方案详情

文

以氯仿 甲醇 2:1作为有机溶剂通过索克森全自动快速索氏萃取 由污水污泥生产的生物柴油,并进行酯交换反应The production of biodiesel from sewage sludge via soxtherm extraction using chloroform and methanol in ratio 2 1 as the organic solvent and transesterification reaction

方案详情

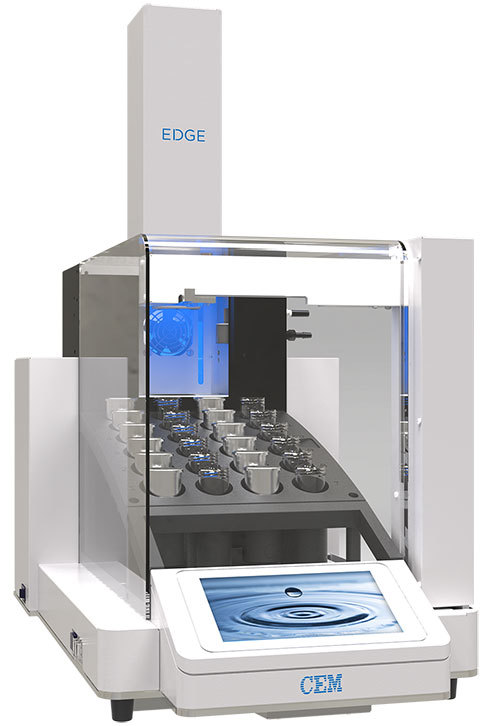

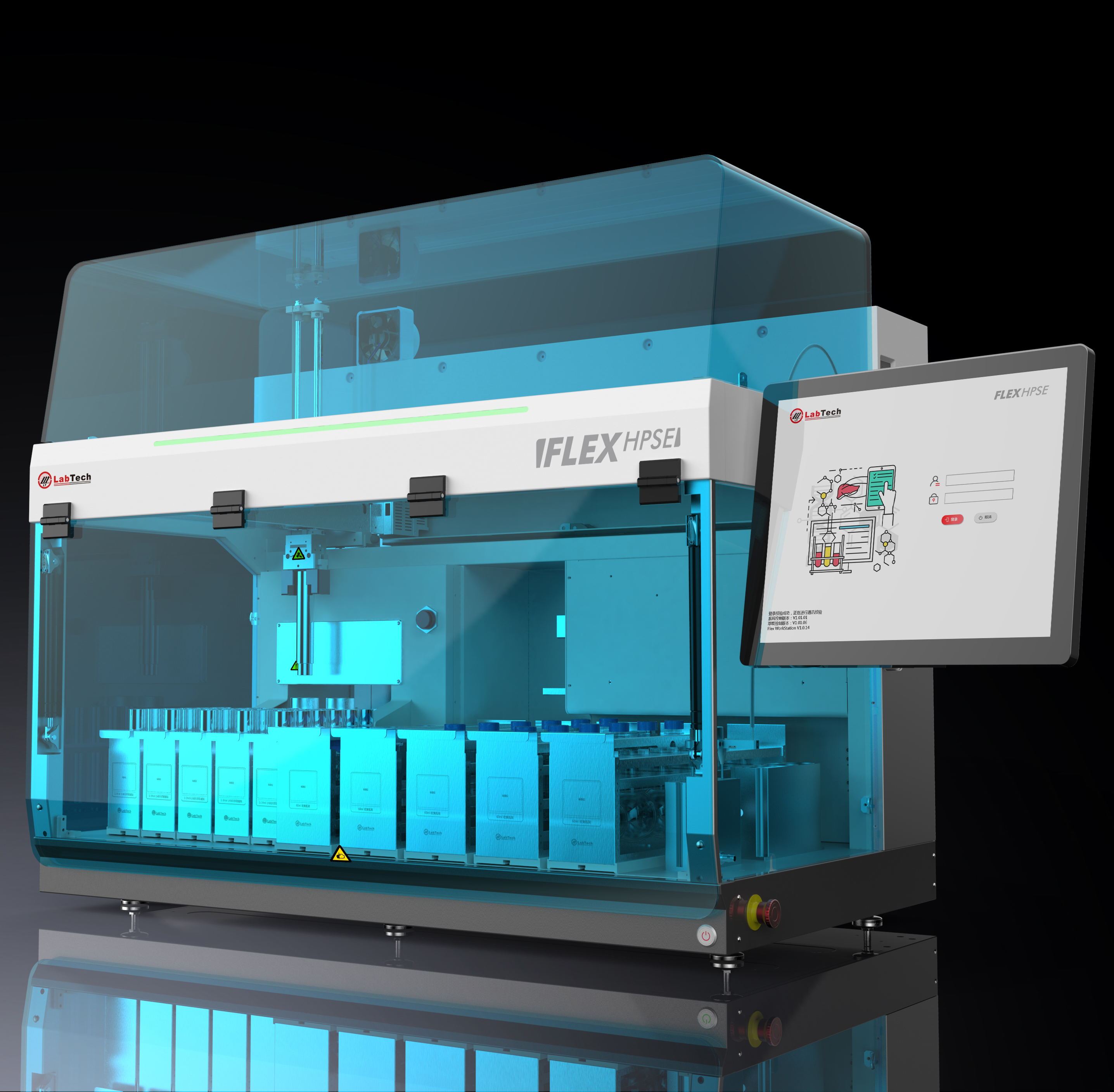

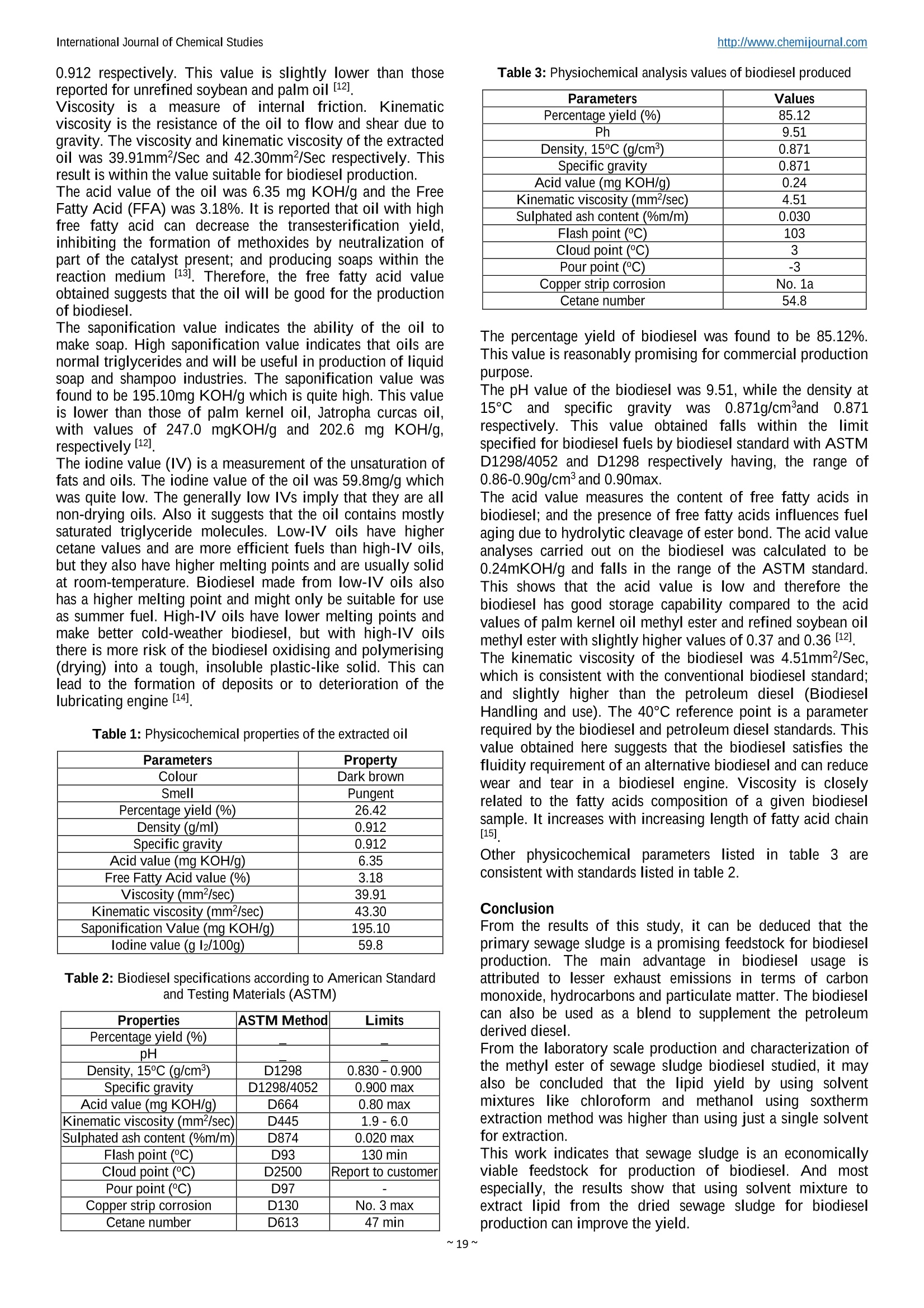

以氯仿 甲醇 2:1作为有机溶剂通过索克森全自动快速索氏萃取 由污水污泥生产的生物柴油,并进行酯交换反应The production of biodiesel from sewage sludge via soxtherm extraction using chloroform and methanol in ratio 2 1 as the organic solvent and transesterification reactionInternational Journal of Chemical Studies 2020; 8(4): 17-20 International Journal of Chemical Studieshttp://www.chemijournal.com International Journal of Chemical Studies The production of biodiesel from sewage sludge via soxtherm extraction using chloroform and methanol in ratio 2:1 as the organic solvent and transesterification reaction E-ISSN: 2321–4902 www.chemijournal.com IJCS 2020; 8(4): 17-20 © 2020 IJCS Received: 26-04-2020 Accepted: 07-06-2020 尼日利亚联邦石油资源大学化学系 Ivwurie W Department of Chemistry, Federal University of Petroleum Resources, PMB 1221, Effurun, Delta State, Nigeria Ediale P Department of Chemistry, Federal University of Petroleum Resources, PMB 1221, Effurun, Corresponding Author:Ivwurie W Department of Chemistry, Federal University of Petroleum Resources, PMB 1221, Effurun, Delta State, Nigeria 以氯仿甲醇 2:1作为有机溶剂通过索克森全自动快速索氏 萃取由污水污泥生产的生物柴油,并进行酯交换反应 Abstract Soxtherm apparatus was used to extract oil/lipids from a primary sewage sludge using chloroform and methanol (2:1) as the organic solvent. Biodiesel was produced from the extracted lipid via transesterification process. The physiochemical properties of the extracted lipid and the biodiesel were determined. A percentage yield of 26.42% was obtained for lipids extraction which proved that the solvent mixture of chloroform and methanol (2:1) gave a reasonably higher yield than using a single solvent for lipid extraction. For biodiesel production from the extracted lipid, a percentage yield of 85.12% was obtained. The results gotten from analysis carried out on both lipids and biodiesel were consistent with available literature and suggests that as much as primary sewage sludge is a good feedstock for biodiesel production, using chloroform and methanol (2:1) as an extracting solvent for lipids would improve lipid yield as well as the biodiesel quantity. Keywords: biodiesel, lipid, transesterification, sewage sludge, soxtherm Introduction As the world population and industrialization continues to grow, humanity will consistently consume more energy. As we consider the future, the expansion of the global economy, the development of new technologies, new industry and an increase in the world’s population, it becomes obvious there will be an increase in the demand for world energy [1]. According to the International Energy Agency, the world will need 37% more energy in 2040 than today [2]. Therefore, we are entering a phase of very high energy consumption growth. In addition, the environmental problems associated with excessive usage of fossil fuels such as air pollution, greenhouse gas emissions (GHG), and global warming, consequently limits the utilization of these sources in the future. The high energy demand in the industrialized world as well as in the domestic sector; and pollution problems caused due to the widespread use of fossil fuels, make it increasingly n n e e c c e e s s s s a a r r y y t t o o d d e e v v e e l l o o p p t t h h e e r r e e n n e e w w a a b bl le e e e n n e e r rg gy y s s o o u u r r c c e e s s o o f f l l i i m m i i t t l l e e s s s s d d u u r r a a t t i i o o n n w w i i t t h h s s m m a a l l l l e e r r environmental impactthanthetraditional one[3].Thishasstimulated recent interest in alternative sources for petroleum based fuels, that must be technically feasible, economically competitive, environmentally acceptable, and readily available [4]. B B i i o o f f u u e e l l s s a a r r e e a a t t y y p p e e o o f f f f u u e e l l d d e e r r i i v v e e d d f f r r o o m m o o r r g g a a n n i i c c m m a a t t t t e e r r ((b b r r o o a a d d l l y y d d e e s s c c r r i i b b e e d d a a s s b b i i o o m m a a s s s s )) produced by living organisms i.e. plants and animals. According to the International Energy Agency (IEA), biofuels have the potential to meet more than a quarter of world demand for transportation fuels by 2050 [5]. Biofuels are fuels based on renewable biomass. Amongst the biofuels, including biogas, bioethanol and biodiesel, the greatest demand is for biodiesel, which is considered as an alternative to petroleum-based fuel. Biodiesel mainly consists of fatty acid methyl esters (FAMEs) obtained by reacting vegetable oils and animal fats with an alcohol in the presence of a catalyst. Biodiesel is renewable, less toxic and has low environmental impact, when compared to petroleum-based diesel. The competitive potential of biodiesel is currently limited bythe priceof the common lipid feedstock, which constitutes 70-85% of the overall biodiesel production cost, thus strongly influencing the final price of this biofuel and raising the concerns of food shortage versus fuel crisis [6]. However, municipal sewage sludge from wastewater treatment plants (WWTPs) is gaining more attention nowadays as a lipid feedstock for the production of biodiesel; as the dry sludge can contain up to 30 wt% of lipids [7]. In fact, sewage sludge is a waste that needs specific treatment before disposal and represents a major cost in the WWTP operation. In addition, the WWTPs annually produces higher amounts ofsludge due to the expansion of urbanized and industrialized areas. Therefore, the sewage sludge can be envisaged as a relatively cheap, readily available, and abundant feedstock, which can make the biodiesel production profitable. Furthermore, it is one possible alternative to take advantage of the excess sludge, reusing it as a source of lipid fortheproductionofbiodiesel,consequentlyloweringthe waste water treatment plant operation cost [8]. Sewage sludge is the waste formed during treatment of waste water. These waste water treatment plant produces primary and secondary sludge. Lipids could yield an unexploited source of cheap and readily available feedstock for biodiesel production [1]. Lipids are generally soluble in organic solvents, so we can use solvents to extract lipids from sludge. Some solvents such as ethanol, ethyl ether, petroleum ether, hexane and methanol have been used for extraction of lipids. In which hexane and methanol are widely used [9]. Transesterification, also called alcoholysis, is the displacement of alcohol from an ester by another alcohol in a process similar to hydrolysis. This process has been widely used to reduce the viscosity of triglycerides, thereby enhancing the physical properties of renewable fuels to improve engine performance. This research is basically focused on how best the production of biodiesel can be carried out from sewage sludge. Owing to the fact that over the years, biodiesel has been produced from common sources such as vegetable oils, animal fats, plant seeds, more recently sewage sludge which has become potential feedstock, given that humans faeces are readily available,and otherlipid-containing wastes.Thisresearch covers the possibility of extracting the lipid from the sewage sludge using chloroform and methanol (2:1) as the organic solvent and how biodiesel can be produced from the extracted lipid via transesterification reaction. Materials and methods Sample collection and preparation The sample collection for primary sewage sludge was carried out in a sewage sludge treatment plant in Lagos State, Nigeria. The thick sludge was collected from the bottom of the settling tank into a 10-liter bucket and covered with a lid. After the sample was sun dried for 7 days and then air dried for another 3 days, the dried primary sludge was reduced in particles by using a pestle and mortar, where it was pounded until the big particles of the dried sewage sludge reduced to granules. The particle size was further reduced using an industrial blender to undergo a highly efficient extraction. Extraction of the lipid The Soxtherm extractor was used in extracting the lipid (oil) from the blended sewage sludge. The sample was put into the thimbles and then inserted into the extraction beakers. About 140ml of the solventmixture was added to the extraction beakers which were pushed against the rear limit stop of the hot plate of the extractor in other to achieve correct positioning. The Soxtherm extractor was then programmed to heat at 1500C which is a boiling point higher than that of the solvent being used and the lipid was extracted Physiochemical analysis of the oil The extracted lipid was then analyzed to determine its percentage yield, density, acid value, free fatty acid and other properties. Transesterification The oil was transesterified by preparing a methoxide solution which was carried out by dissolving 1% NaOH of the weight in mass of the lipid in 20% methanol of the weight in mass of the lipid andwasheated at a steadytemperature of 60°C monitored by a thermometer for an hour with constant stirring of the mixture using a hot plate magnetic stirrer. After the reaction process, the mixture was transferred into a separatory funnel and was allowed to settle and cooled while the separation of the two phase layer took place to separate into the methyl ester phase and glycerin phase as the upper and lower phase respectively [10]. Glycerol was removed by means of a separating funnel, and the remaining ester layer was washed four times with distilled warm water to remove soap, residual alcohol, catalyst, and unreacted tri, di-, and monoglycerides. The number of washing processes was not increased because increasing the washing beyond four times does not have further benefit. The biodiesel washing sometimes leaves the biodiesel looking a bit cloudy. This means there's still a little water in it. It was heatedslowly to100oCand heldthereuntil all moisture present was evaporated. The biodiesel was then kept in a glass bottle. Physiochemical characterization of biodiesel After the separation and washing process, characterization of thebiodieselwascarried outtodetermineits pH,cetane number, viscosity, pour point, flash point and other important physiochemical characterizations. Results and discussion The results for the determination of the physiochemical properties of extracted lipid (oil) from the sewage sludge and the biodiesel produced are presented in Tables 1 and 3, while the ASTM specifications is presented in table 2. The oil extracted gave a brownish black colour and a pungent smell.Thisisquitedifferentfromtheregularthecolours reported for other biodiesel produced from different sources like Garlic which is light yellow [11]. This variation could be because of the primary sewage sludge used as a feedstock which possesses same characteristic properties. Palm Kernel oil, unrefined oil soybean oils and Jatrophacurcas oil gave goldenyellow colour,while palm oil and refined soybean gave red and light yellow colours, respectively [12]. The percentage yield of the lipid extracted was 26.42% using a mixture of Chloroform and Methanol in ratio 2:1 as the extracting solvent. Although, the percentage yield is low, the availability of human faeces in good quantity makes the use of lipids from this source a viable alternative [8]. The acid value of oil is used as a measure of quality The density of oil is the ratio of the mass or weight of the oil to the volume of the oil (ml). Specific gravity which is the ratio of the density of a respective substance to the density of water at 4°C. For the extracted oil, the density and specific gravity of the extracted oil was found to be 0.912 g/ml and 0.912 respectively. This value is slightly lower than those reported for unrefined soybean and palm oil [12]. Viscosity is a measure of internal friction. Kinematic viscosity is the resistance of the oil to flow and shear due to gravity. The viscosity and kinematic viscosity of the extracted oil was 39.91mm2/Sec and 42.30mm2/Sec respectively. This result is within the value suitable for biodiesel production. The acid value of the oil was 6.35 mg KOH/g and the Free Fatty Acid (FFA) was 3.18%. It is reported that oil with high free fatty acid can decrease the transesterification yield, inhibiting the formation of methoxides by neutralization of part of the catalyst present; and producing soaps within the reaction medium[13].Therefore, the free fattyacid value obtained suggests that the oil will be good for the production of biodiesel. The saponificationvalue indicates the ability of the oil to make soap. High saponification value indicates that oils are normal triglycerides and will be useful in production of liquid soap and shampoo industries. The saponification value was found to be 195.10mg KOH/g which is quite high. This value is lower than those of palm kernel oil, Jatropha curcas oil, with values of 247.0 mgKOH/g and 202.6 mg KOH/g, respectively [12]. The iodine value (IV) is a measurement of the unsaturation of fats and oils. The iodine value of the oil was 59.8mg/g which was quite low. The generally low IVs imply that they are all non-drying oils. Also it suggests that the oil contains mostly saturated triglyceride molecules. Low-IV oils have higher cetane values and are more efficient fuels than high-IV oils, but they also have higher melting points and are usually solid at room-temperature. Biodiesel made from low-IV oils also has a higher melting point and might only be suitable for use as summer fuel. High-IV oils have lower melting points and make bettercold-weatherbiodiesel,butwithhigh-IVoils there is more risk of the biodiesel oxidising and polymerising (drying) into a tough, insoluble plastic-like solid. This can lead to the formation of deposits or to deterioration of the lubricating engine [14]. Table 1: Physicochemical properties of the extracted oil Parameters Property Colour Dark brown Smell Pungent Percentage yield (%) 26.42 Density (g/ml) 0.912 Specific gravity 0.912 Acid value (mg KOH/g) 6.35 Free Fatty Acid value (%) 3.18 Viscosity (mm2/sec) 39.91 Kinematic viscosity (mm2/sec) 43.30 Saponification Value (mg KOH/g) 195.10 Iodine value (g I2/100g) 59.8 Table 2: Biodiesel specifications according to American Standard and Testing Materials (ASTM) Properties ASTM Method Limits Percentage yield (%) _ _ pH _ _ Density, 15oC (g/cm3) D1298 0.830 - 0.900 Specific gravity D1298/4052 0.900 max Acid value (mg KOH/g) D664 0.80 max Kinematic viscosity (mm2/sec) D445 1.9 - 6.0 Sulphated ash content (%m/m) D874 0.020 max Flash point (oC) D93 130 min Cloud point (oC) D2500 Report to customer Pour point (oC) D97 - Copper strip corrosion D130 No. 3 max Cetane number D613 47 min Table 3: Physiochemical analysis values of biodiesel produced Parameters Values Percentage yield (%) 85.12 Ph 9.51 Density, 15oC (g/cm3) 0.871 Specific gravity 0.871 Acid value (mg KOH/g) 0.24 Kinematic viscosity (mm2/sec) 4.51 Sulphated ash content (%m/m) 0.030 Flash point (oC) 103 Cloud point (oC) 3 Pour point (oC) -3 Copper strip corrosion No. 1a Cetane number 54.8 The percentage yield of biodiesel was found to be 85.12%. This value is reasonably promising for commercial production purpose. The pH value of the biodiesel was 9.51, while the density at 15°C and specific gravity was 0.871g/cm3and 0.871respectively. This value obtained falls within the limit specified for biodiesel fuels by biodiesel standard with ASTM D1298/4052 and D1298respectivelyhaving,the range of 0.86-0.90g/cm3 and 0.90max. The acid value measures the content of free fatty acids in biodiesel; and the presence of free fatty acids influences fuel aging due to hydrolytic cleavage of ester bond. The acid value analyses carried out on thebiodieselwas calculated to be 0.24mKOH/g and falls in the range of the ASTM standard. This shows that the acid value is low and therefore the biodiesel has good storage capability compared to the acid values of palm kernel oil methyl ester and refined soybean oil methyl ester with slightly higher values of 0.37 and 0.36 [12]. The kinematic viscosity of the biodiesel was 4.51mm2/Sec, which is consistent with the conventional biodiesel standard; and slightly higher than the petroleum diesel (Biodiesel Handling and use). The 40°C reference point is a parameter required by the biodiesel and petroleum diesel standards. This value obtained here suggests that the biodiesel satisfies the fluidity requirement of an alternative biodiesel and can reduce wear and tear in a biodiesel engine. Viscosity is closely related to the fatty acids composition of a given biodiesel sample. It increases with increasing length of fatty acid chain [15]. Other physicochemical parameters listed in table 3 are consistent with standards listed in table 2. Conclusion From the results of thisstudy, it can be deduced that the primary sewage sludge is a promising feedstock for biodiesel production. The main advantage in biodiesel usage is attributed to lesser exhaust emissions in terms of carbon monoxide, hydrocarbons and particulate matter. The biodiesel canalsobeusedasablendtosupplementthepetroleum derived diesel. From the laboratory scale production and characterization of the methyl ester of sewage sludge biodiesel studied, it may also be concluded that the lipid yield by using solvent mixtures like chloroform and methanol using soxtherm extraction method was higher than using just a single solvent for extraction. This work indicates that sewage sludge is an economically viable feedstock for production of biodiesel. And most especially, the results show that using solvent mixture to extract lipid from the dried sewage sludge for biodiesel production can improve the yield. Reference 1. Olkiewicz M, Fortuny A, Stüber F, Fabregat A, Font J, Bengoa C. Evaluation of different sludges from WWTP as a potential source for biodiesel production. Procedia Eng. 2012; 42:634-64. 2. International Energy Agency. Key World Energy Statistics 2014, IEA, Paris Cedex 15, France, 2014, 82. 3. Bharathi P, Karthiga R, Shamli M, Vivetha K, Subathra M. Extraction of Lipids from Municipal Sewage Sludge for Production of Biodiesel via Transesterfication process. International Journal of Pharma and Bio Sciences. 2014; 5(4):B132-B141. 4. MeherLC,Sagar DV,Naik SN. Technical aspects of biodiesel production by transesterification. Renewable and Subtainable Energy Reviews, 2004, 1-21. 5. Meghan G. IEA says biofuels can displace 27% of transportation fuels by 2050. Platts @http://www.platts.com/RSSFeedDetailedNews/RSSFee d/Oil/6017103, 2001. 6. Kwon EE, Kim S, Jeon YJ, Yi H. Biodiesel production from sewage sludge: new paradigm for mining energy from municipal hazardous material, Environ Sci. Technol. 2012; 46(18):10222-10228. 7. Pastore C, Lopez A, Lotito V, Mascolo G. Biodiesel from dewatered waste water sludge: A two-step process for a more advantageous production. Chemosphere. 2013;92:667-673. 8. Dufreche S, Hernandez R, French T, Sparks D, Zappi M, Alley E. Extraction of lipids from municipal wastewater plant microorganisms for production of biodiesel. J Am Oil Chem Soc. 2007; 84(2):181-187. 9. Fenfen Z, Zhao L, Zhang Z, Jiang H. Procedia Environmental Sciences. 2012; 16:352-356. 10. Gerpen JV, Shanks B, Pruszko R, Clements D, Knothe G. BiodieselProductionTechnology.NationalRenewable Energy Laboratory. Colorado, 2004, 105. 11. Hassan LG, Sani NA. Comparative Studies on the Physico-chemical Properties of Bottle Gourd Lageneriasiceraria seeds oils Extracted by two methods. NigeriaJournalofBasicandAppliedSciences.2007;15(1), (2):50-51. 12. Ankapong E. The influence of physiochemical characteristics of vegetable oils on the quality of Biodiesel produced from palm oil, palm kernel oil, refined soyabean oil, unrefined soyabean oil and jatrophacurcasoil. MSc. Thesis, Kwame Nkrumah University of Science and Technology, Kumasi, 2010. 13. Barabás, I. and Todoruţ, I. Biodiesel Quality, Standards andProperties,Biodiesel-Quality,EmissionsandBy-Products, Dr. Gisela Montero (Ed.), ISBN: 978-953-307-784-0, InTech, Available from:http://www.intechopen.com/books/biodiesel-quality-emissions-and-by-products/biodiesel-quality-standards-and-properties, 2011. 14. Mittelbach M. Diesel fuel derived from vegetable oils:VI. Specifications and quality control of biodiesel. Bioresour Technol.1996; 56(1): 7-11. 15. Odiganma D. Production of Biodiesel from sewage sludge, a constituent of human excrement using n-Hexane as the organic solvent. BSc. Thesis. Department of Chemistry. Federal University of Petroleum Resources, Effurun, 2016.

确定

还剩2页未读,是否继续阅读?

中国格哈特为您提供《以氯仿 甲醇 2:1作为有机溶剂通过索克森全自动快速索氏萃取污水污泥中脂肪含量》,该方案主要用于生物质能中脂肪检测,参考标准--,《以氯仿 甲醇 2:1作为有机溶剂通过索克森全自动快速索氏萃取污水污泥中脂肪含量》用到的仪器有格哈特全自动快速溶剂萃取仪Sox416、格哈特传统经典索氏提取/萃取仪EV6 AII16、格哈特快速干燥仪STL56、德国移液器MM

相关方案

更多