方案详情

文

木薯浆在序批式反应器与连续搅拌罐反应器中沼气生产性能的比较研究Comparative Study of Biogas Production from Cassava Pulp in a Sequencing Batch Reactor and a Continuous Stirred Tank Reactor

方案详情

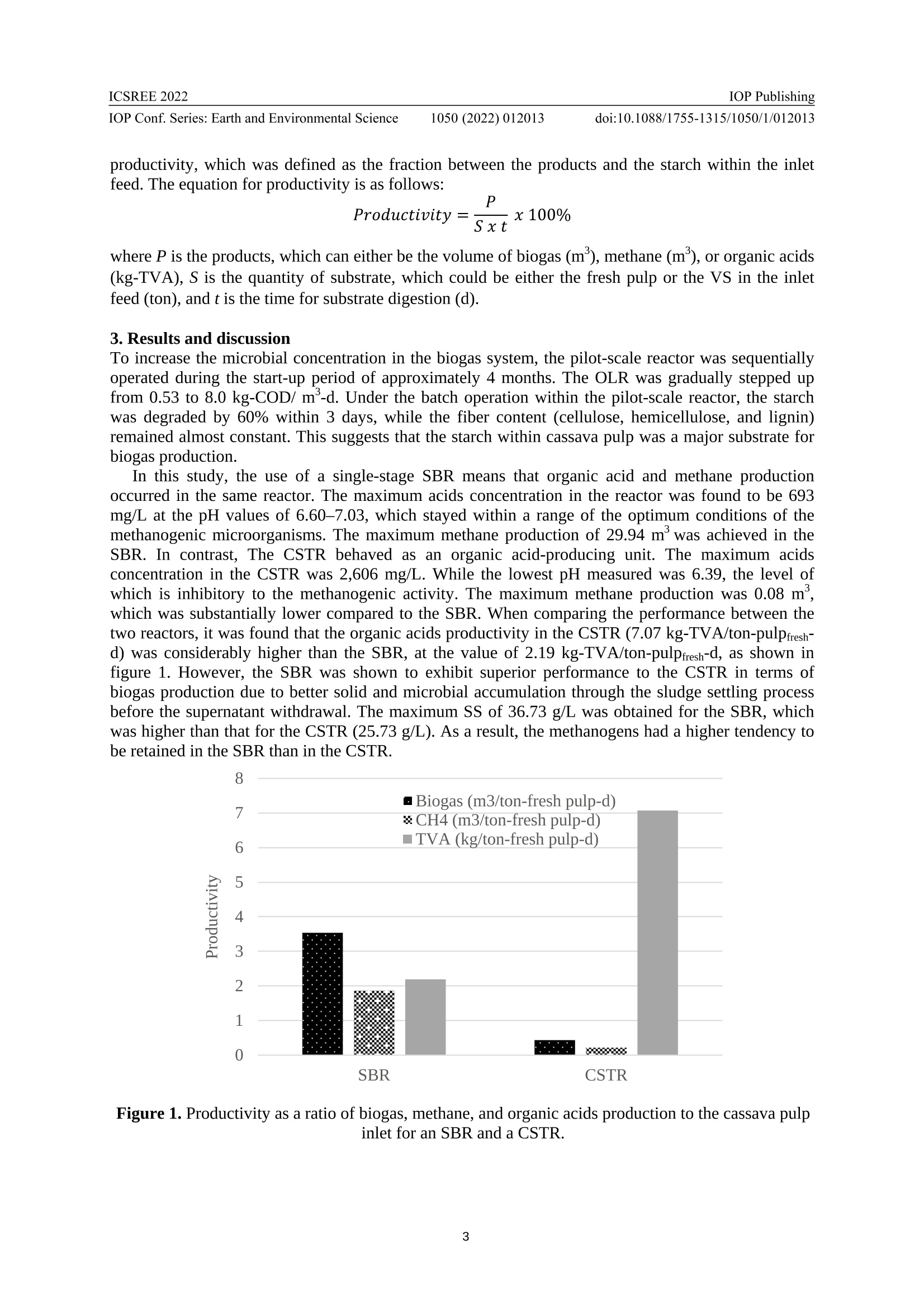

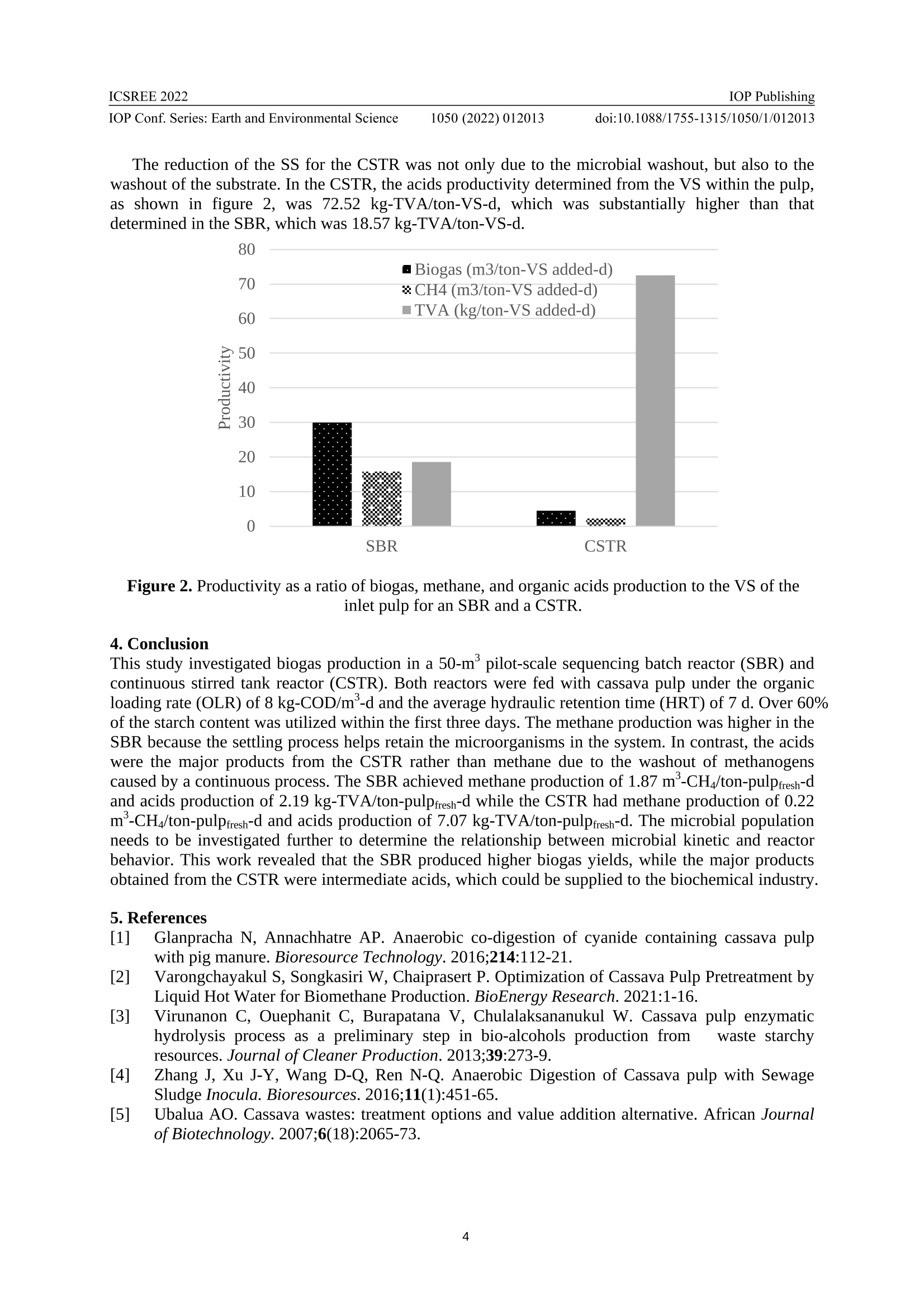

木薯浆在序批式反应器与连续搅拌罐反应器中沼气生产性能的比较研究Comparative Study of Biogas Production from Cassava Pulp in a Sequencing Batch Reactor and a Continuous Stirred Tank ReactorIOP Conference Series: Earth and Environmental Science IOP PublishingICSREE 2022doi:10.1088/1755-1315/1050/1/0120131050 (2022) 012013IOP Conf. Series: Earth and Environmental Science 木薯浆在序批式反应器与连续搅拌罐反应器中沼气生产性能的比较研究 PAPER·OPEN ACCESS You may also like Comparative Study of Biogas Production from Cassava Pulp in a Sequencing Batch Reactor and a Continuous Stirred Tank Reactor -Comparison of methane production from cattle, buffalo, goat, rab b it , c h icken, and duck manure 一 -Pr os pect of Fe n on -h e m e o n co f fee f lour made f ro m s olid coffee waste: Mini r e vi e w R H Setyobudi,L Zalizar, S K Wahono et al. ECS Toyota Young Investigator Fellowship For young professionals and scholars pursuing research in batteries,fuel cells and hydrogen, and future sustainable technologies. At least one $50,000 fellowship is available annually. More than $1.4 million awarded since 2015! Application deadline: January 31, 2023 Comparative Study of Biogas Production from Cassava Pulp in a Sequencing Batch Reactor and a Continuous Stirred Tank Reactor T. Ruttithiwapanich", C. Waewsak’, o. Laopitinan’, K. Saengchan, K.Lueangwattanapong, W. Songkasiri, National Center for Genetic Engineering and Biotechnology, National Science and Technology Development Agency (NSTDA), Pathum Thani, Thailand Pilot Plant Development and Training Institute, King Mongkut's University of Technology Thonburi, Bangkok, Thailand Faculty of Science and Technology, Muban Chombueng Rajabhat University, Ratchaburi, Thailand *tarworn.rut@biotec.or.th Abstract. Thai cassava starch i ndustry generates solid waste or pulp approximately of 9.5 Mt/y (w i th a moisture content of 70-80%). Biogas produc t ion technology has been i ntroduced for severa l decades in Thai l and. However, the i mplementation of biogas production using cassava pulp as a feedstock i s still limited due to the complex lignocellulosic structure, which diminishes hydrolysis. This work i nvestigated biogas produc t ion f rom cassava pulp in a 50-m’pilot-scale sequencing batch reactor (SBR) and continuous st i rred tank reactor (CSTR). Both reactors were fed with cassava pulp, under t he organic loading rate (OLR) of 8 kg-COD/m'-d and the average hydraulic retention time (HRT) of 7 d . Under the batch operation, more than 60% of the starch content was utilized within the first three days. The SBR achieved methane production of 1.87 m'-CH/ton-pulpr r esh-d and acids production of 2.19 kg-TVA/ton-pulpfr e sh-d while the CSTR had methane production of 0.22 m'-CH/ton-pulpfresh-d and acids production of 7.07 kg-TVA/ton-pulpfresh-d. The methane production was higher in the SBR because the settling process helped microorganisms remain in the system. In CSTR, acids rather than methane were produced due to the washout of methanogenic microorganisms. This work revealed that the SBR yielded higher biogas produc t ion, while the CSTR produced intermediate acids, which could be supplied to the biochemical i ndustry. 1.Introduction Thailand i s the largest producer of cassava starch for domestic consumption and export i n 2019. The cassava starch industry in Thailand had generated a large amount of cassava pulp. The approximate generation of cassava pulp is 2.5 ton per one ton of cassava starch; this is equivalent to 9.5 Mt/y of cassava pulp with 80% moisture content [1]. The pulp is rich in organic compounds composed of 47.9-75.1% of starch as the major component, followed by cellulose, hemicellulose, and lignin at 4.11-25.8%, 4.20-16.8%, and 1.2-8.2% (dry basis), respectively. It also contains fat and protein in small proportions [2-4]. However, inappropriate management of cassava pulp leads to environmental pollution [5]. To date, cassava pulp can be used as a raw material for the production of fertilizer, doi:10.1088/1755-1315/1050/1/012013 mushroom growing media, animal f eed, bioethanol, and biogas [1]. Biogas production from the pulp can create a positive i mpact on the economy and environment [6]. Anaerobic digestion (AD) is a process for t ransforming organic substrates into biogas through the hydrolysis, acetogenesis, acetogenesis, and methanogenesis steps [7]. There are several biogas reactor configurations such as continuous stirred tank reactor (CSTR), anaerobic contact reactor, f luidized bed reactor, anaerobic f ixed f ilm reactor, upflow anaerobic sludge blanket (UASB), and sequencing batch reactor (SBR) reactor [8-9]. Among these biogas reactors, the CSTR and SBR have been considered the most practical for most industries [9-10]. The CSTR is simpler to operate than the SBR, while the SBR is often chosen for treating complex substrates, which need a long sludge retention t ime [11]. The aim of this study was to investigate the performance of anaerobic digestion of cassava pulp in the CSTR and SBR to evaluate the efficiency of organic acids and biogas production. 2. Materials and methods 2.1. Substrate and inoculum Fresh cassava pulp was sourced from a cassava starch factory in Nakhon Ratchasima province,Thailand. The characteristics of the fresh cassava pulp are presented i n table 1. The pulp was mainly composed of starch (68%) and fiber, which was a combination of cellulose, lignocellulose, and l ignin.The sludge from a biogas plant t reating starch-wastewater was used as an inoculum. Table 1. The characteristics of the fresh cassava pulp i n this study Cassava pulp’s component % Composition Moisture 88.00 Starch Cellulose B Hemicellulose Lignin Protein 327 Other 2.2. Experimental setup A 50 m’pilot-scale reactor was fed with cassava pulp at an organic loading rate (OLR) of 8 kg-COD/m -d and an average hydraulic retent i on time (HRT) of 7 d. The SBR operation consisted of five steps: feeding, mixing, reaction, settling, and supernatant withdrawal, while the CSTR reactor was operated with the fill-draw method once a day. The pumps used for feeding were controlled by a t imer.Both reactors were stirred by an agitator at 100 rpm. The reactor was started by filling 20 m’ of the inoculum i nto a tank (at a total solid of 30 g/L).Then, the biogas effluent was added to t he reactor until t he working volume of 37 m’ was reached Cassava pulp was used as a sole carbon source with the basal medium supplemented. During the start-up of the SBR, the OLR was initially set at 0.57 kg-COD/ m’-d and t hen increased. The study began after the OLR of 8 kg-COD/m-d 2.3. Analytical methods productivity, which was defined as the fraction between the products and the starch within the i nlet feed. The equation for productivity is as follows: where P is the products, which can either be the volume of biogas (m’), methane (m’), or organic acids (kg-TVA), S is the quantity of substrate, which could be either the fresh pulp or the VS in the inlet feed (ton), and t is the time for substrate digestion (d). 3. Results and discussion To increase the microbial concentration in the biogas system, the pilot-scale reactor was sequentially operated during the start-up period of approximately 4 months. The OLR was gradually stepped up from 0.53 to 8.0 kg-COD/ m’-d. Under the batch operat i on within the pilot-scale reactor, the starch was degraded by 60% within 3 days, while the fiber content (cellulose, hemicellulose, and lignin)remained almost constant. This suggests that the starch within cassava pulp was a major substrate for biogas production. In this study, the use of a single-stage SBR means that organic acid and methane production occurred in the same reactor. The maximum acids concentration in the reactor was found to be 693mg/L at the pH values of 6.60-7.03, which stayed within a range of the optimum conditions of the methanogenic microorganisms . The maximum methane production of 29.94 m’ was achieved in t he SBR. In contrast, The CSTR behaved as an organic acid-producing unit. The maximum acids concentration in the CSTR was 2,606 mg/L. While the lowest pH measured was 6.39, the level of which is inhibitory to the methanogenic activity. The maximum methane production was 0.08 m,which was substantially lower compared to the SBR. When comparing the performance between the two reactors, i t was found that the organic acids productivity i n the CSTR (7.07 kg-TVA/ton-pulpfresh"d) was considerably higher than the SBR, at the value of 2.19 kg-TVA/ton-pulpfresh-d, as shown i n figure 1. However, the SBR was shown to exhibi t superior performance to the CSTR in terms of biogas production due to better solid and microbial accumulation through the sludge sett l ing process before t he supernatant withdrawal. The maximum SS of 36.73 g/L was obtained for t he SBR, which was higher than t hat for the CSTR (25.73 g/L). As a result, the methanogens had a higher tendency to be retained in the SBR than in the CSTR. Figure 1. Productivity as a ratio of biogas, methane, and organic acids production to the cassava pulp inlet for an SBR and a CSTR. The reduction of the SS for the CSTR was not only due to the microbial washout, but also to the washout of the substrate. In the CSTR, the acids productiv i ty determined from the VS within the pulp,as shown in figure 2, was 72.52 kg-TVA/ton-VS-d, which was substant i ally higher than that determined in the SBR, which was 18.57 kg-TVA/ton-VS-d. Figure 2. Productivity as a ratio of biogas, methane, and organic acids production to the VS of the inlet pulp for an SBR and a CSTR. 4. Conclusion This study investigated biogas production i n a 50-m’ pilot-scale sequencing batch reactor (SBR) and continuous stirred tank reactor (CSTR). Both reactors were fed with cassava pulp under the organic loading rate (OLR) of 8 kg-COD/m'-d and the average hydraulic retent i on time (HRT) of 7 d. Over 60%of the starch content was utilized within the f irst three days. The methane production was higher in the SBR because the settl i ng process helps retain the microorganisms in the system. I n contrast, the acids were the major products from the CSTR rather than methane due to the washout of methanogens caused by a continuous process. The SBR achieved methane production of 1.87 m-CHa/ton-pulpfresh-d and acids production of 2.19 kg-TVA/ton-pulpfresh-d while the CSTR had methane production of 0.22m’-CHa/ton-pulpf r esh-d and acids production of 7.07 kg-TVA/ton-pulpfresh-d. The microbial population needs to be investigated further to determine the relationship between microbial kinetic and reactor behavior. This work revealed that the SBR produced higher biogas yields, while the major products obtained from the CSTR were intermediate acids, which could be supplied to the biochemical industry. 5.References [1] Glanpracha N, Annachhatre AP. Anaerobic co-digestion of cyanide containing cassava pulp with pig manure. Bioresource Technology. 2016;214:112-21. [21 Varongchayakul S, Songkasiri W, Chaiprasert P. Optimization of Cassava Pulp Pretreatment by Liquid Hot Water for Biomethane Production. BioEnergy Research. 2021:1-16. [31 V i runanon C, Ouephanit C, Burapatana V, Chulalaksananukul W. Cassava pulp enzymatic hydrolysis process as a preliminary step in bio-alcohols production from waste starchy resources. Journal of Cleaner Production. 2013;39:273-9. [4] Zhang J, Xu J-Y, Wang D-Q, Ren N-Q. Anaerobic Digestion of Cassava pulp with Sewage Sludge Inocula. Bioresources. 2016;11(1):451-65. [5] Ubalua AO. Cassava wastes: treatment options and value addition alternative. African Journal of Biotechnology. 2007;6(18):2065-73. [6] Lerdlattaporn R, Phalakornkule C, Trakulvichean S, Songkasiri W. Implementing circular economy concept by converting cassava pulp and wastewater to biogas for sustainable production i n starch industry. Sustainable Environment Research. 2021;31(1). [7] Li Y, Park SY, Zhu J. Sol i d-state anaerobic digestion for methane production from organic waste. Renewable and Sustainable Energy Reviews. 2011;15(1):821-6. [81 Kaparaju P, Serrano M, Angelidaki I . Effect of reactor configuration on biogas production from wheat straw hydrolysate. Bioresource Technology. 2009;100:6317-23. [91 Andualem M, Seyoum L, Karoli NN. Kinetic analysis of anaerobic sequencing batch reactor for the treatment of tannery wastewater. African Journal of Environmental Science and Technology.2017;11(6):339-48. [10]Wilkie AC, Castro HF, Cubinski KR, Owens JM, Yan SC. Fixed-film Anaerobic Digestion of Flushed Dairy Manure after Primary Treatment: Wastewater Production and Characterisation.Biosystems Engineering. 2004;89(4):457-71. [11]Wichern M, Lubken M, Horn H. Optimizing sequencing batch reactor (SBR) reactor operation for t reatment of dairy wastewater with 1aerobic Cgranular sludge.Water Sci Technol.2008;58(6):1199-206. [12]Mertens DR. Gravimetric determination of amylase-treated neutral detergent fiber in feeds with refluxing in beakers or crucibles: collaborative study. Journal of AOAC International.2002;85(6):1217-40. [13]McC l eary BV, Gibson TS, Mugford DC. Measurement of Total starch in Cereal Products by Amyloglucosidase-a-Amylase Method: Collaborative Study. Journal of AOAC International.1997;80(3):571-9. [14]Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, et al. Determination of Structural Carbohydrates and Lignin in Biomass. National Renewable Energy Laboratory 2008;1617:1-16. Acknowledgements The author would like to thank the financial support was from the National Research Council of Thailand (NRCT), National Science and Technology Development Agency (NSTDA) and King Mongkut ’s University of Technology Thonburi (KMUTT ).

确定

还剩4页未读,是否继续阅读?

产品配置单

中国格哈特为您提供《木薯浆中纤维素、半纤维素、木质素含量的测定》,该方案主要用于生物质能中纤维素、半纤维素、木质素检测,参考标准--,《木薯浆中纤维素、半纤维素、木质素含量的测定》用到的仪器有格哈特全自动型纤维分析仪FT12、德国加液器MM

推荐专场

纤维测定仪、纤维素测定仪、纤维分析仪

更多

相关方案

更多