方案详情

文

The Electric Particulate Suspension (EPS) is a combustion ignition system being developed at Iowa State University for evaluating quenching effects of powders in microgravity (quenching distance, ignition energy, flammability limits). Because of the high cloud uniformity possible and its simplicity, the EPS method has potential for ‘benchmark’ design of quenching flames that would provide NASA and the scientific community with a new fire standard.

Microgravity is expected to increase suspension uniformity even further and extend combustion testing to higher concentrations (rich fuel limit) than is possible at normal gravity. Two new combustion parameters are being investigated with this new method: (1) the particle velocity distribution and (2) particle-oxidant slip velocity. Both walls and (inert) particles can be tested

as quenching media. The EPS method supports combustion modeling by providing accurate measurement of flame-quenching distance as a parameter in laminar flame theory as it closely relates to characteristic flame thickness and flame structure. Because of its design simplicity, EPS is suitable for testing on the International Space Station (ISS). Laser scans showing stratification effects at 1-g have been studied for different materials, aluminum, glass, and

copper. PTV/PIV and a leak hole sampling rig give particle velocity distribution with particle slip velocity evaluated using LDA. Sample quenching and ignition energy curves are given for aluminum powder. Testing is planned for the KC-135 and NASA’s two second drop tower.

Only 1-g ground-based data have been reported to date.

方案详情

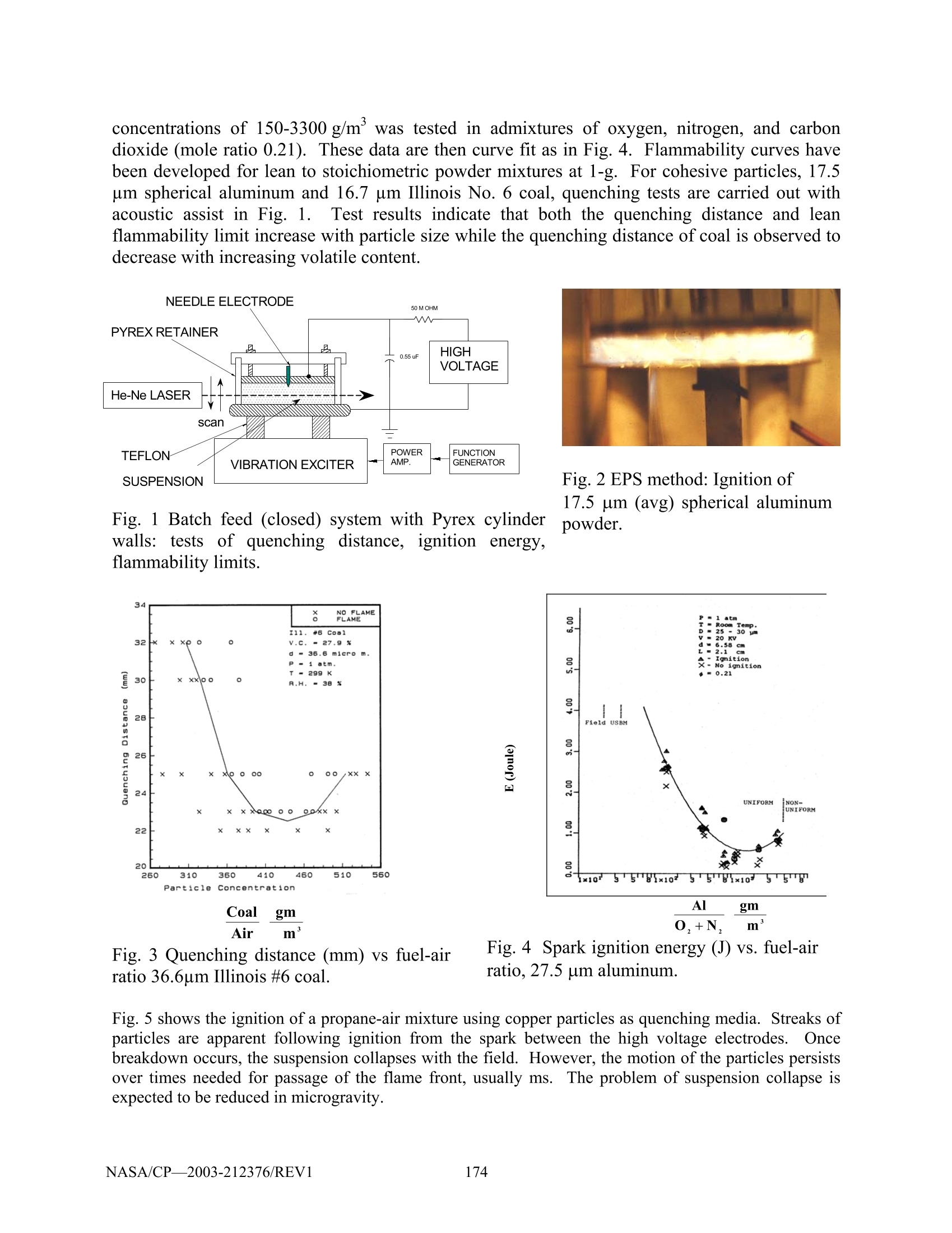

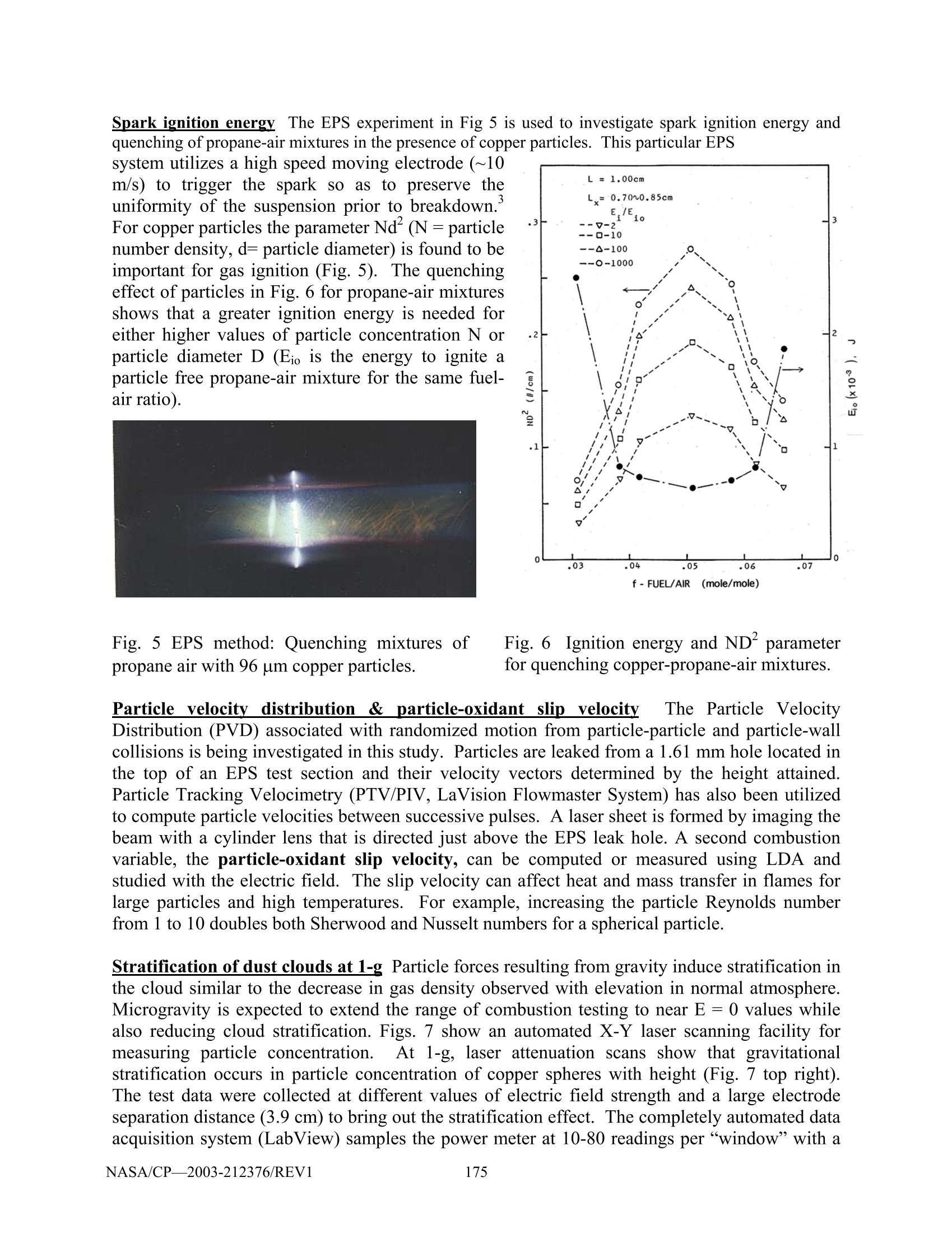

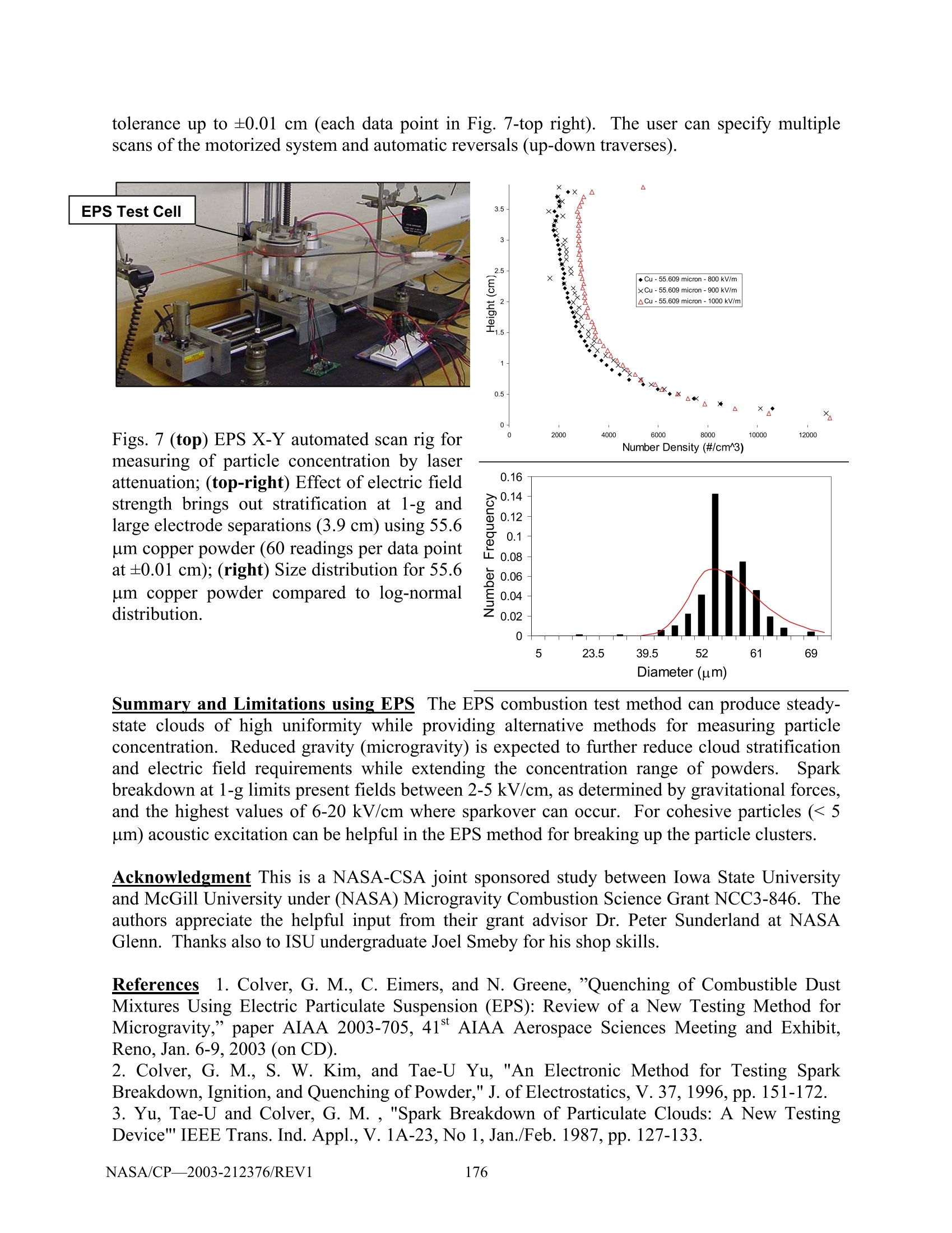

QUENCHING COMBUSTIBLE DUST MIXTURES USING ELECTRICPARTICULATE SUSPENSIONS (EPS): A NEW TESTING METHOD FOR MICROGRAVITY Gerald M.Colver,Nathanael Greene, David Shoemaker, Hua Xu Department of Mechanical Engineering Iowa State University, Ames, IA. 50011 AbstractThe Electric Particulate Suspension (EPS) is a combustion ignition system beingdeveloped at Iowa State University for evaluating quenching effects of powders in microgravity(quenching distance, ignition energy, flammability limits). Because of the high cloud uniformitypossible and its simplicity, the EPS method has potential for ‘benchmark’design of quenchingflames that would provide NASA and the scientific community with a new fire standard.Microgravity is expected to increase suspension uniformity even further and extend combustiontesting to higher concentrations (rich fuel limit) than is possible at normal gravit.y .T Twwo newcombustion parameters are being investigated with this new method: (1) the particle velocitydistribution and (2) particle-oxidant slip velocity. Both walls and (inert) particles can be testedas quenching media. The EPS method supports combustion modeling by providing accuratemeasurement of flame-quenching distance as a parameter in laminar flame theory as it closelyrelates to characteristic flame thickness and flame structure. Because of its design simplicity,EPS is suitable for testing on the International Space Station (ISS). Laser scans showingstratification effects at 1-g have been studied for different materials, aluminum, glass, andcopper. PTV/PIV and a leak hole sampling rig give particle velocity distribution with particleslip velocity evaluated using LDA. Sample quenching and ignition energy curves are given foraluminum powder. Testing is planned for the KC-135 and NASA’s two second drop tower.Only 1-g ground-based data have been reported to date. EPS Design An electric particulate suspension (EPS) utilizes a high voltage electric field todisperse a powder of semi-insulating or conductive material in a cloud of (oppositely) chargedparticles.The resulting steady state suspension is subsequently ignited by a spark dischargefrom a stationary (or moving) needle electrode, Fig.1. Particle motion in the direction of theelectric field is confined between two parallel plate electrodes with diffusive motion in thehorizontal direction confined by a Pyrex cylindrical retainer. High voltage capacitors provide thenecessary energy for the spark. Wall quenching tests involve adjusting the height distancebetween the parallel plate electrodes and testing for flame propagation following the spark.Quenching by inert powders is accomplished by suspending various amounts of copper or glassparticles with a combustible powder or gas mixture and igniting the mixture. Acoustic vibrationis utilized to aid the suspension of cohesive particle such as coal dust or other fine particles (Fig.1). The centered spark kernel produces a cylindrically outward propagating flame. Fig. 3 showsa photograph of quench (batch) test of aluminum powder 25-35 um using the system in Fig. 2. Powder quenching Powder (wall) quenching studies carried out to date at 1-g include themeasurement of quenching and ignition energy curves for aluminum powder and coal dust invarious admixtures of oxygen,nitrogen, and carbon dioxide at ambient conditions of temperatureand pressure. Example quenching and ignition curves for coal dust and aluminum powder areshown in Figs. 3 and 4 respectively, using the setup of Fig. 1. Aluminum powder 25-30 um in concentrations of 150-3300 g/m’ was tested in admixtures of oxygen, nitrogen, and carbondioxide (mole ratio 0.21). These data are then curve fit as in Fig. 4. Flammability curves havebeen developed for lean to stoichiometric powder mixtures at 1-g. For cohesive particles, 17.5um spherical aluminum and 16.7 um Illinois No. 6 coal, quenching tests are carried out withacoustic assist in Fig. 1.Test results indicate that both the quenching distance and leanflammability limit increase with particle size while the quenching distance of coal is observed todecrease with increasing volatile content. Fig. 2 EPS method: Ignition of17.5 um (avg) spherical aluminumpowder. Fig. 1 Batch feed (closed) system with Pyrex cylinderwalls:i: tests of quenching distance, ignition energy,flammability limits. Air m Fig. 3 Quenching distance (mm) vs fuel-airratio 36.6um Illinois #6 coal. Fig. 4 Spark ignition energy (J) vs. fuel-airratio, 27.5 um aluminum. Fig. 5 shows the ignition of a propane-air mixture using copper particles as quenching media. Streaks ofparticles are apparent following ignition from the spark between the high voltage electrodes.. OOncebreakdown occurs, the suspension collapses with the field. However, the motion of the particles persistsOV6 needed for passage of the flame front, usually ms. The problem of suspension cc isexpected to be reduced in microgravity. quenching of propane-air mixtures in the presence of copper particles. This particular EPSsystem utilizes a high speed moving electrode (~10m/s) to trigger the spark so as to preserve the L=1.00cmuniformity of the suspension prior to breakdown. 4=0.700.85cmFor copper particles the parameter Nd' (N =particle .3io--V-2--0-10number density,d= particle diameter) is found to be --A-100important for gas ignition (Fig. 5). The quenching --O-1000effect of particles in Fig. 6 for propane-air mixturesshows that a greater ignition energy is needed foreither higher values of particle concentration N orparticle diameter D (Eio is the energy to ignite aparticle free propane-air mixture for the same fuel-air ratio). 一E会.10 L.03 .04 .05 .06 .07f-FUEL/AIR (mole/mole) Fig. 5 EPS method: Quenching mixtures ofpropane air with 96 um copper particles. Fig. 6 Ignition energy and ND’ parameterfor quenching copper-propane-air mixtures. Particle velocity distribution & particle-oxidant slip velocityThe Particle VelocityDistribution (PVD) associated with randomized motion from particle-particle and particle-wallcollisions is being investigated in this study. Particles are leaked from a 1.61 mm hole located inthe top of an EPS test section and their velocity vectors determined by the height attained.Particle Tracking Velocimetry (PTV/PIV, LaVision Flowmaster System) has also been utilizedto compute particle velocities between successive pulses. A laser sheet is formed by imaging thebeam with a cylinder lens that is directed just above the EPS leak hole. A second combustionvariable, the particle-oxidant slip velocity, can be computed or measured using LDA andstudied with the electric field. The slip velocity can affect heat and mass transfer in flames forlarge particles and high temperatures. For example, increasing the particle Reynolds numberfrom 1 to 10 doubles both Sherwood and Nusselt numbers for a spherical particle. Stratification of dust clouds at 1-g Particle forces resulting from gravity induce stratification inthe cloud similar to the decrease in gas density observed with elevation in normal atmosphere.Microgravity is expected to extend the range of combustion testing to near E =0 values whilealso reducing cloud stratification. Figs. 7 show an automated X-Y laser scanning facility formeasuring particle concentration. At1-g, laser attenuation scans show that gravitationalstratification occurs in particle concentration of copper spheres with height (Fig. 7 top right).The test data were collected at different values of electric field strength and a large electrodeseparation distance (3.9 cm) to bring out the stratification effect. The completely automated dataacquisition system (LabView) samples the power meter at 10-80 readings per “window”with a tolerance up to ±0.01 cm (each data point in Fig. 7-top right).. The user can specify multiplescans of the motorized system and automatic reversals (up-downtraverses). Figs. 7 (top) EPS X-Y automated scan rig formeasuring of particle concentration by laserattenuation; (top-right) Effect of electric fieldstrength brings out stratification at 1-g andlarge electrode separations (3.9 cm) using 55.6um copper powder (60 readings per data pointat±0.01 cm); (right) Size distribution for 55.6um copper powder compared to log-normaldistribution. Summary and Limitations using EPS The EPS combustion test method can produce steady-state clouds of high uniformity while providing alternative methods for measuring particleconcentration. Reduced gravity (microgravity) is expected to further reduce cloud stratificationand electric field requirements while extending the concentration range of powders.Sparkbreakdown at 1-g limits present fields between 2-5 kV/cm, as determined by gravitational forces,and the highest values of 6-20 kV/cm where sparkover can occur. For cohesive particles (< 5um) acoustic excitation can be helpful in the EPS method for breaking up the particle clusters. Acknowledgment This is a NASA-CSA joint sponsored study between Iowa State Universityand McGill University under (NASA) Microgravity Combustion Science Grant NCC3-846. Theauthors appreciate the helpful input from their grant advisor Dr. Peter Sunderland at NASAGlenn. Thanks also to ISU undergraduate Joel Smeby for his shop skills. References1. Colver, G. M., C. Eimers, and N. Greene, "Quenching of Combustible DustMixtures Using Electric Particulate Suspension (EPS): Review of a New Testing Method forMicrogravity,”paper AIAA 2003-705, 41 AIAA Aerospace Sciences Meeting and Exhibit,Reno, Jan. 6-9,2003 (on CD). 2. Colver, G. M., S. W. Kim, and Tae-U Yu, "An Electronic Method for Testing SparkBreakdown, Ignition, and Quenching of Powder," J. of Electrostatics, V. 37, 1996, pp. 151-172. 3. Yu, Tae-U and Colver, G. M.,"Spark Breakdown of Particulate Clouds: A New TestingDevice""IEEE Trans. Ind. Appl.,V. 1A-23, No 1, Jan./Feb. 1987, pp.127-133. NASA/CP—REV

确定

还剩2页未读,是否继续阅读?

北京欧兰科技发展有限公司为您提供《电致颗粒悬浮,可燃尘埃混合体中流场,速度场,速度矢量场检测方案(粒子图像测速)》,该方案主要用于其他中流场,速度场,速度矢量场检测,参考标准--,《电致颗粒悬浮,可燃尘埃混合体中流场,速度场,速度矢量场检测方案(粒子图像测速)》用到的仪器有德国LaVision PIV/PLIF粒子成像测速场仪、PLIF平面激光诱导荧光火焰燃烧检测系统、Imager LX PIV相机

推荐专场

相关方案

更多

该厂商其他方案

更多