方案详情

文

采用LaVison公司的智能成像测量系统中的平面激光诱导荧光测量方法,用丙酮做示踪剂,研究了超音速气体引射器中的混合过程。

方案详情

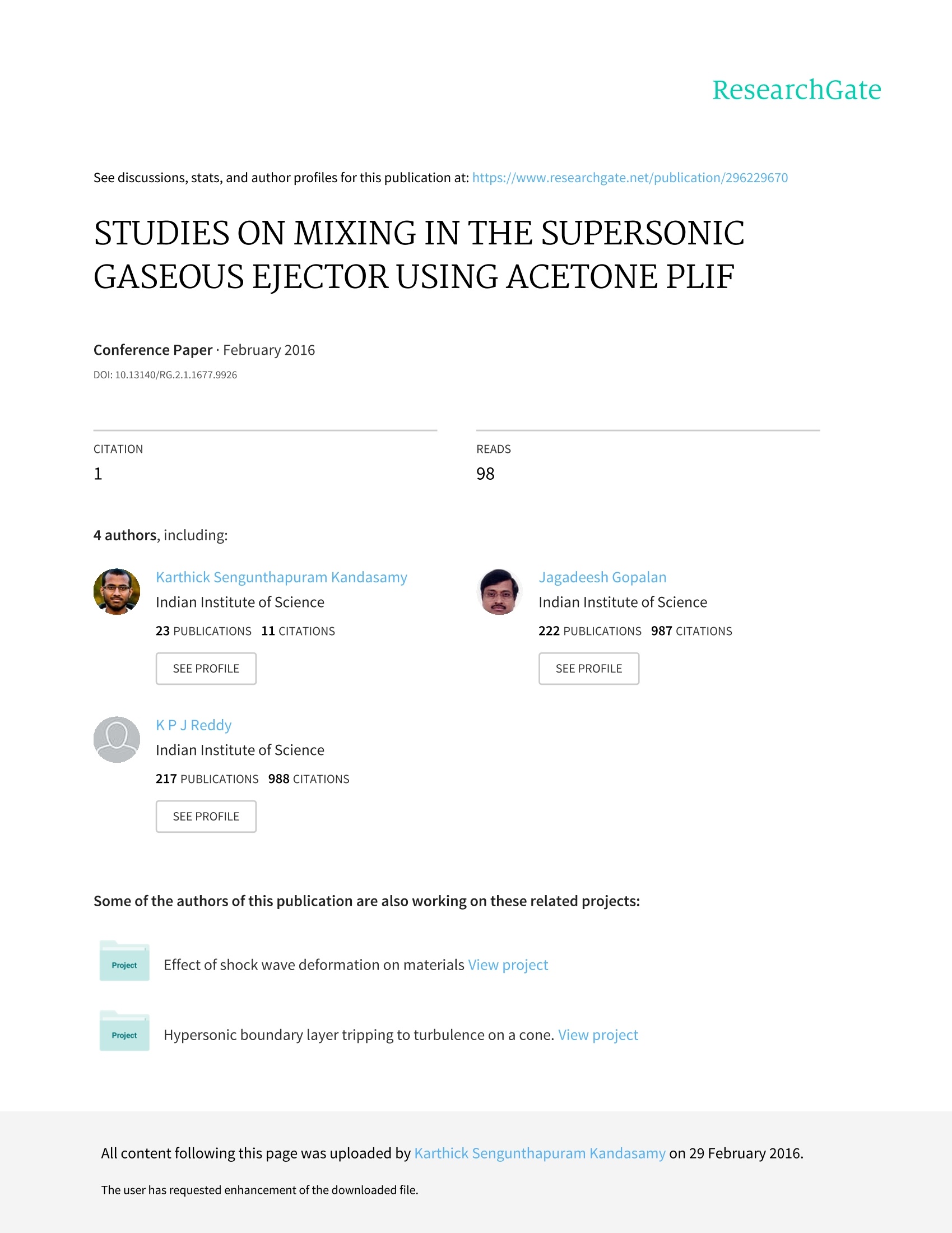

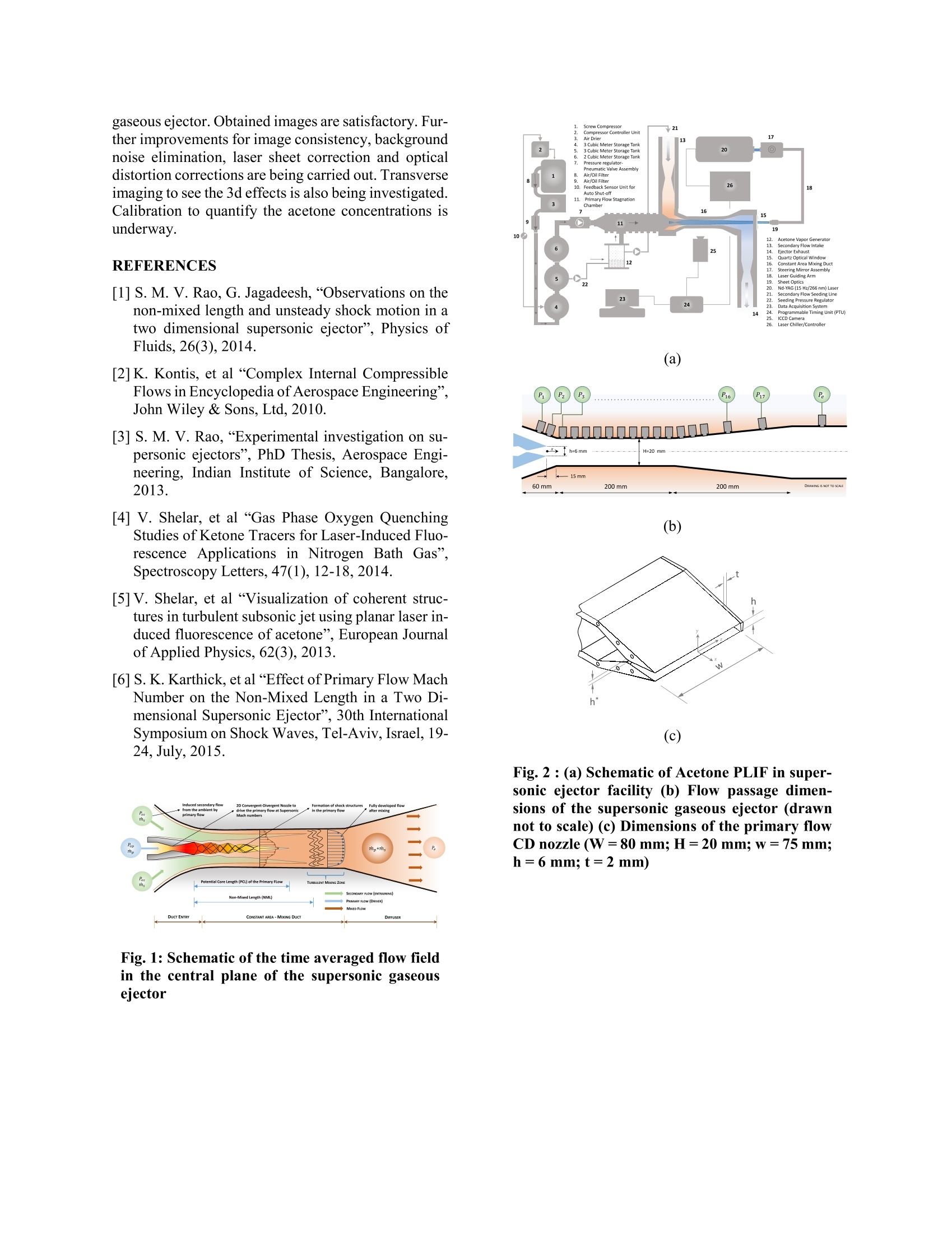

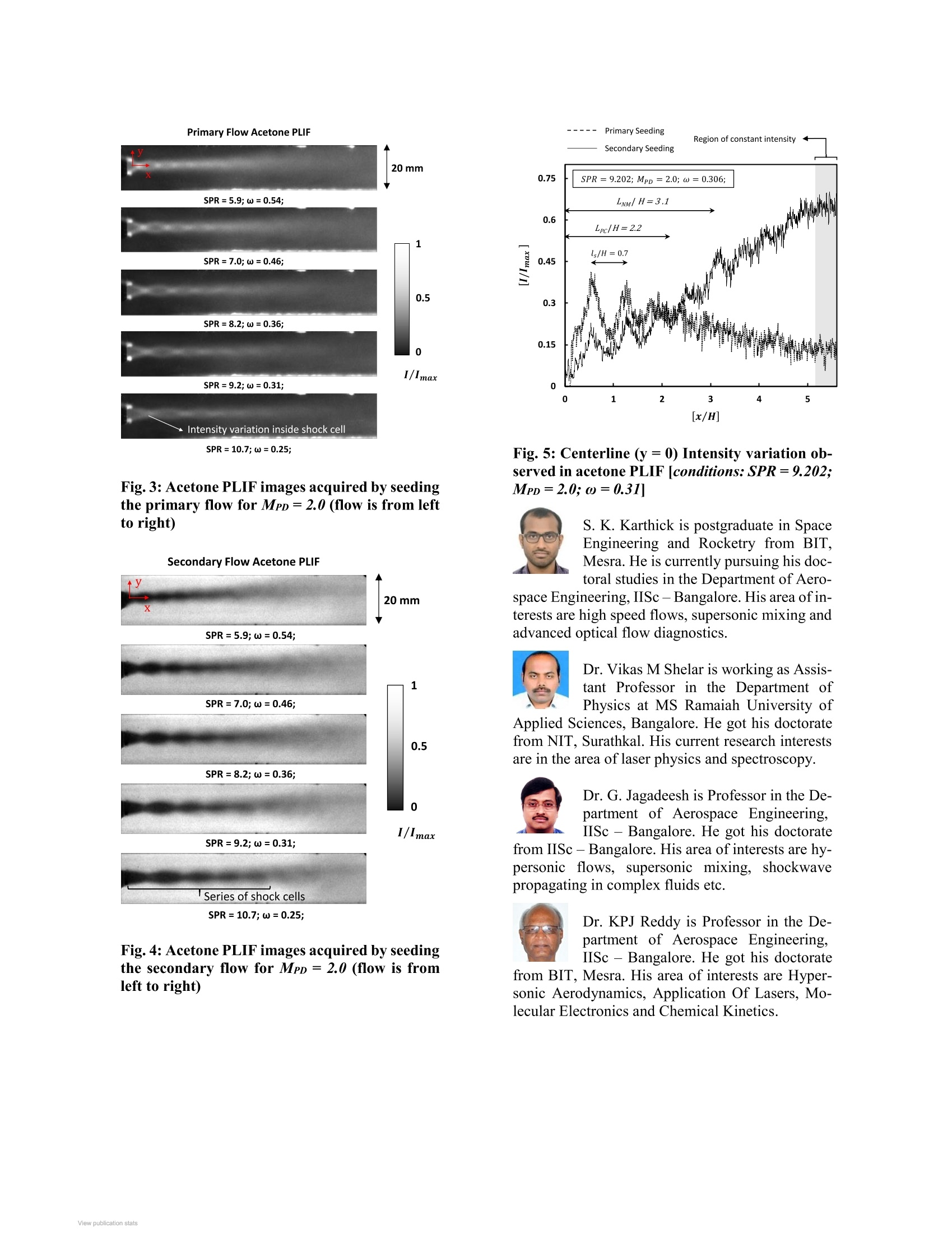

ResearchGateView publication stats See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/296229670 STUDIES ON MIXING IN THE SUPERSONICGASEOUS EJECTOR USING ACETONE PLIF Conference Paper· February 2016 DOI: 10.13140/RG.2.1.1677.9926 READS CITATION198 4 authors,including: Karthick Sengunthapuram KandasamyIndian Institute of Science Jagadeesh GopalanIndian Institute of Science 23 PUBLICATIONS 11 CITATIONS 222 PUBLICATIONS 987 CITATIONS SEE PROFILE SEE PROFILE K PJReddy Indian Institute of Science 217 PUBLICATIONS 988 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: Project Effect of shock wave deformation on materials View project Project Hypersonic boundary layer tripping to turbulence on a cone. View project All content following this page was uploaded by Karthick Sengunthapuram Kandasamy on 29 February 2016.The user has requested enhancement of the downloaded file. STUDIES ON MIXING IN THE SUPERSONIC GASEOUS EJECTORUSING ACETONE PLIF S. K. Karthick, Vikas M Shelar’, G.Jagadeesh and K. P. J. Reddyl 'Department of Aerospace Engineering, Indian Institute of Science, Bangalore, 560012, India skkarthick@ymail.com,jaggie@aero.iisc.ernet.in&laser@aero.iisc.ernet.in Department of Physics, M. S. Ramaiah University of Applied Sciences, Bengaluru, 560 058, Indiavikas.pi.sh@msruas.ac.in ABSTRACT Supersonic mixing studies are important in the design and development of efficient supersonicejectors. As a gas-dynamic device, supersonic ejector pumps up the secondary flow using thehigher kinetic energy of the primary flow itself. Conventional techniques have limited access toacquire data in such kind of flows to calculate the mixing efficiency.Reacting flows poses furtherchallenge in instrumentation. Experiments in cold flows manage to reveal important aspects onsupersonic mixing. Advanced optical flow diagnosis helps in probing the flow without large intru-sion. One of such non-intrusive flow diagnostics is Acetone PLIF. A low area ratio supersonicejector, operating at a Mpp of 2.0 for the range of Pop from 4.89 bar to 8.89 bar is taken intoconsideration for this experiment. Secondary air intake duct is kept open during this operation andthe ejector is operated in the mixed flow regime. Concentration distribution is qualitatively evalu-ated in this experimentation and few basic flow features are captured. Diffusion of secondary flowinto the primary flow and thickening mixing layers are clearly captured. NML computed fromPLMS experiments are also cross verified with current experiments as the mixing process is foundto be happening well above the NML as expected. Keywords: Acetone PLIF, Supersonic Ejector, Supersonic Mixing width Supersonic mixing[1] studies are important in thedesign and development of efficient Scramjet engines,Supersonic Ejector[2] etc. The flow process through asupersonic ejector is dominated by the interaction be-tween the secondary stream and primary stream,which happens through a supersonic mixing layer. Thegas-dynamics of this mixing process is complex, threedimensional and unsteady. A typical time averagedflow field encountered in the central plane of the su-personic gaseous ejector is illustrated in Fig. 1. React-ing flows pose challenges in instrumentation and con-ventional techniques have limited access to acquiredata in such kind of wall bounded flows, especially su-personic mixing. Experiments in cold flows manage toreveal important aspects on supersonic mixing and ad-vanced optical flow diagnostics helps in probing theflow with minimal intrusion. One of such non-intru-sive flow diagnostics is acetone PLIF. Studies on theaspects of mixing between the supersonic primaryflow and the entrained subsonic secondary flow in arectangular supersonic gaseous (air-air) ejector usingacetone PLIF will be presented here. Experimental methodology and preliminary observations are elabo-rated as the work is under progress. 2.EXPERIMENTAL SETUP A typical layout of the established supersonicejector facility [3] where mixing studies are performedusing acetone PLIF is shown in Fig. 2.Air is com-pressed using screw compressor. Dried, filtered air isstored in the storage tank of 8 cubic meter. Com-pressed air from the storage tank is released and thetotal pressure can be monitored at the end of the stag-nation chamber. Pilot operated pressure regulator isused and a pneumatic rotary valve opens up the flowthrough a switch operation. Bypassing compressed airunderneath the small chamber which contains acetonein liquid phase, acetone vapors are produced. Pro-duced vapors are fed into the primary flow stagnationchamber for primary flow seeding by operating theunit at an over pressure of 2 bar. To see the secondaryflow, vapors are introduced near the secondary air in-take duct. 3. EXPERIMENTAL METHODOLOGY In the area of investigation, one of the mixingflow is seeded with acetone vapors [4] [5] well before.A 266 nm (90 mJ) Nd-YAG laser, operating at 10 Hzis used to excite the acetone molecules in the flowfield. Using appropriate sheet optics, laser beam(<10mm beam width) is collimated in to a sheet ofconstant height (25 mm) with a thickness of 1 mm andpassed through the quartz window present at the exitof the diffuser. Imaging is done along the flow direc-tion at the central plane of the ejector. Gated (5 ns)ICCD camera captures the fluorescence signal with agood SNR. LIF filter with 90% optical transmissionaround 400 nm is used to collect fluorescence signals.PTU connected with a computer, syncs the laser pulseand the ICCD camera gate. Nearly 50 images are cap-tured for time averaging. Acquired images are pre andpost processed in DaVis 8.3 for getting the quantitativevalues of acetone concentration, once the flow field iscalibrated. 4.PRELIMINARY RESULTS Supersonic ejector is fitted with a primary flownozzle, operating at a Mpp of 2.0. Pop is varied from4.89 bar to 8.89 bar to achieve SPR in the range of 6to 11 and ER in the range of 0.25 to 0.54. Primary noz-zle exit plane is kept 15 mm away from the constantarea duct so that the secondary flow will not choke andthe ejector can operate in the mixed flow regime. Moredetails regarding the measurement of Pop and ER canbe found in Ref. [3]. Secondary air intake duct is keptfully open during this operation. Time averaged ace-tone PLIF images by seeding the primary and second-ary flow individually are shown in Fig. 3 and Fig. 4. In Fig. 3, presence of varying intensity in the shockcells can be seen clearly. In Fig. 4. Secondary flowseeding marks the shock cell boundaries throughoutthe flow. Far downstream from the nozzle, uniformfluorescence signals can be seen across the width ofthe ejector which indicates the mixing process. In Fig.3 two bright spots are seen near the exit of the nozzlewhich is nothing but parasite reflections from the inci-dent laser sheet. In Fig. 5, centerline (y=0) intensityvariation for a particular case is shown in detail. Dot-ted line shows the variation while seeding the primaryflow and the solid line shows the variation while seed-ing the secondary flow. The trend that is observed inthe centerline intensity variation of primary flow issimilar to a typical centerline density variation ob-served in such flows (which is not shown in the graph).Sudden peaks observed in such imaging give infor-mation about the shock cell spacing. Typical distancebetween the first and second shock cell is found to bearound 0.7H. Comparatively smaller but similar peakscan also be found in the centerline intensity variationby seeding the secondary flow. From the experimental results that are obtainedthrough the PLMS imaging [6], LNM is found to be3.1H. LNM stand as a characteristic measure for thenon-mixed region. In Fig. 5, region of constant inten-sity starts to appear along the centerline after 5H. Sim-ilar kind of intensity plateauing can also be seen after5H in the secondary flow seeding. This observationconfirms that a thorough mixing process happens onlyafter 5H and LNM values are well within it. UnlikePLMS imaging through secondary seeding, acetonePLIF has not given a clear indication of Lec but con-firms the mixing process. Initially while seeding thesecondary flow, away from the centerline, one can seethat the intensity is large. SNR values are really highin case of secondary seeding near the entry region dueto the surplus amount of acetone vapors in the nearambient condition. When mixing happens through theshear layer, acetone is gradually taken into the poten-tial core. A linear rise in the centerline intensity con-firms the mixing layer growth and the small jumpsmark the shock cell termination. After LNM, one cansee in the secondary flow seeded images that the in-tensities are found to be faint. It once again confirmsthe rapid transport of acetone vapors or mixing. Detailset of experiments to quantify the mixing is underway.Calibration procedure is bit tricky here, as the fluores-cence signal depends on both temperature and pres-sure. 5. FURTHER WORK Preliminary acetone PLIF images are acquired for cer-tain conditions by seeding primary flow and secondaryflow individually in the central plane of the supersonic gaseous ejector.Obtained images are satisfactory. Fur-ther improvements for image consistency, backgroundnoise elimination, laser sheet correction and opticaldistortion corrections are being carried out. Transverseimaging to see the 3d effects is also being investigated.Calibration to quantify the acetone concentrations isunderway. REFERENCES [1] S.M.V. Rao, G. Jagadeesh,“Observations on thenon-mixed length and unsteady shock motion in atwo dimensional supersonic ejector”, Physics ofFluids, 26(3),2014. [2]K. Kontis, et al“Complex Internal CompressibleFlows in Encyclopedia of Aerospace Engineering”,John Wiley & Sons, Ltd, 2010. [3] S. M. V.Rao, “Experimental investigation on su-personic ejectors”, PhD Thesis, Aerospace Engi-neering, Indian Institute of Science, Bangalore,2013. [4] V. Shelar, et al“Gas Phase Oxygen QuenchingStudies of Ketone Tracers for Laser-Induced Fluo-rescence Applications in Nitrogen Bath Gas”,Spectroscopy Letters, 47(1), 12-18,2014. [5]V. Shelar, et al“Visualization of coherent struc-tures in turbulent subsonic jet using planar laser in-duced fluorescence of acetone”, European Journalof Applied Physics, 62(3), 2013. [6] S. K. Karthick, et al“Effect of Primary Flow MachNumber on the Non-Mixed Length in a Two Di-mensional Supersonic Ejector”, 30th InternationalSymposium on Shock Waves, Tel-Aviv, Israel, 19-24, July,2015. Fig. 1: Schematic of the time averaged flow fieldin the central plane of the supersonic gaseousejector t (PTU (a) 60 mm 200mm 200 mm DRAWING IS NOT TO 5CALE (b) (c) Fig.2:(a) Schematic of Acetone PLIF in super-sonic ejector facility (b) Flow passage dimen-sions of the supersonic gaseous ejector (drawnnot to scale) (c) Dimensions of the primary flowCD nozzle (W=80 mm;H=20 mm; w=75 mm;h=6 mm; t=2 mm) Fig. 3: Acetone PLIF images acquired by seedingthe primary flow for Mpp = 2.0 (flow is from leftto right) SPR=10.7;w=0.25; Fig. 4: Acetone PLIF images acquired by seedingthe secondary flow for Mpp = 2.0 (flow is fromleft to right) Primary Seeding Fig. 5: Centerline (y=0) Intensity variation ob-served in acetone PLIF [conditions: SPR=9.202;MPD=2.0; ω=0.31] S. K. Karthick is postgraduate in SpaceEngineering and Rocketry from BIT,Mesra. He is currently pursuing his doc-toral studies in the Department of Aero-space Engineering, IISc-Bangalore. His area of in-terests are high speed flows, supersonic mixing andadvanced optical flow diagnostics. Dr. Vikas M Shelar is working as Assis-tant Professor in the Department ofPhysics at MS Ramaiah University ofApplied Sciences, Bangalore. He got his doctoratefrom NIT, Surathkal. His current research interestsare in the area of laser physics and spectroscopy. Dr. G. Jagadeesh is Professor in the De-partment of Aerospace Engineering,IISc - Bangalore. He got his doctoratefrom IISc-Bangalore. His area of interests are hy-personic flows, supersonic mixing, shockwavepropagating in complex fluids etc. Dr. KPJ Reddy is Professor in the De-partment of Aerospace Engineering,IISc - Bangalore. He got his doctoratefrom BIT, Mesra. His area of interests are Hyper-sonic Aerodynamics, Application Of Lasers, Mo-lecular Electronics and Chemical Kinetics. Supersonic mixing studies are important in the design and development of efficient supersonicejectors. As a gas-dynamic device, supersonic ejector pumps up the secondary flow using thehigher kinetic energy of the primary flow itself. Conventional techniques have limited access toacquire data in such kind of flows to calculate the mixing efficiency. Reacting flows poses furtherchallenge in instrumentation. Experiments in cold flows manage to reveal important aspects onsupersonic mixing. Advanced optical flow diagnosis helps in probing the flow without large intrusion.One of such non-intrusive flow diagnostics is Acetone PLIF. A low area ratio supersonicejector, operating at a MPD of 2.0 for the range of POP from 4.89 bar to 8.89 bar is taken intoconsideration for this experiment. Secondary air intake duct is kept open during this operation andthe ejector is operated in the mixed flow regime. Concentration distribution is qualitatively evaluatedin this experimentation and few basic flow features are captured. Diffusion of secondary flowinto the primary flow and thickening mixing layers are clearly captured. NML computed fromPLMS experiments are also cross verified with current experiments as the mixing process is foundto be happening well above the NML as expected.

确定

还剩3页未读,是否继续阅读?

北京欧兰科技发展有限公司为您提供《超音速气体引射器中混合过程检测方案(粒子图像测速)》,该方案主要用于航空中混合过程检测,参考标准--,《超音速气体引射器中混合过程检测方案(粒子图像测速)》用到的仪器有德国LaVision PIV/PLIF粒子成像测速场仪、PLIF平面激光诱导荧光火焰燃烧检测系统、Imager sCMOS PIV相机、LaVision DaVis 智能成像软件平台

推荐专场

相关方案

更多

该厂商其他方案

更多