方案详情

文

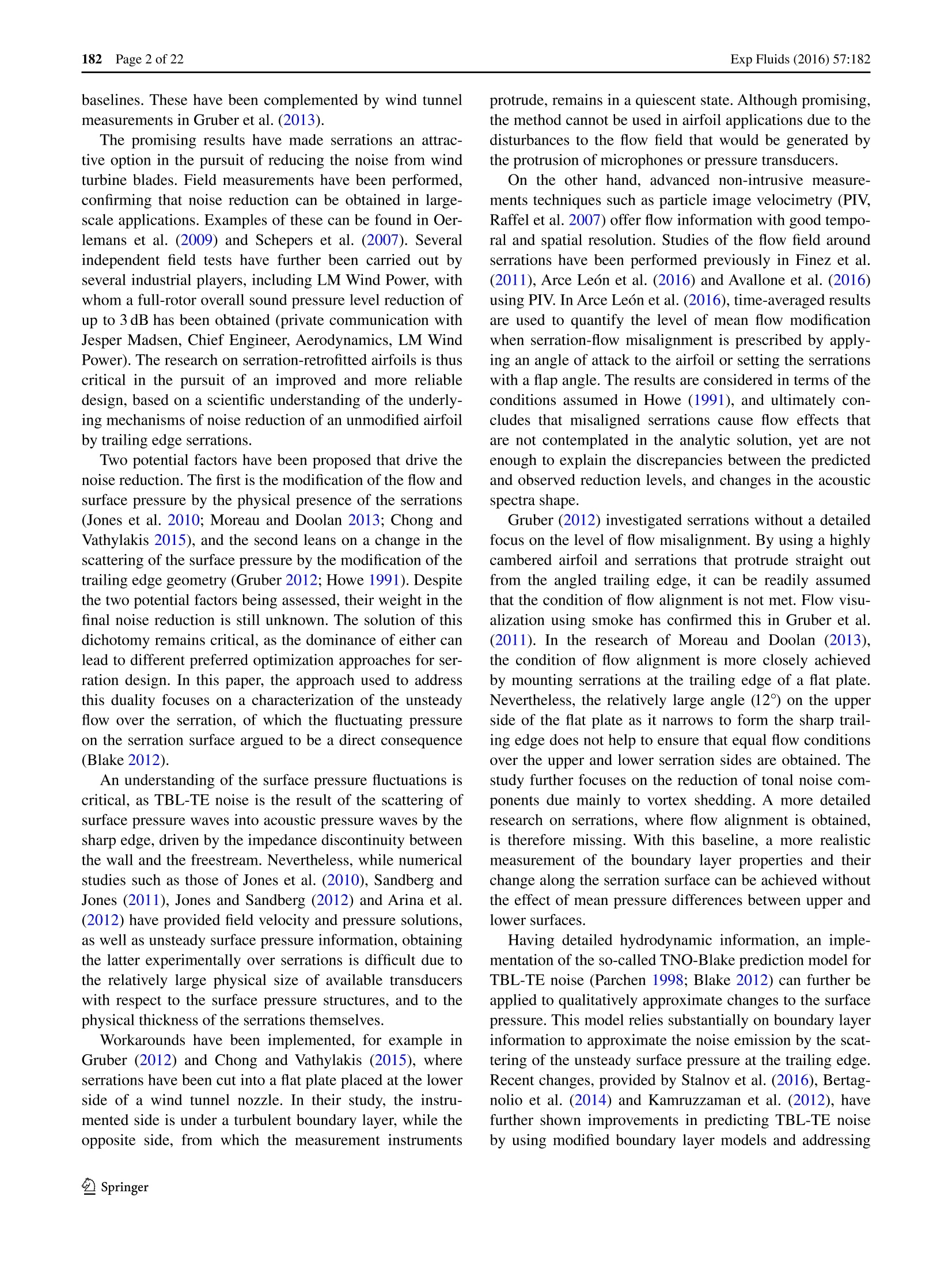

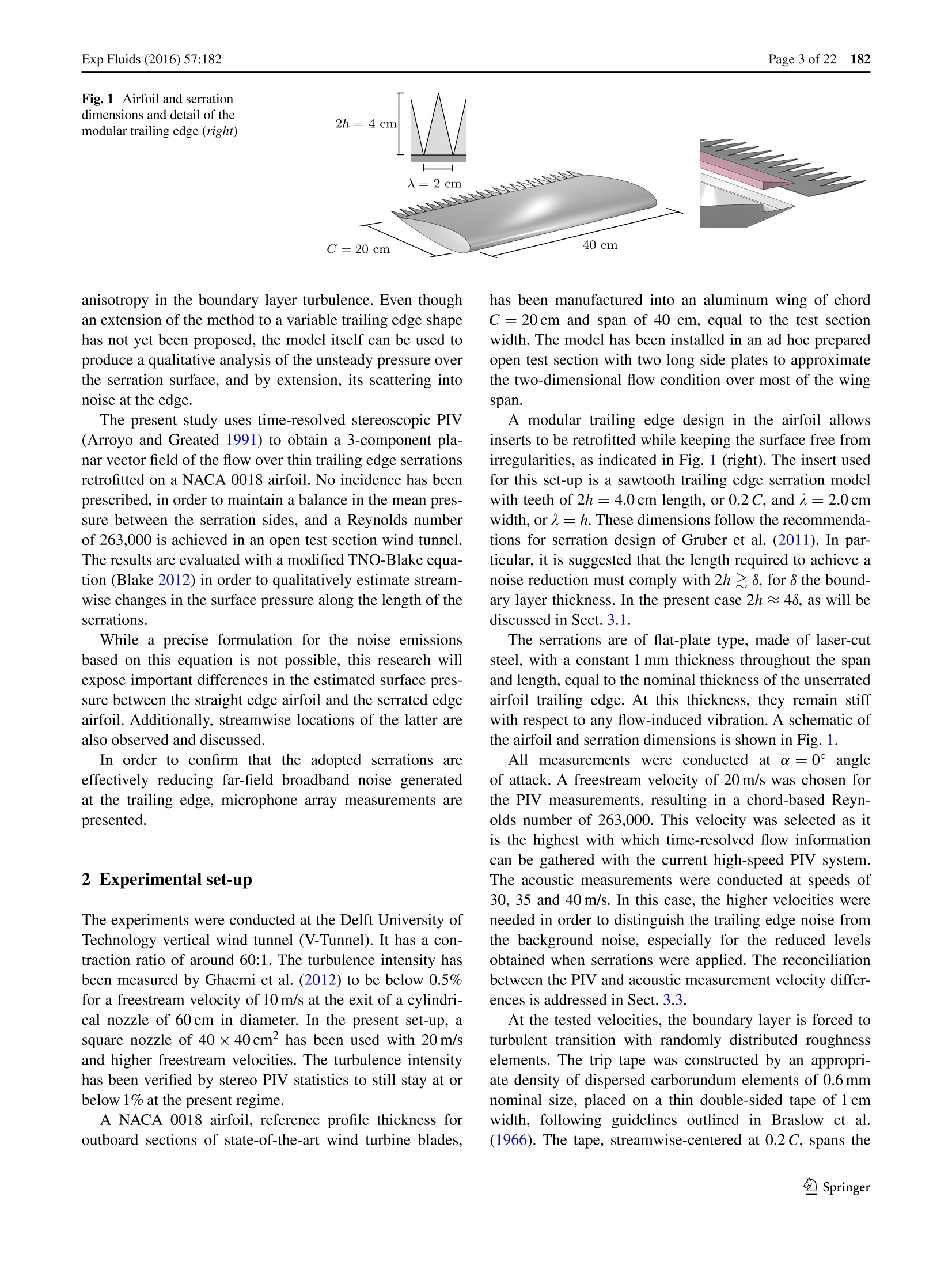

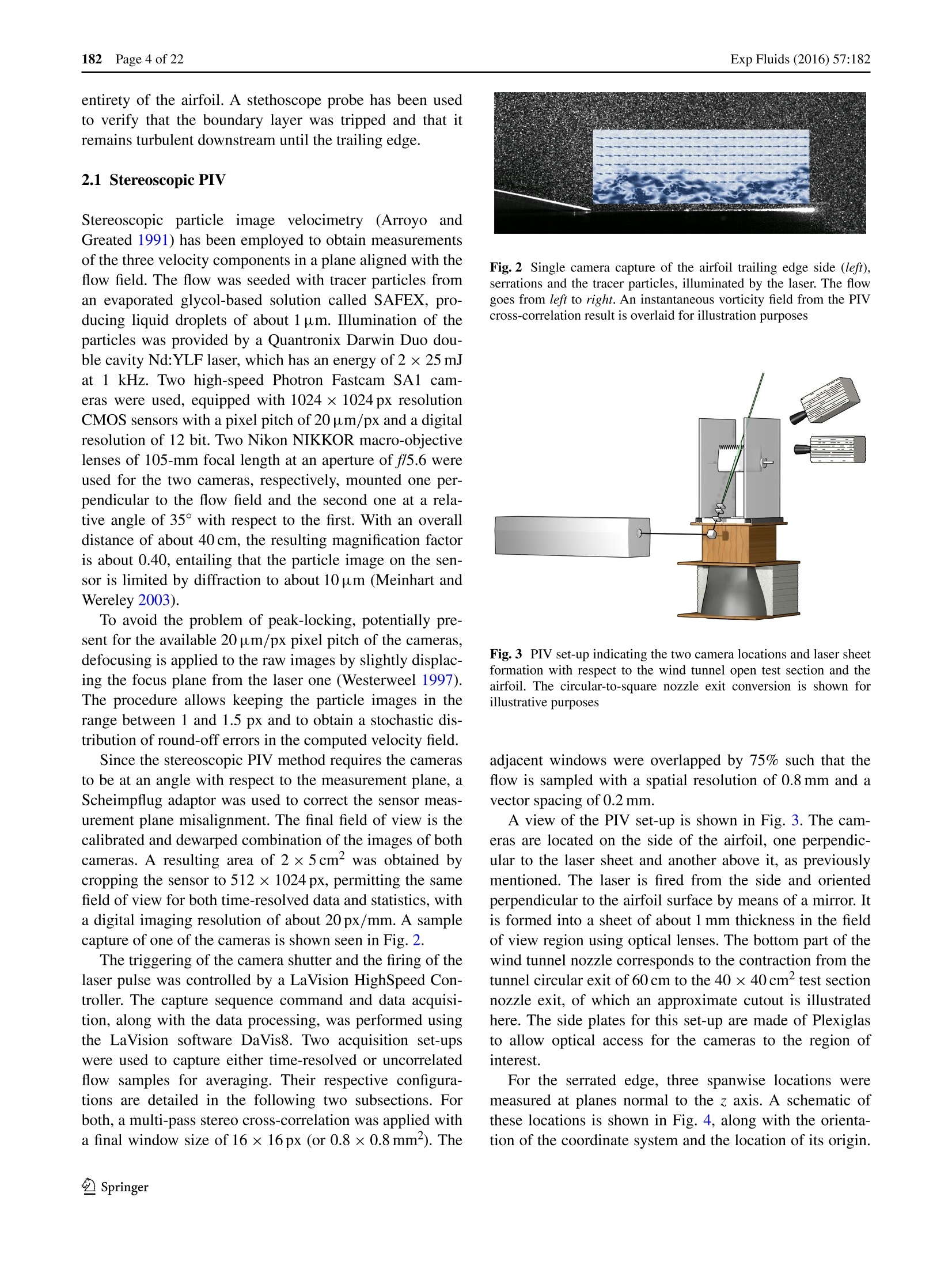

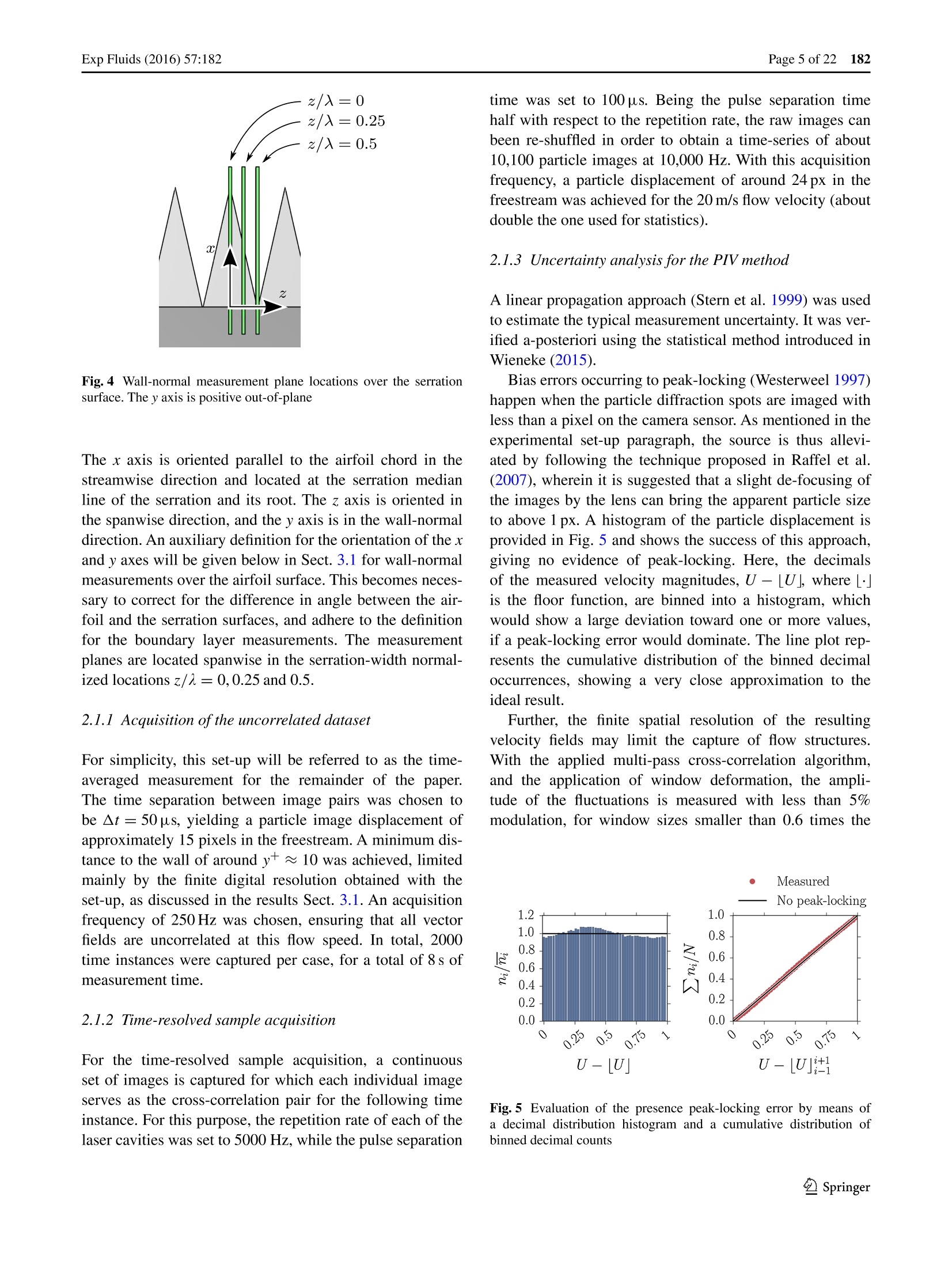

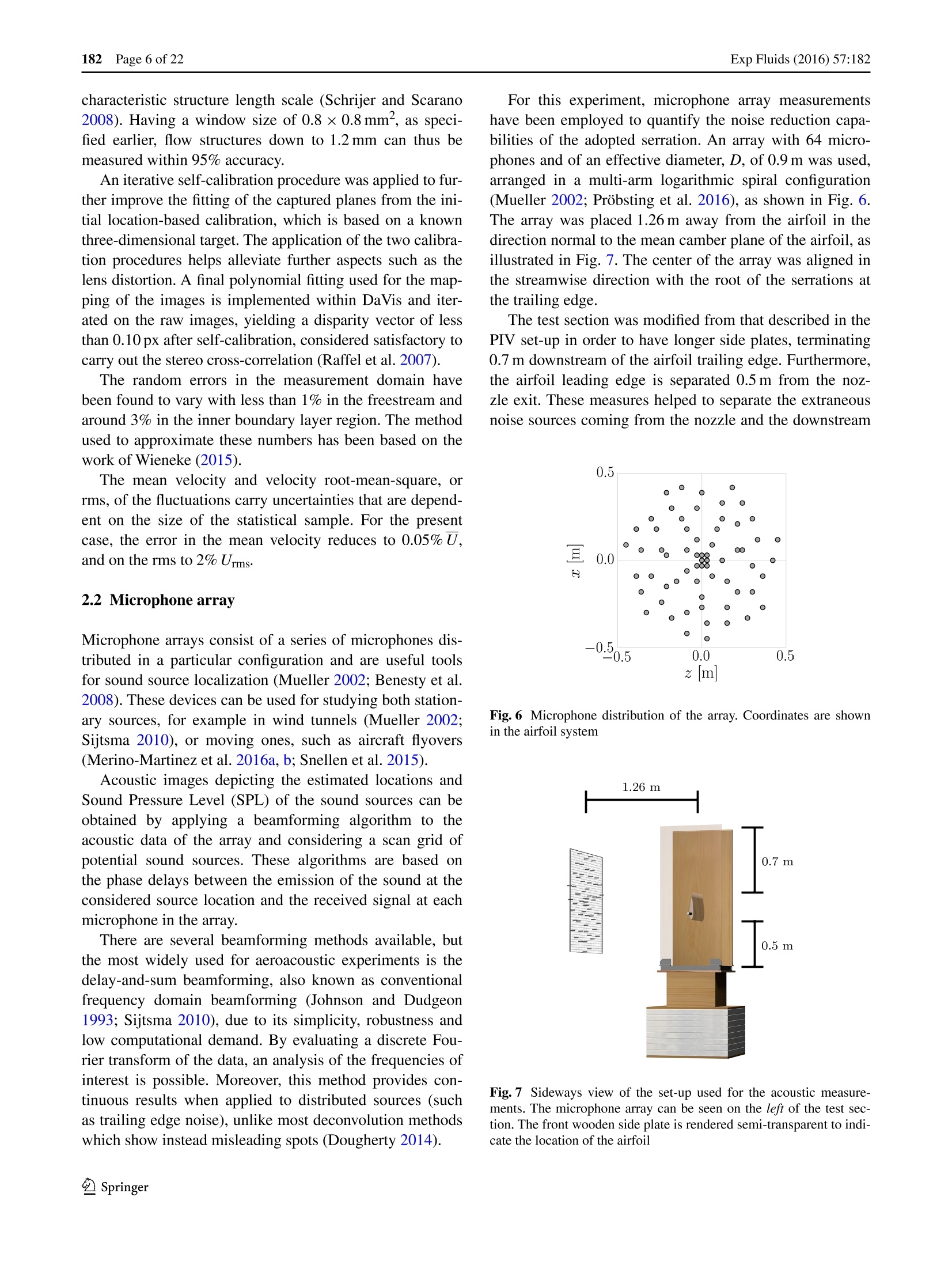

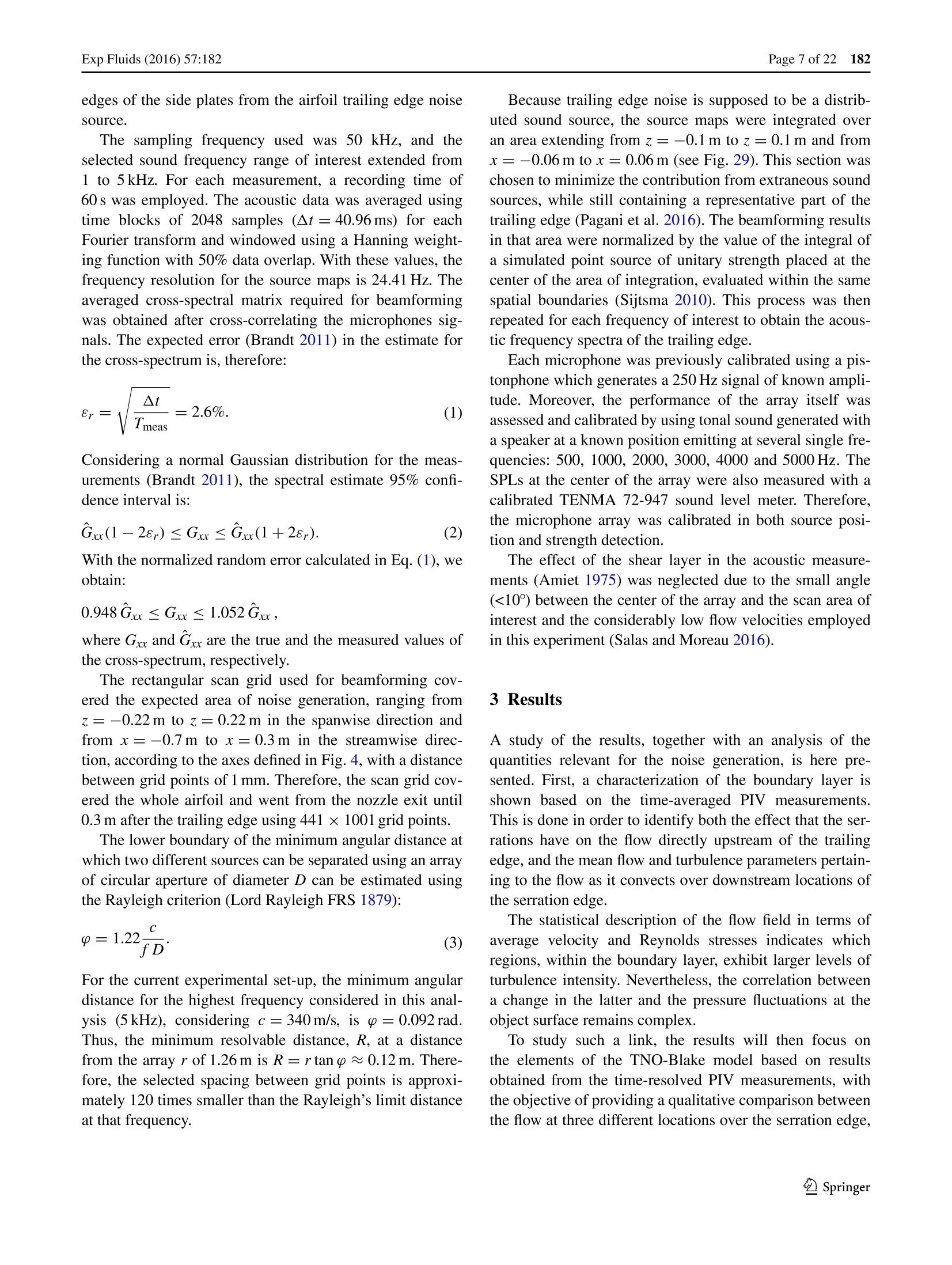

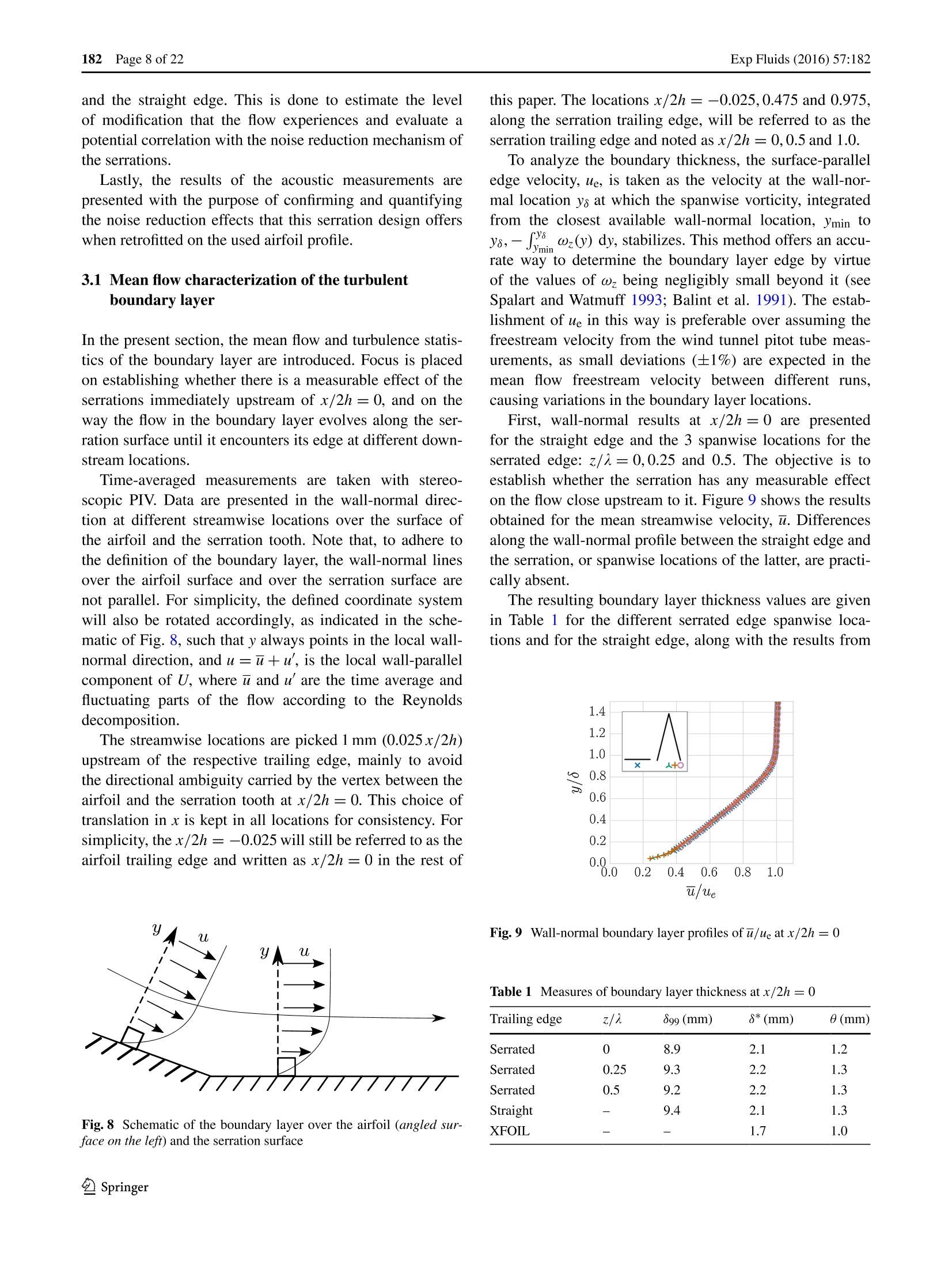

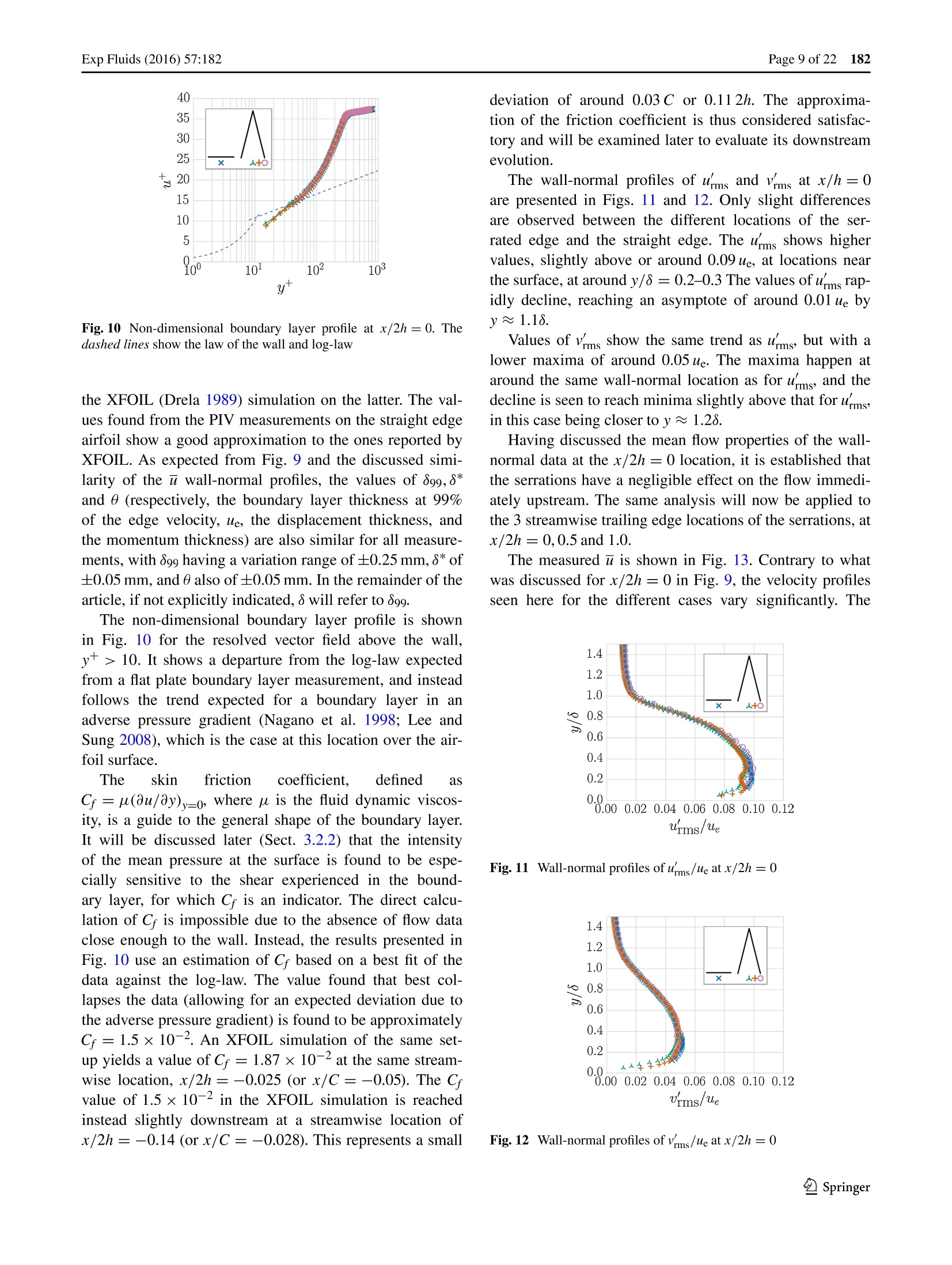

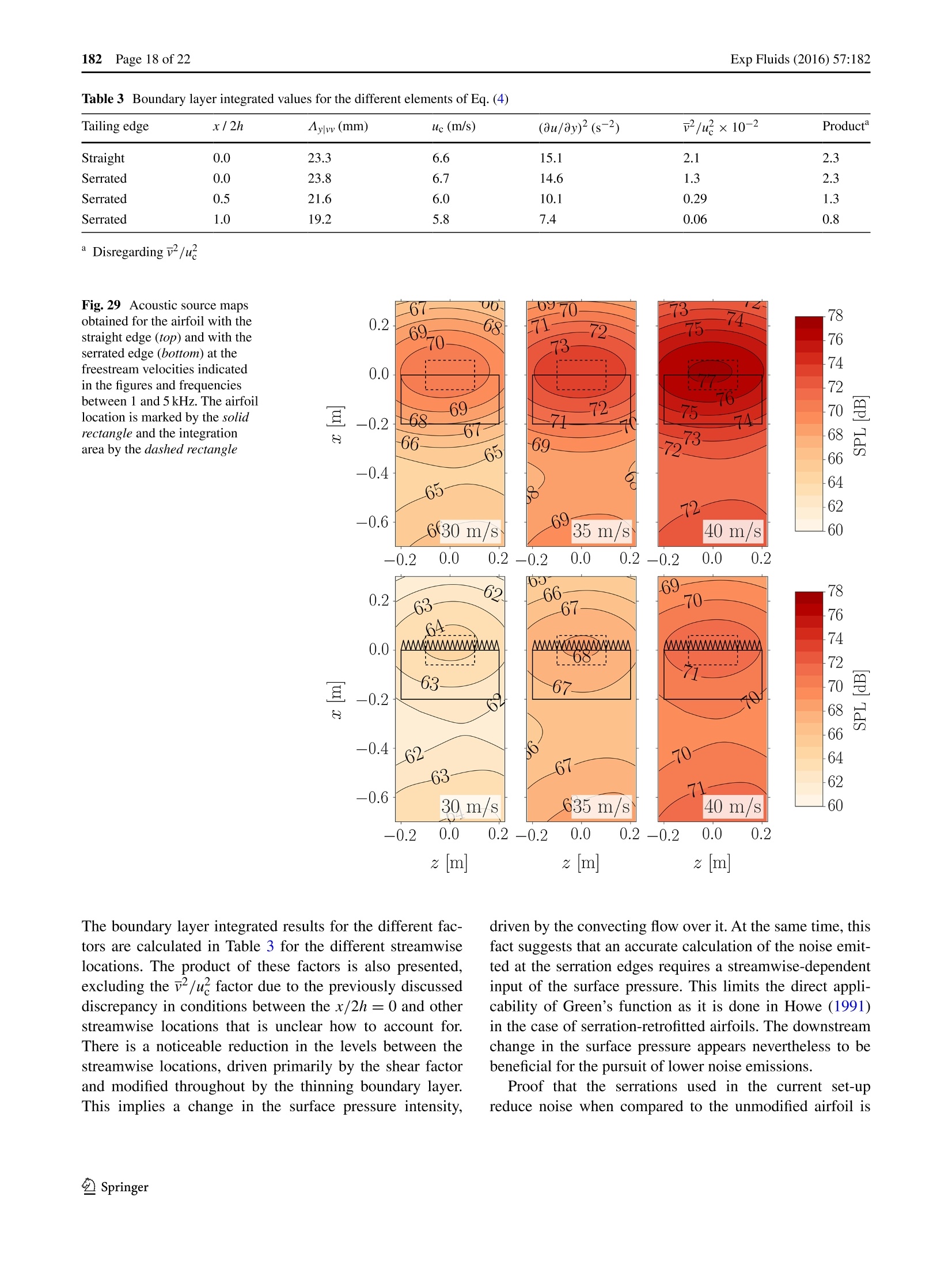

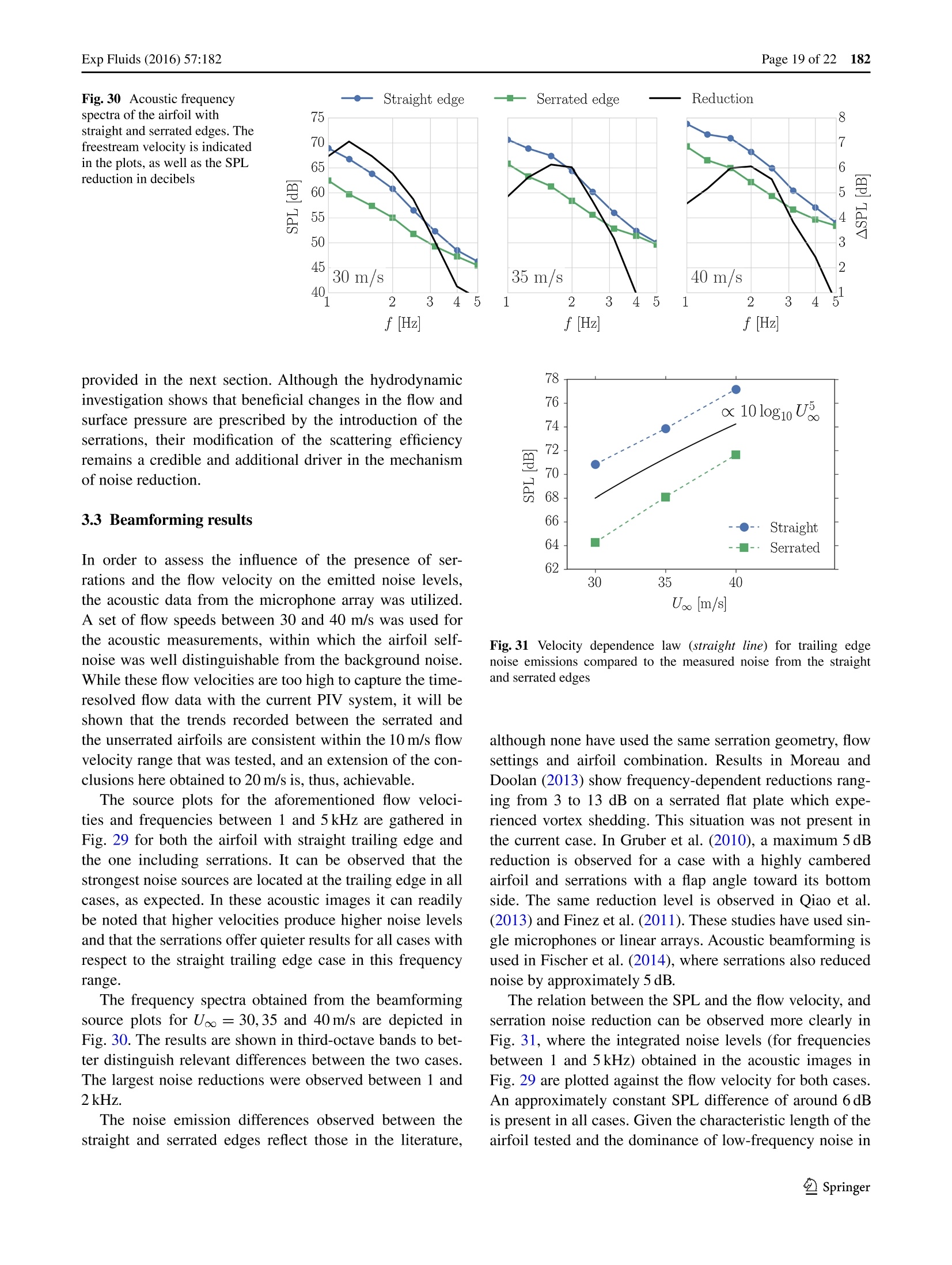

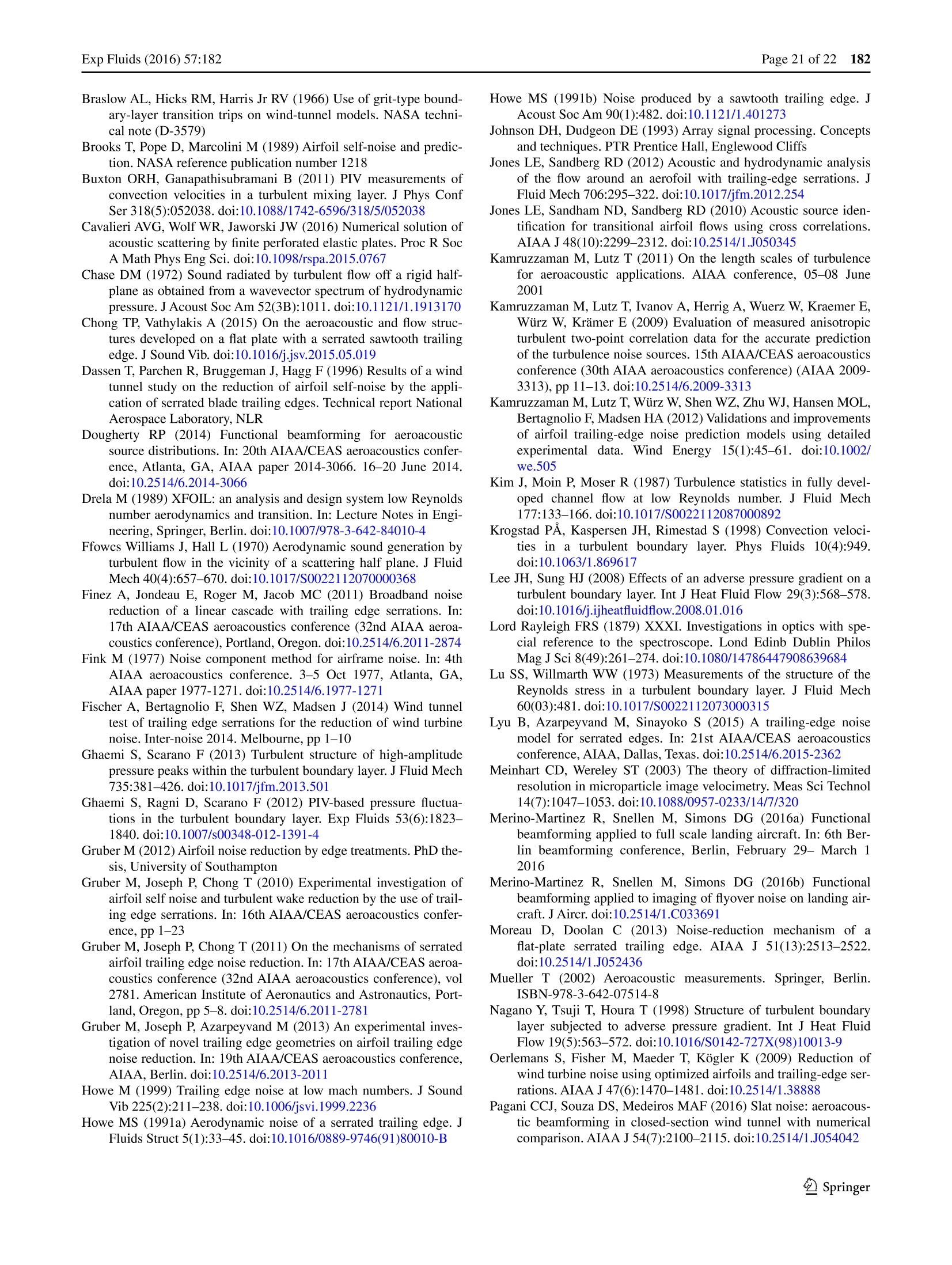

采用一台Quantronix公司生产的Darwin Duo型双腔Nd:YLF激光器作光源。该激光器输出2 × 25 mJ 单脉冲能量,重复频率1 kHz。采用两台Photron Fastcam SA1 相机作成像器件。构成一套时间分辨高重复频率立体3维粒子成像测量系统。对NACA 0018翼型,加装整齐排列的锯齿状后缘时的流动的边界层特性和声学特性进行了测量。和未加装翼型的特性做比较,得到加装锯齿状后缘,可降低气动噪声的结论。

方案详情