方案详情

文

玻璃材料和塑料材料被广泛的使用在生物技术领域。比如注射器,浓缩装置的滤网或者容量瓶等,都是由塑料或者玻璃组成。而蛋白质都有通过疏水效果被动的吸附在玻璃和塑料的表面上的趋势,而这会给类似大规模制备重组蛋白生产带来损失。所以说材料的选择对于减少这种损失由很大帮助。本文中通过使用QCM-D技术,实时检测了蛋白在PVDF和硼硅酸盐表面的吸附情况。

方案详情

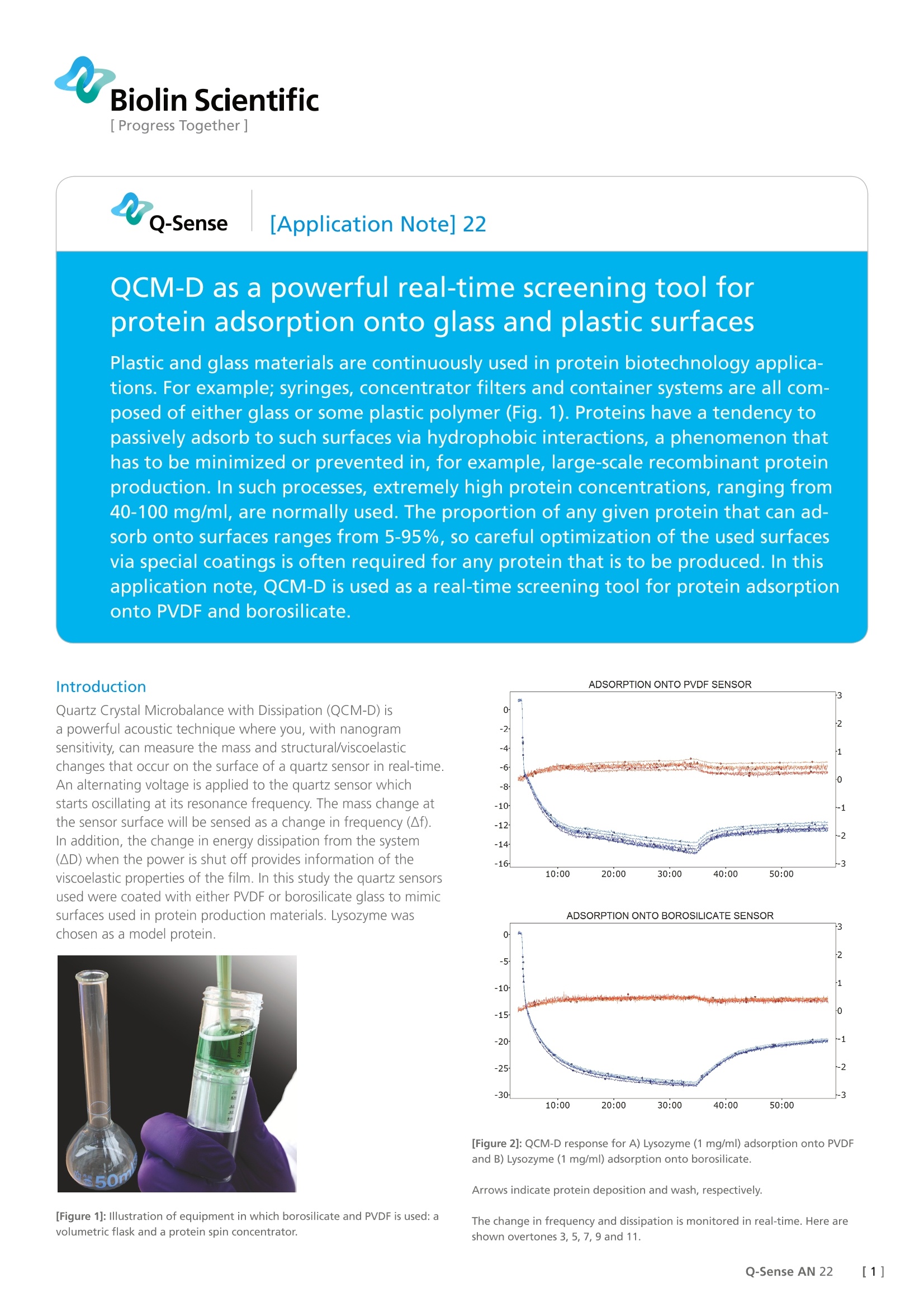

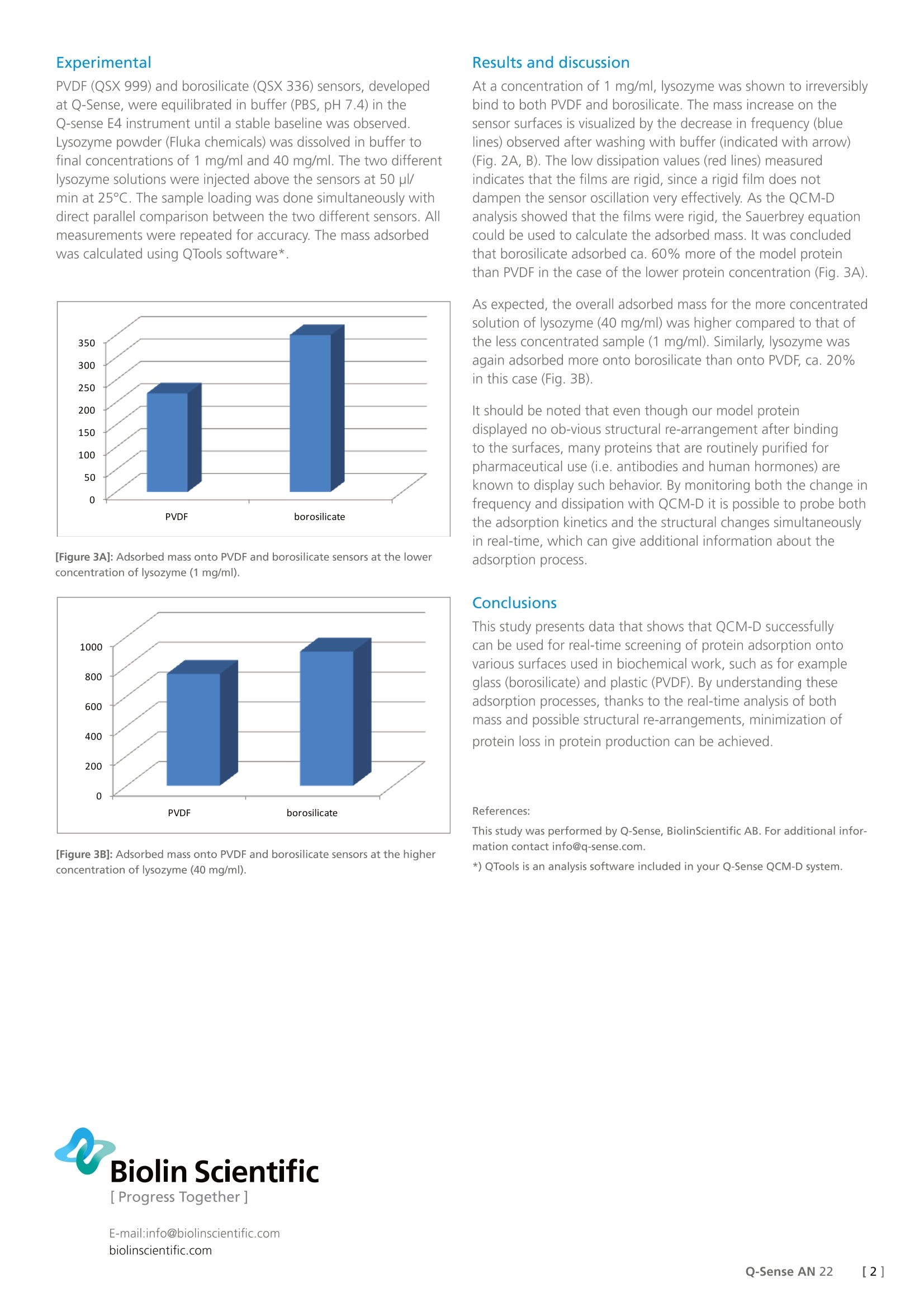

Biolin Scientific[ Progress Together ] [Application Note] 22 QCM-D as a powerful real-time screening tool forprotein adsorption onto glass and plastic surfacesPlastic and glass materials are continuously used in protein biotechnology applica-tions. For example; syringes, concentrator filters and container systems are all com-posed of either glass or some plastic polymer (Fig. 1). Proteins have a tendency topassively adsorb to such surfaces via hydrophobic interactions, a phenomenon thathas to be minimized or prevented in, for example, large-scale recombinant proteinproduction. In such processes, extremely high protein concentrations, ranging from40-100 mg/ml, are normally used. The proportion of any given protein that can ad-sorb onto surfaces ranges from 5-95%, so careful optimization of the used surfacesvia special coatings is often required for any protein that is to be produced. In thisapplication note, QCM-D is used as a real-time screening tool for protein adsorptiononto PVDF and borosilicate. Introduction Quartz Crystal Microbalance with Dissipation (QCM-D) isa powerful acoustic technique where you, with nanogramsensitivity, can measure the mass and structural/viscoelasticchanges that occur on the surface of a quartz sensor in real-time.An alternating voltage is applied to the quartz sensor whichstarts oscillating at its resonance frequency. The mass change atthe sensor surface will be sensed as a change in frequency (Af).In addition, the change in energy dissipation from the system(AD) when the power is shut off provides information of theviscoelastic properties of the film. In this study the quartz sensorsused were coated with either PVDF or borosilicate glass to mimicsurfaces used in protein production materials. Lysozyme waschosen as a model protein. [Figure 1]: Illustration of equipment in which borosilicate and PVDF is used: avolumetric flask and a protein spin concentrator. ADSORPTION ONTO BOROSILICATE SENSOR [Figure 2]:QCM-D response for A) Lysozyme (1 mg/ml) adsorption onto PVDFand B) Lysozyme (1 mg/ml) adsorption onto borosilicate. Arrows indicate protein deposition and wash, respectively. The change in frequency and dissipation is monitored in real-time. Here areshown overtones 3, 5, 7, 9 and 11. PVDF (QSX 999) and borosilicate (QSX 336) sensors, developedat Q-Sense, were equilibrated in buffer (PBS, pH 7.4) in theQ-sense E4 instrument until a stable baseline was observed.Lysozyme powder (Fluka chemicals) was dissolved in buffer tofinal concentrations of 1 mg/ml and 40 mg/ml. The two differentlysozyme solutions were injected above the sensors at 50 ul/min at 25℃. The sample loading was done simultaneously withdirect parallel comparison between the two different sensors. Allmeasurements were repeated for accuracy. The mass adsorbedwas calculated using QTools software*. [Figure 3A]: Adsorbed mass onto PVDF and borosilicate sensors at the lowerconcentration of lysozyme(1 mg/ml). [Figure 3B]: Adsorbed mass onto PVDF and borosilicate sensors at the higherconcentration of lysozyme (40 mg/ml). Results and discussion At a concentration of 1 mg/ml, lysozyme was shown to irreversiblybind to both PVDF and borosilicate. The mass increase on thesensor surfaces is visualized by the decrease in frequency (bluelines) observed after washing with buffer (indicated with arrow)(Fig. 2A, B). The low dissipation values (red lines) measuredindicates that the films are rigid, since a rigid film does notdampen the sensor oscillation very effectively. As the QCM-Danalysis showed that the films were rigid, the Sauerbrey equationcould be used to calculate the adsorbed mass. It was concludedthat borosilicate adsorbed ca. 60% more of the model proteinthan PVDF in the case of the lower protein concentration (Fig. 3A). As expected, the overall adsorbed mass for the more concentratedsolution of lysozyme (40 mg/ml) was higher compared to that ofthe less concentrated sample (1 mg/ml). Similarly, lysozyme wasagain adsorbed more onto borosilicate than onto PVDF, ca. 20%in this case (Fig. 3B). It should be noted that even though our model proteindisplayed no ob-vious structural re-arrangement after bindingto the surfaces, many proteins that are routinely purified forpharmaceutical use (i.e. antibodies and human hormones) areknown to display such behavior. By monitoring both the change infrequency and dissipation with QCM-D it is possible to probe boththe adsorption kinetics and the structural changes simultaneouslyin real-time, which can give additional information about theadsorption process. Conclusions This study presents data that shows that QCM-D successfullycan be used for real-time screening of protein adsorption ontovarious surfaces used in biochemical work, such as for exampleglass (borosilicate) and plastic (PVDF). By understanding theseadsorption processes, thanks to the real-time analysis of bothmass and possible structural re-arrangements, minimization ofprotein loss in protein production can be achieved. References: This study was performed by Q-Sense, BiolinScientific AB. For additional infor-mation contact info@q-sense.com. *) QTools is an analysis software included in your Q-Sense QCM-D system. []Q-Sense AN

确定

还剩1页未读,是否继续阅读?

瑞典百欧林科技有限公司为您提供《使用QCM-D技术检测蛋白在玻璃和塑料表面的吸附》,该方案主要用于其他中--检测,参考标准--,《使用QCM-D技术检测蛋白在玻璃和塑料表面的吸附》用到的仪器有QSense卓越版四通道石英晶体微天平、QSense Explorer扩展版石英晶体微天平、QSense全自动八通道石英晶体微天平

推荐专场

相关方案

更多

该厂商其他方案

更多