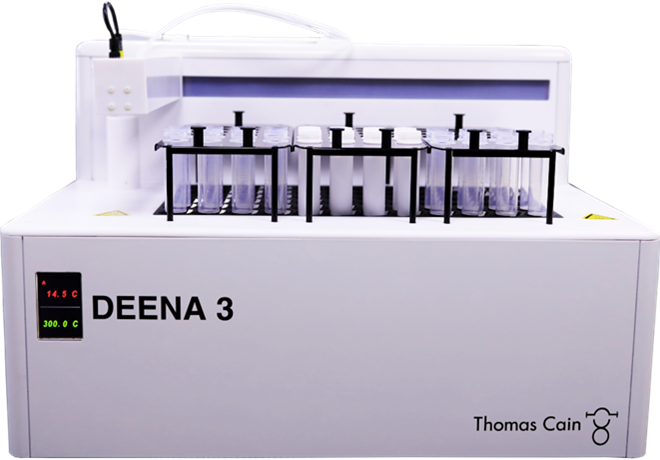

使用Gerhardt格哈特公司Vapodest维普得 全自动凯氏定氮仪测量普通芦苇和玉米青贮生物质燃料中总凯氮含量。

方案详情