方案详情

文

WSF-2000MH系列(日本ATTO)通过自动持续测量并记录各种样品在微生物发酵过程中产生的气体总量和产气速度的变化曲线,来有效地评估酵母等微生物的发酵能力、培养基(面团、啤酒等)发酵特性及样品的发酵条件等,也可以长时间监测面包面团、酒类酿造、生物乙醇相关的发酵过程以及BP(发酵粉=化学膨胀剂)等化学过程产气量。

方案详情

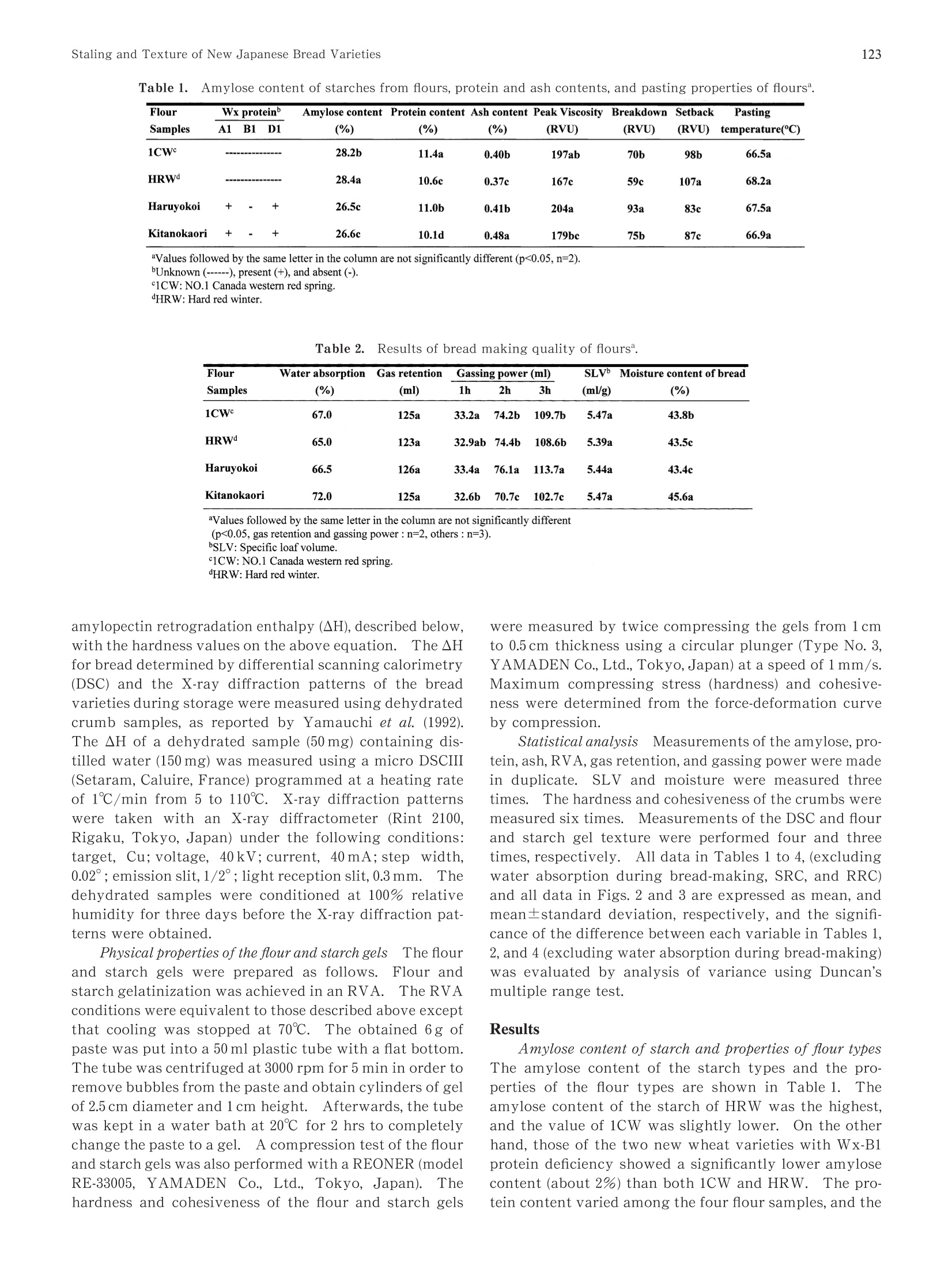

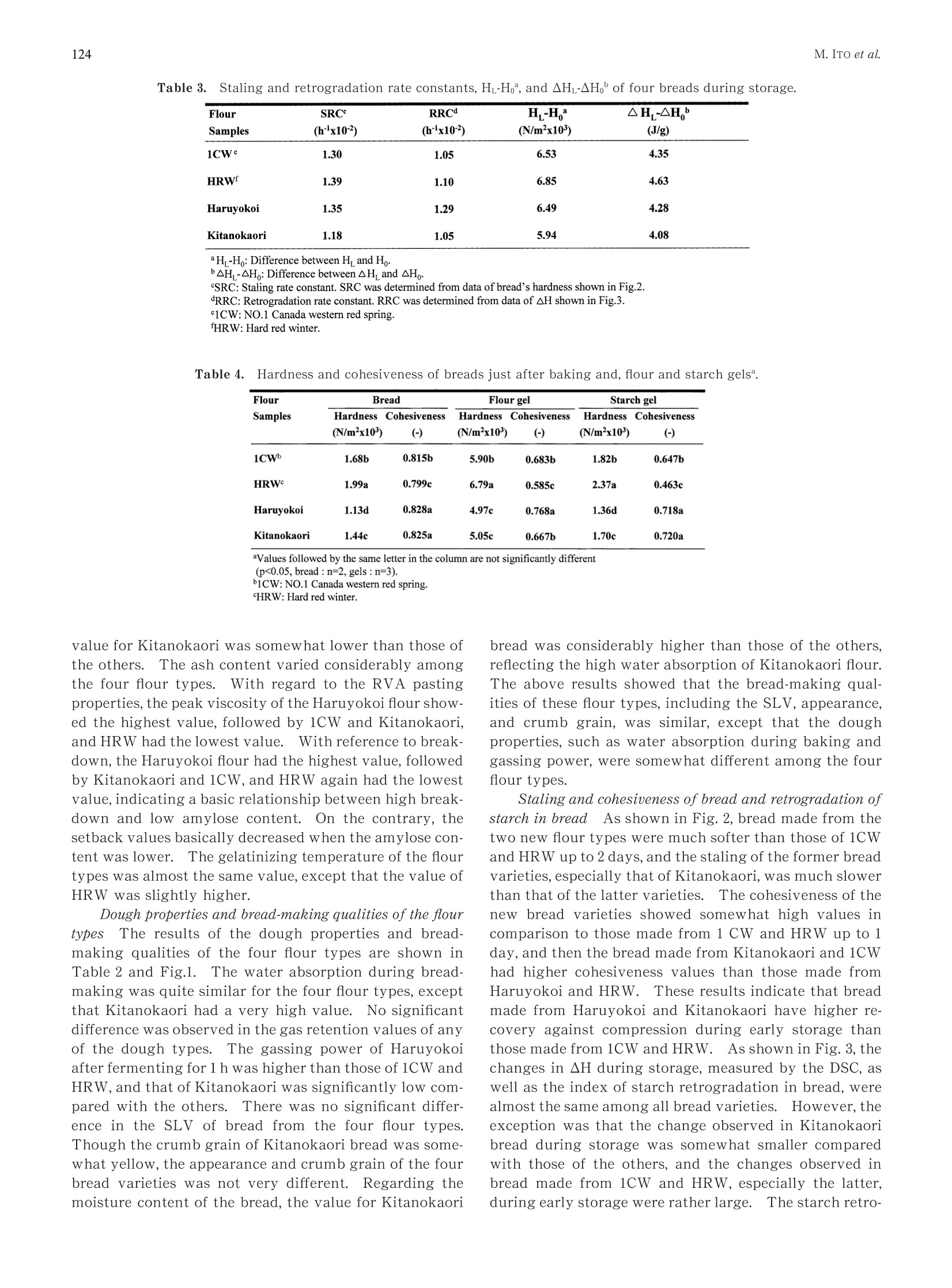

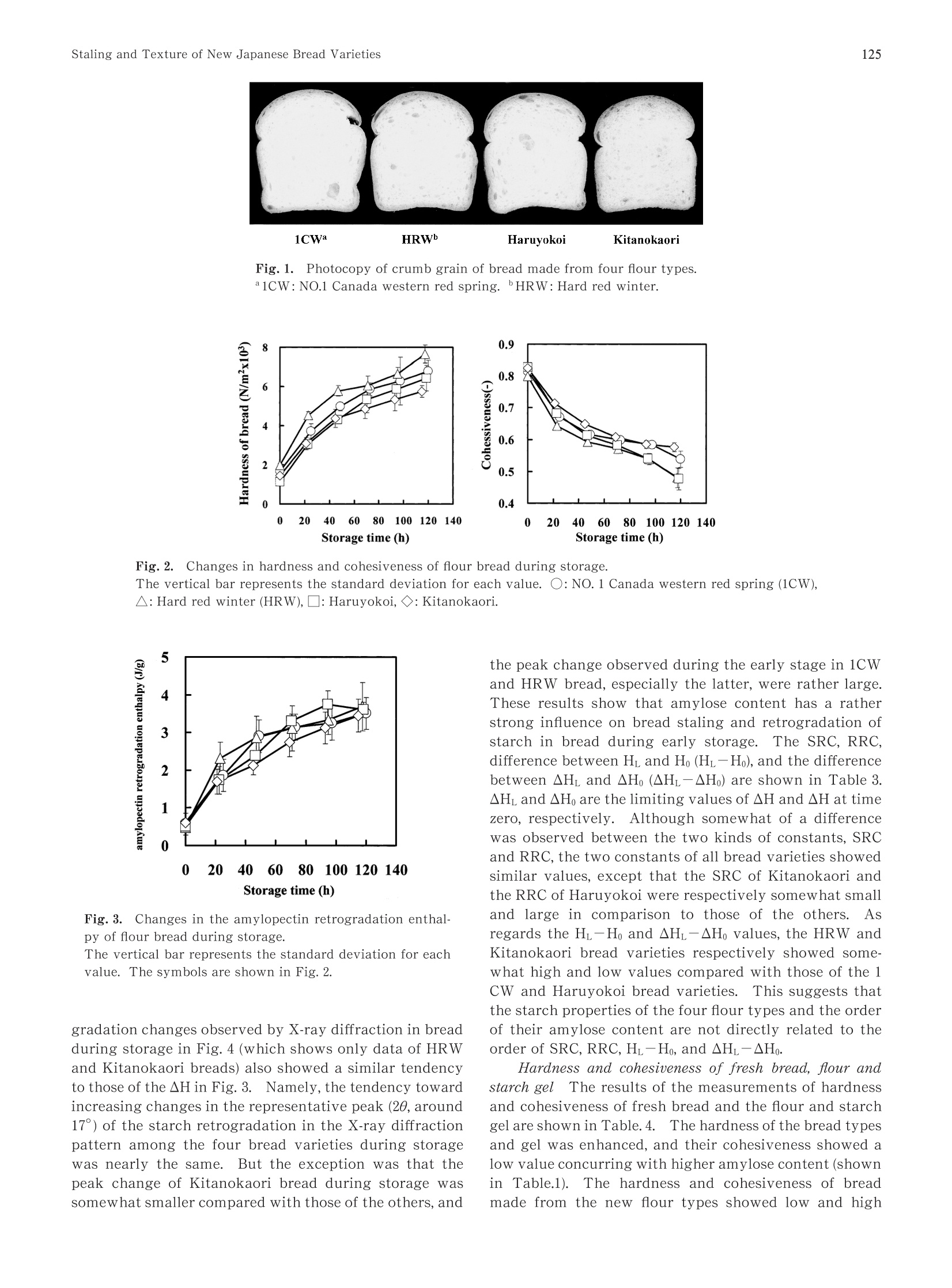

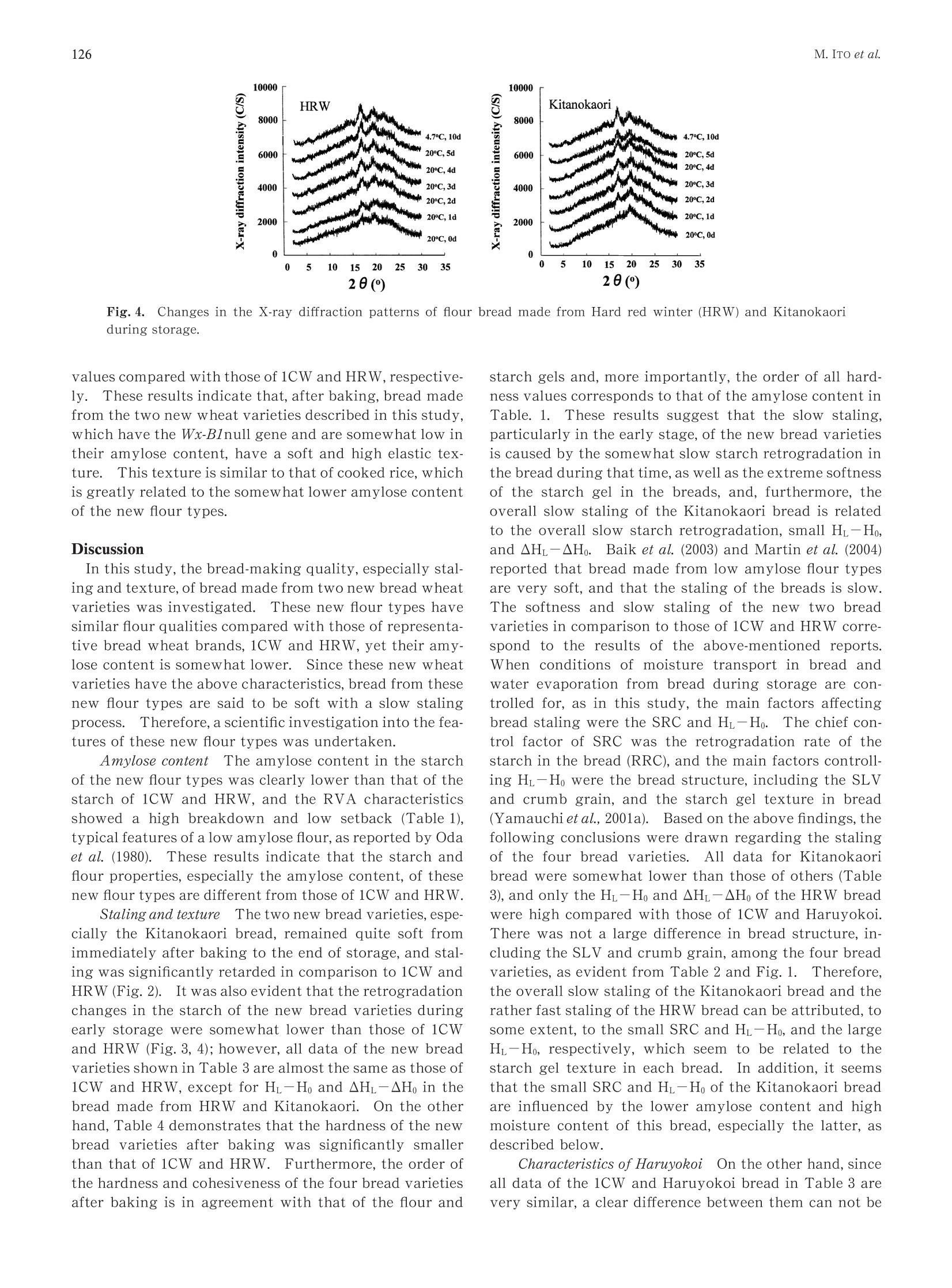

1.实验材料与设备实验样品四种小麦粉:1CW(Canada western red spring)、HRW(Hard red winter)、以及日本国产Haruyokoi和Kitanokaori实验条件:20克面团,30℃下分别监测1h、2h、3h的产气量检测设备:发酵特性分析仪(日本ATTO)2.实验分析与结论4种面粉在面包制作过程中的吸水率基本一致,但Kitanokaori吸水率较高。两类面团的留气值均无显著差异。Haruyoko 1h后的产气量显著高于1CW和HRW,Kitanokaori 1h后的产气量显著低于其他品种,面团发力比较弱。4种面粉对面包的体积比无显著差异。虽然Kitanokaori面包屑颗粒略显黄色,但四种面包品种的外观和面包屑颗粒差异不大。在面包含水率Kitanokaori面包的含水率明显高于其他面包,这反映了Kitanokaori面粉的高吸水性。结果表明,4种面粉的制面包品质,包括面包的体积比、外观和面包屑颗粒,都是相似的,但面团性能,如烘烤时的吸水率和发气性,在4种面粉中有所不同。文献标题:Staling and Texture of Bread Prepared from New Japanese Bread Wheat Varieties with Slightly Low-Amylose Starch发表期刊:Food Sci. Technol. Res3.实验主要设备介绍发酵特性分析仪WSF-2000MH系列(日本ATTO)通过自动持续测量并记录各种样品在微生物发酵过程中产生的气体总量和产气速度的变化曲线,来有效地评估酵母等微生物的发酵能力、培养基(面团、啤酒等)发酵特性及样品的发酵条件等,也可以长时间监测面包面团、酒类酿造、生物乙醇相关的发酵过程以及BP(发酵粉=化学膨胀剂)等化学过程产气量。应用领域微生物产生的气体量变化是细菌代谢和活动的重要指标。本装置的测定数据可用于各种工艺的过程控制,最佳培养基组成和发酵条件的探索等。微生物:菌株的育种、烘焙制品、酒类酿造、酱油、食品腐败、工业酒精以及甲烷氢气等领域,如小麦粉品质评价、酿造品质控制、微生物菌株筛选等。化学方面:食品膨胀剂、发泡剂、洗涤剂、入浴剂以及医药等领域,如膨化剂、发泡剂等新品开发和质量管控等。Food Sci. Technol. Res., +- (,), +,+12+,2, ,**1 122M. ITO et al. Staling and Texture of Bread Prepared from New Japanese Bread Wheat Varieties with Slightly Low-Amylose Starch Miwako ITO +, Sun-JuKIM +, Zaidul-IslamSARKER +, NaotoHASHIMOTO +, TakahiroNODA +, ShigenobuTAKIGAWA +, ChieMATSUURA-ENDO +, TetsuyaHORIBATA ,, Yoshiko NAKAURA ,, Naoyoshi INOUCHI ,, Michihiro FUKUSHIMA -andHiroaki YAMAUCHI +1* +MemuroUpland Farming Research Station,NationalAgricultural Research Center forHokkaido Region,Memuro,Hokkaido *2,21**1+, Japan ,Department ofApplied Biological Science, FukuyamaUniversity, Fukuyama 1,3-0*,3,, Japan -Department of Bioresource Science, ObihiroUniversity ofAgriculture andVeterinaryMedicine, Obihiro *2*0-2///, Japan Received April +0, ,**0; Accepted December +/, ,**0 Thebread-makingquality offlourmade from twonew Japanese breadwheatvarieties, Haruyokoi and Kitanokaori, was evaluated, and the staling and texture of bread made from these flour types were compared with those of flour made from representative bread wheat classes, No.+ Canada western red spring (+CW)andHard redwinter (HRW). Therewasnota largedi #erence in thebread-makingquality of the above four flour types, except that the water absorption of the Kitanokaori flour was high, and the gassingpower of thedoughwas low. Breadmade from the twoabove-mentioned Japaneseflour types (two new bread varieties) were quite soft after baking, and the degree of staling (changes in hardness) were somewhat lower than those madewith +CWandHRW. The cohesiveness of the twonewbreadvarieties, i. e., the index ofbreadelasticity, showedhighervalues than those of othersup to +dayof storage. From the analysis of bread stalingand the retrogradation of starch inbread, itwasproven that the staling rate and starch retrogradation rate constants of the twonewbreadvarieties were approximately the sameas those of breadmade from +CWandHRWbut the starch retrogradation of thenewbreadvarieties was somewhat slower than that of the others up to ,days of storage. The analysis of hardness and cohesiveness of the flourandstarchgel from theabove fourflour types indicated that the softnessandhigh cohesiveness of the twonewbreadvarieties after bakingwere, to agreat extent, the result of the soft texture of starchgel in thesevarieties. These results showed that the somewhat slow staling, especially staling in the early stage, andthe extreme softnessafterbakingof the twonewbreadvarietieswereattributed to the soft textureand low retrogradation of starchgel in thebread,whichwas related to the lower amylose content of these new flour types. Keywords: bread, staling, texture, wheat starch, retrogradation Introduction In recentyears, thebreedingofhigh-qualityhardwheat with high protein content, used to make bread and Chi-nese yellow alkaline noodles, which are in significant demand, has been the focus of manybreedingprograms in Japan, especially inHokkaido. As a result, the spring wheat, Haruyokoi, and the winter wheat, Kitanokaori, were successively raised. The expansion of the cultiva-tion area used for these wheat cultivars is smoothly ad-vancing, since the agricultural characteristics andbaking quality of flour made from thesecultivars aresignifi-cantly better than those of conventional Japanese bread wheat, Haruyutaka (Yamauchi et al., ,**+b). At present,flour made from the two above-mentionednew Japanese breadwheatvarieties are beingused tomake some of the **Towhom correspondence should be addressed. E-mail: yamauti@a #rc.go.jp wheat bread for the domestic market, and the bread is receiving significant customer approval. Themain reason for the goodquality of these bread varieties is estimated tobe that thesenewvarieties areWx-B +null, a factor that results in slightly low amylose content. There have also been some reports on the influence of amylose content on the staling and texture of bread (Bhattacharya et al., ,**,; Lee et al., ,**+). Ithas alsobeen reported thatbread from doublenull andWx-B +nullwheatflour types are soft and show slow staling(Baik et al., ,**-; Martin et al., ,**.), and that the staling of bread made from blends to which partiallywaxy starch andflour are added is lower (Ghiasi et al., +32.; Morita et al., +332; Morita et al., ,**,; Takata et al., ,**/). However,nodetailed studies of thebread-makingqual-ity of the two new flour types and the texture ofthe resultingbread, especially, the staling of the bread, have been carried out to date. Therefore, di #erences in the baking quality and staling of bread between two new flour types and representativebreadflour types, +CW and HRW, remain to be clarified. Thus, in this study, the bread-makingquality of twonewflour typeswas evaluated and compared with those of +CW and HRW, and the staling characteristicsofthe bread made from the above four flour types were analyzed indetail usingkinetic analysis (Yamauchi et al.,+33-; Yamauchi et al., ,**+a). Subse-quently, the retrogradation of the starch in thebread and the texture of the starch gel, among other features, were examined to clarify the e #ectof the flour starch pro-perties on the staling andphysicalproperties of the above breadvarieties. In this study, staling is expressedby the change inbreadhardness during storage, and the staling rate is discussed in relation to the staling rate constant. Materials and Methods Flour and starch samples Twobreadwheat classes, +CW and HRW, and two varieties of Japanese domestic bread wheat, Haruyokoi and Kitanokaori, were used in this study. These domestic varieties have recently been released, andWx-B + protein deficiencywas identifiedusing themethod ofNakamura et al. (+33-). Thebread-making quality of theseflour typeswasdemonstrated tobebetter than that of the conventional domestic breadwheat vari-ety,Haruyutaka. The commercialflour types, +CW,HRW, andKitanokaori were purchased fromEbetsuFlour Mill-ing Co., Ltd. (Ebetsu, Japan), and the commercial flour, Haruyokoiwasbought fromYokoyamaFlourMillingCo., Ltd. (Sapporo, Japan). Topreventqualitydegradation of theflour types, theywerepreserved at /℃C 5 andused after returning to room temperature under controlled condi-tions inwhich thefloursdidnot absorbmoisture. Starch preparation from theflour followed the traditionalmethod of Mangalika et al. (,**-) and moisture content was es-timated by oven-drying a +g sample at ++/1C 5 for -h. Flour and starch properties The amylose content per +**mg of starch granules was colorimetrically deter-mined using an Auto Analyzer System II (Bran L L +ubbe Co., Ltd., Norderstedt, Germany), as described by Miura andTanii (+33.). In this system, estimates of the amylose content were compared to the amylose content of com-mercial wheat starch standards in which the amylose contenthasbeenproven. Theprotein content of theflour types was measured using a near-infrared reflectance in-strument (Inframatic 2+,*, PerCon Co., Hamburg, Germa-ny). The ash content of the flour types was measured according to the method of the American Association of Cereal Chemist (AACC) (+33+a). The pasting properties ofthe flour types were measured using a Rapid Visco Analyser (RVA) (RVA-., Newport Scientific Pty. Ltd., Warriewood, Australia). Flour (,.2,g, dwb) was mixed with ,/ml of distilled water to prepare a +*.* f flour suspension (w/w). The suspensionwas held for +min at /*0C ℃,heated to 3/9C 5 at +,.0℃C 6/min,kept at 3/9C 5 for ,./min, then cooled to /*5C 0 at ++.2℃C 8/min, andfinallykept at /*5C 0 for ,min. The peak viscosity, breakdown (di #erence be-tween peak and minimum viscosity), setback viscosity (di #erencebetween thefinal andminimumviscosity), and pasting temperature were recorded from the RVA curve. All values for viscosity parameters were expressed in RVAunits (RVU). Bread-making and bread evaluation The bread-making testswere conductedusing theno-timemethod, following the standard white bread formulation: ,**g of flour, +*g of sugar, +*g of shortening (Snowlight, Kaneka Corp., Osaka, Japan), .g of salt, .g of yeast (Regular yeast, Nip-pon Beet Sugar Mfg Co., Ltd, Tokyo, Japan),,*mg of ascorbic acid, and a suitablequantity ofwater (Yamauchi et al., ,**+a). The optimal water absorption of the tests was estimated using a Farinograph at /**BU, according to the method used by the AACC (+33+b). The dough wasmixed to justbeyondpeakdevelopment, as indicated by the current curve of the mixing motor, and then divided into two +**gpieces, rounded, and allowed to rest for ,*min in a fermentation cabinet at -*3C 0. The pieces werepanned andproofed at -23C 8 and 2/% humidity for 1*min and then baked at ,**0C 0 for ,/min. A slice of each bread variety was photocopied using a copy machine to evaluate the crumbgrain. The specific loaf volume (SLV) after cooling at room temperature for + hr after baking was measuredby the rapeseed-replacement method. The moisture content of the bread was measuredusingbread-crumbs dried for -h at ++/1C 5. Dough properties Thevacuumexpansion of the dough (gas retention)wasmeasuredusing themethod ofYamauchi et al. (,***), which requires ,*g of dough after proofing. Thegas retentionwas evaluatedbymeasuring the maxi-mumvolume of the dough in a cylinder under low pres-sure. Total gassing power at -*3C 0 for +, ,, and -h was measured with a Fermograph II (ATTOCo., Ltd., Tokyo, Japan) with ,*g of dough after bench time. Bread staling and starch retrogradation The staling characteristics of thebreadwere evaluatedbymeasuring the hardness and cohesiveness of crumbs using the method developed by Yamauchi et al. (,**+a). Immedi-ately after baking, the loaves were cut into , cm-thick slices, and a square (- cm o -m cm) of crumbs was cut from the center of the slice using an ultrasonic cutter (model USC---*/, Yamaden Co., Ltd., Tokyo, Japan). The cut crumbs were stored at ,*2C 0 for / days in an aluminum laminate bag to prevent water evaporation. The hard-ness and cohesiveness of six crumbs were measured by twice compressing the crumbs from a , cm to a + cm thickness at approximately daily intervals. The meas-urement was begun at the time the crumbs werecut. The limitingvalue of crumbhardness (the highest possi-ble value) was determined from the hardness of the cut crumbs stored at ..1℃C 7 for +*days, as reportedbyAxford et al. (+302). The staling rate constant (SRC) of thebread and the retrogradation rate constant (RRC) of starch in the bread were obtained using the methoddevelopedby Yamauchi et al. (,**+a). The former constant was deter-minedusing the equation: ln )(}HL {H (*)/(HL =kt.Ho andHt are thehardness of the cut crumbs at time zero and t, respectively. HL, k, and t are the limitingvalue of the hardness, the SRC, and the storage time, respectively. The latter constant (RRC)wasdecidedbysubstitutingthe Table +. Amylose content of starches from flours, protein and ash contents, andpastingproperties of floursa. Flour Wx protein Amylose content Protein content Ash content Peak Viscosity Breakdown Setback Pasting Samples A1 B1 D1 (%) (%) (%) (RVU) (RVU) (RVU) temperature(C) 1CWe 28.2b 11.4a 0.40b 197ab 70b 98b 66.5a HRWd 28.4a 10.6c 0.37c 167c 59c 107a 68.2a Haruyokoi 十 十 26.5c 11.0b 0.41b 204a 93a 83c 67.5a Kitanokaori 十 十 26.6c 10.1d 0.48a 179bc 75b 87c 66.9a Values followed by the same letter i n the column are not significantly di f ferent (p<0.05,n =2). bUnknown (------), present (+), and absent (-). 1CW: NO.1 Canada western red spring . HRW : Hard red winter. Table ,. Results of bread makingquality of floursa. Flour Water absorption Gas retention Gassing power (ml) SLVb Moisture content of bread Samples (%) (ml) 1h 2h 3h (ml/g) (%) 1CWC 67.0 125a 33.2a 74.2b 109.7b 5.47a 43.8b HRWd 65.0 123a 32.9ab 74.4b 108.6b 5.39a 43.5c Haruyokoi 66.5 126a 33.4a 76.1a113.7a 5.44a 43.4c Kitanokaori 72.0 125a 32.6b 70.7c 1 102.7c 5.47a 45.6a a Values followed by the sa me l etter i n the column are not s ignific a ntly different (p<0.05, gas retention and gassing power : n =2, others : n =3). bSLV : Specific loaf volume. c 1CW: NO.1 Canada western red spring. d HRW: Hard red winter. amylopectin retrogradation enthalpy (D H), described below, with thehardnessvalues on the above equation. The D H forbreaddeterminedbydi #erential scanning calorimetry (DSC) and the X-ray di #raction patterns of the bread varietiesduring storageweremeasuredusingdehydrated crumb samples, asreported by Yamauchi et al.(+33,). The D H of a dehydrated sample (/*mg) containing dis-tilled water (+/*mg) was measured using a micro DSCIII (Setaram, Caluire, France) programmed at a heating rate of +℃C 1/min from / to ++*1C 0. X-ray di #raction patterns were taken with an X-ray di #ractometer (Rint ,+**, Rigaku, Tokyo, Japan) under the following conditions:target, Cu; voltage, .*kV; current, .*mA; step width,*.*,2°; emission slit, +/,2°; light reception slit, *.-mm. The dehydrated samples wereconditioned at +**ve relative humidity for three days before the X-ray di #raction pat-terns were obtained. Physical properties of the flour and starch gels Theflour and starch gels were prepared as follows. Flour and starchgelatinizationwas achieved in anRVA. TheRVA conditionswere equivalent to those described above except that cooling was stopped at 1*℃C .. The obtained 0g of paste was put into a /*mlplastic tubewith aflat bottom. The tubewas centrifuged at -*** rpmfor /min in order to removebubbles from thepaste andobtain cylinders ofgel of ,./ cmdiameter and + cmheight. Afterwards, the tube was kept in a water bath at ,*2C 0 for ,hrs to completely change thepaste to agel. A compression test of theflour andstarchgelswas alsoperformedwith aREONER(model RE---**/, YAMADEN Co., Ltd., Tokyo, Japan). The hardness and cohesiveness of the flour and starch gels were measured by twice compressing the gels from + cm to *./ cm thickness using a circular plunger (Type No. -, YAMADENCo.,Ltd.,Tokyo, Japan) at a speed of +mm/s. Maximum compressing stress (hardness)and cohesive-ness were determined from the force-deformation curve by compression. Statistical analysis Measurements of the amylose, pro-tein, ash,RVA, gas retention, and gassing powerweremade in duplicate. SLV and moisture were measured three times. Thehardness and cohesiveness of the crumbswere measured six times. Measurements of theDSC andflour and starch gel texture were performed four and three times, respectively. All data in Tables + to ., (excluding water absorption during bread-making, SRC, and RRC) and all data in Figs. , and - are expressed as mean, and standard deviation, respectively, and the signifi-cance of thedi #erence between eachvariable inTables +,,, and . (excludingwater absorption during bread-making) was evaluated by analysisof variance using Duncan’s multiple range test. Results Amylose content of starch and properties of flour types The amylosecontent ofthe starch types and the pro-perties of the flour types are shown in Table +. The amylose content of the starch of HRW was the highest, and the value of +CWwas slightly lower. On the other hand, those of the two new wheat varieties with Wx-B +protein deficiency showed a significantly lower amylose content (about ,W ) .than both +CW andHRW. The pro-tein contentvaried among the fourflour samples, and the Table -. Staling and retrogradation rate constants, HL-H *a, and D HL-D H *b of four breads during storage. Flour SRCC RRCd H-H ▲H-AH Samples (hx102) (hx10) (N/m²x10) (J/g) 1CWe 1.30 1.05 6.53 4.35 HRWI 1.39 1.10 6.85 4.63 Haruyokoi 1.35 1.29 6.49 4.28 Kitanokaori 1.18 1.05 5.94 4.08 Flour Bread Flour gel Starch gel Samples Hardness Cohesiveness Hardness Cohesiveness Hardness Cohesiveness (N/m²x10) (-) (N/m²x10) (-) (N/m²x10) (-) 1CWb 1.68b 0.815b 5.90b 0.683b 1.82b 0.647b HRWe 1.99a 0.799c 6.79a 0.585c 2.37a 0.463c Haruyokoi 1.13d 0.828a 4.97c 0.768a 1.36d 0.718a Kitanokaori 1.44c 0.825a 5.05c 0.667b 1.70c 0.720a Value s fol l ow e d by t he same l e tt e r in t he column a re not signi f icantly d i f ferent (p <0.05, bre a d : n =2,gels :n =3). b 1CW : NO.1 Canada western red spring . HRW: Hard red winter . value for Kitanokaori was somewhat lower than those of the others. The ash content varied considerably among the four flour types. With regard to the RVA pasting properties, thepeakviscosity of theHaruyokoiflour show-ed the highest value, followed by +CW and Kitanokaori, andHRWhadthe lowestvalue. With reference tobreak-down, theHaruyokoi flourhad thehighest value, followed byKitanokaori and +CW, andHRW againhad the lowest value, indicating abasic relationshipbetweenhighbreak-down and low amylosecontent. On the contrary, the setbackvaluesbasicallydecreasedwhen the amylose con-tentwas lower. Thegelatinizing temperature of the flour typeswas almost the samevalue, except that thevalue of HRWwas slightlyhigher. Dough properties and bread-making qualities of the flour types The resultsofthe dough propertiesand bread-making qualitiesofthe four flour types areshown in Table , and Fig.+. The water absorption during bread-makingwas quite similar for the four flour types, except that Kitanokaori had a very high value. No significant di #erencewas observed in thegas retentionvalues of any of the dough types. The gassing power of Haruyokoi after fermentingfor +hwashigher than those of +CWand HRW, and that of Kitanokaori was significantly low com-pared with the others. There was no significant di #er-ence in the SLV of bread from the four flour types. Though the crumbgrain of Kitanokaori breadwas some-what yellow, the appearance and crumbgrain of the four bread varieties was not very di #erent. Regarding the moisture content of the bread, the value for Kitanokaori bread was considerably higher than those of the others, reflecting thehighwater absorption of Kitanokaori flour. The above results showed that the bread-making qual-ities of these flour types, including the SLV, appearance, and crumb grain, was similar, except that the dough properties, such as water absorption during baking and gassingpower, were somewhat di #erent among the four flour types. Staling and cohesiveness of bread and retrogradation of starch in bread As shown inFig. ,, breadmade from the twonewflour types were much softer than those of +CW andHRWupto ,days, andthe stalingof the formerbread varieties, especially that ofKitanokaori,wasmuch slower than that of the latter varieties. The cohesiveness of the new bread varieties showed somewhat high values in comparison to those made from +CW andHRWup to +day, and then thebreadmade fromKitanokaori and +CW had higher cohesiveness values than those made from Haruyokoi andHRW. These results indicate that bread made from Haruyokoi and Kitanokaori have higher re-covery against compression during early storage than thosemade from +CWandHRW. As shown inFig. -, the changes in D Hduring storage, measured by the DSC, as well as the index of starch retrogradation inbread, were almost the same among allbreadvarieties. However, the exception was that the change observed in Kitanokaori bread during storage was somewhat smallercompared with those ofthe others,and the changes observed in bread made from +CW and HRW, especially the latter, during early storagewere rather large. The starch retro- Fig. ,. Changes in hardness and cohesiveness of flour bread during storage. The vertical bar represents the standard deviation for each value. ): ,NO. +Canada western red spring (+CW),: Hard red winter (HRW),i : .Haruyokoi,i : .Kitanokaori. 0 20 40 60 80100 120 140Storage time (h) Fig. -. Changes in the amylopectin retrogradation enthal-py of flour bread during storage. The vertical bar represents the standard deviation for each value. The symbols are shown inFig. ,. gradation changes observedbyX-raydi #raction inbread during storage in Fig. . (which shows onlydata of HRW and Kitanokaori breads) also showed a similar tendency to those of the D HinFig. -. Namely, the tendency toward increasing changes in the representativepeak (,q , around ) of the starch retrogradation in the X-ray di #raction pattern among the four bread varieties during storage was nearly the same. But the exception was that the peak change of Kitanokaori bread during storage was somewhat smaller comparedwith those of the others, and the peak change observedduring the early stage in +CW and HRW bread, especially the latter, were rather large. Theseresultsshow that amylosecontent has a rather strong influence on bread staling and retrogradation of starch in bread during early storage. The SRC, RRC, di #erence betweenHL andH * (HL n H *), and the di #erence between D HL and D H * (D HL n D H *) are shown in Table -. D HL and D H * are the limitingvalues of D H and D H at time zero,respectively. Although somewhat of a di #erence was observed between the two kinds of constants, SRC andRRC, the two constants of all breadvarieties showed similar values, except that the SRC of Kitanokaori and theRRC of Haruyokoi were respectively somewhat small and large in comparison to those of the others. As regards the HL e H * and D HL h D e H * values, the HRW and Kitanokaori bread varietiesrespectively showed some-what high and low values compared with those of the +CW and Haruyokoi bread varieties. This suggests that the starchproperties of the fourflour types and the order of their amylose content are not directly related to the order of SRC, RRC, HL ,H *, and D HL Hardness and cohesiveness of fresh bread, flour and starch gel The results of the measurements of hardness and cohesiveness of fresh bread and the flour and starch gel are showninTable. .. Thehardness of thebread types and gel was enhanced, and their cohesiveness showed a lowvalue concurringwithhigher amylose content (shown in Table.+). The hardness and cohesiveness of bread made from the new flour types showed low and high Fig. .. Changes in the X-ray di #raction patterns of flour bread made from Hard red winter (HRW) and Kitanokaori during storage. values comparedwith those of +CWandHRW, respective-ly. These results indicate that, after baking,breadmade from the twonewwheatvarieties described in this study, whichhave the Wx-B +nullgene and are somewhat low in their amylose content, have a soft and high elastic tex-ture. This texture is similar to that of cooked rice, which isgreatly related to the somewhat lower amylose content of the newflour types. Discussion In this study, thebread-makingquality, especially stal-ingandtexture, ofbreadmade from twonewbreadwheat varieties was investigated. These new flour types have similar flourqualities comparedwith those of representa-tive bread wheat brands, +CW and HRW, yet their amy-lose content is somewhat lower. Since these newwheat varieties have the above characteristics, bread from these new flour types are said to be soft with a slow staling process. Therefore, a scientific investigation into the fea-tures of these newflour types was undertaken. Amylose content The amylose content in the starch of the newflour types was clearly lower than that of the starch of +CW and HRW, and the RVA characteristics showed a high breakdown and low setback (Table +), typical features of a low amyloseflour, as reportedbyOda et al. (+32*). These results indicate that the starch and flour properties, especially the amylose content, of these newflour types are di #erent from those of +CW andHRW. Staling and texture The twonewbreadvarieties, espe-ciallythe Kitanokaori bread, remained quite softfrom immediately after baking to the end of storage, and stal-ingwas significantly retarded in comparison to +CW and HRW(Fig. ,). Itwas also evident that the retrogradation changes in the starch of the new bread varieties during early storage were somewhat lower than those of +CW and HRW (Fig. -, .); however, all data of the new bread varieties showninTable - are almost the same as those of +CW and HRW, except for HL d H * and D HL n D d H * in the bread made from HRW and Kitanokaori. On the other hand,Table .demonstrates that the hardness of the new bread varieties after baking was significantly smaller than that of +CW and HRW. Furthermore, the order of thehardness and cohesiveness of the fourbreadvarieties after baking is in agreement with that of the flour and starch gels and, more importantly, the order of all hard-nessvalues corresponds to that of the amylose content in Table. +. These results suggest thatthe slow staling, particularly in the early stage, of the newbreadvarieties is causedby the somewhat slow starch retrogradation in thebreadduringthat time, aswell as the extreme softness of the starch gel in the breads, and, furthermore, the overall slow staling of the Kitanokaori bread is related to the overall slow starch retrogradation, small HL and D HL Baik et al. (,**-) and Martin et al. (,**.) reported that bread made from low amylose flour types are very soft, and that the staling of the breads is slow. The softness and slow staling of the new two bread varieties in comparison to those of +CW andHRW corre-spond to the results of the above-mentioned reports. When conditions of moisture transport in bread and waterevaporation from bread during storage are con-trolled for,asin this study, the main factorsa #ecting bread staling were the SRC and HL The chief con-trol factor of SRC was the retrogradation rate ofthe starch in the bread (RRC), and the main factors controll-ing HL g H * were the bread structure, including the SLV and crumb grain, and the starch gel texture in bread (Yamauchi et al., ,**+a). Based on the abovefindings, the following conclusions were drawn regarding the staling of the four bread varieties. All data for Kitanokaori bread were somewhat lower than those of others (Table -), and only the HL e H * and D HL h D e H * of the HRWbread were high compared with those of +CW and Haruyokoi. There was not a large di #erence in bread structure, in-cluding the SLV and crumbgrain, among the four bread varieties, as evident from Table , andFig. +. Therefore, the overall slow staling of the Kitanokaori bread and the rather fast staling of theHRWbread canbe attributed, to some extent, to the small SRC andHL d H *, and the large HL respectively, which seem to be related to the starch gel texture in each bread. In addition, it seems that the small SRC andHL d H * of the Kitanokaori bread areinfluenced by the lower amylosecontent and high moisture content of this bread, especially the latter, as describedbelow. Characteristics ofHaruyokoi On the other hand, since all data of the +CW and Haruyokoi bread in Table - are very similar, a clear di #erence between them can not be identifiedusing the SRC andHL However, it seems that, as described above, the comparably slow staling of the Haruyokoi bread, particularly in the early stage, is mainly due to its extremely soft texture and somewhat slow retrogradation of starch gel during the early stage, which is certainly related to the low amylose content of the Haruyokoi flour. E #ect of moisture content The di #erence in the stal-ing of the two bread varieties from the new flour types, whichdonot di #er greatly inboth starch characteristics, such as their amylose content, and bread-making qual-ities, such as theSLVandcrumbgrain, is as follows. The moisture content of Kitanokaori bread was about higher than that ofHaruyokoi (Table ,),whichwasdue to the high water absorption of Kitanokaori flour. There-fore, it seems that bread moisture content is one of the only factors a #ecting the staling of bread that di #ered largely between these two bread varieties. It has been reported that high-moisture bread and starch gel were responsible forslow staling and retrogradation, respec-tively (Piazza andMasi, +33/; Rogers et al., +322; Zeleznak and Hoseney, +320). Therefore,it would seem that the most significant factor responsible for the slower staling of Kitanokaori bread compared to Haruyokoi bread was the high moisture content of the former bread and that, from the considerable di #erence in the SRC and HL between these bread varieties (Table -), it seems that the moisture content ofbreadhas amore significant influence on overallbread stalingthan the amylose content offlour. Texture of the newtwo bread varieties The data, except forsome data in Table .,show that the hardness and cohesiveness ofthe new flour types wererespectively lower and higher than those of +CW and HRW. These resultsindicatethat the texture of starch gel in bread greatly influences thehardness and cohesiveness ofbread after baking, and that these features ofthe new bread varieties afterbaking are chieflydue to the specific starch characteristics of these flour types, such as the relatively low amylose content. Furthermore, it seems that the soft texture of starch gel in the new bread varieties greatly influences the softness and slow starch retrogradation of the bread during the early stage. These results corre-spond to previous research, which demonstrated that bread made from low amylose flour and gel from low amylose starch are very soft, which contributes to slow staling and retrogradation (Baik et al., ,**-; Bhattacharya et al., ,**,; Hayakawa et al., +331; Lee et al., ,**+; Martin et al., ,**.). Characteristics of the two new Japanese bread wheat varieties As shown above, it was proven that the new flour types prepared from the new, recently raised Japa-nese bread wheat varieties displayed almost the same bread-making anddoughproperties as the representative bread flour types, +CW and HRW. Furthermore, it was demonstrated that the staling of the resultingbread was somewhat slow, and, during the short storage time after baking,hadgood texture, as shownby their softness and highelasticity. These features of thenewbreadvarieties were mainly causedby the specific starch characteristics of the newflour types, such as the low amylose content. In general, Japanese tend to prefer a soft and elastic bread texture similar to that of cooked rice. Therefore, many large Japanese baking companies have recently developed bread with such a texture by improving the baking method and composition. These bread varieties have now become major products for these companies. The bread made from the new flour types in this study have the texture that Japanese people generally prefer, regardlessof baking method and composition. There-fore,ifthese new Japanese wheat varietiesincreasein popularity and stable production is established, bread with good texture made from these flour types are ex-pected to be produced in abundance in the near future. Acknowledgements This work wassupported in part by the Research andDevelopmentProgram forNewBio-industry Initia-tives ofBio-orientedTechnologyResearchAdvancement Institu-tion, the ElizabethArnoldFuji Foundation for the Promotion of BakingScience andTechnology, and the Regional Research and Development Program for the New Industry Initiatives of the Ministry of Economy, Trade, and Industry of Japan. References American Association of Cereal Chemists (+33+a). Approved Methods of the AACC, 2th ed. Method /.4-,+. The Association:St. Paul, MN. American Association of Cereal Chemists (+33+b). Approved Methods of the AACC, 2th ed. Method *28-*+. The Association:St. Paul, MN. Axford, D.W.E., Colwell, K.E. Cornford, S.J. and Elton G.A.E.(+302). E #ect of specific loaf volume on the rate and extent of staling inbread. J. Sci. FoodAgric., +3, 3/5-+*+. Baik, B.K., Park, C.S., Paszczynska, B. and Konzak, C. F. (,**-). Characteristicsof noodles and bread prepared from double-null partial waxywheat. Cereal Chem., 2*, 0,17-0--. Bhattacharya, M., Erazo-Castrejo´n, S.V., Doehlert, D.C. and Mc-Mullen,M.S. (,**,).Staling ofbread as a #ectedbywaxywheat flour blends. Cereal Chem., 13, +128-+2,. Ghiasi, K. Hoseney, R.C., Zeleznak, K. and Rogers, D.E. (+32.). E #ectof waxy barley starch and reheating on firmness of bread crumb. Cereal Chem., 0+, ,2+1-,2/. Hayakawa,K.,Tanaka,K.,Nakamura,T.,Endo,S. andHoshino,T.(+331).Quality characteristics ofwaxyhexaploidwheat (Triticum acestivumL): Properties of starchgelatinization and retrogra-dation. Cereal Chem., 1., /106-/2*. Lee, M.R., Swanson, B.G. andBaik, B.K. (,**+). Influence of amy-lose content on properties of wheat starch andbread making quality of starch andglutenblends. Cereal Chem., 12, 1*+1-1*0. Mangalika, W.H.A., Miura, H., Yamauchi and Noda, T. (,**-). Properties of starches from near-isogenic wheat lines with di #erent wxprotein deficiencies. Cereal Chem., 2*, 00,2-000. Martin, J.M., Talbert, L.E., Habernicht, D.K., Lanning, S.P., Sher-man, J.D.,Carlson,G. andGiroux,M.J. (,**.). Reduced amylose e #ect onbread andwhite salted noodle quality. Cereal Chem.,2+, +22-1+3-. Miura, T. and Tanii, S. (+33.). Endosperm starch propertiesin several wheat cultivars preferred for Japanese noodles. Euphy-tica., 1,, +1+1-+1/. Morita, N., Fujita, S., Domon, E., Ando, H. and Mitsunaga, T.(+332). E #ect of substitution of waxy barley flour on the viscoelastic properties of wheat dough and bread making. J. Appl. Glycosci., ./, -2/85-3+. Morita, N., Maeda, T., Miyazaki, M., Yamamori, M., Miura, H. and Ohtsuka, I. (,**,). E #ect of substitution of waxy wheat flour for common flour on dough and baking properties. Food Sci. Technol. Res., 2, ++3-1+,.. Nakamura, T., Yamamori, M., Hirano, H. and Hidaka, S. (+33-). Identification of three wx proteins in wheat. Biochem. Genet.,-+, 1/5-20. Oda, M., Yasuda, S., Okazaki, S. Yamauchi, Y. andTokoyama, Y.(+32*). A method of flour quality assessment for Japanese noodles. Cereal Chem., /1, ,/--2,/.. Piazza, L. andMasi, P. (+33/). Moisture redistribution throughout the bread loaf during staling and itse #ecton mechanical properties. Cereal Chem., 1,, -,*0--,/. Rogers, D.E., Zeleznak, K.J., Lai, C.S. and Hoseney, R.C. (+322). E #ect of native lipids, shortening, and bread moisture on bread firming. Cereal Chem., 0/, -328-.*+. Takata, K., Nishio, Z., Iriki, N., Tabiki, T., Funatsuki, W. and Yamauchi, H. (,**/). Comparison of quality characteristics of waxywheat using anear isogenic line. Breeding Sci., //, 217-3,. Yamauchi, H., Fujimura, M., Ohya, K., Hirakawa, T. and Ko-bayashi, T. (+33,). Role of shortening and monoglyceride on staling of white breadmade by straight doughmethod.Nihon ShokuhinKogyo Gakkaishi, -3, -2-83-3* (in Japanese). Yamauchi, H., Ichinose, Y., Takata, K., Iriki, N. andKuwabara, T.(,***). Simple estimation of bread-making quality of wheat flour by modified expansion test under reduced pressure. Nihon ShokuhinKagakuKogakuKaishi, .1, .06-.3 (in Japanese). Yamauchi,H.,Kaneshige,H.,Fujimura,M.,Nosho,Y.,Hashimoto, S., Kato, M., Kodama, K. and Kobayashi, T. (+33-). A kinetic study of the staling of white bread treated with microwave-heating. J. Chem. Eng. Jpn., ,0, 1.39-1/,. Yamauchi,H.,Nishio,Z.,Takata,K.,Oda,Y.,Yamaki,K., Ishida,N. andMiura, H.(,**+a). The bread-makingquality of a domestic flour blended with an extra strong flour and staling of the bread made from the blended flour. Food Sci. Technol. Res., 1,+,*0-+,/. Yamauchi, H., Takata, K. Yamaki, K and Abiko, T. (,**+b). The present and future of production, breeding and utilization of the wheatfor bread-making in Hokkaido. Nihon Shokuhin KagakuKogakuKaishi, .2, 1328-2*0 (in Japanese). Zeleznak, K.J. andHoseney, R.C. (+320). The role of water in the retrogradation of wheat starch gels andbread crumbs. Cereal Chem., 0-, .*17-.+*.

确定

还剩6页未读,是否继续阅读?

北京盈盛恒泰科技有限责任公司为您提供《面团性质和面包品质分析》,该方案主要用于小麦粉中面团发酵能力检测,参考标准--,《面团性质和面包品质分析》用到的仪器有日本ATTO发酵特性分析仪

推荐专场

相关方案

更多

该厂商其他方案

更多