方案详情

文

This paper presents observations and analysis of the time-dependent behaviour of a 10 kW

partially pre-mixed, swirl stabilized methane-air flame exhibiting self-excited thermo-acoustic

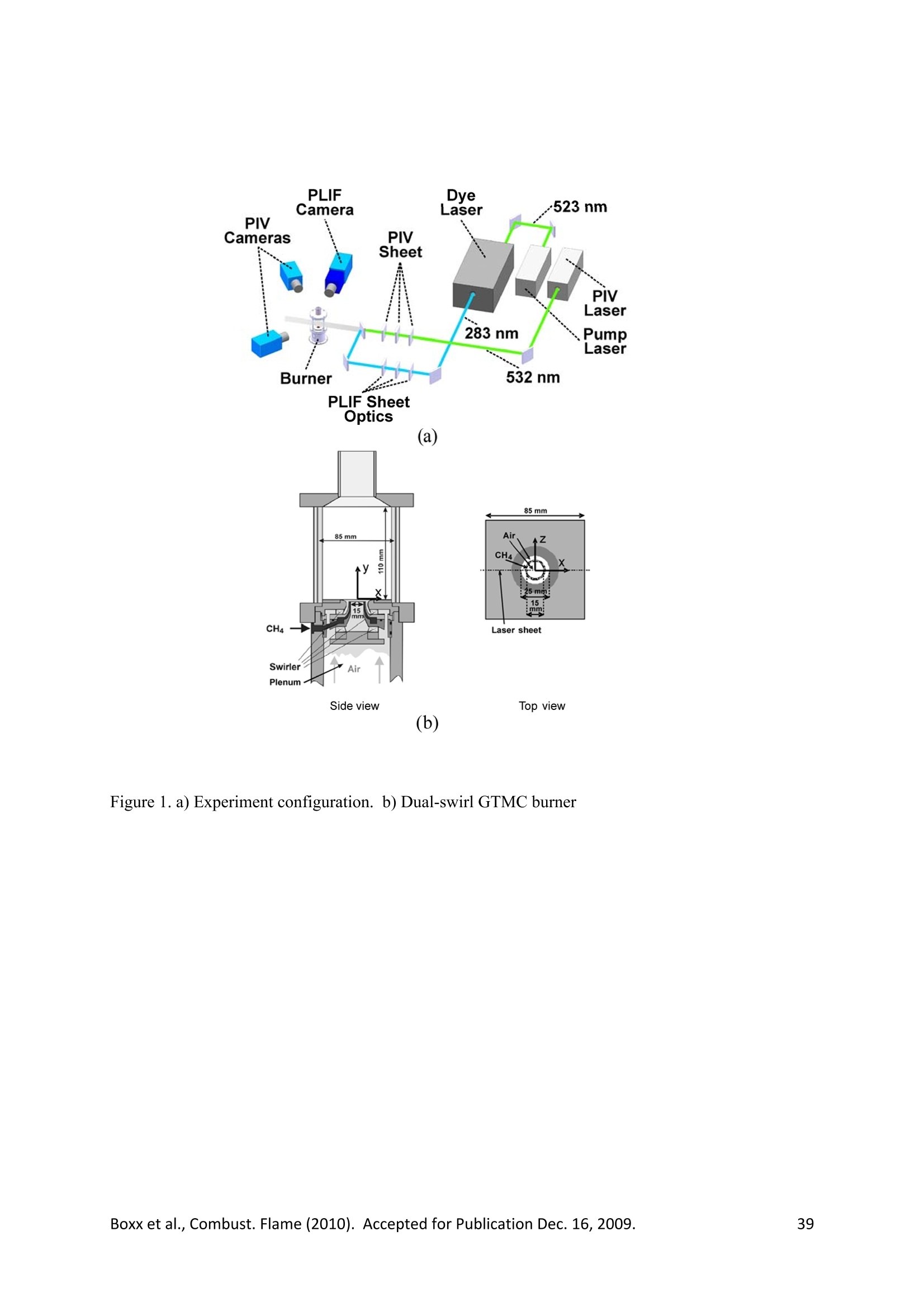

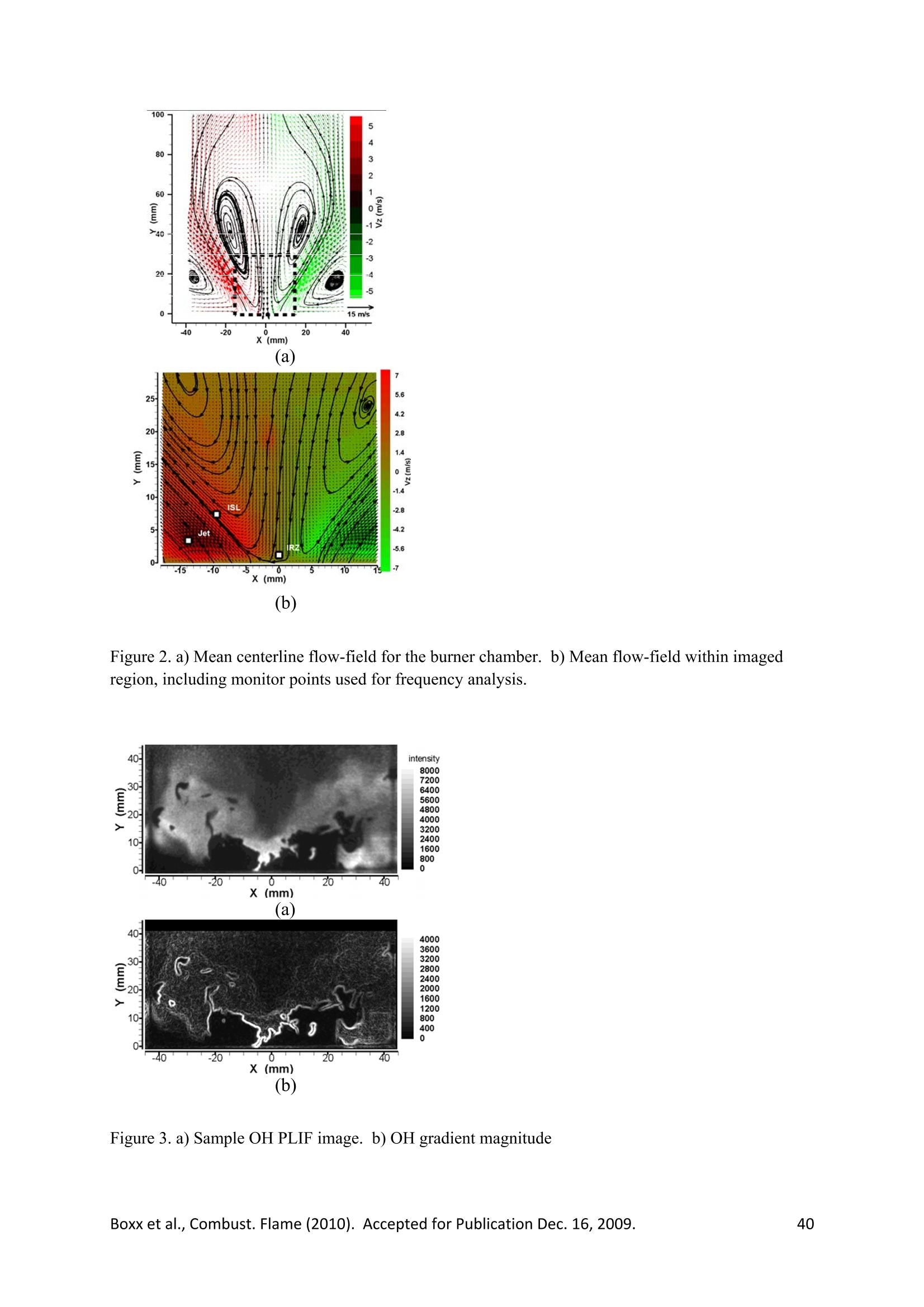

oscillations. This analysis is based on a series of measurements wherein particle image

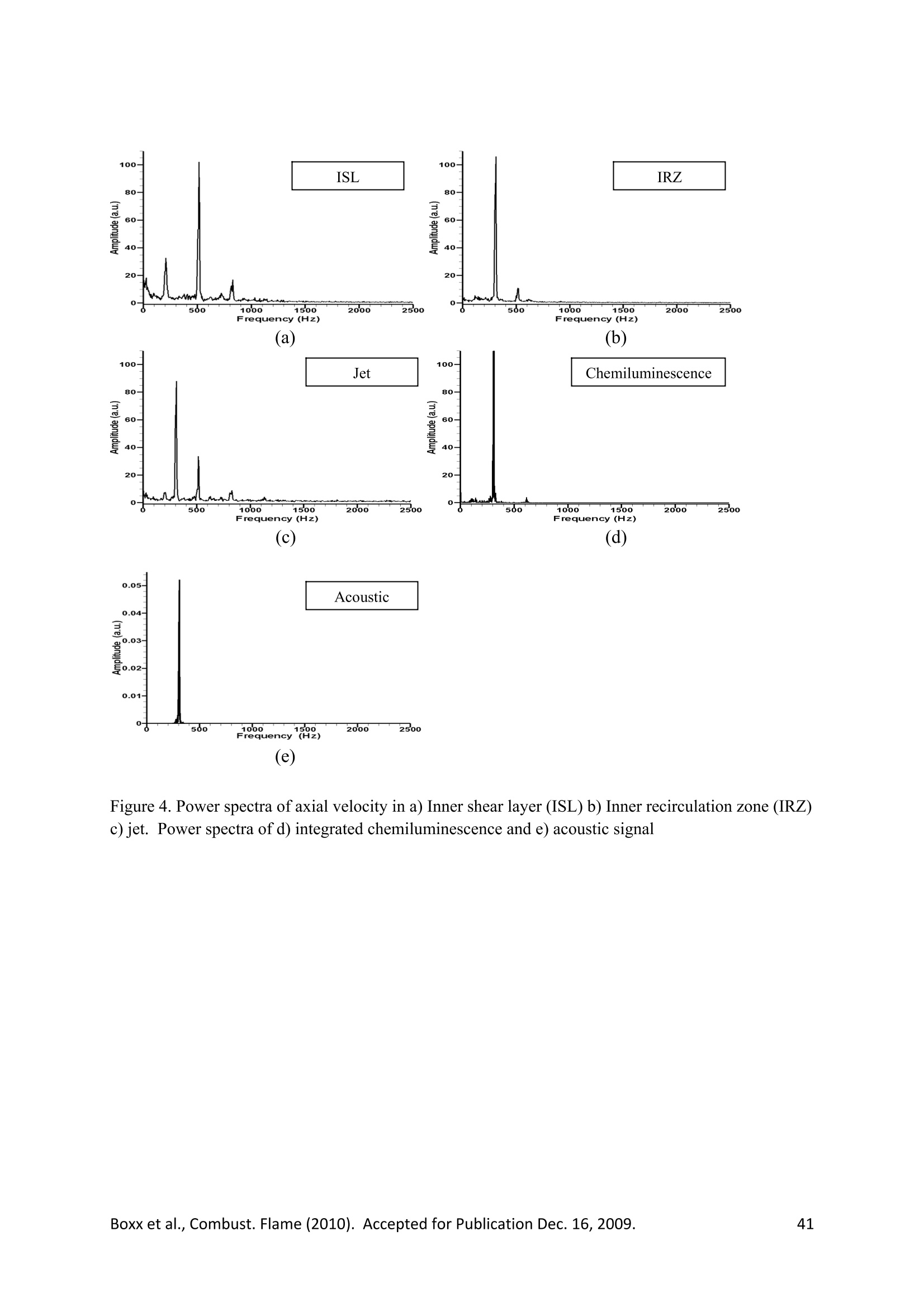

velocimetry (PIV) and planar laser-induced fluorescence (PLIF) of the OH radical were

performed simultaneously at 5 kHz repetition rate over durations of 0.8s. Chemiluminescence

imaging of the OH* radical was performed separately, also at 5 kHz over 0.8s acquisition

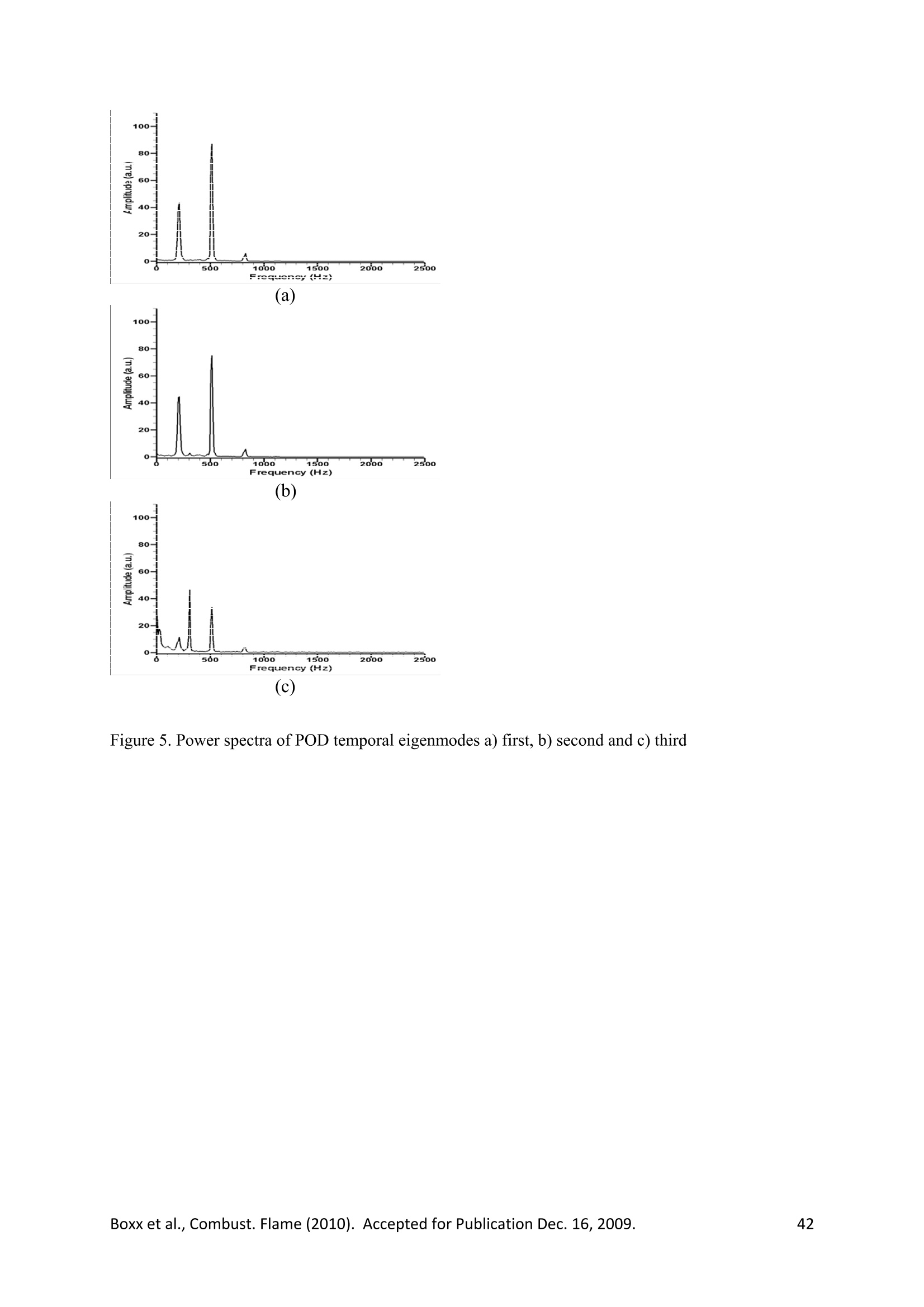

runs. These measurements were of sufficient sampling frequency and duration to extract

usable spatial and temporal frequency information on the medium to large-scale flow-field

and heat-release characteristics of the flame. This analysis is used to more fully characterize

the interaction between the self-excited thermo-acoustic oscillations and the dominant flowfield

structure of this flame, a precessing vortex core (PVC) present in the inner recirculation

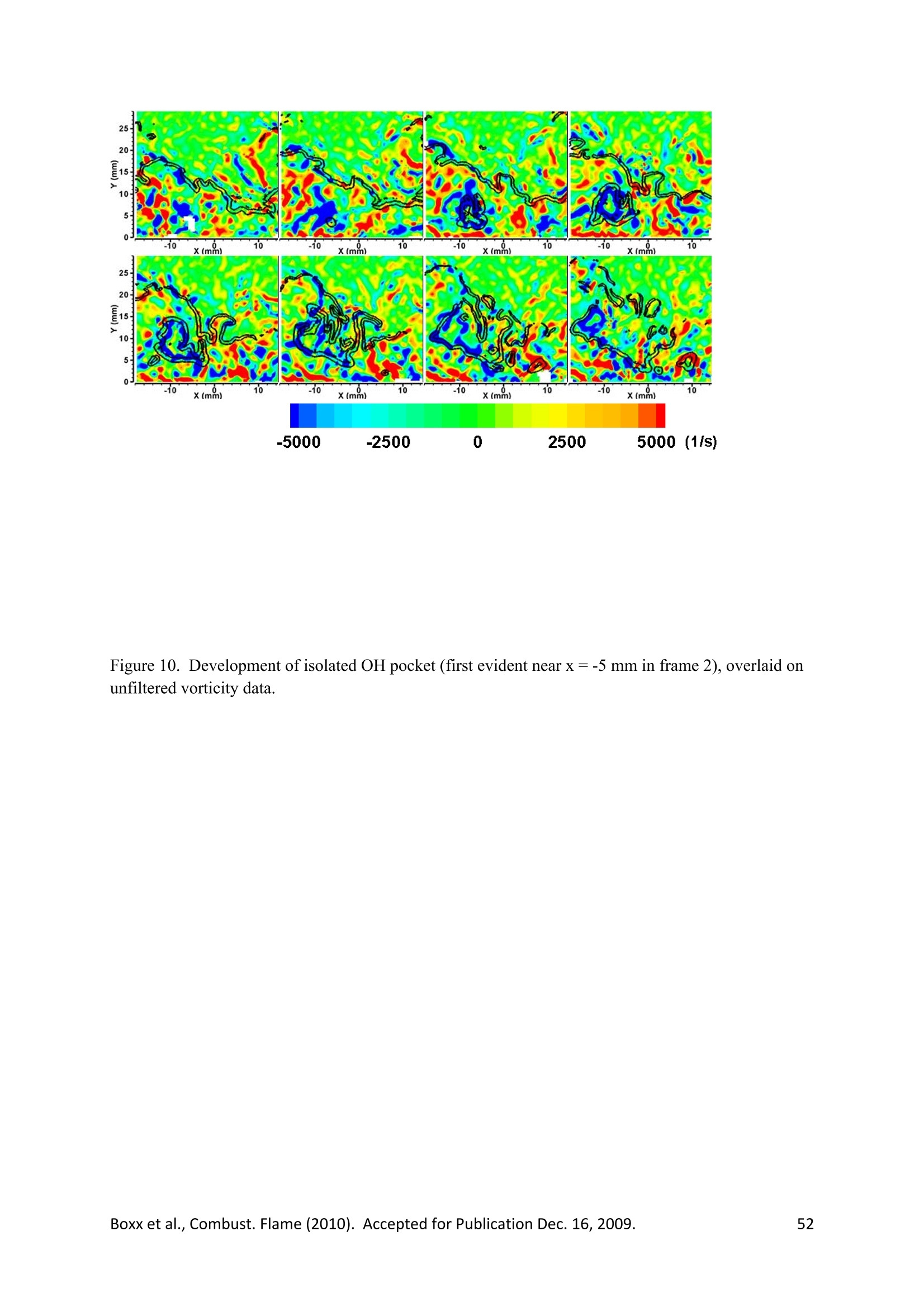

zone. Interpretation of individual measurement sequences yielded insight into various

physical phenomena and the underlying mechanisms driving flame dynamics. It is observed

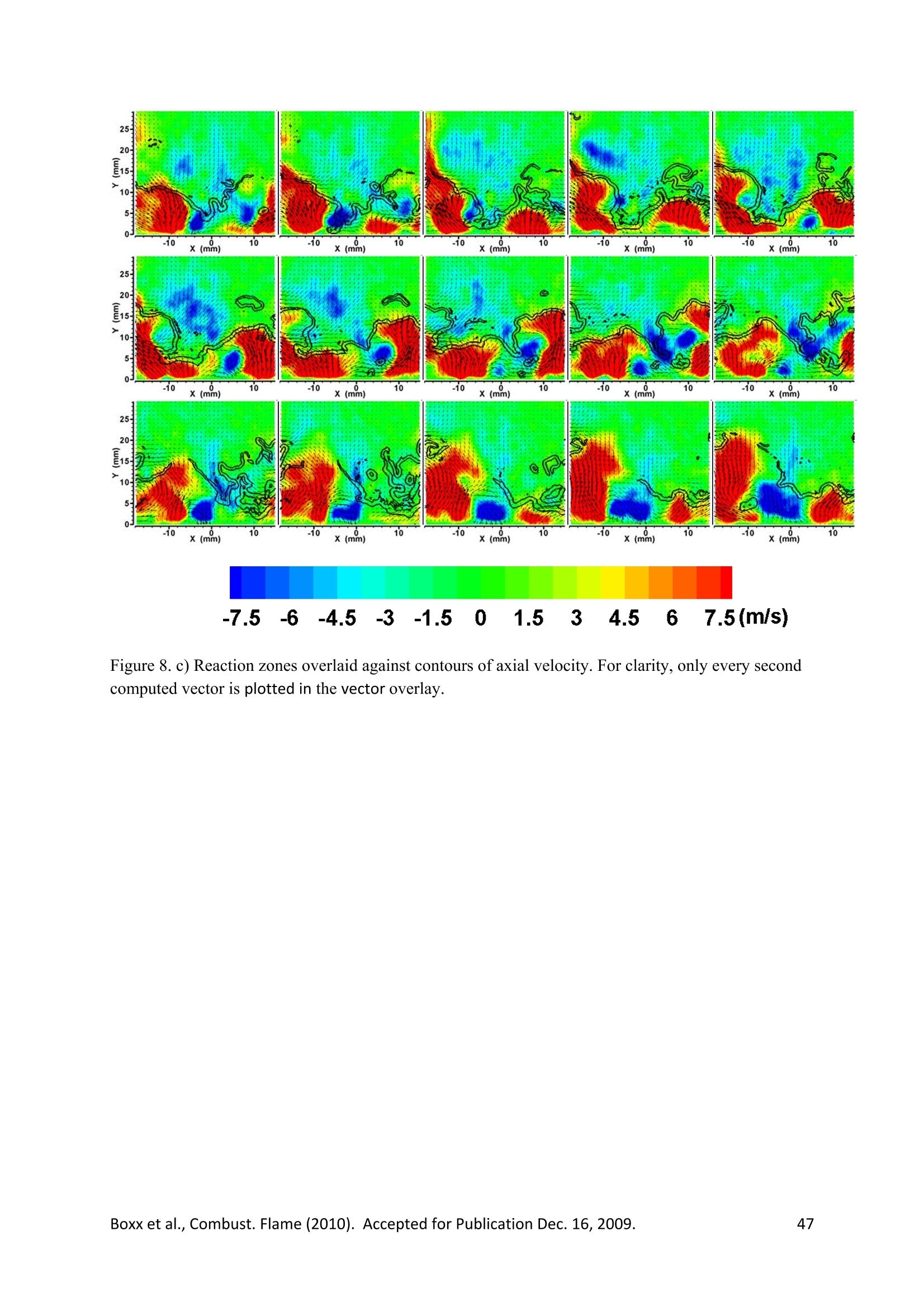

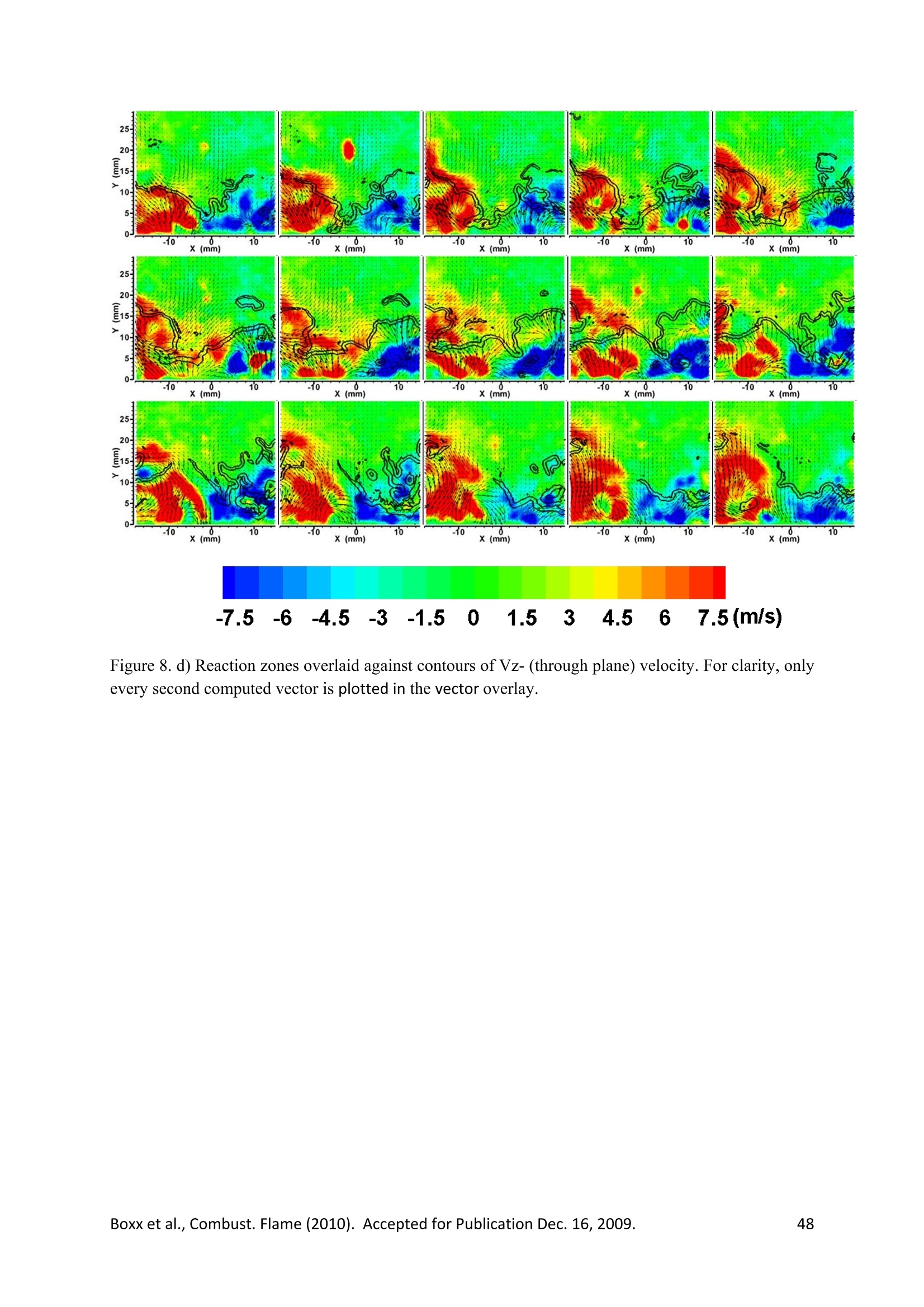

for this flame that location of the reaction zone tracks large-scale fluctuations in axial velocity

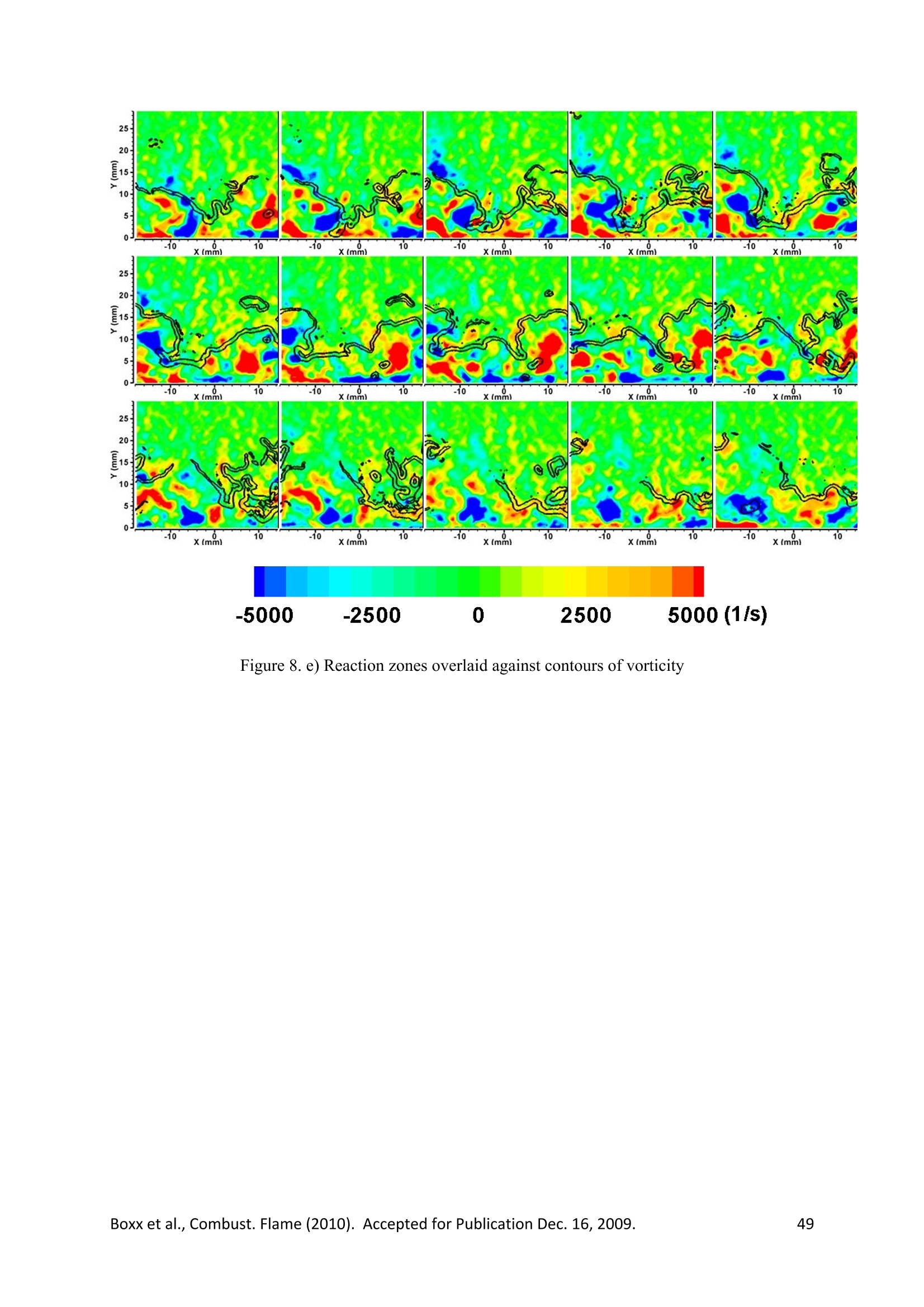

and also conforms to the passage of large-scale vortical structures through the flow-field.

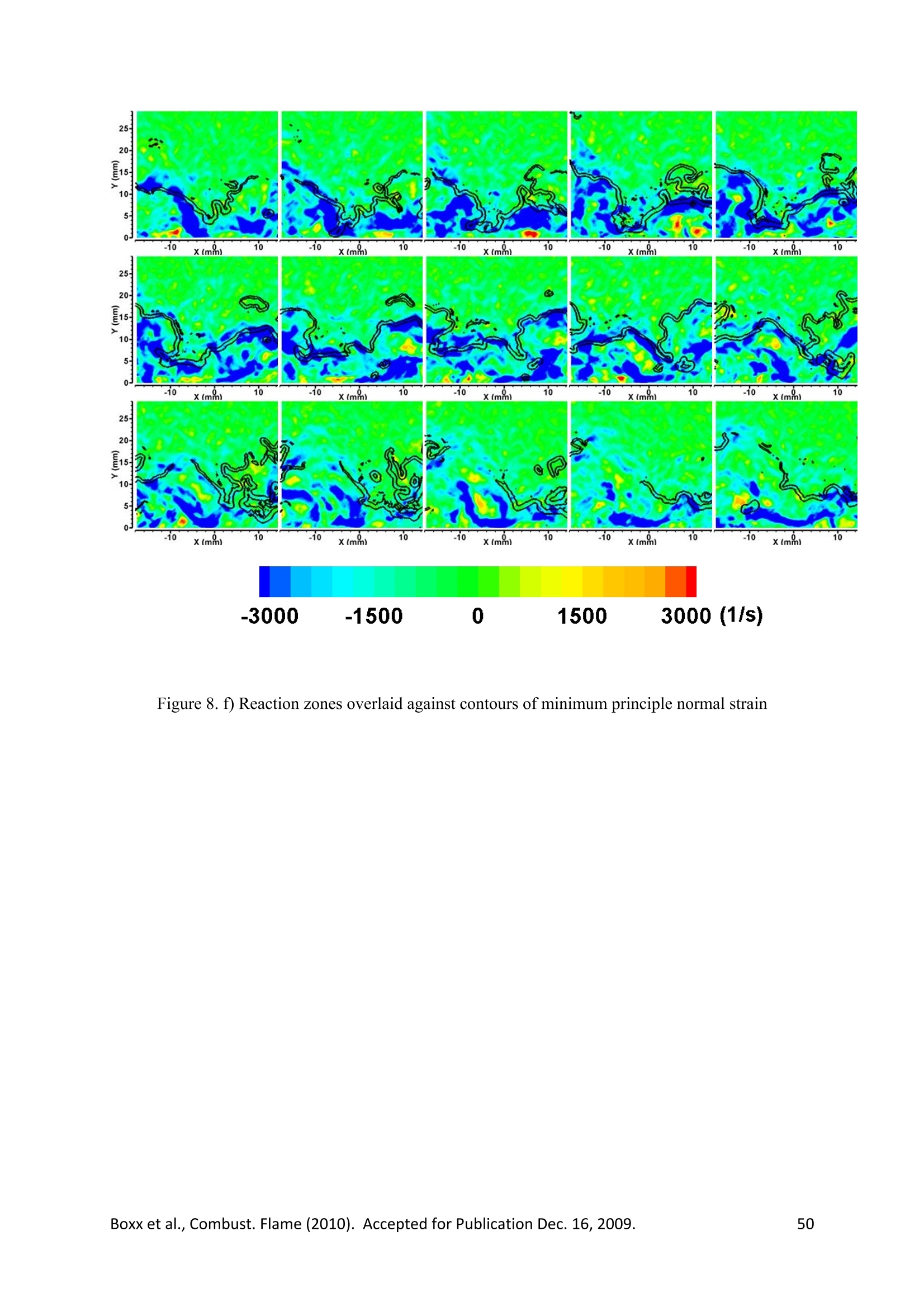

Local extinction of the reaction zone in regions of persistently high principal compressive

strain is observed. Such extinctions, however, are seen to be self healing and thus do not

induce blow-out. Indications of auto-ignition in regions of unburned gas near the exit are also

observed. Probable auto-ignition events are frequently observed coincident with the centers of

large-scale vortical structures, suggesting the phenomenon is linked to the enhanced mixing

and longer residence times associated with fluid at the core of the PVC as it moves through

the flame.

方案详情