方案详情

文

应用EASY RIPE乙烯发生器(Ethy-Gen II®浓缩物)在65m³冷库环境催熟芒果15小时情况下能否替代自然成熟方法研究,有助于芒果的栽培期管理

方案详情

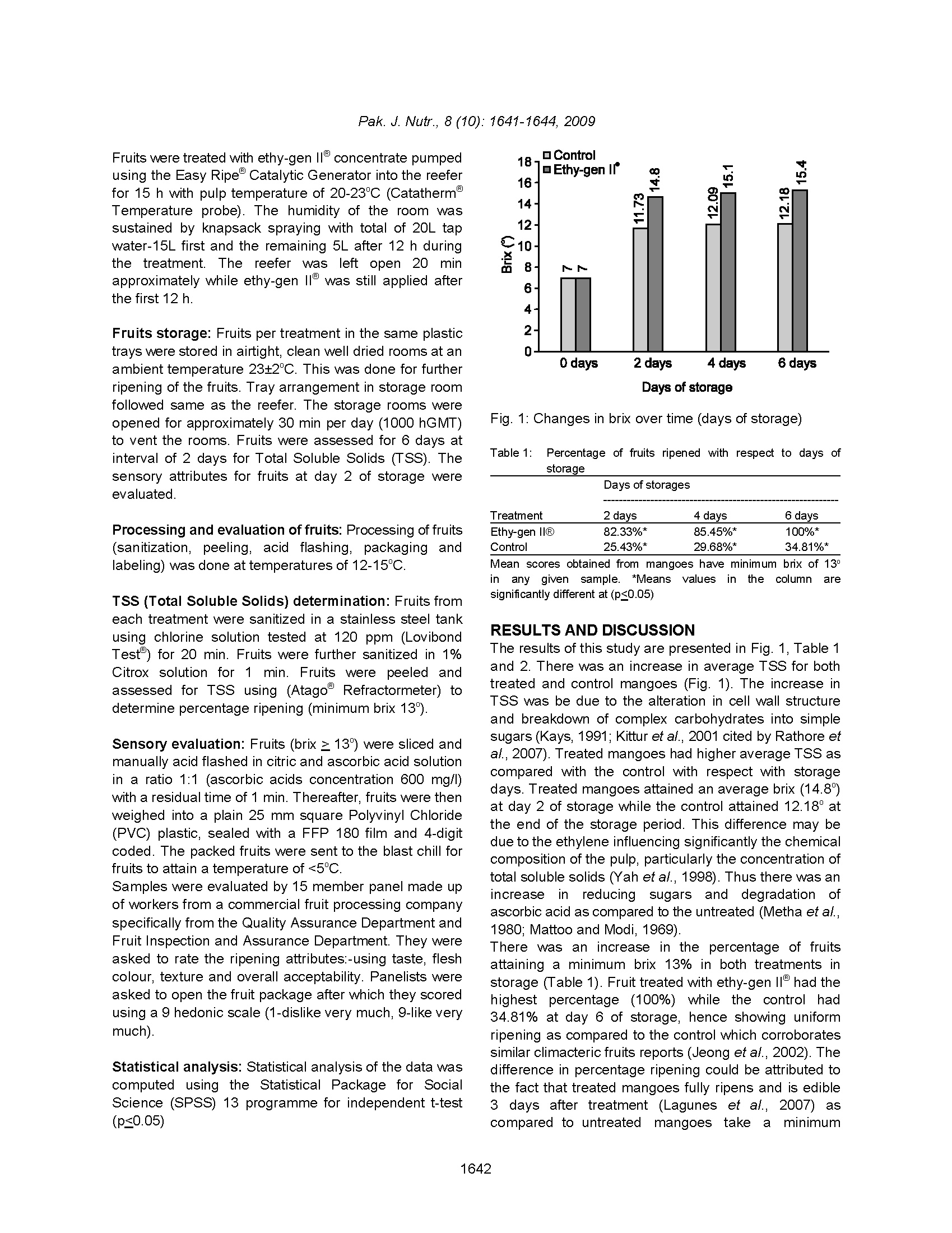

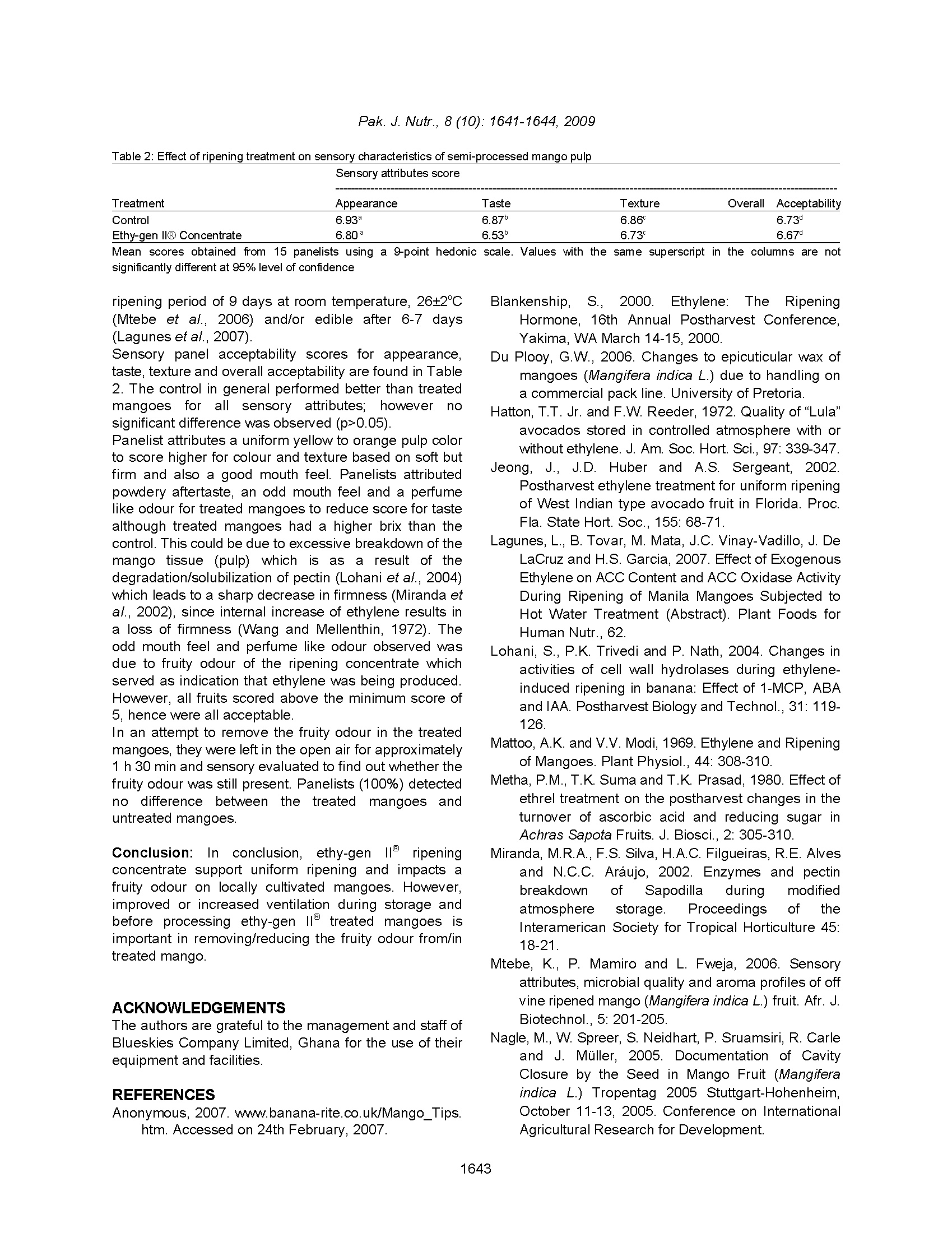

Pakistan Journal of Nutrition 8 (10):1641-1644,2009ISSN 1680-5194@ Asian Network for Scientific Information, 2009 Pak. J. Nutr., 8 (10): 1641-1644, 2009 Effect of Ethy-Gen IIRipening Concentrate on Ripening andSensory Properties of Mangoes (Mangifera indica L.) William Ofori Appaw, Ibok Oduro and William Otto Ellis Department of Food Science and Technology, Kwame Nkrumah University of Science and Technology, Kumasi, Ghana Abstract: This study investigates whether the use of ethy-gen II ripening concentrate (150-300ppm ofethylene) as an alternative to the traditional method of off vine ripening would support ripening of locallycultivated mangoes. Mangoes, Keith variety, were treated with the ripening concentrate for 15 h in Graff"standard reefer of 66.5 m. Humidity was sustained by knapsack spraying of 20 litres of water inside thereefer. Fruits were stored for 6 days after treatment at ambient temperature 23±2℃, vented 30 min per day(1000 hGMT) in an air tight room to further ripe the mangoes. Total Soluble Solids (TSS) and sensory qualitywere studied at an interval of 2 days during the storage period. Sensory quality was assessed specificallyon day 2 of storage. Results showed that ethy-gen I1 treated mangoes ripened uniformly and faster thanuntreated mangoes Treated mangoes had higher average TSS, attaining an average brix (14.8) at day 2 ofstorage. The control had brix of 12.18° at the end of the storage period. Treated mangoes had the highestpercentage (100%) while the control had 34.81% at day 6 of storage. The fruity odour of the ripeningconcentrate had an impact on the taste of treated mangoes, however sensory evaluation revealed nosignificant difference (p≤0.05) among treatments. Ethylene produced from ethy-gen li supports uniformripening of locally cultivated mangoes and increased period of ventilation during storage helps to removethe fruity odour. Key words: Ripening concentrate, uniform ripening, mango (keith variety), sensory attributes INTRODUCTION Mango (Mangifera indica L.) is an increasingly popularfruit grown in tropical and subtropical regions. Recentlythe global production of mango is known to haveattained 26.5x10° Mt in 2004 (Nagle et al., 2005). It ismost probably based on this recent demand thatprompted the global drive to step-up the approach ofselecting desired as well known commercial cultivars(Du Plooy, 2006). The importance of ripening fruits “offvine” is underscored in avoiding post-harvest lossescaused by tree ripening (Mtebe et al., 2006). It is hasbeen reported that the ripening stages of avocado isinitiated by low concentration of ethylene as low as0.1ppm (Hatton and Reeder, 1972) even though severalripening techniques have also adopted ethylene. Ethylene gas has served a great deal in the ripening offruit suchas tomatoes, bananas,pears, etc incommercial quantities. According to Blankenship (2000),ethylene initiates post-harvest ripening via three mainways namely: a)gas from a cylinder, b) catalyticgenerator and c) ethephon. In Ghana, the increasingpreference,, production and seasonality of locallycultivated mangoes cumulatively suggest the need todevice economic and feasible ripening methods whichwould limit post-harvest lossesandpromote wideacceptability of the mango fruit. Thus in this study work the use of catalytic generator toproduce ethylene from ethy-gen Ii concentrate to support uniform ripening was investigated on locallycultivated mangoes (Keith variety). MATERIALS AND METHODS Sampling and selection of fruits: Locally cultivatedmango fruits (Keith variety) for this study were obtainedfrom the FIAT (Fruit Inspection and Assurance Team)Department of Blueskies Company, Dobro and EasternRegion of Ghana. A total of 450 fruits were randomlyselected for the study. Selection of fruits was based onthe following attributes; a) uniformity of size, b) absenceof physical defects, c) no sign of infection, d) attainmentof maturity and e) no sign of ripeness. They were dividedinto two equal groups, control (untreated) and treatedrespectively. Fruits per group were divided into threeequal groups. Each group was further divided into threegroups and used as replicates. Fruit treatment: The method of Anonymous (2007) wasadopted with modification. Fruits were kept in box-likenet perforated plastic trays. Each tray contained anaverage of 15 mangoes. Trays were placed in a Graffstandard reefer on plastic pallets spaced equidistantlyalong each other. The Graff standard reefer has avolume of 66.5 mand air temperature of 23±1℃ andequipped with a regulated circulation system. The palletserved to avoid the tray from touching the metal floor ofthe reefer. Fruits were treated with ethy-gen lI concentrate pumpedusing the Easy RipeCatalytic Generator into the reeferfor 15 h with pulp temperature of 20-23℃ (CatathermTemperature probe). The humidity of the room wassustained by knapsack spraying with total of 20L tapwater-15L first and the remaining 5L after 12 h duringthe treatment. The reeferrwas left open 20 minapproximately while ethy-gen II was still applied afterthe first 12 h. Fruits storage: Fruits per treatment in the same plastictrays were stored in airtight, clean well dried rooms at anambient temperature 23±2C. This was done for furtherripening of the fruits. Tray arrangement in storage roomfollowed same as the reefer. The storage rooms wereopened for approximately 30 min per day (1000 hGMT)to vent the rooms. Fruits were assessed for 6 days atinterval of 2 days for Total Soluble Solids (TSS). Thesensory attributes for fruits at day 2 of storage wereevaluated. Processing and evaluation of fruits: Processing of fruits(sanitization, peeling, acid flashing, packaging andlabeling) was done at temperatures of 12-15℃. TSS (Total Soluble Solids) determination: Fruits fromeach treatment were sanitized in a stainless steel tankusing chlorine solution tested at 120 ppm (LovibondTest) for 20 min. Fruits were further sanitized in 1%Citrox solution for 1 min. Fruits were peeled andassessed for TSS using (Atago Refractormeter) todetermine percentage ripening (minimum brix 13). Sensory evaluation: Fruits (brix 13) were sliced andmanually acid flashed in citric and ascorbic acid solutionin a ratio 1:1 (ascorbic acids concentration 600 mg/l)with a residual time of 1 min. Thereafter, fruits were thenweighed into a plain 25 mm square Polyvinyl Chloride(PVC) plastic, sealed with a FFP 180 film and 4-digitcoded. The packed fruits were sent to the blast chill forfruits to attain a temperature of <5℃. Samples were evaluated by 15 member panel made upof workers from a commercial fruit processing companyspecifically from the Quality Assurance Department andFruit Inspection and Assurance Department. They wereasked to rate the ripening attributes:-using taste, fleshcolour, texture and overall acceptability. Panelists wereasked to open the fruit package after which they scoredusing a 9 hedonic scale (1-dislike very much, 9-like verymuch). Statistical analysis: Statistical analysis of the data wascomputeddusing the Statistical Package for SocialScience (SPSS) 13 programme for independent t-test(ps0.05) Fig. 1: Changes in brix over time (days of storage) Table1: Percentage of fruits ripened with respect to days ofstorage Treatment 2 days 4 days 6 days Ethy-gen ll@ 82.33%* 85.45%* 100%* Control 25.43%* 29.68%* 34.81%* Mean scores obtained from mangoes have minimum brix of 13in any given sample. *Meansi vvalues inthe columnnaresignificantly different at (ps0.05) RESULTS AND DISCUSSION The results of this study are presented in Fig. 1,Table 1and 2. There was an increase in average TSS for bothtreated and control mangoes (Fig. 1). The increase inTSS was be due to the alteration in cell wall structureand breakdown of complex carbohydrates into simplesugars (Kays, 1991; Kittur et al., 2001 cited by Rathore etal., 2007). Treated mangoes had higher average TSS ascompared with the control with respect with storagedays. Treated mangoes attained an average brix (14.8)at day 2 of storage while the control attained 12.18 atthe end of the storage period. This difference may bedue to the ethylene influencing significantly the chemicalcomposition of the pulp, particularly the concentration oftotal soluble solids (Yah et al.,1998). Thus there was anIncreaseinreducing sugars and degradationofascorbic acid as compared to the untreated (Metha et al.,1980;Mattoo and Modi, 1969). There was an increase in the percentage of fruitsattaining a minimum brix 13% in both treatments instorage (Table 1). Fruit treated with ethy-gen lI had thehighest percentage (100%)) while the control had34.81% at day 6 of storage, hence showing uniformripening as compared to the control which corroboratessimilar climacteric fruits reports (Jeong et al.,2002). Thedifference in percentage ripening could be attributed tothe fact that treated mangoes fully ripens and is edible3 days after treatment (Lagunes et al., 2007) ascompared to untreatedmangoessitakeaaminimum Table 2: Effect of ripening treatment on sensory characteristics of semi-processed mango pulp Sensory attributes score Treatment Appearance Taste Texture Overall Acceptability Control 6.93 6.87 6.86° 6.73 Ethy-gen IIQ Concentrate 6.80 6.53 6.73 6.67 Mean scores obtained from 15 panelists using a 9-point hedonic scale. Values with the same superscript in the columns are notsignificantly different at 95% level of confidence ripening period of 9 days at room temperature, 26±2'℃ (Mtebe et al., 2006) and/or edible after 6-7 days(Lagunes et al., 2007). Sensory panel acceptability scores for appearance,taste, texture and overall acceptability are found in Table2. The control in general performed better than treatedmangoes forr allsensory attributes; however nosignificant difference was observed (p>0.05). Panelist attributes a uniform yellow to orange pulp colorto score higher for colour and texture based on soft butfirm and also a good mouth feel. Panelists attributedpowdery aftertaste, an odd mouth feel and a perfumelike odour for treated mangoes to reduce score for tastealthough treated mangoes had a higher brix than thecontrol. This could be due to excessive breakdown of themango tissue (pulp) which is as a result of thedegradation/solubilization of pectin (Lohani et al., 2004)which leads to a sharp decrease in firmness (Miranda etal., 2002), since internal increase of ethylene results ina loss of firmness (Wang and Mellenthin, 1972). Theodd mouth feel and perfume like odour observed wasdue to fruity odour of the ripening concentrate whichserved as indication that ethylene was being produced.However, all fruits scored above the minimum score of5, hence were all acceptable. In an attempt to remove the fruity odour in the treatedmangoes, they were left in the open air for approximately1 h 30 min and sensory evaluated to find out whether thefruity odour was still present. Panelists (100%) detectedno differencebetweenthe treatedmangoeess aanduntreated mangoes. Conclusion::Inl conclusion,eethy-gen riripeningconcentrate support uniform ripening and impacts afruity odour on locally cultivated mangoes. However,improved or increased ventilation during storage andbefore processing ethy-gen li treated mangoes isimportant in removing/reducing the fruity odour from/intreated mango. ACKNOWLEDGEMENTS The authors are grateful to the management and staff ofBlueskies Company Limited, Ghana for the use of theirequipment and facilities. REFERENCES Anonymous, 2007. www.banana-rite.co.uk/Mango_Tips.htm. Accessed on 24th February, 2007. ( Blankenship, ) , s s., : 2000. . E thylene: The R ipeningHormone, 16th Annual P ostharvest Conference, Yakima, WA March 14-15, 2000. ) ( Du P looy, G .W., 2006. Changes to ep i cuticular wax of mangoes (Mangifera indica L . ) due to handling on a commercial pack line. University of Pretoria. ) ( Hatton, T.T. Jr . and F.W. Reeder, 1972. Quality of"Lula”avocados stored i n controlled atmosphere with orwithout ethylene. J . Am. Soc. Hort. Sci., 97:339-347. ) ( Jeong, J ., J .D. Huber a nd A.S. S e rgeant, 2 0 02.Postharvest ethylene treatment for u niform r ipening of West I n dian type avocado fru i t in Florida. P r oc. Fla. State Hort. Soc., 155:68-71. ) ( Lagunes, L., B. Tovar, M. Mata, J.C. Vinay-Vadillo, J .DeLaCruz and H.S. Garcia, 2007. E f fect of ExogenousEthylene on ACC Content and ACC Oxidase Activity During Ripening of Manila Mangoes Subjected t o Hot Water Treatment (Abstract). P lant F oods forHuman Nutr., 6 2. ) ( Lohani, S., P.K. Trived i and P . Nath , 2004. Changes inactivities of cell wall hydrolases d uring e t hylene- induced ripening in banana: Effect of 1-MCP, ABA and IAA. P ostharvest Biology and Technol., 31: 119- 126. ) Mattoo, A.K. and V.V. Modi, 1969. Ethylene and Ripeningof Mangoes. Plant Physiol., 44: 308-310. ( Metha, P .M., T .K. Suma and T.K. Pr a sad, 198 0 . Eff e ct of ethrel treatment o n t he postharvest changes in the turnover o f ascorbic a cid and reducing s u gar inAchras Sapota F r uits. J . Biosci. , 2:305-310. ) ( Miranda, M.R.A., F.S. Silva, H .A.C. Filgueiras, R.E. Alvesand N.C.C. A raujo, 2002. Enzymes and p e ctin breakdown of Sapodilla during modified atmosphere storage. Proceedings of the Interamerican Society for Tropical H orticulture 45: 18-21. ) ( Mtebe, K ., P. Mamiro a nd L. F weja, 2 006. S ensoryattributes, microbial quality and aroma profiles of offvine ripened mango (Mangifera indica L.) fruit. Afr. J.Biotechnol.,5:201-205. ) ( Nagle, M., W . Spreer, S . N e idhart, P . Sruamsiri, R. Carle and J. Muller, 2005. D ocumentation of Cavity Closure by t he S eed i n Mango Fr u it ( M angifera indica L.) Tropentag 2005 Stuttgart-Hohenheim, October 11-13, 2 005. Conference on International Agricultural Research f or Development. ) Rathore, H.A., T. Masud, S. Sammi and A.H. Soomro,2007. Effect ofstorage oon physico-chemicalcomposition and sseennsory properties of mango(Mangifera indica L.) Variety Dosehari. Pak. J. Nutr.,6:143-148. Wang, C.Y. and W.M. Mellenthin, 1972. Internal ethylenelevels during ripening and Climacteric in AnjonPears. Plant Physiol., 50: 311-312. ( Y ah,C . A.R., G.S.A. Novelo, T.J.A. Cortes, J.J. Argumedoand S.E. Duch, 1998. The effect of Ethephon on thecolour, composition a nd q u ality yc of mango (Mangifera indica, cv Kent). Food Sci. and Technol. Int., 3 : 199-205. ) 本文研究应用EASY RIPE乙烯发生器(Ethy-Gen II®浓缩物)在65m³冷库环境催熟芒果15小时情况下能否替代自然成熟方法研究,有助于芒果的栽培期管理This study investigates whether the use of ethy-gen II® ripening concentrate (150-300ppm of ethylene) as an alternative to the traditional method of off vine ripening would support ripening of locally cultivated mangoes. Mangoes, Keith variety, were treated with the ripening concentrate for 15 h in Graff® standard reefer of 66.5 m3. Humidity was sustained by knapsack spraying of 20 litres of water inside the reefer. Fruits were stored for 6 days after treatment at ambient temperature 23±2oC, vented 30 min per day (1000 hGMT) in an air tight room to further ripe the mangoes. Total Soluble Solids (TSS) and sensory quality were studied at an interval of 2 days during the storage period. Sensory quality was assessed specifically on day 2 of storage. Results showed that ethy-gen II® treated mangoes ripened uniformly and faster than untreated mangoes Treated mangoes had higher average TSS, attaining an average brix (14.8o) at day 2 of storage. The control had brix of 12.18o at the end of the storage period. Treated mangoes had the highest percentage (100%) while the control had 34.81% at day 6 of storage. The fruity odour of the ripening concentrate had an impact on the taste of treated mangoes, however sensory evaluation revealed no significant difference (p<0.05) among treatments. Ethylene produced from ethy-gen II® supports uniform ripening of locally cultivated mangoes and increased period of ventilation during storage helps to remove the fruity odour...

确定

还剩2页未读,是否继续阅读?

图拉扬科技有限公司为您提供《芒果中成熟度检测方案(作物无损检测)》,该方案主要用于其他水果制品中理化分析检测,参考标准--,《芒果中成熟度检测方案(作物无损检测)》用到的仪器有

相关方案

更多

该厂商其他方案

更多