用户多,发表论文多。

XH-100B型祥鹄电脑微波催化合成/萃取仪,是应用先进的微波技术作为物理催化手段的新型化学反应装置。主要由微波催化仪主机、微电脑智能控制系统、高精度温度传感器、回流冷凝系统等组成。仪器使用先进的温度传感器,对反应温度进行实时精确监测;采用独创的电脑自学习技术,自动调节微波功率,智能控温保温,控温精度达±1℃。大容量不锈钢腔体,耐腐蚀,耐高温。反应容积微波泄漏符合国家标准。仪器操作简单,界面友好,您可轻松制订各种实验方案,并对实验过程进行全程监控。

方案详情

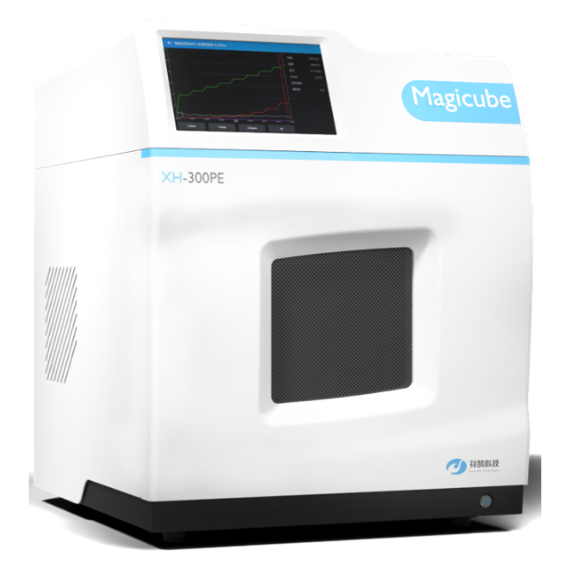

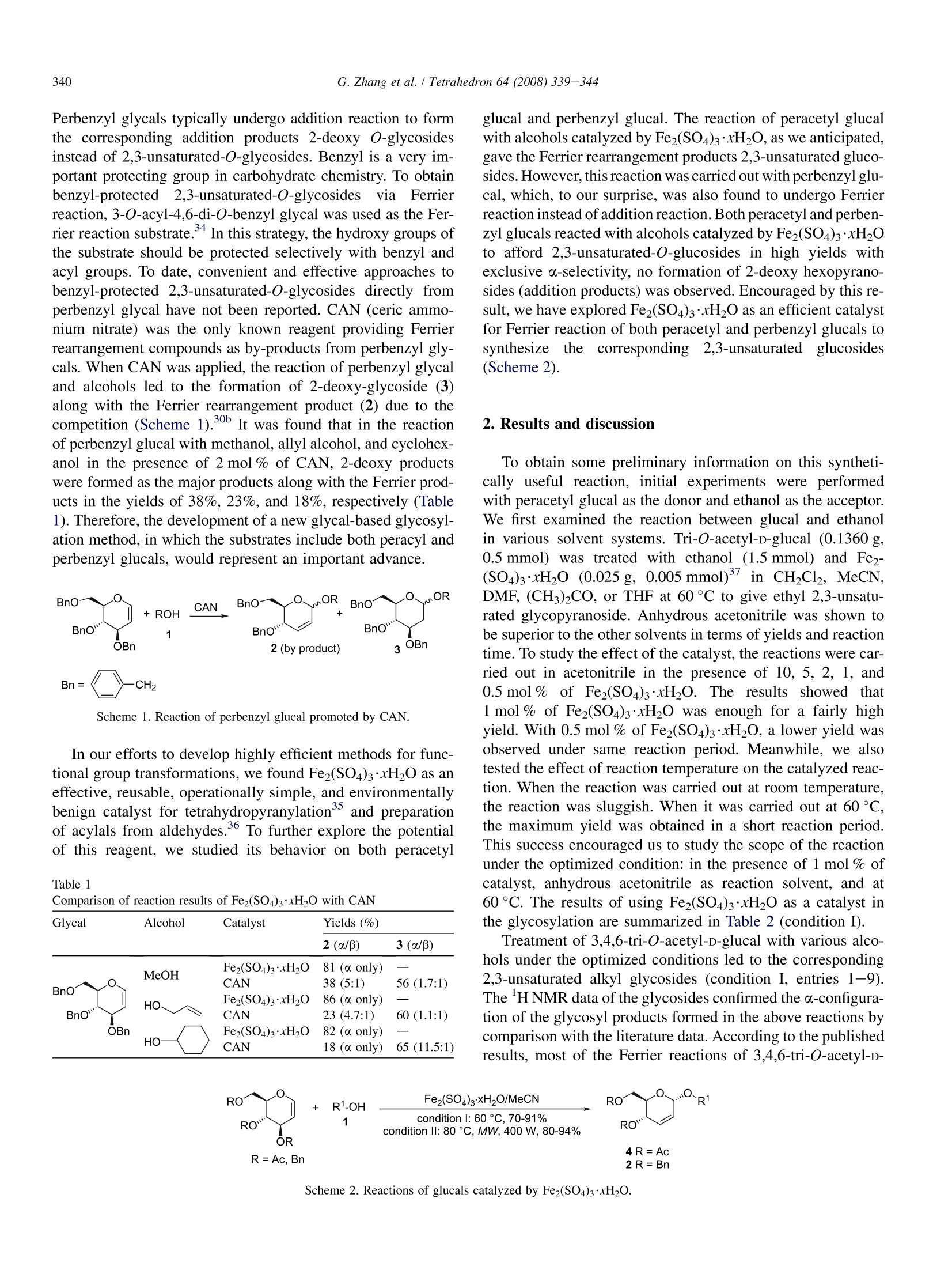

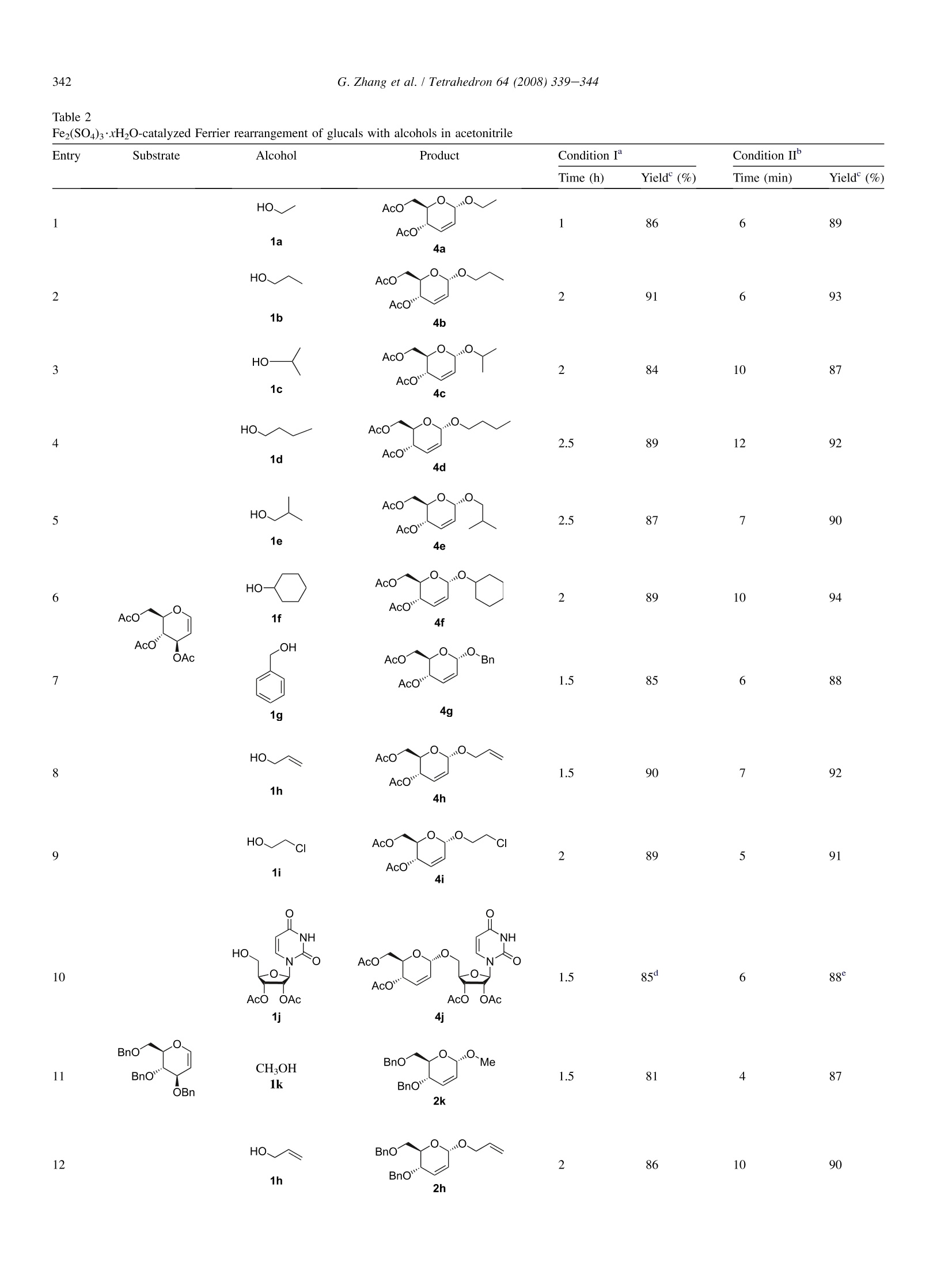

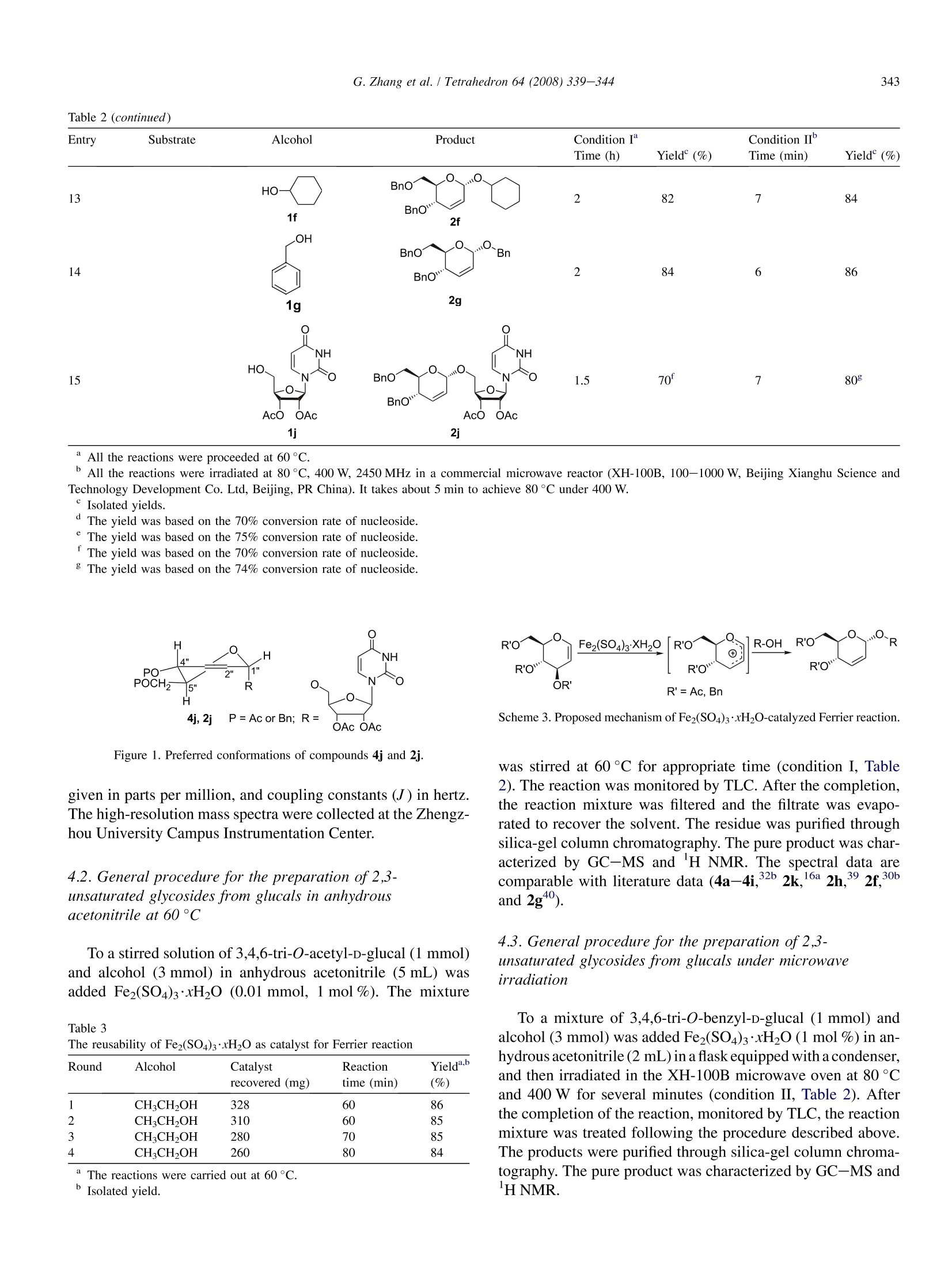

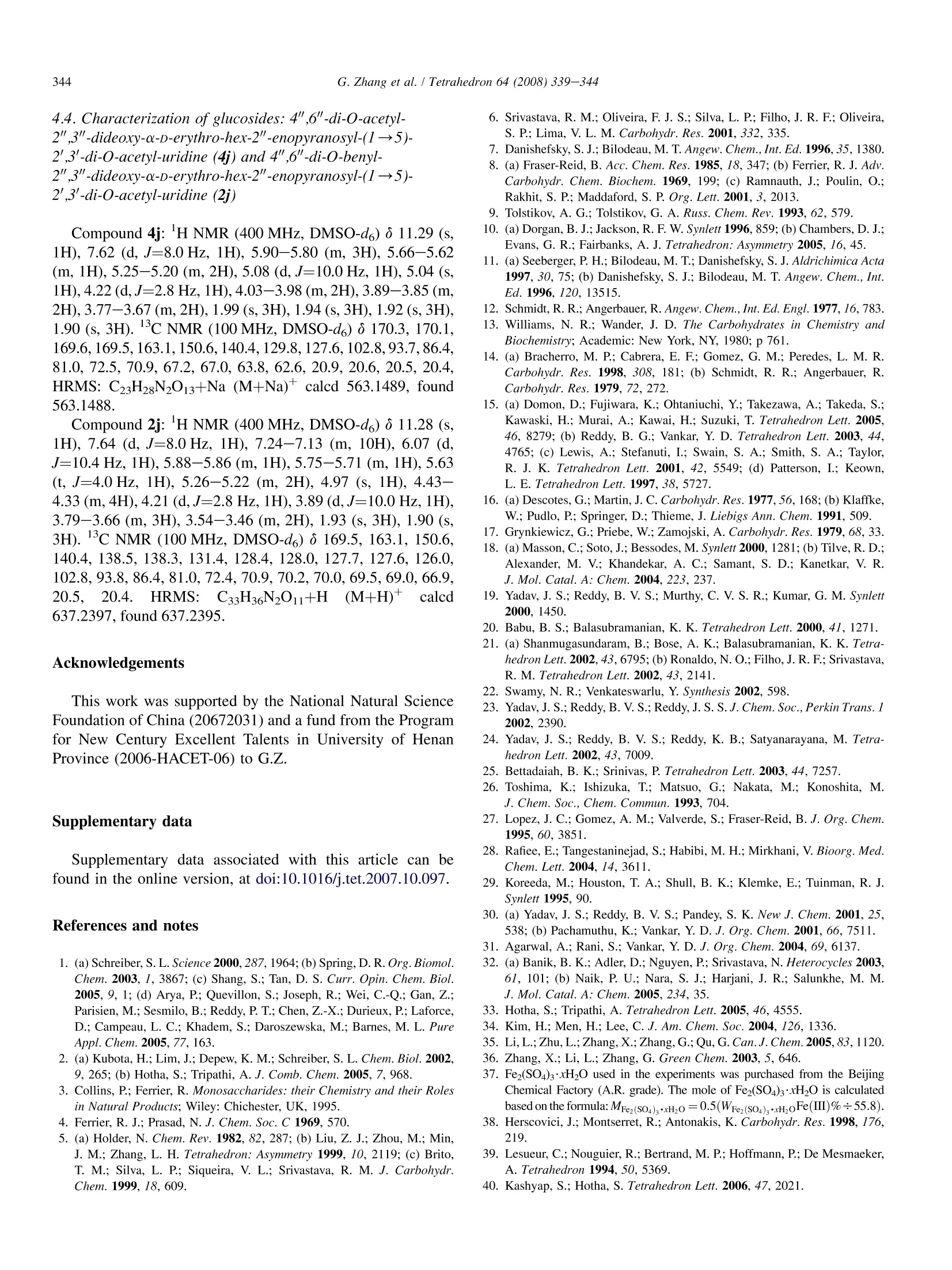

Available online at www.sciencedirect.comScienceDirectTetrahedron 64 (2008) 339-344www.elsevier.com/locate/tet 340G. Zhang et al./Tetrahedron 64 (2008)339-344 C Tetrahedron Ferric sulfate hydrate-catalyzed O-glycosylation using glycalswith or without microwave irradiation Guisheng Zhang*, Qingfeng Liu, Lei Shi, Jiuxia Wang School of Chemical and Environmental Sciences, Henan Normal University, 46 East Construction Road, Xinxiang, Henan 453007, PR China Received 24 August 2007;received in revised form 24 October 2007; accepted 26 October 2007Available online 1 November 2007 Abstract We have developed a novel glycal-based O-glycosylation reaction, in which the substrates are not only peracetyl glycals but also perbenzylglucals to afford the corresponding 2,3-unsaturated-O-glycosides via Ferrier rearrangement. The reaction of the perbenzyl glucal with variousalcohols catalyzed by ferric sulfate hydrate (Fe2(SO4)3xH2O) was successfully carried out to give 2,3-unsaturated D-O-glucosides with exclu-sive a-selectivity and no formation of addition products 2-deoxy hexopyranosides was observed. It is the first report on peralkyl glycal efficientlyundergoing Ferrier rearrangement instead of addition of alcohols catalyzed by Lewis acids. Fe2(SO4)3xH2O is an effective, convenient, andenvironmentally benign heterogeneous catalyst. It has low catalytic loading and recyclable without significant loss of activity.@ 2007 Elsevier Ltd. All rights reserved. Keywords: O-Glycosylation; Ferrier rearrangement; Ferric sulfate hydrate; Peracetyl or perbenzyl glucal; 2,3-Unsaturated O-glycosides 1. Introduction Ferrier rearrangement is an allylic rearrangement of glycalestersin the presence of alcohols leading to 2,3-unsaturatedglycosides. Since Ferrier rearrangement was discovered in1969, it has been routinely used in the area of carbohydratechemistry. The unsaturated glycosides obtained through Ferrierrearrangement play an important role in the transformation ofthese compounds into other interesting carbohydrates.2,3-Unsaturated glycosides° have a unique place in carbohydratechemistry, since they can be further functionalized and serveas chiral intermediate°8a.9 in the synthesis of biologically active11compounds, such as glycopeptide blocks,oligosaccharides,and modified carbohydrates. In addition, 2,3-unsaturatedglycosides have also been employed in the synthesis of someimportant antibiotics,13nucleosides,4natural product-likecompounds,an2db various natural products.15 The catalysts for the synthesis of 2,3-unsaturated glycosidesvia Ferrier rearrangement have continuously received extensive ( *Corresponding author. Tel./fax: +86 373 3325250. ) ( E-mail address: zgs6668@yahoo.com (G. Z h ang). ) ( 0040-4020/$ -see front ma t ter @ 2007 Else v ier Ltd. All rights reserved.doi:10.1016/j.tet.2007 . 10.097 ) attention. A wide range of catalysts have been employed to form2.3-unsaturated1glycosides, such as BF3·OEt2,16SnCl4,17FeCl3,188dSc(OTf)3,InCl3,20Montmorillonite K-10.BiCl,22Dy(OTf)33,23CeCl3·7H2O,24ZnCl,25DDQ,26NIS,7 KsCo-W12040,12,2.99CAN..30HClO4-SiO2,Bi(NO3)3.5H2O,Fe(NO3)3·9H2O,,and NbCls.These catalysts included Lewisacid catalysts and redox reagents. The acid catalysts,usually em-ployed in sub-stoichiometric amount, generally provide goodanomeric selectivity for the product under ambient conditions.However, they often suffer from the limited use of acid-labileglycal donors and acceptors. The oxidants are often required instoichiometric amount, and long reaction time and/or high tem-perature are unavoidable. In addition, the reactions under theseconditions usually give low anomeric selectivity for the product.Moreover, some of the catalysts are moisture sensitive and expen-sive. As a result, most of those methods do not satisfy the rule ofgreen chemistry, and entail the problems of tedious work-upprocedures and expensive reagents and equipment. Therefore,searching for environmentally benign and more economicsynthetic methods with greater efficiency and more convenientprocedures is still in strong demand. In general, the substrates of Ferrier rearrangement are per-acyl glycals or the glycals at least with 3-O-acyl group. Perbenzyl glycals typically undergo addition reaction to formthe corresponding addition products 2-deoxy O-glycosides1instead of 2,3-unsaturated-O-glycosides. Benzyl is a very im-portant protecting group in carbohydrate chemistry. To obtainbenzyl-protected2,3-unsaturated-O-glycosidesVviaFerrierreaction, 3-0-acyl-4,6-di-O-benzyl glycal was used as the Fer-rier reaction substrate.In this strategy, the hydroxy groups ofthe substrate should be protected selectively with benzyl andacyl groups. To date, convenient and effective approaches tobenzyl-protected 2,3-unsaturated-O-glycosides directly fromperbenzyl glycal have not been reported. CAN (ceric ammo-nium nitrate) was the only known reagent providing Ferrierrearrangement compounds as by-products from perbenzyl gly-cals. When CAN was applied, the reaction of perbenzyl glycaland alcohols led to the formation of 2-deoxy-glycoside (3)along with the Ferrier rearrangement product (2) due to thecompetition (Scheme 1).30b It was found that in the reactionof perbenzyl glucal with methanol, allyl alcohol, and cyclohex-anol in the presence of 2 mol % of CAN, 2-deoxy productswere formed as the major products along with the Ferrier prod-ucts in the yields of 38%, 23%, and 18%, respectively (Table1). Therefore, the development of a new glycal-based glycosyl-ation method, in which the substrates include both peracyl andperbenzyl glucals, would represent an important advance. Scheme 1. Reaction of perbenzyl glucal promoted by CAN. In our efforts to develop highly efficient methods for func-tional group transformations, we found Fe2(SO4)3*xH2O as aneffective, reusable, operationally simple, and environmentallylatinn35 andrbenign catalyst for tetrahydropyranylation and preparationof acylals from aldehydes. To further explore the potentialof this reagent, we studied its behavior on both peracetyl Table 1Comparison of reaction results of Fe2(SO4)3xH2O with CAN Glycal Alcohol Catalyst Yields (%) 2(a/) 3(a/B) BnO BnO MeOH Fe2(SO4)3·xH20 81 (a only) CAN 38 (5:1) 56 (1.7:1) Fe2(SO4)3xH2O 86 (a only) HO、 CAN 23 (4.7:1) 60(1.1:1) OBn Fe2(SO4)3·xH20 82 (a only) HO- CAN 18 (a only) 65 (11.5:1) glucal and perbenzyl glucal. The reaction of peracetyl glucalwith alcohols catalyzed by Fe2(SO4)3·xH2O, as we anticipated,gave the Ferrier rearrangement products 2,3-unsaturated gluco-sides. However, this reaction was carried out with perbenzylglu-cal, which, to our surprise, was also found to undergo Ferrierreaction instead of addition reaction. Both peracetyl and perben-zyl glucals reacted with alcohols catalyzed by Fe2(SO4)3·xH2Oto afford 2,3-unsaturated-O-glucosides in high yields withexclusive a-selectivity, no formation of 2-deoxy hexopyrano-sides (addition products) was observed. Encouraged by this re-sult, we have explored Fe2(SO4)3xH20as an efficient catalystfor Ferrier reaction of both peracetyl and perbenzyl glucals tosynthesize tltheCcorresponding2.3-unsaturatedglucosides(Scheme 2). 2. Results and discussion To obtain some preliminary information on this syntheti-cally useful reaction, initial experiments were performedwith peracetyl glucal as the donor and ethanol as the acceptor.We first examined the reaction between glucal and ethanolin various solvent systems. Tri-O-acetyl-D-glucal (0.1360g,0.5 mmol) was treated with ethanol (1.5 mmol) and Fe2-(SO4)3.xH20 (0.025 g, 0.005 mmol) in CHCl2, MeCN,DMF, (CH3)2CO, or THF at 60°C to give ethyl 2,3-unsatu-rated glycopyranoside. Anhydrous acetonitrile was shown tobe superior to the other solvents in terms of yields and reactiontime. To study the effect of the catalyst, the reactions were car-ried out in acetonitrile in the presence of 10, 5, 2, 1, and0.5 mol% of Fe2(SO4)3xH2O. The results showed that1 mol % of Fe2(SO4)3.xH2O was enough for a fairly highyield. With 0.5 mol% of Fe(SO4)3xH20, a lower yield wasobserved under same reaction period. Meanwhile, we alsotested the effect of reaction temperature on the catalyzed reac-tion. When the reaction was carried out at room temperature,the reaction was sluggish. When it was carried out at 60°C,the maximum yield was obtained in a short reaction period.This success encouraged us to study the scope of the reactionunder the optimized condition: in the presence of 1 mol % ofcatalyst, anhydrous acetonitrile as reaction solvent, and at60°C. The results of using Fe2(SO4)3.xH20 as a catalyst inthe glycosylation are summarized in Table 2 (condition I). Treatment of 3,4,6-tri-O-acetyl-D-glucal with various alco-hols under the optimized conditions led to the corresponding2,3-unsaturated alkyl glycosides (condition I, entries 1-9).The H NMR data of the glycosides confirmed the a-configura-tion of the glycosyl products formed in the above reactions bycomparison with the literature data. According to the publishedresults, most of the Ferrier reactions of 3,4,6-tri-O-acetyl-D- glucal gave 2,3-unsaturated glycosides as a mixture of a- andp-anomers except Montmorillonite K-102and NbCl5From the aspects of cost, efficiency, and stereoselectivity,Fe2(SO4)3·xH2O is superior to the other catalysts used in mostof the known methods. In general, perbenzyl glycal catalyzed by Lewis acid un-dergoes addition of alcohols to form the corresponding additionproducts 2-deoxy O-glycosides instead of undergoing Ferrierrearrangement to afford2,3-unsaturated-O-glycosides. Toextend the scope of our catalyst, we also performed Fe-(SO4)3·xH2O-catalyzed reactions of perbenzyl glucal with var-ious alcohols (condition I, entries 11-14). These reactions, toour surprise, also underwent Ferrier reaction instead of additiononto the glucal. 2,3-Unsaturated-O-glucosides were producedin high yields with exclusive a-selectivity and no formationof 2-deoxy hexopyranosides (addition products) was observed.It is noteworthy that Fe2(SO4)3xH20 was the first reagent tocatalyze peralkyl glycal undergoing Ferrier rearrangement toproduce 2,3-unsaturated glycoside as the exclusive product. The scope of the new glycosylation was further examinedin the context of disaccharide synthesis (entries 10 and 15).It has been found that many natural antibiotics possessing sig-nificant antitumor and antiviral activities contain O-glycosy-latednucleosidee substructure. 2,3-Unsaturateddglycosidesconnected to nucleosides resulting from Ferrier rearrange-ments are the important intermediates for O-glycosylatednucleoside. We chose 2 ,3'-di-O-acetyl-uridine (1j) as the gly-cosyl acceptor to react with both peracetyl and perbenzyl glu-cals. As shown in Table 2, these reactions also gave highyields and a-selectivity exclusively. It has been reported thatthe a-anomer of the 2,3-unsaturated glycosides adopted the°Hs conformation and the B-anomer the Ho conformation.38of.ITwo anomers could be identified by the value of Ja,s" in 'HNMR spectrum. The H NMR of the products 4j and 2jshowed that the Ja",s" values (4j: 10.0 Hz, 2j: 10.0 Hz) werein accord with a favorable a-anomer, in which 4"-H and 5"-H were at anti-quasi-axial positions (Fig.1).5b Meanwhile, in our endeavor to develop a more efficient,rapid, and eco-friendly method for O-glycosylation, the micro-wave irradiation-assisted Ferrier rearrangement of peracetyland perbenzyl glucals was explored (condition II, Scheme2). It was found that the reaction of 3,4,6-tri-O-acetyl-D-glucalwith alcohols (1.5 equiv) in the presence of Fez(SO4)3xH20(1 mol%) in acetonitrile under microwave irradiation affordedthe Ferrier rearrangement products in good yields with veryhigh a-selectivity. Therefore, further investigations were car-ried out to explore the optimized reaction conditions. Effects of the reaction temperature and the power of micro-wave to the yield of Ferrier product were studied by using thereaction of 3,4,6-tri-O-acetyl-D-glucal with ethanol. At differenttemperatures and under different powers of microwave, the bestyield (up to 89%) was obtained with the microwave irradiationpower of 400 W at 80 °C for 6 min. A variety of alcohols thenreacted with glucals in the presence of Fe2(SO4)3xH2O(1 mol %) following the same procedure and the results aresummarized in Table 2 (condition II). Compared with the resultsobtained using condition I, condition II also demonstrated excellent stereoselectivity with even higher yields and signifi-cant shorter reaction time. In view of green chemistry, recyclable catalysts are highlypreferred. In our process, Fe2(SO4)3xH20 was easily recov-ered from the reaction mixture by filtration and subsequentlyused directly for the next reaction cycle. Using condition Ifor the glycosylation of alcohol with the recycled catalyst,this recycle protocol was repeated four times and the percent-age of the catalyst recovery was always more than 90%, whilethe yields were always more than 84% (Table 3). Mechanistically, it is proposed that Fe2(SO4)3xH20 as aweak Lewis acid could prompt the glycal to an allylic oxo-nium intermediate via cleavage of the C3 substituent, as shownin Scheme 3. The exclusive formation of the a-anomer mayarise from the thermodynamic anomeric effect. 3. Conclusion In conclusion, we have demonstrated a new glycal-based gly-cosylation method to produce 2,3-unsaturated-O-glycosides via.FFeerrrrier rearrangement, in which the substrates can be eitherperacetyl glucal or perbenzyl glucal. This is the first report onperalkyl glycals efficiently undergoing Ferrier rearrangementwithout formation of addition products 2-deoxy hexopyrano-sides. Both peracetyl and perbenzyl glucals underwent the Fer-rier rearrangement in the presence of Fe2(SO4)3*xH2O to affordthe corresponding 2,3-unsaturated-O-glycosides in excellentyields and exclusive a-selectivity with or without microwaveirradiation. Fe(SO4)3xH2O is an efficient, convenient, andenvironmentally benign heterogeneous catalyst, used in verylow percentage, and can be recovered and reused without signif-icant loss of activity. The excellent a-selectivity, inexpensive,and reusable catalyst, and environmentally benign charactersmake this method an attractive way to prepare 2,3-unsatu-rated-O-glycosides from glycals. 4. Experimental section 4.1. General remarks Acetonitrile was distilled from P205 followed by distillationfrom CaH2 prior to use. All reagents were obtained from com-mercial sources and used without further purification. Prepara-tion of 2',3'-di-O-acetyl-uridine followed the known reactionin literature. The reactions under microwave irradiation wereperformed in a commercial microwave reactor (XH-100B,100-1000 W, Beijing Xianghu Science and Technology Devel-opment Co. Ltd, Beijing, PR China). The temperature of thereaction mixture was measured by an immersed platinum resis-tance thermometer. The reactions were all carried out undera positive pressure of nitrogen and were monitored by TLC onsilica gel 60 F254 (0.25 mm, E. Merck). Column chromatogra-phy was performed on silica gel 60 (230-400 mesh). The raticbetween silica gel and crude product ranged from 100 to 50:1(w/w). 'H and 13c NMR spectra were recorded on BrukerAC-400 NMR spectrometer in solutions of CDCl3 or DMSO-d6using tetramethylsilane as the internal standard, o values are G. Zhang et al. / Tetrahedron 64 (2008) 339-344342 Table2 Fe(SO4)3xHzO-catalyzed Ferrier rearrangement of glucals with alcohols in acetonitrile Entry Substrate Alcohol Product Condition I Condition II' Entry Substrate Alcohol Product Condition I Time (h) Yield° (%) Condition II’ Time (min) Yield (%) 13 14 HO· BnO 2 82 7 84 BnO 2f O. Bn 1f OH BnO BnO 2 84 6 86 1g 2g 0 HO、 NH NH 15 D BnO BnO AcO 2j 0 1.5 70 7 80 1j AcOOAc OAc All the reactions were proceeded at 60°C. °All the reactions were irradiated at 80 °C, 400 W, 2450 MHz in a commercial microwave reactor (XH-100B, 100-1000 W, Beijing Xianghu Science andTechnology Development Co. Ltd, Beijing, PR China). It takes about 5 min to achieve 80°C under 400 W. Isolated yields. The yield was based on the 70% conversion rate of nucleoside. 8 The yield was based on the 74% conversion rate of nucleoside. Figure 1. Preferred conformations of compounds 4j and 2j. given in parts per million, and coupling constants (J) in hertz.The high-resolution mass spectra were collected at the Zhengz-hou University Campus Instrumentation Center. 4.2. General procedure for the preparation of 2,3-unsaturated glycosides from glucals in anhydrousacetonitrile at 60°C To a stirred solution of 3,4,6-tri-O-acetyl-D-glucal (1 mmol)and alcohol (3 mmol) in anhydrous acetonitrile (5mL) wasadded Fe2(SO4)3xH2O (0.01 mmol, 1mol%). The mixture Table 3The reusability of Fez(SO4)3.xH20 as catalyst for Ferrier reaction Round Alcohol Catalyst Reaction Yielda,b recovered (mg) time (min) (%) 1 CH,CH2OH 328 60 86 2 CH,CH2OH 310 60 85 3 CH,CH2OH 280 70 85 4 CH,CHOH 260 80 84 a The reactions were carried out at 60°C. Scheme 3. Proposed mechanism of Fe2(SO4)3·xH2O-catalyzed Ferrier reaction. was stirred at 60°C for appropriate time (condition I, Table2). The reaction was monitored by TLC. After the completion,the reaction mixture was filtered and the filtrate was evapo-rated to recover the solvent. The residue was purified throughsilica-gel column chromatography. The pure product was char-acterized by GC-MS and 'H NMR. The spectral data arecomparable with literature data (4a-4i,22k,a 2h,2f,30band 2g40). 4.3. General procedure for the preparation of 2,3-unsaturated glycosides from glucals under microwaveirradiation To a mixture of 3,4,6-tri-O-benzyl-D-glucal (1mmol) andalcohol (3 mmol) was added Fe2(SO4)3xH20(1 mol%) in an-hydrous acetonitrile (2mL)in a flask equipped with a condenser,and then irradiated in the XH-100B microwave oven at 80°Cand 400 W for several minutes (condition II, Table 2). Afterthe completion of the reaction, monitored by TLC, the reactionmixture was treated following the procedure described above.The products were purified through silica-gel column chroma-tography. The pure product was characterized by GC-MS andH NMR. 4.4. Characterization of glucosides: 4",6"-di-O-acetyl-2",3"-dideoxy-a-D-erythro-hex-2"-enopyranosyl-(1→5)-2',3'-di-O-acetyl-uridine (4j) and 4",6"-di-O-benyl-2",3"-dideoxy-a-D-erythro-hex-2"-enopyranosyl-(1→5)-2',3'-di-O-acetyl-uridine (2j) Compound 4j: H NMR (400MHz, DMSO-d6) 6 11.29 (s,1H), 7.62 (d, J=8.0 Hz, 1H), 5.90-5.80 (m, 3H), 5.66-5.62(m, 1H), 5.25-5.20(m, 2H), 5.08 (d,J=10.0 Hz, 1H), 5.04 (s,1H), 4.22 (d,J=2.8 Hz,1H), 4.03-3.98(m,2H),3.89-3.85(m,2H),3.77-3.67 (m,2H), 1.99 (s,3H), 1.94 (s, 3H), 1.92(s,3H),1.90 (s, 3H). 13C NMR (100 MHz, DMSO-d) 6170.3,170.1,169.6,169.5,163.1,150.6,140.4,129.8,127.6,102.8,93.7,86.4,81.0,72.5,70.9,67.2,67.0,63.8,62.6,20.9,20.6,20.5,20.4,HRMS: C23H28N2013+Na (M+Na)+ calcd 563.1489, found563.1488. Compound 2j: H NMR (400 MHz, DMSO-d6) 6 11.28 (s,1H), 7.64 (d, J=8.0 Hz, 1H), 7.24-7.13 (m, 10H), 6.07 (d,J=10.4 Hz, 1H),5.88-5.86(m,1H), 5.75-5.71(m, 1H), 5.63(t, J=4.0 Hz, 1H), 5.26-5.22 (m, 2H), 4.97 (s, 1H),4.43-4.33 (m,4H), 4.21 (d,J=2.8 Hz, 1H), 3.89 (d,J=10.0 Hz,1H),3.79-3.66 (m, 3H), 3.54-3.46 (m,2H), 1.93 (s, 3H), 1.90 (s,3H). 13c NMR (100 MHz, DMSO-d6) 8 169.5, 163.1, 150.6,140.4,138.5,138.3,131.4,128.4,128.0,127.7,127.6,126.0,102.8,93.8, 86.4,81.0,72.4,70.9,70.2,70.0,69.5,69.0,66.9,20.5,20.4.+.HRMS:l: C33H36N2O11+H (M+H)+calcd637.2397, found 637.2395. Acknowledgements This work was supported by the National Natural ScienceFoundation of China (20672031) and a fund from the Programfor New Century Excellent Talents in University of HenanProvince (2006-HACET-06) to G.Z. Supplementary data Supplementary data associated with this article can befound in the online version, at doi:10.1016/j.tet.2007.10.097. References and notes ( 1. (a) Schreiber,S. L. Science 2000, 287, 1964;(b) Spring,D. R. Org. Biomol.Chem. 2003, 1, 3 867;( c ) Shang, S.; Tan, D. S. Curr. O pin. C hem. Biol. 2005, 9 , 1 ; (d) Arya, P ; Q uevillon, S .; Joseph, R.; Wei, C .-Q.; Gan, Z.; P arisien, M.; S esmilo, B.; Reddy, P. T.; C hen, Z.-X.; Durieux, P.; Laforce,D.; Campeau, L. C.; Khadem, S . ; Daroszewska, M.; B a rnes, M. L . Pure Appl. C hem. 2005,77,163. ) ( 2. ( a) Kubota, H.; Lim, J.; Depew, K . M.; S chreiber, S. L. Chem. B iol. 2002, 9 ,265; (b) H otha, S .; Tripathi, A. J. Comb. Chem. 2005, 7, 968. ) ( 3. Collins, P.; Ferrier, R. Monosaccharides: their Chemistry and their Roles in Natural Products; W iley: Chichester, U K, 1 9 95. ) ( 4 . F errier, R. J.; Prasad, N. J . Chem. Soc. C 1 969,570. ) ( 5. ( a) Holder, N. Chem. R ev. 1982, 82,2 8 7;(b) Li u , Z. J.;Zhou, M. ; Min,J. M.; Zhang, L. H. T e trahedron: Asymmetry 1999, 10, 2 119 ; (c) Brit o , T . M.; S ilva, L. P ; S iqueira, V. L .; S rivastava, R. M. J . C arbohydr.Chem. 1 999,18, 609. ) ( 6. S rivastava, R . M.; Ol i veira, F. J . S. ; Si l va,L. P.; Filho, J. R. F .; Oliveira, S. P; Lima, V. L. M. Carbohydr. Res. 2001, 332,335. ) 7. Danishefsky,S. J.; Bilodeau, M. T. Angew. Chem., Int. Ed. 1996, 35,1380. ( 8 . ( a) Fraser- R eid, B . A cc. Chem. R e s. 19 8 5, 18, 347; (b) Ferrier, R. J. A d v.Carbohydr. Chem. Biochem. 19 6 9, 199 ; (c) Ramnauth, J.; Po u l i n, O.; Rakhit, S. P.; Maddaford, S. P. Org. Lett. 2001,3,2013. ) ( 9. Tolstikov, A. G.; Tolstikov, G. A. Russ . Chem. Rev . 1993, 62, 5 79. ) ( 1 0. (a) Dorgan,B. J.; Jackson,R. F. W.Synlett 1 996, 8 59; (b) Chambers,D.J.;Evans, G . R .; Fairbanks, A. J. Tetrahedron: Asymmetry2005,16,45. ) ( 1 1 . ( a) Seeberger, P. H.; B ilodeau, M. T.; D a nishefsky, S. J. Aldrichi m ica Acta 1997,30, 7 5 ; (b) Danishefsky, S. J.; Bilodeau, M. T . A ngew. C h em., Int.Ed. 1996,120, 1 3515. ) ( 12. Schmidt, R. R.; Angerbauer, R. Angew. Chem., Int. Ed.Engl. 19 7 7,16,783. ) ( 1 3 . Williams, N. R.; W ander, J . D . T he C a rbohydrates in Chemistry an d Biochemistry; Academic: New Y o rk, NY, 1 9 80; p 7 6 1. ) ( 14. (a) Bracherro, M. P .; Cabrera, E. F.; Gomez, G. M .; P e redes, L. M . R . Carbohydr. R es. 1 9 98, 308, 1 8 1; ( b ) Schmidt, R . R.; A n gerbauer, R. Carbohydr. Res. 1979, 72, 2 72. ) ( 15. (a) Domon, D . ; Fujiwara, K . ; O h taniuchi, Y.; Takezawa, A.; Ta k eda, S.; Kawaski, H.; Murai, A . ;Ka w ai, H.; Su z uki, T. Te t rahedron Let t . 20 0 5, 46, 8279; ( b) Reddy, B . G .; V ankar, Y. D. T e trahedron L e tt. 2 003, 44,4765; (c) L ewis, A . ; S t efanuti, I; Swain, S. A.; Sm i th, S. A. ; Ta y lor, R . J . K . T etrahedron Lett. 2 001, 4 2, 5 549; (d) P atterson, I .; Keown,L. E. Tetrahedron Lett.1997, 38, 5727. ) ( 16. (a) Descotes,G.; M artin, J. C. Carbohydr. Res. 1977, 56, 1 6 8;(b) Klaffke,W.; P udlo, P .; Springer, D. ; Thieme, J . Liebigs Ann. Chem. 1991,509. ) ( 17. Grynkiewicz, G.; Priebe, W.; Zamojski, A. Carbohydr. Res. 1979, 68, 3 3 . ) ( 18. (a) Masson, C.;Soto, J.; B essodes, M . S y nlett 2 0 00, 1281;(b) Tilve,R. D.;Alexander, M . V.; Khandekar, A . C.; Samant, S. D. ; Kanetkar, V. R . J. Mol. Catal. A: Chem. 2004,223,237. ) ( 19. Yadav, J . S.; Reddy, B. V. S.; M urthy, C. V . S . R .; Kumar, G. M. Synlett 2000, 1 450. ) ( 20. Babu, B . S.; Balasubramanian, K . K . Tetrahedron Lett. 2000, 4 1,1 2 71. ) ( 21. (a) Shanmugasundaram, B . ; Bose, A. K.; B alasubramanian, K . K . T etra- hedron Lett. 2002, 43, 6795;(b)Ronaldo, N. O.; F i lho, J.R. F; Srivastava, R. M . T etrahedron Lett. 2002, 4 3, 2141. ) 22. Swamy, N. R.; Venkateswarlu, Y. Synthesis 2002, 598. ( 23. Y adav,J. S . ;Reddy, B. V. S.;Re d dy, J. S. S. J.Chem. Soc., Perkin Trans. 1 2002,2390. ) ( 24. Yadav, J . S.; Reddy, B. V. S.; Reddy, K . B .; S atyanarayana, M . Tetra- hedron Lett. 2002, 43,7009. ) ( 25. B ettadaiah, B.K.; Srinivas, P. Tetrahedron Lett.2003, 44, 7257. ) ( 26. Toshima, K.; Ishizuka, T.; Matsuo, G .; N akata, M .; K onoshita, M.J. Chem. Soc., Chem. Commun.1 9 93,7 0 4. ) ( 27. L opez, J. C.; G omez, A. M. ; Valverde, S.; Fraser-Reid, B. J . Org. Chem.1995,60,3851. ) ( 28. R afiee,E.; T angestaninejad,S . ; Habibi, M. H . ; M i rkhani, V. Bioorg. Med.Chem.Lett. 2004, 14,3611. ) ( 29. Koreeda, M .; Houston, T. A.; Shull, B. K .; Klemke, E.; T uinman, R. J.Synlett 1995, 90. ) ( 30. (a) Yadav, J. S. ; Reddy, B . V . S.; Pandey, S. K. New J. Chem. 2001,25, 538; ( b) Pachamuthu, K.; V ankar, Y . D. J. Org. Chem. 2 001, 66, 7 511 . ) ( 31. A garwal, A.; R ani, S .; Vankar, Y. D. J . Org. Chem. 2004,69,6 1 37. ) ( 32. (a) Banik, B. K.; Adler, D.; Nguyen, P.; Srivastava , N. Heterocycles2003,61, 1 01; (b) Naik, P . U . ; N a r a, S. J. ; Harjani, J. R . ; S a lunkhe, M. M. J. Mol. Catal. A: Chem. 2005, 234,35. ) ( 33. H otha, S.; Tripathi, A. Tetrahedron Lett. 2005, 46,4555. ) ( 34. Kim, H.; M en, H.; Lee, C. J . Am. Chem. Soc.2004, 126,1336. ) ( 35. Li,L.;Zhu, L.;Zhang,X.; Zhang, G.; Qu, G. Can. J. Chem.2005,83,1120. ) 36. Zhang, X.; Li, L.; Zhang, G. Green Chem. 2003, 5, 646. ( 37. Fe(SO4)3·xH20 us e d in the experiments was purchased fr o m the Be i jingChemical F a ctory (A.R. grade). T h e mole of Fez(SO4)3.xH2O is ca l culated based on the formula: MFe(SOa)xHz0 = 0.5(WFez(SOa)xH0Fe(Ⅲ)%-55.8). ) 38. Herscovici, J.; Montserret, R.; Antonakis, K. Carbohydr. Res. 1998,176,219. 39. Lesueur, C.; Nouguier, R.; Bertrand, M. P; Hoffmann, P.;De Mesmaeker,A. Tetrahedron 1994, 50, 5369. ( 40. K ashyap, S . ; Hotha, S . Tetrahedron Lett. 2006, 47,20 2 1. )

确定

还剩4页未读,是否继续阅读?

北京祥鹄科技发展有限公司为您提供《枣核中总黄酮检测方案(微波合成仪)》,该方案主要用于水果中总黄酮检测,参考标准--,《枣核中总黄酮检测方案(微波合成仪)》用到的仪器有祥鹄电脑微波催化合成/萃取仪

推荐专场

相关方案

更多

该厂商其他方案

更多