方案详情

文

咖啡和牛奶的组合越来越受欢迎,如何科学的研究泡沫十分重要。本文使用DFA100测试了四中不同类型的牛奶,得到了温度以及泡沫大小和排布的关系。

方案详情

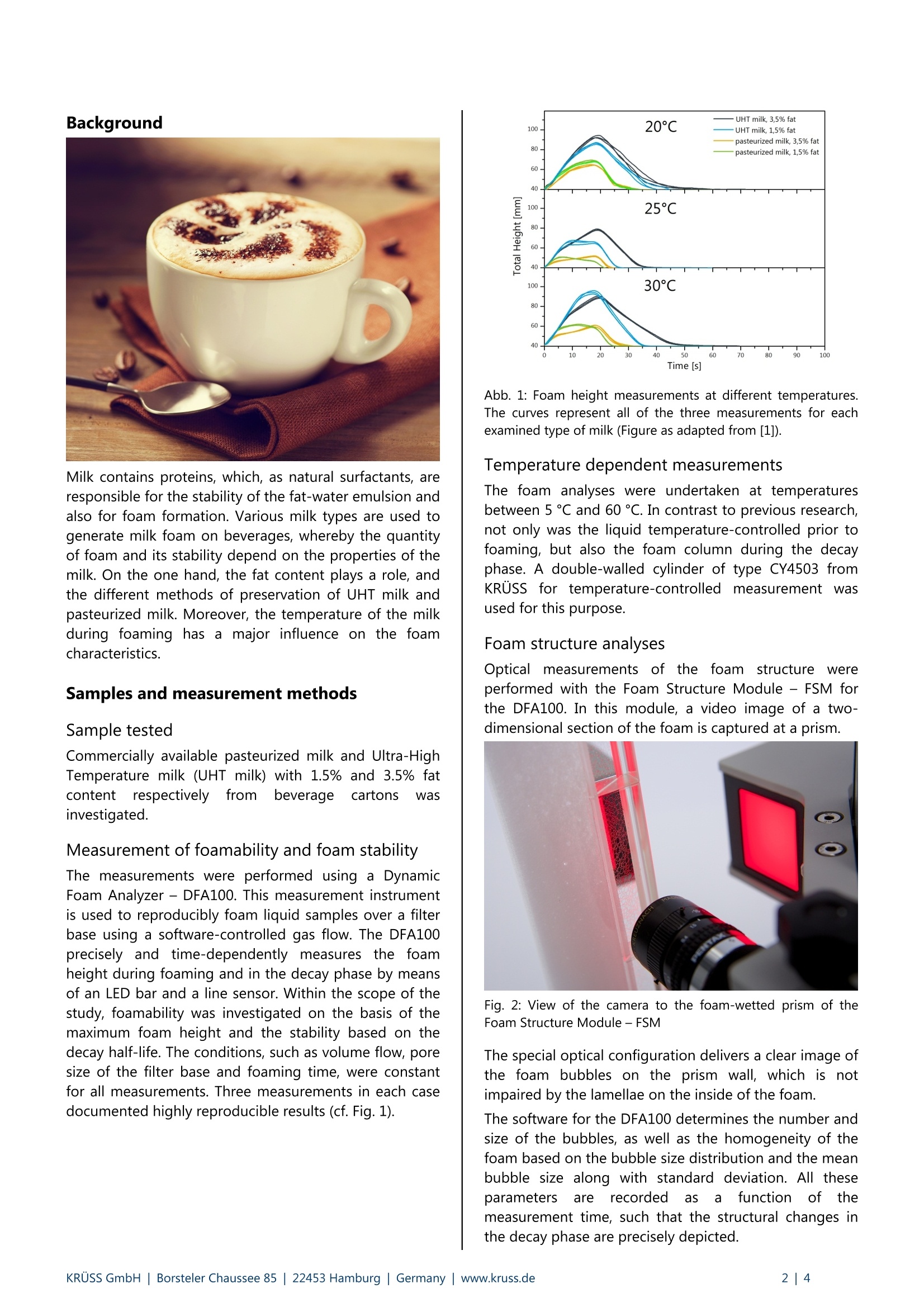

Background KRUSS Application Report Application report: AR 274 Industry section: Food industry Author: KO, CBK, MMA, TW Date: 03/2015 Method: Dynamic Foam Analyzer- DFA100 with Foam Structure DFA100 Module- FSM Keywords: Milk foam, foamability, foam stability, foam structure, temperature dependency Foamability of different milk types, and stability and structureof the foam produced Scientific milk foam analyses at different temperatures Long-lasting, small-pore foam with a pattern of scattered-on cocoa, which does not cause the foam to collapse: That'show most coffee drinkers envisage their perfect milk coffee or cappuccino. Coffee with foamed milk generated for singlecups is becoming increasingly popular - a situation reflected in the growing research efforts into milk foamingcharacteristics. In this application report, we summarize a published scientific study [1] on milk foam, which we compiledin our application laboratory. In the course of the study we investigated four different milk types (pasteurized milk and UHT milk with 1.5%and 3.5% fatrespectively) using our Dynamic Foam Analyzer-DFA100. The measurements focused on the foamability and the foamstability, both dependent upon the milk type and temperature. We also analyzed the foam structure in terms of thebubble size and bubble size distribution in order to investigate the relationship between these measurement results andthe stability parameters determined. Milk contains proteins, which, as natural surfactants, areresponsible for the stability of the fat-water emulsion andalso for foam formation. Various milk types are used togenerate milk foam on beverages, whereby the quantityof foam and its stability depend on the properties of themilk. On the one hand, the fat content plays a role, andthe different methods of preservation of UHT milk andpasteurized milk. Moreover, the temperature of the milkduring foaming has a major influence on the foamcharacteristics. Samples and measurement methods Sample tested Commercially available pasteurized milk and Ultra-HighTemperature milk (UHT milk) with 1.5% and 3.5% fatcontent respectivelyfrom beverage cartons wasinvestigated. Measurement of foamability and foam stability The measurements were performed using a DynamicFoam Analyzer - DFA100. This measurement instrumentis used to reproducibly foam liquid samples over a filterbase using a software-controlled gas flow. The DFA100precisely and time-dependently measures the foamheight during foaming and in the decay phase by meansof an LED bar and a line sensor. Within the scope of thestudy, foamability was investigated on the basis of themaximum foam height and the stability based on thedecay half-life. The conditions, such as volume flow, poresize of the filter base and foaming time, were constantfor all measurements. Three measurements in each casedocumented highly reproducible results (cf. Fig.1). Abb. 1: Foam height measurements at different temperatures.The curves represent all of the three measurements for eachexamined type of milk (Figure as adapted from [1]). Temperature dependent measurements The foam analyses were undertaken at temperaturesbetween 5 ℃ and 60℃. In contrast to previous research,not only was the liquid temperature-controlled prior tofoaming, but also the foam column during the decayphase. A double-walled cylinder of type CY4503 fromKRUSS for temperature-controlledmeasurement wasused for this purpose. Foam structure analyses Optical11measurements of the foam structurewereperformed with the Foam Structure Module - FSM forthe DFA100. In this module, a video image of a two-dimensional section of the foam is captured at a prism. Fig. 2: View of the camera to the foam-wetted prism of theFoam Structure Module -FSM The special optical configuration delivers a clear image ofthe foam bubbles on the prism wall, which is notimpaired by the lamellae on the inside of the foam. The software for the DFA100 determines the number andsize of the bubbles, as well as the homogeneity of thefoam based on the bubble size distribution and the meanbubble size along with standard deviation. All theseparameters are recorded as a function ofthemeasurement time, such that the structural changes inthe decay phase are precisely depicted. Measurement results Foamabilitv Within the framework of our study, we managed toconfirm some of the general statements from currentresearch: At low temperature, UHT milk tends to be morefoamable than pasteurized milk, and semi-skimmed milkbetter than whole milk. At higher temperatures, all milktypes are easily foamable and the differences betweenthe samples level out. Fig. 3: Investigation of foamability based on the maximum totalheight during foaming (Figure as adapted from [1]). As apparent from the figure, our investigations confirman anomaly found in research that anminimum infoamability of milk containing fat occurs at 25℃. Theauthors in [2] attribute this effect to the fact that at 25℃thesemi-crystalline structureddfattglobuleshave anegative effect on foam formation Foam stability In [2] the described minimum around 25C only occurredfor foamability, but not with regard to foam stability. Thisis remarkable, because generally the foam-inhibitingsubstances in a liquid also have an influence on thestability of the foam formed. In contrast, the results of our study also identified thefoamstabilityaattthe sameminimumnat225C, asexpected. Fig. 4: Measurement of the foam stability on the basis of thedecay half-life. Due to the considerable stability differences inthe samples, a logarithmic scale was chosen for the y-axis(Figure as adapted from [1]). In our view, the differing findings relate to the fact that,although foaming was temperature-controlled in [2], thedecay behavior was measured without temperaturecontrol. We consider that this led to uncontrolled thermaleffects during cooling of the foam, which superposed themolecular mechanisms. However, in our analyses thefoam column was also temperature-controlled during thedecay phase. As a result, the foamability and the stabilitybehavior showedasimilar course ofritemperaturedependency, as anticipated. While the foam height formed at 40℃ was almostidentical for all four milk types (cf. Fig. 3), the stability atthis temperature varies significantly with the fat content.The milk fat does no longer affect foamability and isactually stabilizing. Foam structure For the evaluation of milk foam, the bubble structure isinteresting in two ways. Firstly, consumers generallyprefer small-pore, homogeneous milk foam, such thatthe structure has a direct influence on the sense ofpleasure. Secondly, the stability also depends on thebubble size and the size distribution. Ostwald ripening is an accelerating mechanism in foamdecay, which dependss on the pressure differencesbetween large and small foam bubbles, whereby thenumber of small bubbles reduces with time, whereaslarge bubbles become larger. The more homogeneousthe foam, the lower the pressure differences between thebubbles and therefore the slower the Ostwald ripening. This relationship is also confirmed by the foam structuremeasurements as shown in the following Figure (5): Fig. 5: Representation of number of bubbles (a), the meanbubble size (b) and the standard deviation of the mean value (c)immediately after foaming of UHT milk (3.5% and 1.5%) at40 ℃. The images below show the bubbles determined byimage recognition after foaming and after 1800 s decay time(Figure as adapted from [1]). According to the foam height measurement, the moststable foam arose from UHT milk (3.5% fat) at 40 ℃(cf. Fig. 4). The structural investigation for this foamrevealed the smallest bubbles with the lowest standarddeviation from the mean bubble size and therefore thegreatest homogeneity (Fig.5 left). The foam from 1.5%UHT milk (right), which was far more unstable in thedecay measurement, displays larger bubbles with lowhomogeneity straight after foaming. The two structuralimages after 1800 s decay time illustrate the stabilitydifference between the samples. Summary The foam characteristics of four milk samples withdifferences in production methods (pasteurized or UHTmilk) and fat content (3.5% and 1.5%) were investigatedwithin the scope of a study. This focused on the influenceof temperature and the nature of the milk on foamabilityand foam stability. We were able to confirm the minimum of foamability at25C, as stated in the research literature. By temperaturecontrolling the foam column, we also demonstrated thesame minimum course for foam stability, contrary to theavailable investigations. Foam structure investigations revealed a correlationbetween the bubble size and its distribution on the onehand, and the foam stability, on the other: The smallestpore,most homogeneous foam (UHT milk with 3.5% fatat 40°C) was, at the same time, the most stable. Finally, some rules-of-thumb for milk foam generationcan be derived from the measurements: For foaming, ideally the milk should come directly fromthe fridge or be heated. Milk at room temperature isnot suitable at all. ▪ Low fat products are more favorable than whole milk,and UHT products are better than pasteurized milk forfoaming cold milk. ▪ A large volume of homogeneous, stable foam arisesfrom foaming warm UHT whole milk. The mainreference [1] for this aapplication reportcontains all the details, such as further individual results,the exact nature of the samples and the measuringconditions for the foam analyses, as well as the completelist of the research literature included. Literature [1]K. Oetjen, Ch. Bilke-Krause, M. Madani, Th. Willers,Temperature effect on foamability, foam stability, andfoam structure of milk, Colloids and Surfaces A:Physicochemical and Engineering Aspects 460 (2014),280-285. [2] S. Kamath, T. Huppertz, A.V. Houlihan, H. Deeth, Theinfluence of temperature on the foaming of milk,International Dairy Journal 18 (2008) 994-1002. KRUSS GmbH|Borsteler Chaussee |Hamburg| Germany|vwww.kruss.de|

确定

还剩2页未读,是否继续阅读?

克吕士科学仪器(上海)有限公司为您提供《牛奶中泡沫性质检测方案(泡沫分析仪)》,该方案主要用于液体乳中理化分析检测,参考标准--,《牛奶中泡沫性质检测方案(泡沫分析仪)》用到的仪器有KRUSS DFA100型全自动泡沫分析仪

推荐专场

相关方案

更多