方案详情

文

与白炽光源相比,LED 拥有许多优点,包括更低的能耗、更长的寿命,以及更高的灵活性。

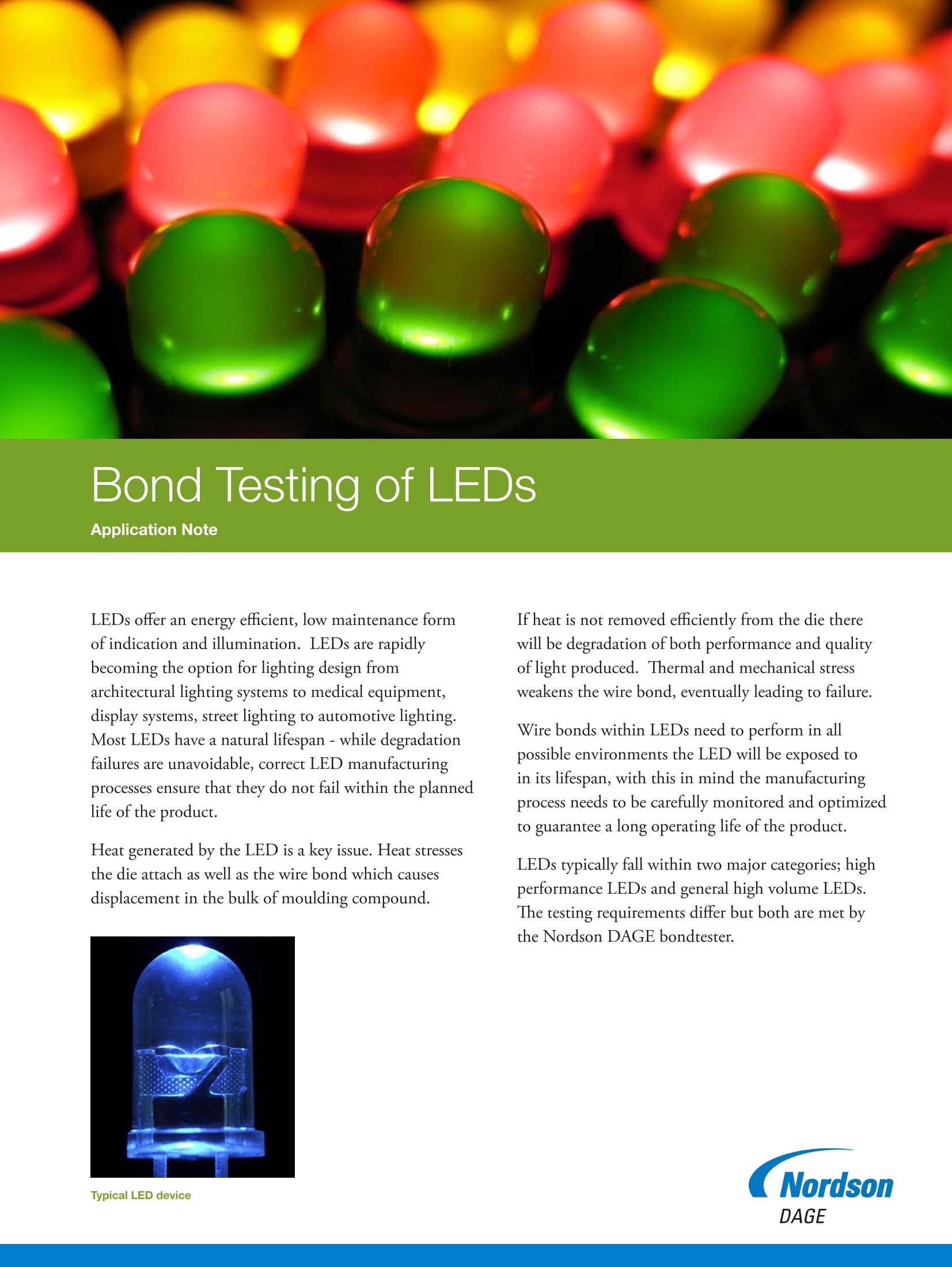

但是现代 LED 亮度极高,所产生的热量导致了温度升高,这一点已渐渐成为不利因素。 LED 产生的热量会压迫晶粒固着和线焊,从而导致大量模塑化合物发生位移。 热应力和机械应力会削弱线焊的焊接强度,最终导致焊线脱落。 考虑到这些因素,在生产过程中需要小心监控和优化制造工艺,以保障产品能有较长的使用寿命。

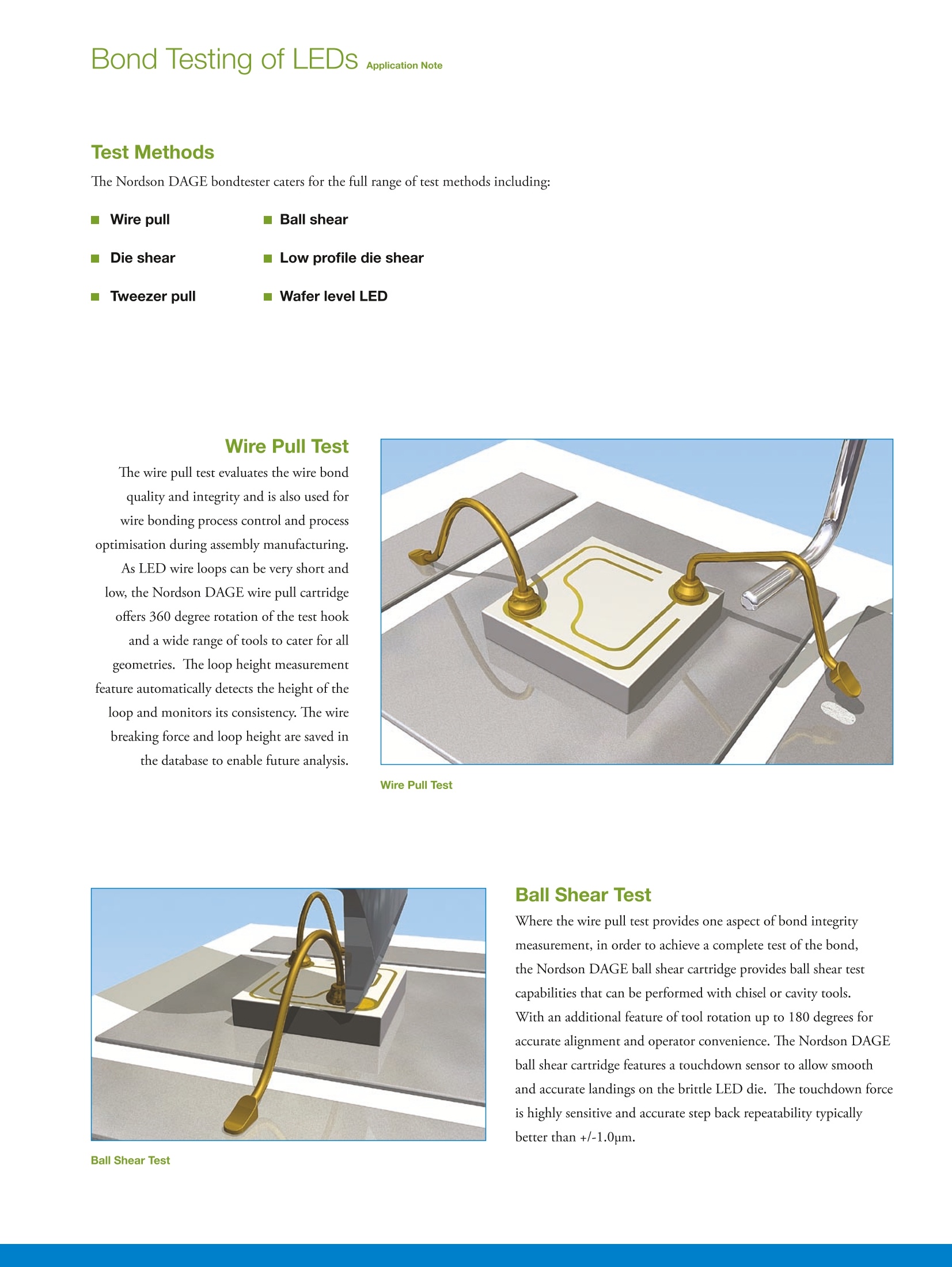

Nordson DAGE 焊接强度测试仪提供市场领先的功能,可以应对发光二极管 (LED) 所带来的测试应用的挑战,包括焊线拉力、锡球剪切力、标准晶粒和低轮廓晶粒的晶粒剪切力测试,以及镊钳和晶圆级别的测试。

方案详情

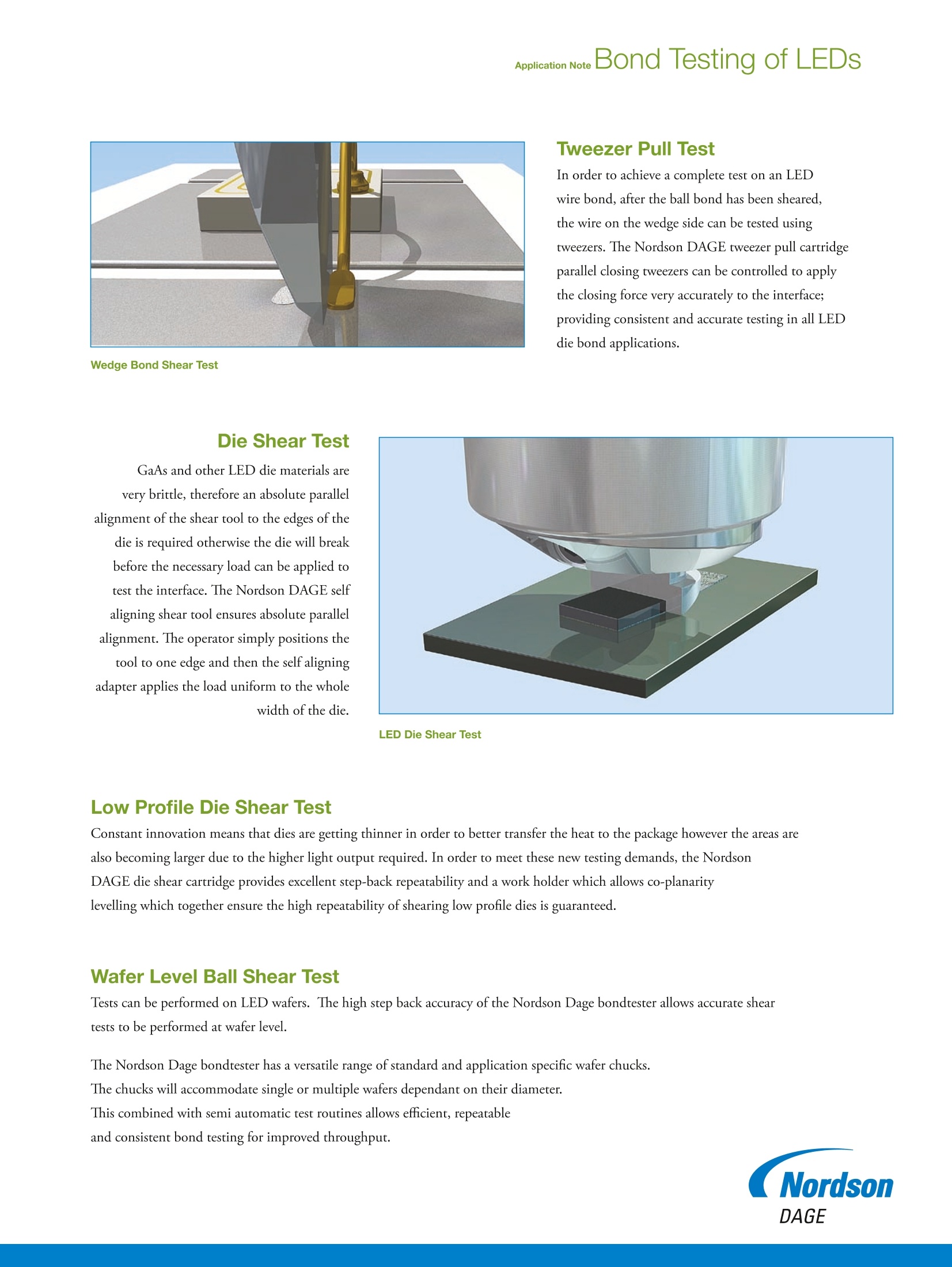

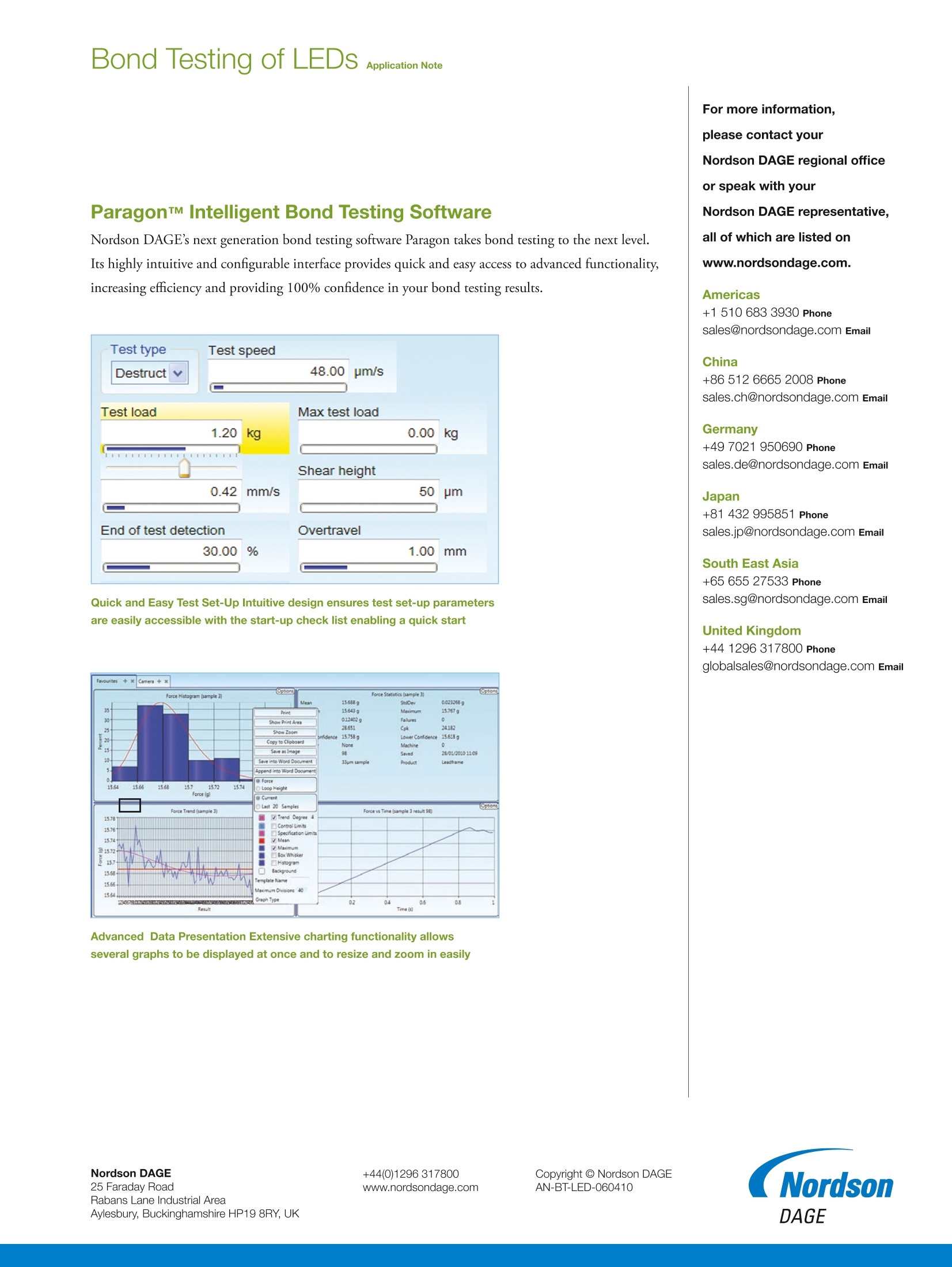

Application NoteBond Testing of LEDs Bond Testing of LEDsSAApplication Note Bond Testing of LEDs LEDs offer an energy efficient, low maintenance formof indication and illumination. LEDs are rapidlybecoming the option for lighting design fromarchitectural lighting systems to medical equipment,display systems, street lighting to automotive lighting.Most LEDs have a natural lifespan- while degradationfailures are unavoidable, correct LED manufacturingprocesses ensure that they do not fail within the plannedlife of the product. Heat generated by the LED is a key issue. Heat stressesthe die attach as well as the wire bond which causesdisplacement in the bulk of moulding compound. If heat is not removed efficiently from the die therewill be degradation of both performance and qualityof light produced. Thermal and mechanical stressweakens the wire bond, eventually leading to failure. Wire bonds within LEDs need to perform in allpossible environments the LED will be exposed toin its lifespan, with this in mind the manufacturingprocess needs to be carefully monitored and optimizedto guarantee a long operating life of the product. LEDs typically fall within two major categories; highperformance LEDs and general high volume LEDs.The testing requirements differ but both are met bythe Nordson DAGE bondtester. Bond Testing of LEDssAApplication Note Test Methods The Nordson DAGE bondtester caters for the full range of test methods including: Wire pull Ball shear Die shear Low profile die shear Tweezer pull Wafer level LED Wire Pull Test The wire pull test evaluates the wire bondquality and integrity and is also used forwire bonding process control and processoptimisation during assembly manufacturing.As LED wire loops can be very short andlow, the Nordson DAGE wire pull cartridgeoffers 360 degree rotation of the test hookand a wide range of tools to cater for allgeometries. The loop height measurementfeature automatically detects the height of theloop and monitors its consistency. The wirebreaking force and loop height are saved in the database to enable future analysis. Ball Shear Test Where the wire pull test provides one aspect of bond integritymeasurement, in order to achieve a complete test of the bondthe Nordson DAGE ball shear cartridge provides ball shear testcapabilities that can be performed with chisel or cavity tools.With an additional feature of tool rotation up to 180 degrees foraccurate alignment and operator convenience. The Nordson DAGEball shear cartridge features a touchdown sensor to allow smoothand accurate landings on the brittle LED die. The touchdown forceis highly sensitive and accurate step back repeatability typicallybetter than +/-1.0pm. Wedge Bond Shear Test Tweezer Pull Test In order to achieve a complete test on an LEDwire bond, after the ball bond has been sheared,the wire on the wedge side can be tested usingtweezers. The Nordson DAGE tweezer pull cartridgeparallel closing tweezers can be controlled to applythe closing force very accurately to the interface;providing consistent and accurate testing in all LEDdie bond applications. Die Shear Test GaAs and other LED die materials arevery brittle, therefore an absolute parallelalignment of the shear tool to the edges of thedie is required otherwise the die will breakbefore the necessary load can be applied totest the interface. The Nordson DAGE selfaligning shear tool ensures absolute parallelalignment. The operator simply positions thetool to one edge and then the self aligningadapter applies the load uniform to the wholewidth of the die. LED Die Shear Test Low Profile Die Shear Test Constant innovation means that dies are getting thinner in order to better transfer the heat to the package however the areas arealso becoming larger due to the higher light output required. In order to meet these new testing demands, the Nordson DAGE die shear cartridge provides excellent step-back repeatability and a work holder which allows co-planarity levelling which together ensure the high repeatability of shearing low profile dies is guaranteed. Wafer Level Ball Shear Test Tests can be performed on LED wafers. The high step back accuracy of the Nordson Dage bondtester allows accurate sheartests to be performed at wafer level. The Nordson Dage bondtester has a versatile range of standard and application specific wafer chucks. The chucks will accommodate single or multiple wafers dependant on their diameter. This combined with semi automatic test routines allows efficient, repeatable and consistent bond testing for improved throughput. ParagonTM Intelligent Bond Testing Software Nordson DAGE's next generation bond testing software Paragon takes bond testing to the next level.Its highly intuitive and configurable interface provides quick and easy access to advanced functionality,increasing efficiency and providing 100% confidence in your bond testing results. Quick and Easy Test Set-Up Intuitive design ensures test set-up parametersare easily accessible with the start-up check list enabling a quick start For more information, please contact yourNordson DAGE regional officeor speak with yourNordson DAGE representative, all of which are listed on www.nordsondage.com. Americas +1 510 683 3930 Phonesales@nordsondage.com Email China +86 512 66652008Phonesales.ch@nordsondage.com Email Germany +49 7021950690 Phonesales.de@nordsondage.com Email Japan +81 432 995851 Phonesales.jp@nordsondage.com Email South East Asia+65 65527533 Phonesales.sg@nordsondage.com Email United Kingdom+44 1296317800 Phoneglobalsales@nordsondage.com Email Typical LED device Ball Shear Test Wire bonds within LEDs need to perform in all possible environments the LED will be exposed to in its lifespan, with this in mind the manufacturing process needs to be carefully monitored and optimized to guarantee a long operating life of the product.LEDs typically fall within two major categories; high performance LEDs and general high volume LEDs. The testing requirements differ but both are met by the Nordson DAGE bondtester.Test MethodsThe Nordson DAGE bondtester caters for the full range of test methods including:·Wire pull·Ball shear·Die shear·Low profile die shear·Tweezer pull Wafer level LED

确定

还剩2页未读,是否继续阅读?

聚擘国际贸易(上海)有限公司为您提供《LED中Wire bonds检测方案(半导体检测仪)》,该方案主要用于电子元器件产品中Wire bonds检测,参考标准--,《LED中Wire bonds检测方案(半导体检测仪)》用到的仪器有DAGE4000多功能推拉力测试机、诺信达格Nordson DAGE多功能推拉力测试机DAGE4000

推荐专场

相关方案

更多

该厂商其他方案

更多