在很多工业中粉末润湿性是成功生产的一个重要参数。本文利用测量结果更好的Washburn法测定了辣椒油对淀粉和盐的接触角。

方案详情

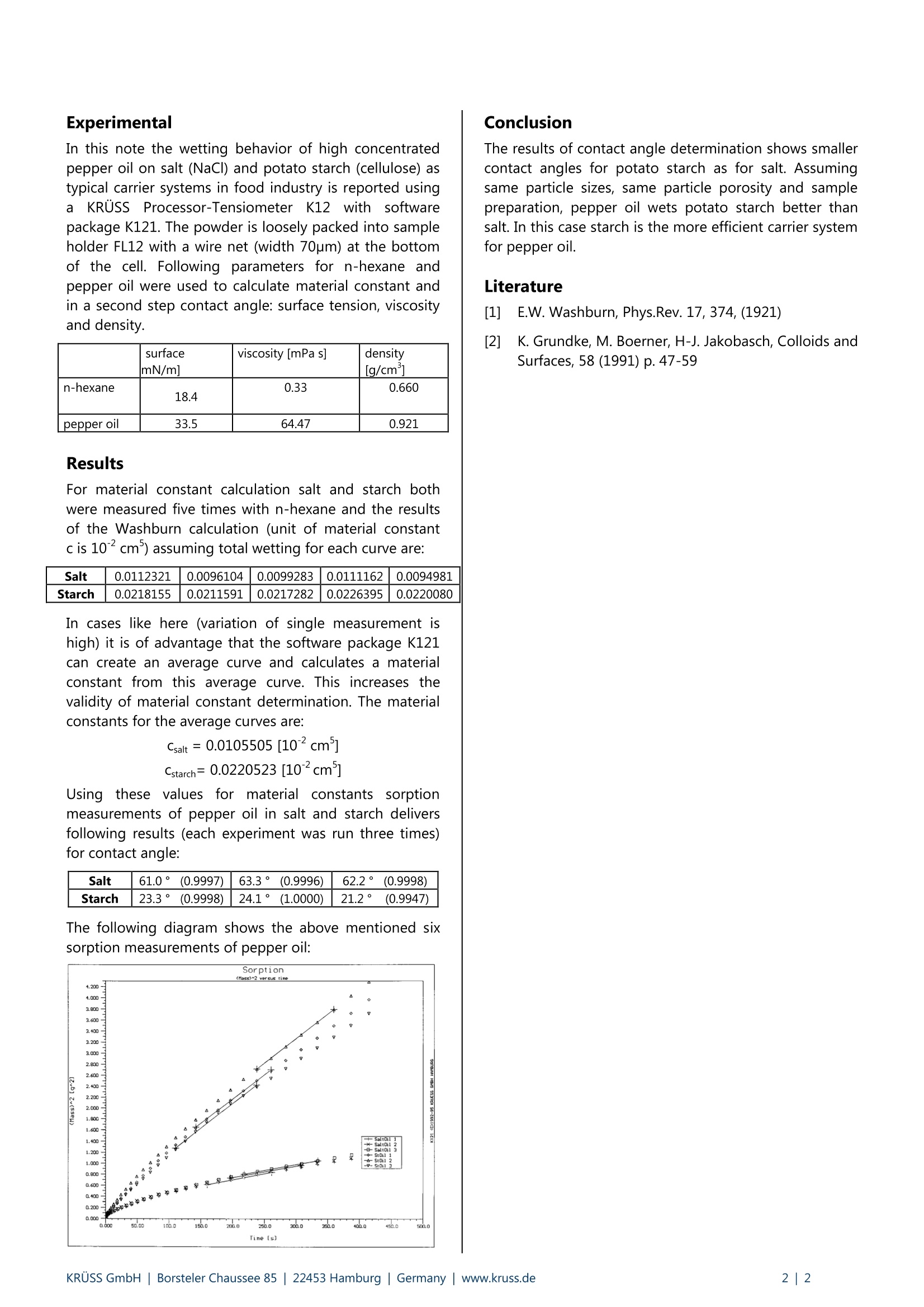

KRUSS Wettability of powder Application report: AR208e Industry section: Food technology Author: HL Date: 1999 Method: Force Tensiometer-K12 Keywords: Washburn method, powder wetting, pepper oil, starch, salt, contact angle, powder carrier system Keywords: Washburn method, powder wetting, pepper oil, starch, salt, contact angle, powder carrier system Contact Angle Measurement of Spice Oil on Powder Carrier Systems Introduction Wettability of powders is in many industrial processes an important parameter for successful production. In food industry it is necessary to cover a porous carrier system with flavor oil to get a spice powder. The oil is sprayed onthe powder or the powder pigments are dispersed in the oil by a mixer. By these ways a flavor oil (mostly highconcentrated) is transisted in a spice powder which is easier to dose and to use in practice. By means of contact angle measurement a pre-selection of carrier systems for specific flavor oil is possible. Carriersystems with small contact angles show a better wetting behavior as those with big one. For development of newproducts it can be very useful to find carrier systems which are wetted well by the liquid. There are two different main approaches to get contact angles of liquids on powder. The first is an optical one by meansof a goniometer using the sessile drop technique, the second one uses a processor tensiometer to run sorptionexperiments and calculate contact angles by a Washburn calculation model [1][2]. The drawback of the sessile droptechnique is that the powder has to be compressed to a block and when the drop is adjusted on the surface it may beabsorbed too fast for optical contact angle measurement. A compressed powder also shows mostly a different wettingbehavior as the powder used in practice. The sessile drop technique is a perfect method for non-porous systems, but forcontact angle measurements of liquids (with angles smaller than 90°on the solid) on porous systems like powders thesecond mentioned method leads to better results. Experimental Conclusion In this note the wetting behavior of high concentratedpepper oil on salt (NaCl) and potato starch (cellulose) astypical carrier systems in food industry is reported usingaKRUSSProcessor-Tensiometer K12 withhsoftwarepackage K121. The powder is loosely packed into sampleholder FL12 with a wire net (width 70um) at the bottomof the cell. Following parameters for n-hexane andpepper oil were used to calculate material constant andin a second step contact angle: surface tension, viscosityand density. The results of contact angle determination shows smallercontact angles for potato starch as for salt. Assumingsame particle sizes, same particle porosity and samplepreparation, pepper oil wets potato starch better thansalt. In this case starch is the more efficient carrier systemtor pepper oil. Literature ( [1] E.W. Washburn, P h ys.Rev. 17, 374, ( 1921) ) surfacemN/m1 viscosity [mPa s] density [g/cm] n-hexane 18.4 0.33 0.660 pepper oil 33.5 64.47 0.921 [2] K. Grundke, M. Boerner, H-J. Jakobasch, Colloids andSurfaces, 58 (1991) p.47-59 Results For material constant calculation salt and starch bothwere measured five times with n-hexane and the resultsof the Washburn calculation (unit of material constant c is 10cm ) assuming total wetting for each curve are: Salt 0.0112321 0.0096104 0.0099283 0.0111162 0.0094981 Starch 0.0218155 0.0211591 0.0217282 0.0226395 0.0220080 In cases like here (variation of single measurement ishigh) it is of advantage that the software package K121can create an average curve and calculates a materialconstant from this average curve. This increases thevalidity of material constant determination. The materialconstants for the average curves are: Usingthese values for material constants sorptionmeasurements of pepper oil in salt and starch deliversfollowing results (each experiment was run three times)for contact angle: Salt 61.0°(0.9997) 63.3°(0.9996) 62.2°(0.9998)Starch 23.3°(0.9998) 24.1°(1.0000) 21.2°(0.9947) The following diagram shows the above mentioned sixsorption measurements of pepper oil: (hass)2 ver sus time 4.200- .: 2vb] zv(ssey) 4.000-3.800-3.6003.400-3.0002.8002.6002.4000-2.20000D-B001.600-1.400-1.2001.000- 0.800 早年是0.600-0.400-0.200 0.000= 000 50.00 100.D 150.0 200.0 250.0 300.0350.0400.045..0500.0lime Ls] KRUSS GmbH|lBorsteler Chaussee Hamburg|Germany|www.kruss.de|

确定

还剩1页未读,是否继续阅读?

克吕士科学仪器(上海)有限公司为您提供《粉末、油中粉末接触角检测方案(表面张力仪)》,该方案主要用于食用植物油中理化分析检测,参考标准--,《粉末、油中粉末接触角检测方案(表面张力仪)》用到的仪器有

相关方案

更多