enhanced isolation of the Nd:YAG laser light and excellent suppressionin the blocking region. Hollow glass spheres, HGS (80A6011, Dantec Dynam-ics), with a nominal diameter of 10 um and a density of-3..1100 kg m-’ were used as seeding particles. Specifically, asmall amount of HGS pv=0.00045 vol.% (as calculatedthroughhan (optimisationstudy) isBtenough to ensureappropriate and accurate tracking of the fluid flow, whileavoiding any possible change in the properties of the testedfluids. For the range of timescales of the experiments, nosettling of the seeding particles was expected. The othercomponents of the PIV apparatus included: optical com-ponentss for the formulation of the thin. laser sheet(<2 mm), a desktop computer with a programmable tim-ing unit, PTU (LaVision), for the reliable synchronisationof the external devices (laser, CCD camera) and software(DaVis 8.2.2, LaVision) for data acquisition, processingand visualisation. Through DaVis software, 2D images of the instantaneous and temporally averaged flow fields, includingvelocity vectors, are generated. Each 2D velocity vectorwas calculated from an interrogation window of 32 × 32pixel with a 75% overlap. The field of view (mask) for thePIV measurements was39.2 mm x 39.2 mm, slightlysmaller than the square windows, since the data close to theedges of the window, where light reflections could affectthe reliability of the results, are neglected.In Fig. 2b, thefield of view (blue-coloured square) and the Cartesiancoordinates for the analysis of the PIV results are depicted.The applied mask provides access to the flow field estab-lished in a square area located 25.5 mm above the lowerfree surface of the cell and 35.5 mm below the upper freesurface of the cell and 30.5 mm away from the verticallateral walls Nanofluid preparation For the study of the underlying physical mechanisms,“pure” nanofluids, without employing the electrostatic orsteric stabilisation methods, were prepared. Dilute Al203-H2O nanofluids with amean concentration offOv-= 0.00026 vol.% were synthesised by following the two-step preparation method, reported in detail in [2]. Highpurity DI (deionised) water (grade 3, ISO 3696) was used with a nominal pH value of 6.9. However, the presence ofCO2 in the atmosphere and the addition of nanoparticlesaffected the pH of the nanofluids. The selected nanoparti-cles were 70:30 8:yAl203(44931, Alfa Aesar). They werespherical in shape, with an average particle size of 45 nm,as verified by transmission electron microscopy (TEM)[36], and a particle density of 3965 kg m. Experimental procedure A constant temperature gradient between the heating andcooling plates of ATh,c =63.2 ℃ and a constant tempera-ture of Te=26.5℃ at the cooling plate were the boundaryconditions in the current experimental study. The systemhence had two control parameters, Rayleigh,Ra=4.1× 10°, and Prandtl, Pr=3.1, and two responseparameters, Nusselt and Nu, and temporally averagedvelocities, Vavg. PIV measurements were obtained at threedifferent planes in the z direction of the coordinate systemof Fig. 1b inside the cell to record the impact ofnanoparticles on the three-dimensional flow structure andproperties of the base fluid. The first plane was at the centreof the cell,z=0 (central plane), the second was at anabsolute distance z of 3 ±1 mm behind the centre (backplane) and the third was at an absolute distance z of4±1 mm in front of the centre (front plane). The dis-tances of the back and front planes from the central planewere deliberately asymmetric to evaluate the geometricsymmetry and coherency of the LSC. Two thousand independent pairs of images of theinstantaneous flow over a long sampling time, at steadystate conditions (reached after 3 h from onset of theexperiment [2]), were recorded and processed, to producethe temporally averaged velocity measurements. Each laserpulse pair was emitted at a rate of 0.25 Hz, with a timeinterval between the pulses of 24 ms. Both water andnanofluid experiments were repeated at least four times toconfirm the repeatability and reliability in the execution ofthe experiment. To minimise random uncertainties, themean values of four repeated experiments per fluid and perplane are presented and compared. The fractional uncer-tainty in the mean of the spatially and temporally averagedabsolute velocity is ≤2.6%. Additional error analysis isprovided in “Error analysis”section. Results and discussion The RB cell operates under the hard turbulent state, wherethe existence of a large-scale circulation (LSC) that spansthe height of the RB cell is expected to develop, as it hasbeen reported in the literature. Based on the geometry ofthe cell (shape and aspect ratio) and the tendency of the LSC to extend along its largest spatial distance that cor-responds to the most stable mode [37], the large-scalecoherent flow evolves along a diagonal plane of the cell[24, 28, 38-41]. Therefore, the reported planar PIV flowmeasurements are projections of the diagonal flow field onthe measurement plane, as seen through the square windowdepicted in Fig. 2. Figures 3-5 show contours of the temporally averagedabsolute velocity for DI water and dilute Al2O3-H20 nanofluids under Ra of 4.1 x10° at the back. central andfront planes, respectively. In the same figures, velocityvectors with arrow lengths proportional to the velocitymagnitude (the vector length equals the pixel displace-ment x10) are also depicted. Firstly, based on the direc-tion and magnitude of the velocity vectors, a single cellularcoherent structure with a preferred clockwise motion-asseen in the 2D PIV images-is observed inside the RB cell.This structure, known as large-scale circulation (LSC), is Fig. 3 Contours of thetemporally averaged absolutevelocity, along with velocityvectors with arrow lengthsproportional to the velocitymagnitude for (a) DI water and(b) a dilute Al2O3-H2Onanofluid under Ra of4.1x10°, in the back plane Fig.4 Contours of thetemporally averaged absolutevelocity, along with velocityvectors with arrow lengthsproportional to the velocitymagnitude for (a) DI water and(b) a dilute Al203-H2Onanofluid under Ra of4.1 ×10°, in the central plane Fig.5 Contours of thetemporally averaged absolutevelocity, along with velocityvectors with arrow lengthsproportional to the velocitymagnitude for (a) DI water and(b) a dilute Al2O3-H2Onanofluid under Ra of4.1 ×10°, in the front plane driven by hot plumes that congregate in an upwelling jet offluid near the left-hand side and a downward jet of coldplumes that occur at the right-hand side of the field of view.Concerning the preferred orientation and direction of theLSC, no conclusive answer has been given so far, neither incylindrical RB cells in which there is rotational symmetry,nor in cubic cells where the LSC evolves along the diag-onals planes. Possible suggested reasons for the behaviourof the LSC include the effect of the earth’s Coriolis force[42], a possible tilt of the cell relative to gravity and con-struction imperfections of the RB cells, mainly at theheating and cooling plates [42, 43]. By comparing the contours of the temporally averagedabsolute velocity between DI water and dilute Al203-H20nanofluids in all three planes, it can be clearly seen that thespatial distribution of the velocity flow field demonstratesdifferences between the tested fluids. Most notably, thearea closer to the heatingsurface, where maximumvelocities (in the field of view) are recorded, is notablylarger for nanofluids than for water. To further evaluate theobservations, the velocity characteristics for both fluids atall three planes are included and compared in Table 1. Following earlier findings [44], it is reconfirmed that themaximumtemporallyaveraged absolute velocityVavg-max, the spatially and temporally averaged absolutevelocity lVlavg and the temporally and spatially averagedstandard deviation of the turbulent velocity fluctuationsStdev are consistently higher for nanofluids than for DIwater in the field of view. Additionally, it is demonstratedthat this trend is consistent in all three planes, with themaximum difference between the velocity characteristicsfor DI water and nanofluid taking place at an absolutedistance z of 4 ±1 mm (front plane) from the centralplane. Starting with the central plane, the presence ofYnanoparticles is found to increase |Vlavg of the base fluid by 2.7%. As far as the back plane is concerned, the increase inlVlavg, 8|Vlaavvgg, is 7.2%, while in the front plane this is10.7%. These differences are partially attributed to theincreased |Vlavg-max for nanofluids compared to DI water,close to the heating plate in the field of view. Due to that, itis also suggested that the range, minimum to maximumvalue, of the temporally averaged absolute velocity Vlavgis broader for nanofluids than for water. Since the PIVmeasurements were performed only in the bulk region ofthe turbulent Rayleigh-Benard convection (RBC), theenhanced velocity characteristics are referred specificallyto this area. However, the addition of nanoparticles to thebase fluid could possibly expand, shrink or slightly shift theLSC with respect to the field of view. In Table 2, the experimental conditions and the heattransfer performance of DI water and dilute Al2O3-H2Onanofluids are included. It is noted that the reported dataare mean values out of 12 experiments (four experimentsper plane), while the methodology for the heat transfercalculations is similar with that reported in previous workby the authors [2]. By comparing the general heat transfer,as expressed with the Nu, no change is observed within theexperimental uncertainty between water and nanofluids,thus verifying earlier PIV experiments conducted in asingle plane close to the centre of the cubic RB cell underthree different Ra [44]. Regardless of the enhanced temporally averaged flowvelocity field in the bulk region of turbulent RBC, noconsistent trend for the general heat transport was noted fordilute Al203-H2O nanofluids. At the first glance, thisfinding seems consistent with the literature, where it hasbeen reported that when the LSC is either suppressed ormodified, no significant variation of the heat transportacross the cell is expected [45]. This is on the basis that theheat transport is determined primarily by boundary layer Table 1 Velocity characteristics for DI water and dilute Al203-H2O nanofluids at three parallel planes in the Rayleigh-Benard cell, in the fieldof view Plane DI water Al203-H2O nanofluids Vlavg-max /cms lVlavg/cms Stdev/cm s -1 lavg-max /cm s 一1 Vavg/c/cm s Stdev/cm s) Back 0.9896 0.3311 0.2604 1.0401 0.3551 0.2651 Central 1.0279 0.3444 0.2635 1.0595 0.3537 0.2673 Front 0.9738 0.3115 0.2578 1.0342 0.3449 0.2662 Table 2 Experimental conditions and heat transfer Ra (x 109) Pr Testing fluid g"/kWm h/W m-2K-1 Nu performance of DI water and 4.1 3.1 DI water 31.38 497 76.3 dilute Al203-H2O nanofluids Al2O3-H2O nanofluid 31.59 500 76.6 instabilities rather than the structure of the LSC [46]. Onthe other hand, due to the enhanced thermal properties ofnanofluids, one would expect enhancement of heat transfer,especially since no nanoparticle sedimentation or otherdeteriorating mechanism was noticed. A possible expla-nation could be the very small concentration of nanopar-ticles in the base fluid-although notable heat transferenhancement has been reported for dilute nanofluids in theliterature [47-49]—in combination with the experimentaluncertainty and the construction of the RB cell. Forinstance, it has been noted that the side walls of the RB cellusually carry a significant part of the heat current. There-fore, the heat exchange between the fluid and the side wallswill affect the fluid flow [50] and the general heat transportcalculation [51]. Another possible reason could be themodified dynamics of the thermal plumes at the boundarylayer due to the addition of nanoparticles to the base fluid.Additional numerical and experimental investigations arerequired to assess the heat and mass transfer phenomenathat occur at the whole volume of a RB cell, including theboundary layers. Error analysis To ensure reliability of the reported results and identify anysystematic uncertainties induced by the PIV technique orthe experimental methodology, all the experiments wererepeated at least four times. For the uncertainties in themean values, the methodology of Kirkup [52] was fol-lowed. Table 3 presents the four individual values of theNusselt number and the spatially and temporally averagedabsolute velocity for DI water and dilute Al203-H2Onanofluids in the central plane. In the same table, the mean(out of four experiments) values are included. At first, itcan be seen the values for each fluid are very close to eachother with the uncertainty in the mean being very small. Byfollowing the same procedure for the rest two planes, thefractional uncertainty in the mean of the Nusselt number is< 1.0%, and the fractional uncertainty in the mean of the Table 3 Repeatability test for DI water and dilute Al2O3-H2Onanofluids at the central plane Experiment DI water Al2O3-H2Onanofluids Nu lVlavg/cm s Nu VLlavg /cms 1st 76.9 0.3455 77.4 0.3494 2nd 77.6 0.3528 77.0 0.3479 3rd 75.3 0.3465 76.1 0.3560 4th 75.1 0.3326 74.6 0.3617 Mean 76.2 0.3444 76.3 0.3537 spatially and temporally averaged absolute velocity is≤ 2.6%. As far as the nominal uncertainty of the PIVmeasurements is concerned, it is related to the minimumdetectable pixel shift according to the employed cameraand the selected calculation parameters. For the values ofthe spatially and temporally averaged velocity employed inthe current study, the minimum detectable shift corre-sponds to ≤0.0007 cms-or ≈ 0.2%. Therefore, theresults presented herein are repeatable, reliable and precise. Conclusions In this study, the heat and mass transfer behaviour of diluteAl203-H20 nanofluids under turbulent natural convectionin a cubic Rayleigh-Benard (RB) cell with optical accesswas experimentally investigated. A high-spatial-resolutionflowwvelocimetry methOciod, particle imageevelocimetry(PIV), was employed to measure the flow velocity at threeparallel planes inside the RB cell for both DI water andnanofluids. The nanofluid results were compared with thoseof DI water that was used as a benchmark. Followingearlier PIV experiments [44], it was confirmed that theaddition of a small amount of Al2O3 nanoparticles to DIwater, v=0.00026 vol.%, modifies the mass transferbehaviour of the base fluid in the field of view, under hardturbulence-Rayleigh number of the order of 10°. It wasdemonstrated that the maximum temporally averagedabsolute velocity |Vlavg-max and the spatially and tempo-ly averaged absolute velocity lavg are higher fnanofluids compared to DI water at all three planes insidethe RB cell. Despite the enhanced velocity characteristicsin the bulk region of turbulent natural convection, noalteration of the heat transfer performance of the base fluidwas noticed with the addition of nanoparticles. Possiblereasons include the small nanoparticle loading in the basefluid and the questionable contribution of the large-scalecirculation on the heat transfer rate. Finally, the altereddynamics of the thermal plumes at the boundary layer dueto the presence of nanoparticles in the base fluid cannot beexcluded as a counteracting mechanism. The current workassesses the heat and mass transfer behaviour of nanofluidsunder turbulent Rayleigh-Benard convection in an attemptto evaluate the applicability of nanofluids to coolingapplications. Acknowledgements This work was funded by the RCUK EnergyProgram and EURATOM. The views and opinions expressed hereindo not necessarily reflect those of the European Commission. We aregrateful to CCFE for the financial support through the CASE EPSRCstudentship that allowed this research and especially Dr. ThomasBarrett for his input to this project. Data supporting this publicationcan be obtained by request from MultiphaseFlows@imperial.ac.uk. “Funding was provided by Engineering and Physical SciencesResearch Council” Open Access This article is distributed under the terms of the CreativeCommons Attribution 4.0 IInternational License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distri-bution, and reproduction in any medium, provided you give appropriatecredit to the original author(s) and the source, provide a link to theCreative Commons license, and indicate if changes were made. References 1. Buongiorno J. Convective transport in nanofluids. J Heat Transf.2006;128(3):240-50. 2. Kouloulias K, Sergis A. FHardalupas Y. Sedimentation innanofluids during a natural convection experiment. Int J HeatMass Transf. 2016:101:1193-203. 3. Murshed SMS, Leong KC, Yang C, Nguyen N-T. Convectiveheat transfer characteristics of aqueous TiO2 nanofluid underlaminar flow conditions. Int J Nanosci. 2008;7(06):325-31. 4. Baby TT, Sundara R. Synthesis and transport properties of metaloxide decorated graphene dispersed nanofluids. J Phys Chem C.2011;115(17):8527-33. 5. Murshed SMS, Nieto de Castro CA, Lourenco MJV, LopesMLM, Santos FJV. A review of boiling and convective heattransferr withnanofluids.S.FRenewSustainnEnergy Rev.2011;15(5):2342-54. 6. Taylor R, Coulombe S, Otanicar T, Phelan P, Gunawan A, Lv W,et al. Small particles, big impacts: a review of the diverseapplications of nanofluids. J Appl Phys. 2013;113(1):011301. 7. Estelle P, Halelfadl S, Mare T. Thermophysical properties andheat transfer performance of carbon nanotubes water-basednanofluids. J Therm Anal Calorim. 2016;127(3):2075-81. 8. Elsheikh AH, Sharshir SW, Mostafa ME, Essa FA, Ahmed AliMK. Applications of nanofluids in solar energy: a review ofrecent advances. Renew Sustain Energy Rev. 2018;82:3483-502. 9. Sergis A, Hardalupas Y. Anomalous heat transfer modes ofnanofluids: a review based on statistical analysis. Nanoscale ResLett. 2011;6(1):391. 10. Minea AA. Comparative study of turbulent heat transfer ofnanofluids. J Therm Anal Calorim. 2015;124(1):407-16. 11. Xuan Y, Li Q.Investigation on convective heat transfer and flowfeatures of nanofluids. J Heat Transf. 2003;125(1):151. 12. Nayak AK, Gartia MR, Vijayan PK. An experimental investi-gation of single-phase natural circulation behavior in a rectan-gular loop with Al2O3 nanofluids. Exp Therm Fluid Sci.2008;33(1):184-9. 13. Hemmat Esfe M, Saedodin S. Turbulent forced convection heattransfer and thermophysical properties of Mgo-water nanofluidwith consideration of different nanoparticles diameter, anempirical study. J Therm Anal Calorim. 2015;119(2):1205-13. 14. Ma Y, Mohebbi R, Rashidi MM, Yang Z. Study of nanofluidforced convection heat transfer in a bent channel by means oflattice Boltzmann method. Phys Fluids. 2018;30(3):032001. 15. Haddad Z, Oztop HF, Abu-Nada E, Mataoui A. A review onnatural convective heat transfer of nanofluids. Renew SustainEnergy Rev. 2012;16(7):5363-78. 16. Savithiri S, Pattamatta A, Das SK. A single-component nonho-mogeneous lattice boltzmann model for natural convection inAl2O3/water rnanofluid. Numer Heat Transf A Appl.2015;68(10):1106-24. 17. Ho CJ, Chen MW, Li ZW. Numerical simulation of naturalconvection of nanofluid in a square enclosure: effects due to uncertainties ofviscosity and thermal conductivity. Int J HeatMass Transf. 2008;51(17-18):4506-16. 18. Boualit A, Zeraibi N, Chergui T, Lebbi M, Boutina L, Laouar S.Natural convection investigation in square cavity filled withnanofluid using dispersion model. Int J Hydrogen Energy.2017;42(13):8611-23. 19. Hafad Bara E, El Hamdani S, Bendou A, Limam K. Parametricstudy on natural convection of nanofluids in a heated chamber.Energy Proc. 2017;139:424-9. 20. Li CH, Peterson GP. Experimental studies of natural convectionheat transfer of Al2O3/DI water nanoparticle suspensions(nanofluids). Adv Mech Eng. 2010;2:742739. 21. Wen D, Ding Y. Natural convective heat transfer of suspensionsof titanium dioxide nanoparticles (nanofluids). IEEE TransNanotechnol. 2006;5(3):220-7. 22. Ni R, Zhou S-Q, Xia K-Q. An experimental investigation ofturbulent thermal convection in water-based alumina nanofluid.Phys Fluids. 2011;23(2):022005. 23. Ilyas SU, Pendyala R, Narahari M. An experimental study on thenatural convection heat transfer in rectangular enclosure usingfunctionalized alumina-thermal oil-based nanofluids. Appl ThermEng. 2017;127:765-75. 24. Xia KQ, Sun C, Zhou SQ. Particle image velocimetry measure-ment of the velocity field in turbulent thermal convection. PhysRev E. 2003;68(6):066303. 25. Fernando HJS. Handbook of environmental fluid dynamics, vol-ume one: overview and fundamentals. Boca Raton: Taylor &Francis Group; 2013. 26. Rohsenow WM, Harnett JP, Cho YI. Handbook of heat transfer.3rd ed. New York: McGraw-Hill; 1998. 27. Heslot F, Castaing B, Libchaber A. Transitions to turbulence inhelium gas. Phys Rev A. 1987;36(12):5870-3. 28. Zocchi G, Moses E, Libchaber A. Coherent structures in turbulentconvection. an experimental study. Phys A.1990;166(3):387-407. 29. Castaing B, Gunaratne G, Heslot F, Kadanoff L, Libchaber A,Thomae S, et al. Scaling of hard thermal turbulence in Rayleigh-Benard convection.J Fluid Mech. 2006;204:1-30. 30. Krishnamurti R, Howard LN. Large-scale flow generation inturbulent convection. Proc Natl Acad Sci USA.1981;78(4):1981-5. 31. Sano M, Wu XZ, Libchaber A. Turbulence in helium-gas freeconvection. Phys Rev A. 1989;40(11):6421-30. 32. Qiu XL, Tong P. Large-scale velocity structures in turbulentthermal convection. Phys Rev E. 2001;64:036304. 33. Shang XD, Qiu XL, Tong P, Xia KQ. Measured local heattransport in turbulent Rayleigh-Benard convection. Phys RevLett. 2003;90(7):074501. 34. Sergis A, Hardalupas Y, Barrett TR. Potential for improvement inhigh heat flux HyperVapotron element performance usingnanofluids. Nucl Fus. 2013;53(11):113019. 35. Dominguez-Ontiveros E, Fortenberry S, Hassan YA. Experi-mental observations of flow modifications in nanofluid boilingutilizingparticle image velocimetry. Nucl Eng Des.2010;240(2):299-304. 36. Kouloulias K, Sergis A, Hardalupas Y, editors. The influence ofnanofluid pH on natural convection. In: 12th International con-ference on heat transfer, fluid mechanics and thermodynamics(HEFAT2016); 11-13 July 2016; Costa del Sol, Spain. 37. Sun C, Xia KQ, Tong P. Three-dimensional flow structures anddynamics of turbulent thermal convection in a cylindrical cell.Phys Rev E. 2005;72:026302. 38. Qiu XL, Xia KQ. Viscous boundary layers at the sidewall of aconvection cell. Phys Rev E. 1998;58(1):486-91. 39. Aziz K. Numerical solution of the three-dimensional equations ofmotion for laminar natural convection. Phys Fluids.1967;10(2):314-24. 40. Foroozani N, Niemela JJ, Armenio V, Sreenivasan KR. Influenceof container shape on scaling of turbulent fluctuations in con-vection. Phys Rev E. 2014;90(6):063003. ( 41. Foroozani N, Niemela J J, Armenio V , Sreenivasan K R. Reori-entations of the large-scale flow in turbulent convection in a c ube. Phys Rev E. 2017;95(3-1):033107. ) ( 42. Brown E , A h lers G. Effect of the e a rth’s coriolis force on the large-scale circulation of turbulent Rayleigh-Benard c o nvection.Phys F luids. 2006;18(12):125108. ) ( 43. Weiss S, Ahlers G . E f fect o f t i lting on t urbulent c onvection: cylindrical samples with aspect ratio T=0.50. J F l uid M e ch.2013;715:314-34. ) ( 44. K ouloulias K, Sergis A, Hardalupas Y , Barrett T R . M e asurementof flow velocity during turbulent natural convection in nanofluids. F us Eng D es. 2 017;123:72-6. ) 45. Ciliberto S, Cioni S, Laroche C. Large-scale flow properties ofturbulent thermal convection. Phys Rev E. 1996;54(6):R5901-4. 46. Ahlers G, Grossmann S, Lohse D. Heat transfer and large scaledynamics in turbulent Rayleigh-Benard convection. Rev ModPhys. 2009;81(2):503-37. 47. Murshed SMS, Milanova D, Kumar R, editors. An experimentalstudy of surface tension-dependent pool boiling characteristcs ofcarbon nanotubes-nanofluids. In: Proceedings of the ASME 20097th international conference on nanochannels, microchannels andminichannels (ICNMM2009); June 22-24, 2009; Pohang, SouthKorea. 48. Kumar DH, Patel HE, Kumar VR, Sundararajan T, Pradeep T,Das SK. Model for heat conduction in nanofluids. Phys Rev Lett.2004;93(14):144301. 49. Patel HE,Das SK, Sundararajan T, Sreekumaran Nair A, GeorgeB, Pradeep T. Thermal conductivities of naked and monolayerprotected metal nanoparticle based nanofluids: manifestation ofanomalous enhancement and chemical effects. Appl Phys Lett.2003;83(14):2931-3. 50. Brown E, Nikolaenko A, Funfschilling D, Ahlers G. Heat trans-port in turbulent Rayleigh-Benard convection: effect of finitetop-and bottom-plate conductivities. Phys Fluids.2005;17(7):1-10. 51. Ahlers G. Effect of sidewall conductance on heat-transportmeasurements for turbulent Rayleigh-Benard convection. PhysRev E. 2001;63:015303. 52. Kirkup L. Experimental methods: an introduction to the analysisand presentation of data. Hoboken: Wiley; 1994. Springer High-performance cooling is of vital importance for the cutting-edge technology of today, from nanoelectronic mechanical systems to nuclear reactors. Advances in nanotechnology have allowed the development of a new category of coolants,termed nanofluids that have the potential to enhance the thermal performance of conventional heat transfer fluids. At thepresent time, nanofluids are a controversial research theme, since there is yet no conclusive answer to explain the underlying physical mechanisms of heat transfer. The current study investigates experimentally the heat and mass transfer behaviour of dilute Al2O3–H2O nanofluids under turbulent natural convection—Rayleigh number of the order of 109—in acubic Rayleigh–Be´nard cell with optical access. Traditional heat transfer measurements were combined with a velocimetry method to obtain a deeper understanding of the impact of nanoparticles on the heat transfer performance of the base fluid. Particle image velocimetry was employed to quantify the resulting mean velocity field and flow structures in dilutenanofluids under natural convection, at three parallel planes inside the cubic cell. All the results were compared with that for the base fluid, i.e. deionised water. It was observed that the presence of a minute amount of Al2O3 nanoparticles in deionised water, uv = 0.00026 vol.%, considerably modifies the mass transfer behaviour of the fluid in the bulk region ofturbulent Rayleigh–Be´nard convection. Simultaneously, the general heat transport, as expressed by the Nusselt number, remained unaffected within the experimental uncertainty.

确定

还剩7页未读,是否继续阅读?

北京欧兰科技发展有限公司为您提供《纳米流体中PIV, 流体速度矢量场检测方案(CCD相机)》,该方案主要用于其他中PIV, 流体速度矢量场检测,参考标准--,《纳米流体中PIV, 流体速度矢量场检测方案(CCD相机)》用到的仪器有德国LaVision PIV/PLIF粒子成像测速场仪、LaVision DaVis 智能成像软件平台

推荐专场

相关方案

更多

该厂商其他方案

更多