方案详情

文

近年来,酿造工业提高了啤酒保质期和质量保证的标准。如何形成均一稳定的啤酒泡沫尤为重要。其形成与天热表面活性剂及生产产生的CO2有关。本文提供了可靠的起泡性,稳定性分析。

方案详情

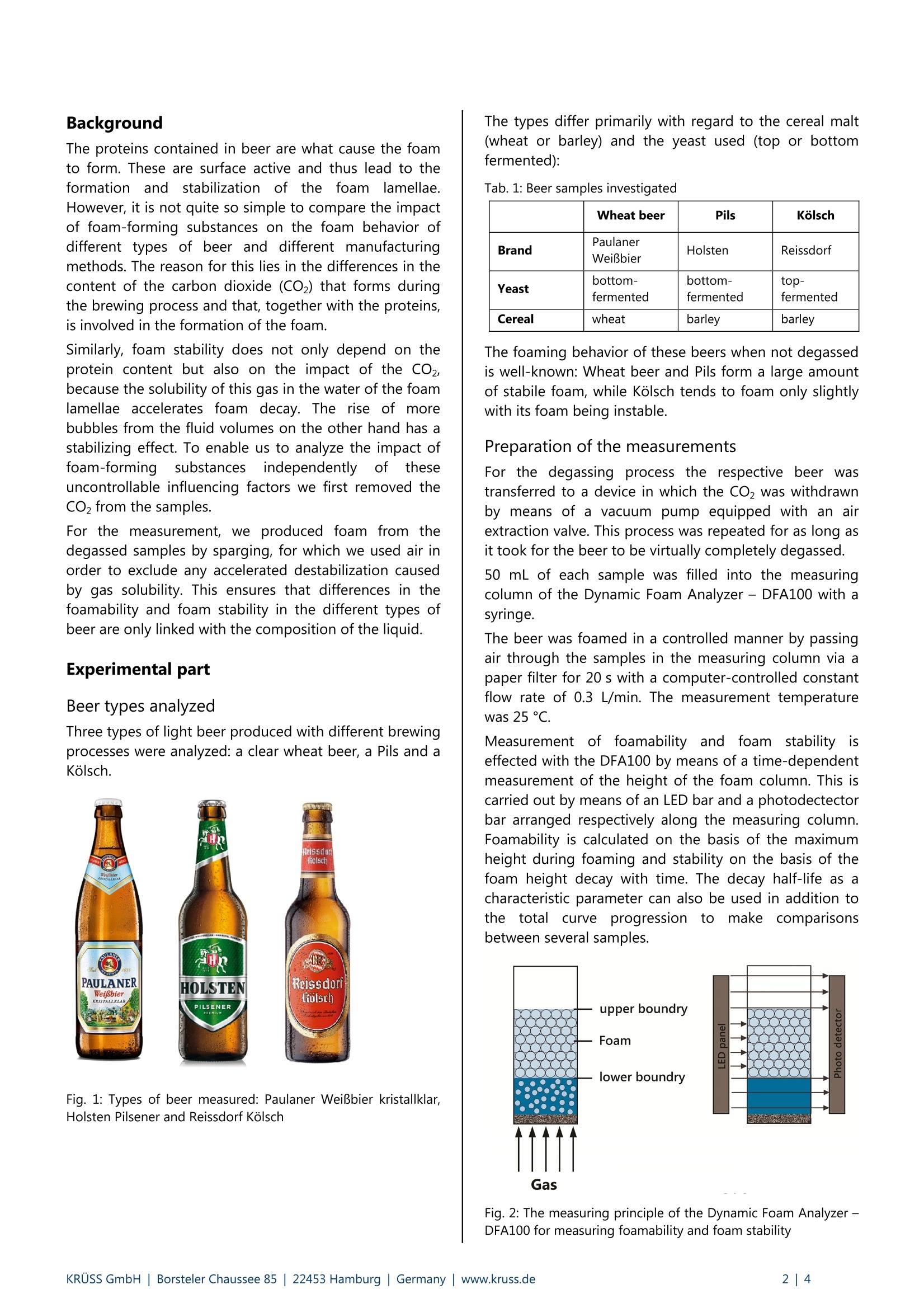

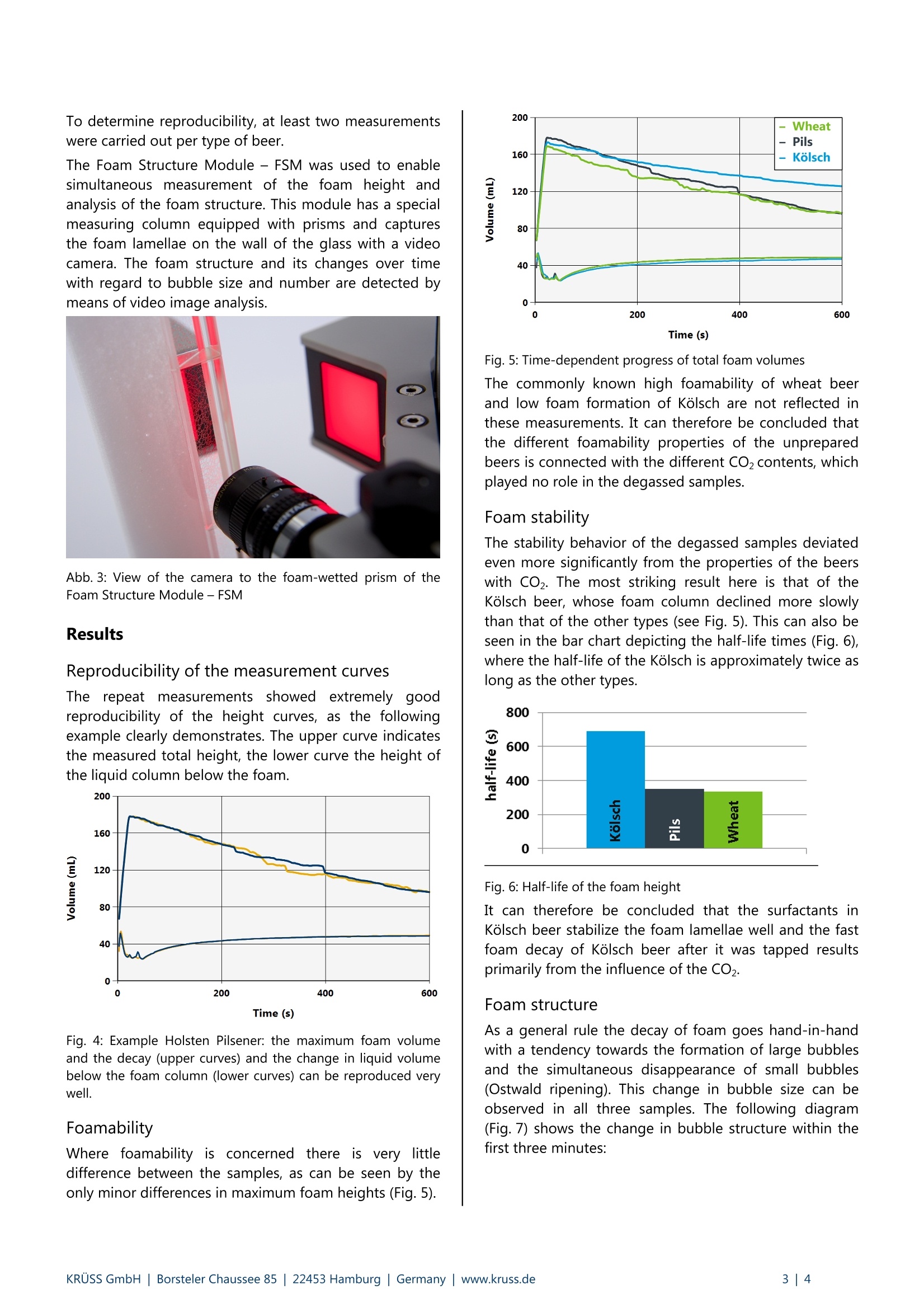

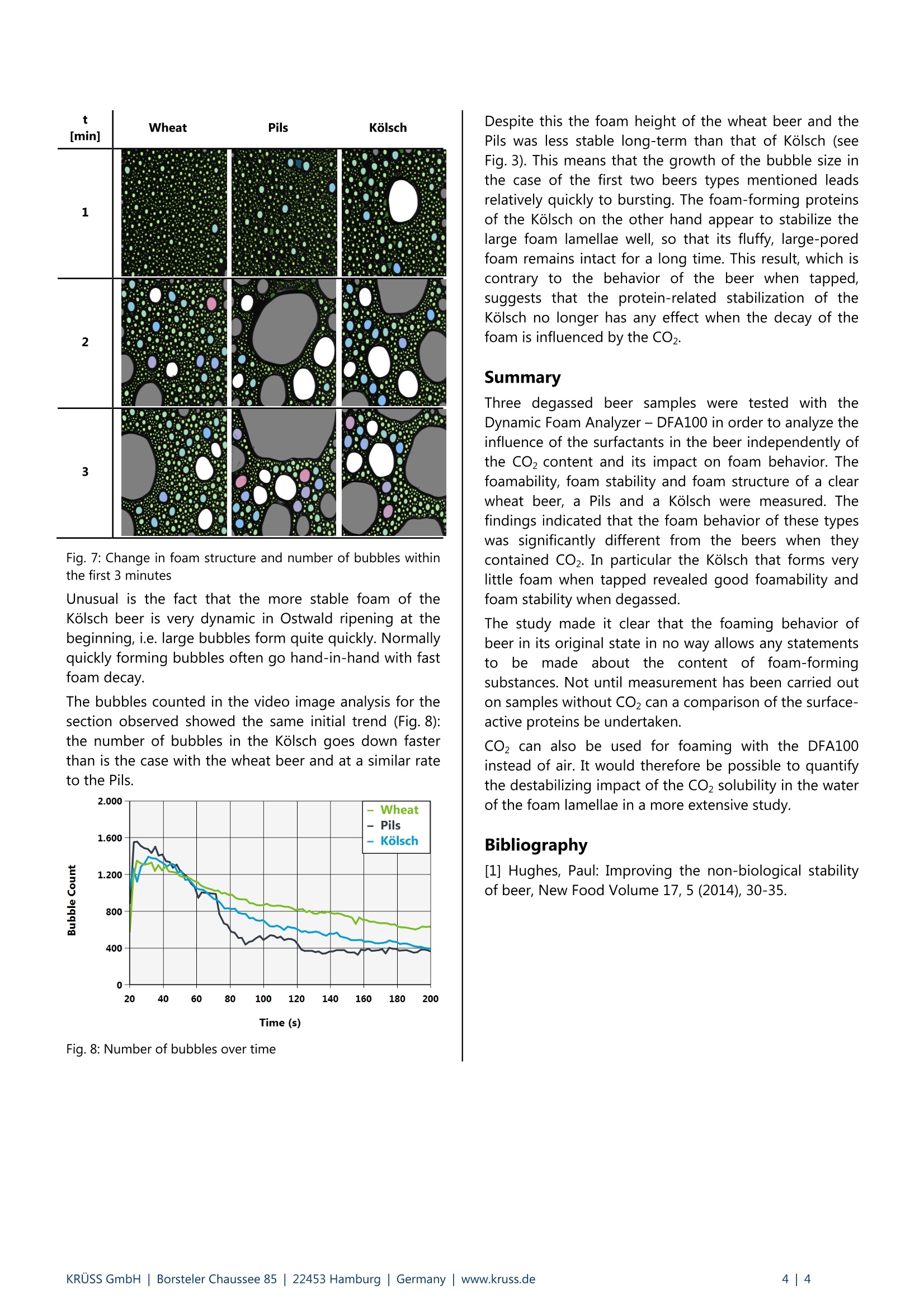

Application Report Application report: AR275 Industry section: Food, Beverages Author: SMO, FT, TWDate: May 2015 Method: DFA100 with Foam Structure Module -FSM Keywords: Beverages, Beer, Foam, Foam Stability, Foamability Comparison of the foam behavior of different types of beerindependently of CO2 content Analysis of the foamability, foam stability and foam structure of degassed beer samples For a long time food-chemical analyses and quality tests for beer were focused primarily on the biological stability of thispopular drink. However, the emphasis in recent years has changed: the brewing industry has developed high and reliablestandards with regard to the shelf life of beer, while research and quality assurance focuses increasingly on the aspect ofenjoyment [1]. In this connection priority is now also being given to topics such as the formation, consistency and stabilityof beer foam. Beer foam forms through the combination of the natural surfactants it contains and the carbon dioxide (CO2) that formsas a reaction product during the brewing process. The latter is not added; the only time additional CO2 is used is duringtapping in order to generate the necessary pressure. This study presents a possibility for analyzing the impact of foam-forming substances on foamability and foam stability independently of the CO2 content. For this purpose the foam heightand foam structure of the beer types Pils, clear wheat beer and Kolsch, a popular German local specialty beer, weremeasured with the CO having been removed in advance of the measurement. The analysis showed that the behavior ofthe foam of the beer samples that had been standardized for the measurement deviated greatly from the properties oftapped beers. In particular the behavior of Kolsch beer that only foams a little when tapped was the cause of muchsurprise during our study. Background The proteins contained in beer are what cause the foamto form. These are surface active and thus lead to theformationlcandsstabilization of the foam lamellae.However, it is not quite so simple to compare the impactof foam-forming substances on the foam behavior ofdifferent types of beer and different manufacturingmethods. The reason for this lies in the differences in thecontent of the carbon dioxide (CO2) that forms duringthe brewing process and that, together with the proteins,is involved in the formation of the foam. Similarly, foam stability does not only depend on theprotein content but also on the impact of the CO2,because the solubility of this gas in the water of the foamlamellae accelerates foam decay. The rise of morebubbles from the fluid volumes on the other hand has astabilizing effect. To enable us to analyze the impact offoam-forming substancesirindependently/oftheseuncontrollable influencing factors we first removed theCO2 from the samples. For the measurement, we produced foam from thedegassed samples by sparging, for which we used air inorder to exclude any accelerated destabilization causedby gas solubility. This ensures that differences in thefoamability and foam stability in the different types ofbeer are only linked with the composition of the liquid. Experimental part Beer types analyzed Three types of light beer produced with different brewingprocesses were analyzed: a clear wheat beer, a Pils and aKolsch. Fig. 1: Types of beer measured: Paulaner WeiBbier kristallklar,Holsten Pilsener and Reissdorf Kolsch The types differ primarily with regard to the cereal malt(wheat or barley) and the yeast used (top or bottomfermented): Tab.1: Beer samples investigated Wheat beer Pils Kolsch Brand Paulaner WeiBbier Holsten Reissdorf Yeast bottom- termented bottom-fermented top- fermented Cereal wheat barley barley The foaming behavior of these beers when not degassedis well-known: Wheat beer and Pils form a large amountof stabile foam, while Kolsch tends to foam only slightlywith its foam being instable. Preparation of the measurements For the degassing process the respective beer wastransferred to a device in which the CO2 was withdrawnby means of a vacuum pump equipped with an airextraction valve. This process was repeated for as long asit took for the beer to be virtually completely degassed. 50 mL of each sample was filled into the measuringcolumn of the Dynamic Foam Analyzer-DFA100 with asyringe. The beer was foamed in a controlled manner by passingair through the samples in the measuring column via apaper filter for 20 s with a computer-controlled constantflow rate of 0.3 L/min. The measurement temperaturewas 25°C. Measurement of foamabilityy andfoam sstabilityiseffected with the DFA100 by means of a time-dependentmeasurement of the height of the foam column. This iscarried out by means of an LED bar and a photodectectorbar arranged respectively along the measuring column.Foamability is calculated on the basis of the maximumheight during foaming and stability on the basis of thefoam height decay with time. The decay half-life as acharacteristic parameter can also be used in addition tothe total curve progression to make comparisonsbetween several samples. Fig. 2: The measuring principle of the Dynamic Foam Analyzer-DFA100 for measuring foamability and foam stability To determine reproducibility, at least two measurementswere carried out per type of beer. The Foam Structure Module-FSM was used to enablesimultaneous measurement of the foam height andanalysis of the foam structure. This module has a specialmeasuring column equipped with prisms and capturesthe foam lamellae on the wall of the glass with a videocamera. The foam structure and its changes over timewith regard to bubble size and number are detected bymeans of video image analysis. Abb. 3: View of the camera to the foam-wetted prism of theFoam Structure Module-FSM Results Reproducibility of the measurement curves The repeat measurements showed eextremely goodreproducibility of the height curves, as the followingexample clearly demonstrates. The upper curve indicatesthe measured total height, the lower curve the height ofthe liquid column below the foam. Fig. 4: Example Holsten Pilsener: the maximum foam volumeand the decay (upper curves) and the change in liquid volumebelow the foam column (lower curves) can be reproduced verywell. Foamability Where foamability is concerned there is very littledifference between the samples, as can be seen by theonly minor differences in maximum foam heights (Fig.5). Fig. 5: Time-dependent progress of total foam volumes The commonly known high foamability of wheat beerand low foam formation of Kolsch are not reflected inthese measurements. It can therefore be concluded thatthe different foamability properties of the unpreparedbeers is connected with the different CO2 contents, whichplayed no role in the degassed samples. Foam stability The stability behavior of the degassed samples deviatedeven more significantly from the properties of the beerswith CO2. The most striking result here is that of theKolsch beer, whose foam column declined more slowlythan that of the other types (see Fig.5). This can also beseen in the bar chart depicting the half-life times (Fig. 6),where the half-life of the Kolsch is approximately twice aslong as the other types. Fig. 6: Half-life of the foam height It can therefore be concluded that the surfactants inKolsch beer stabilize the foam lamellae well and the fastfoam decay of Kolsch beer after it was tapped resultsprimarily from the influence of the CO2. Foam structure As a general rule the decay of foam goes hand-in-handwith a tendency towards the formation of large bubblesand the simultaneous disappearance of small bubbles(Ostwald ripening). This change in bubble size can beobserved in all three samples. The following diagram(Fig.7) shows the change in bubble structure within thefirst three minutes: Fig. 7: Change in foam structure and number of bubbles withinthe first 3 minutes Unusual is the fact that the more stable foam of theKolsch beer is very dynamic in Ostwald ripening at thebeginning, i.e. large bubbles form quite quickly. Normallyquickly forming bubbles often go hand-in-hand with fastfoam decay. The bubbles counted in the video image analysis for thesection observed showed the same initial trend (Fig. 8):the number of bubbles in the Kolsch goes down fasterthan is the case with the wheat beer and at a similar rateto the Pils. Fig.8: Number of bubbles over time Despite this the foam height of the wheat beer and thePils was less stable long-term than that of Kolsch (seeFig. 3). This means that the growth of the bubble size inthe case of the first two beers types mentioned leadsrelatively quickly to bursting. The foam-forming proteinsof the Kolsch on the other hand appear to stabilize thelarge foam lamellae well, so that its fluffy, large-poredfoam remains intact for a long time. This result, which iscontrary to the behavior of the beer when tapped,suggests that the protein-related stabilization of theKolsch no longer has any effect when the decay of thefoam is influenced by the COz Summary Three degassed beer samples were tested with theDynamic Foam Analyzer- DFA100 in order to analyze theinfluence of the surfactants in the beer independently ofthe CO2 content and its impact on foam behavior. Thefoamability, foam stability and foam structure of a clearwheat beer, a Pils and a Kolsch were measured. Thefindings indicated that the foam behavior of these typeswas significantly different from the beers when theycontained CO2. In particular the Kolsch that forms verylittle foam when tapped revealed good foamability and. foam stability when degassed. The study made it clear that the foaming behavior ofbeer in its original state in no way allows any statementstobe made about the content of ffoam-formingsubstances. Not until measurement has been carried outon samples without CO2can a comparison of the surface-active proteins be undertaken. CO2 can also be used for foaming with the DFA100instead of air. It would therefore be possible to quantifythe destabilizing impact of the CO2 solubility in the waterof the foam lamellae in a more extensive study. Bibliography [1] Hughes, Paul: Improving the non-biological stabilityof beer, New Food Volume 17,5 (2014), 30-35. KRUSS GmbH| Borsteler Chaussee Hamburg| Germany|vwww.kruss.de|

确定

还剩2页未读,是否继续阅读?

克吕士科学仪器(上海)有限公司为您提供《啤酒中泡沫检测方案(泡沫分析仪)》,该方案主要用于啤酒中理化分析检测,参考标准--,《啤酒中泡沫检测方案(泡沫分析仪)》用到的仪器有KRUSS DFA100型全自动泡沫分析仪

推荐专场