方案详情

文

锂离子(Li-ion)电池是市场上最重要的储能设备之一。本文使用电化学工作站对锂离子电池进行了充放电测试。

方案详情

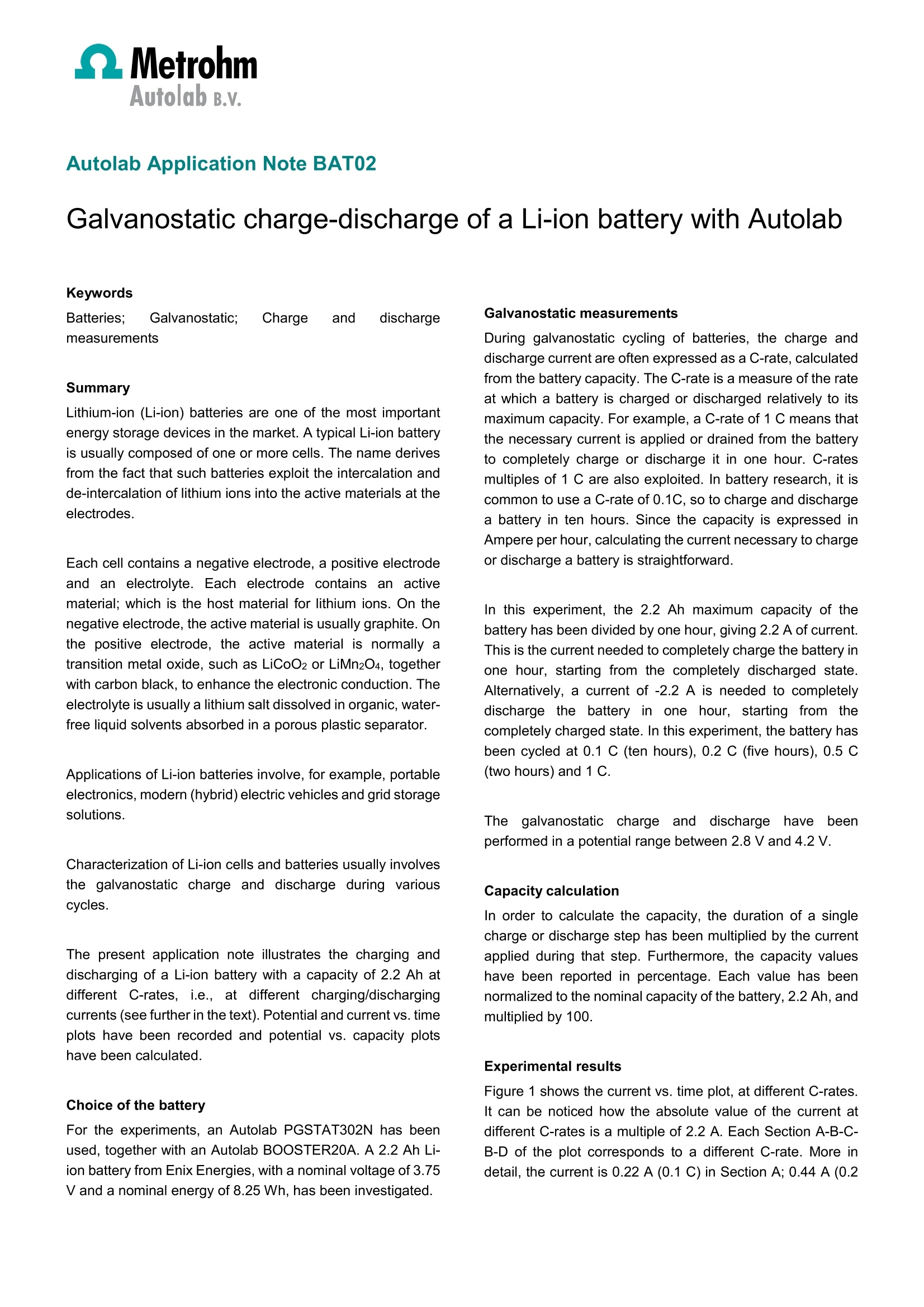

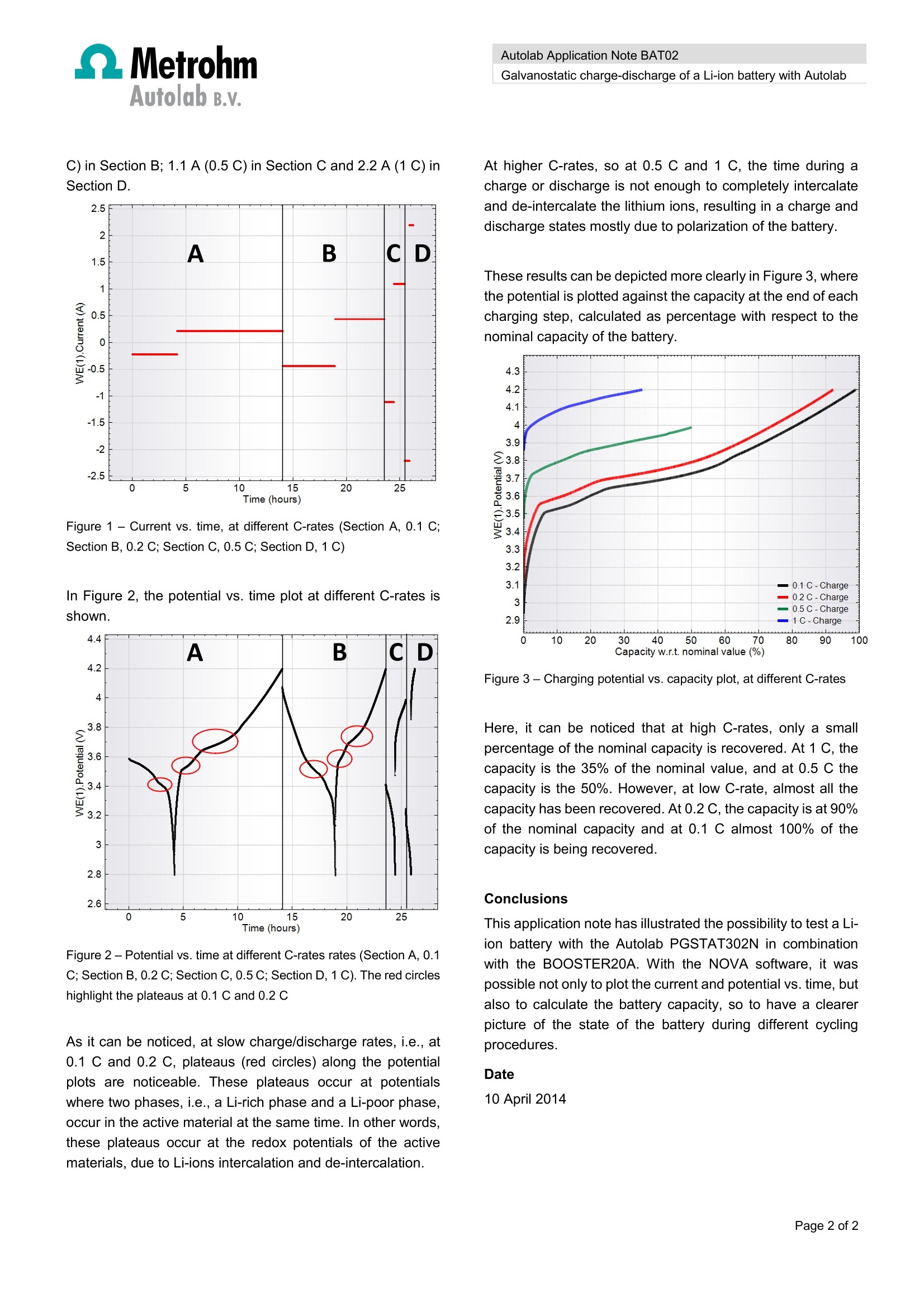

MetrohmAutolab B.v. Autolab Application Note BAT02Galvanostatic charge-dischargeof a Li-ion battery with AutolabAutolab B.v.Page 2 of 2 Galvanostatic charge-discharge of a Li-ion battery with Autolab Keywords Batteries; Galvanostatic: Charge and dischargemeasurements Summary Lithium-ion (Li-ion) batteries are one of the most importantenergy storage devices in the market. A typical Li-ion batteryis usually composed of one or more cells. The name derivesfrom the fact that such batteries exploit the intercalation andde-intercalation of lithium ions into the active materials at theelectrodes. Each cell contains a negative electrode, a positive electrodeand an electrolyte. Each electrode contains an activematerial; which is the host material for lithium ions. On thenegative electrode, the active material is usually graphite. Onthe positive electrode, the active material is normally atransition metal oxide, such as LiCoO2 or LiMn2O4, togetherwith carbon black, to enhance the electronic conduction. Theelectrolyte is usually a lithium salt dissolved in organic, water-free liquid solvents absorbed in a porous plastic separator. Applications of Li-ion batteries involve, for example, portableelectronics, modern (hybrid) electric vehicles and grid storagesolutions. Characterization of Li-ion cells and batteries usually involvesthe galvanostatic charge and discharge during variouscycles. The present application note illustrates the charging anddischarging of a Li-ion battery with a capacity of 2.2 Ah atdifferent C-rates,i.e., at different charging/dischargingcurrents (see further in the text). Potential and current vs. timeplots have been recorded and potential vs. capacity plotshave been calculated. Choice of the battery For the experiments, an Autolab PGSTAT302N has beenused, together with an Autolab BOOSTER20A. A 2.2 Ah Li-ion battery from Enix Energies, with a nominal voltage of 3.75V and a nominal energy of 8.25 Wh, has been investigated. Galvanostatic measurements During galvanostatic cycling of batteries, the charge anddischarge current are often expressed as a C-rate,calculatedfrom the battery capacity. The C-rate is a measure of the rateat which a battery is charged or discharged relatively to itsmaximum capacity. For example, a C-rate of1 C means thatthe necessary current is applied or drained from the batteryto completely charge or discharge it in one hour. C-ratesmultiples of 1 C are also exploited. In battery research, it iscommon to use a C-rate of 0.1C, so to charge and dischargea battery in ten hours. Since the capacity is expressed inAmpere per hour, calculating the current necessary to chargeor discharge a battery is straightforward. In this experiment, the 2.2 Ah maximum capacity of thebattery has been divided by one hour, giving 2.2 A of current.This is the current needed to completely charge the battery inone hour, starting from the completely discharged state.Alternatively,a current of -2.2 A is needed to completelydischarge the battery in one hour, starting from thecompletely charged state. In this experiment, the battery hasbeen cycled at 0.1 C (ten hours), 0.2 C (five hours), 0.5 C(two hours)and 1 C. Thegalvanostatic charge anddischarge hhavebeenperformed in a potential range between 2.8 V and 4.2 V. Capacity calculation In order to calculate the capacity, the duration of a singlecharge or discharge step has been multiplied by the currentapplied during that step. Furthermore, the capacity valueshave been reported in percentage. Each value has beennormalized to the nominal capacity of the battery,2.2 Ah, andmultiplied by 100. Experimental results Figure 1 shows the current vs. time plot, at different C-rates.It can be noticed how the absolute value of the current atdifferent C-rates is a multiple of 2.2 A. Each Section A-B-C-B-D of the plot corresponds to a different C-rate. More indetail, the current is 0.22 A (0.1 C) in Section A; 0.44 A (0.2 C) in Section B; 1.1 A (0.5 C) in Section C and 2.2 A (1 C) inSection D. A B C D Figure 1 - Current vs. time, at different C-rates (Section A, 0.1 C;Section B, 0.2 C; Section C, 0.5 C; Section D, 1C) In Figure 2, the potential vs. time plot at different C-rates isshown. Figure 2 - Potential vs. time at different C-rates rates (Section A, 0.1C; Section B, 0.2 C; Section C, 0.5 C; Section D,1 C). The red circleshighlight the plateaus at 0.1 C and 0.2 C As it can be noticed, at slow charge/discharge rates, i.e., at0.1 C and 0.2 C, plateaus (red circles) along the potentialplots are noticeable. These plateaus occur at potentialswhere two phases, i.e., a Li-rich phase and a Li-poor phase,occur in the active material at the same time. In other words,these plateaus occur at the redox potentials of the activematerials, due to Li-ions intercalation and de-intercalation. At higher C-rates, so at 0.5 C and 1 C, the time during acharge or discharge is not enough to completely intercalateand de-intercalate the lithium ions, resulting in a charge anddischarge states mostly due to polarization of the battery. These results can be depicted more clearly in Figure 3, wherethe potential is plotted against the capacity at the end of eachcharging step, calculated as percentage with respect to thenominal capacity of the battery. Figure 3 -Charging potential vs. capacity plot,at different C-rates Here, it can be noticed that at high C-rates, only a smallpercentage of the nominal capacity is recovered. At 1 C, thecapacity is the 35% of the nominal value, and at 0.5 C thecapacity is the 50%. However, at low C-rate, almost all thecapacity has been recovered. At 0.2 C, the capacity is at 90%of the nominal capacity and at 0.1 C almost 100% of thecapacity is being recovered. Conclusions This application note has illustrated the possibility to test a Li-ion battery with the Autolab PGSTAT302N in combinationwith the BOOSTER20A. With the NOVA software, it waspossible not only to plot the current and potential vs. time, butalso to calculate the battery capacity, so to have a clearerpicture of the state of the battery during different cyclingprocedures. Date 10 April 2014 锂离子(Li-ion)电池是市场上最重要的储能设备之一。本文使用电化学工作站对锂离子电池进行了充放电测试。

确定

还剩1页未读,是否继续阅读?

瑞士万通中国有限公司为您提供《锂离子电池中电流充电和放电检测方案(电化学工作站)》,该方案主要用于锂电池中电流充电和放电检测,参考标准--,《锂离子电池中电流充电和放电检测方案(电化学工作站)》用到的仪器有瑞士万通PGSTAT302N电化学工作站

推荐专场

相关方案

更多

该厂商其他方案

更多