方案详情

文

采用喷雾干燥法(SD)、热风干燥法(AD)、冷冻干燥法(FD)和红外冷冻干燥法(IFD)对鸡骨粉进行干燥。营养成分、抗氧化分别对其性能、物理性能、能耗和风味进行了比较。

方案详情

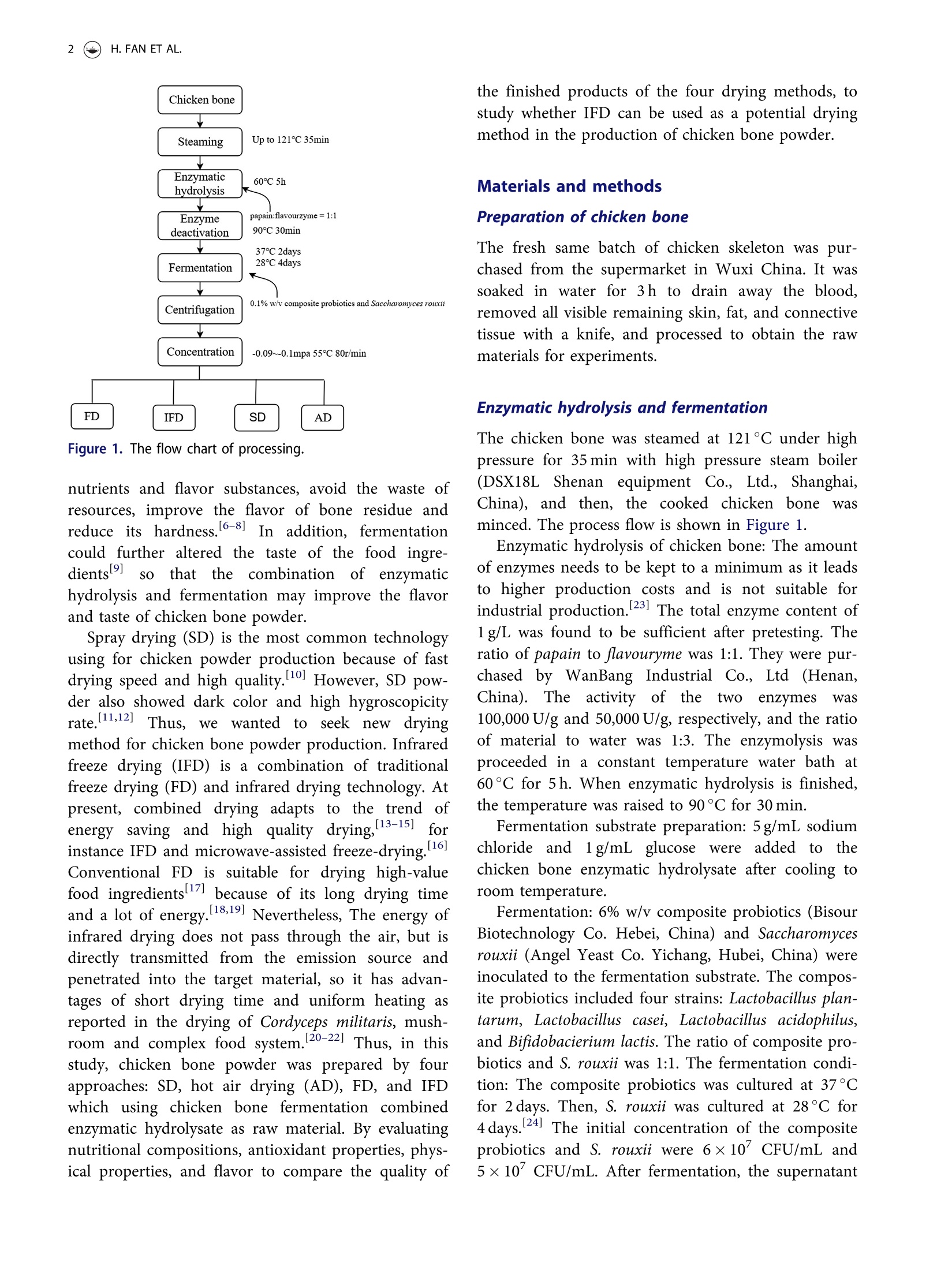

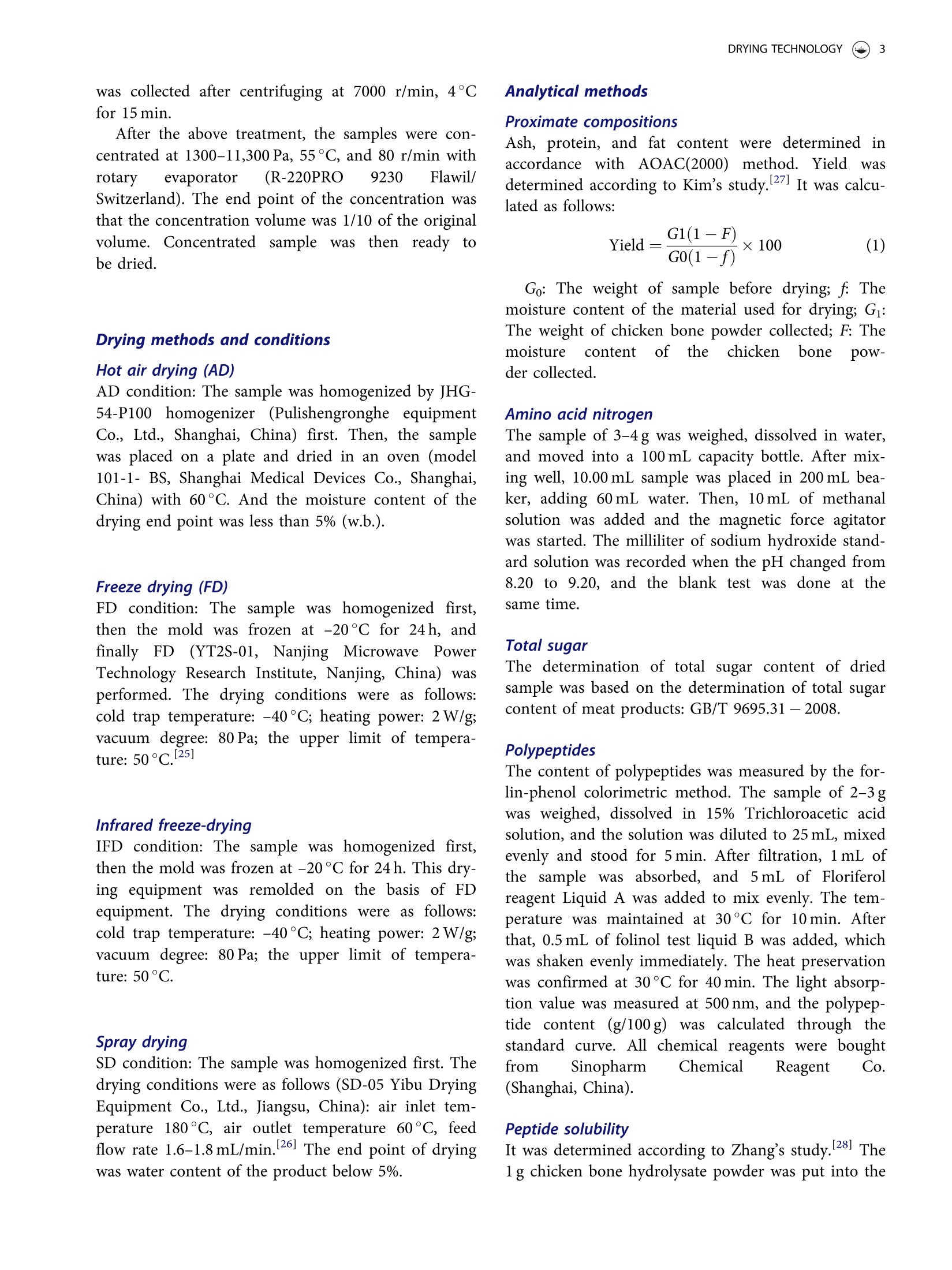

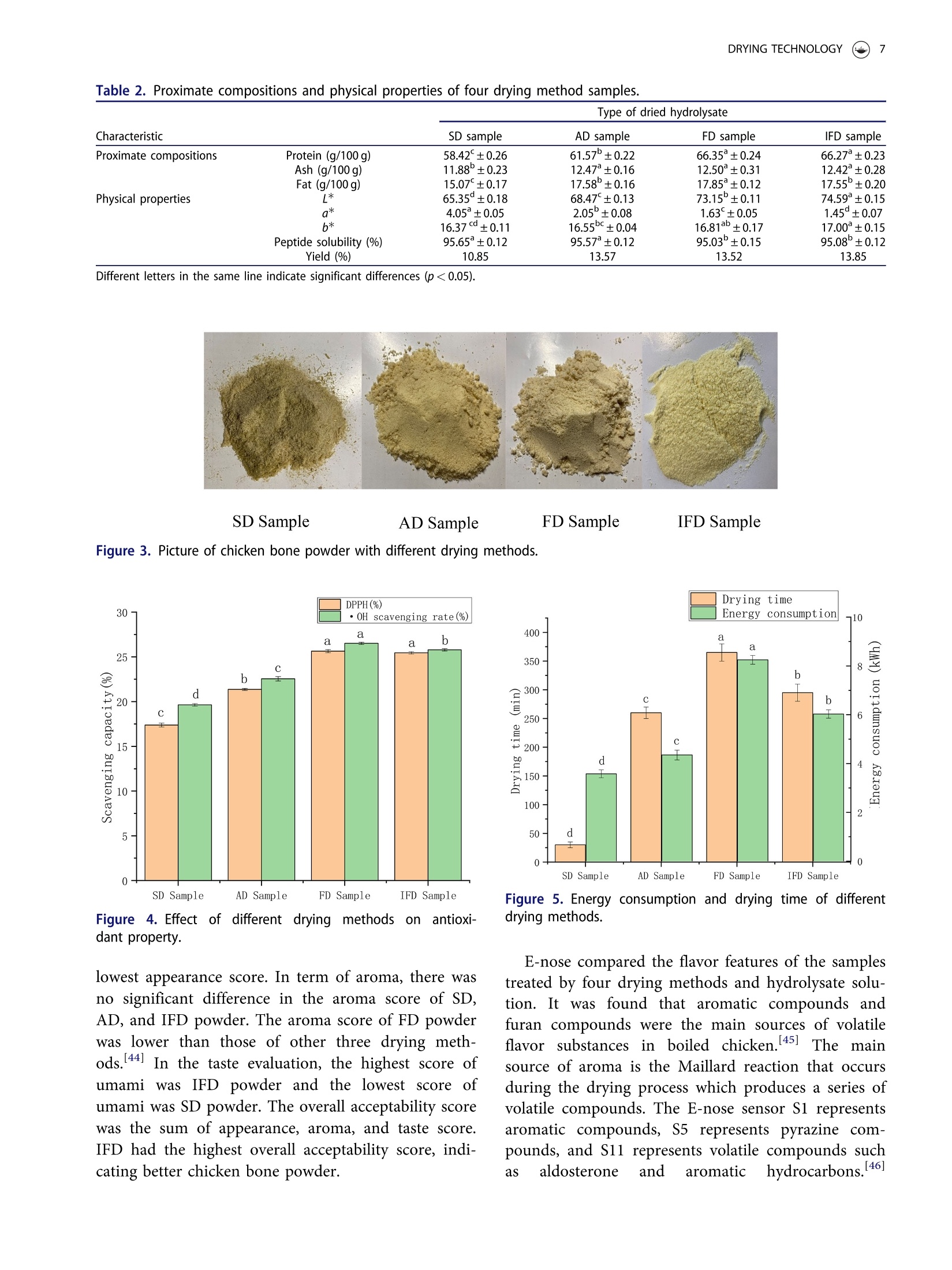

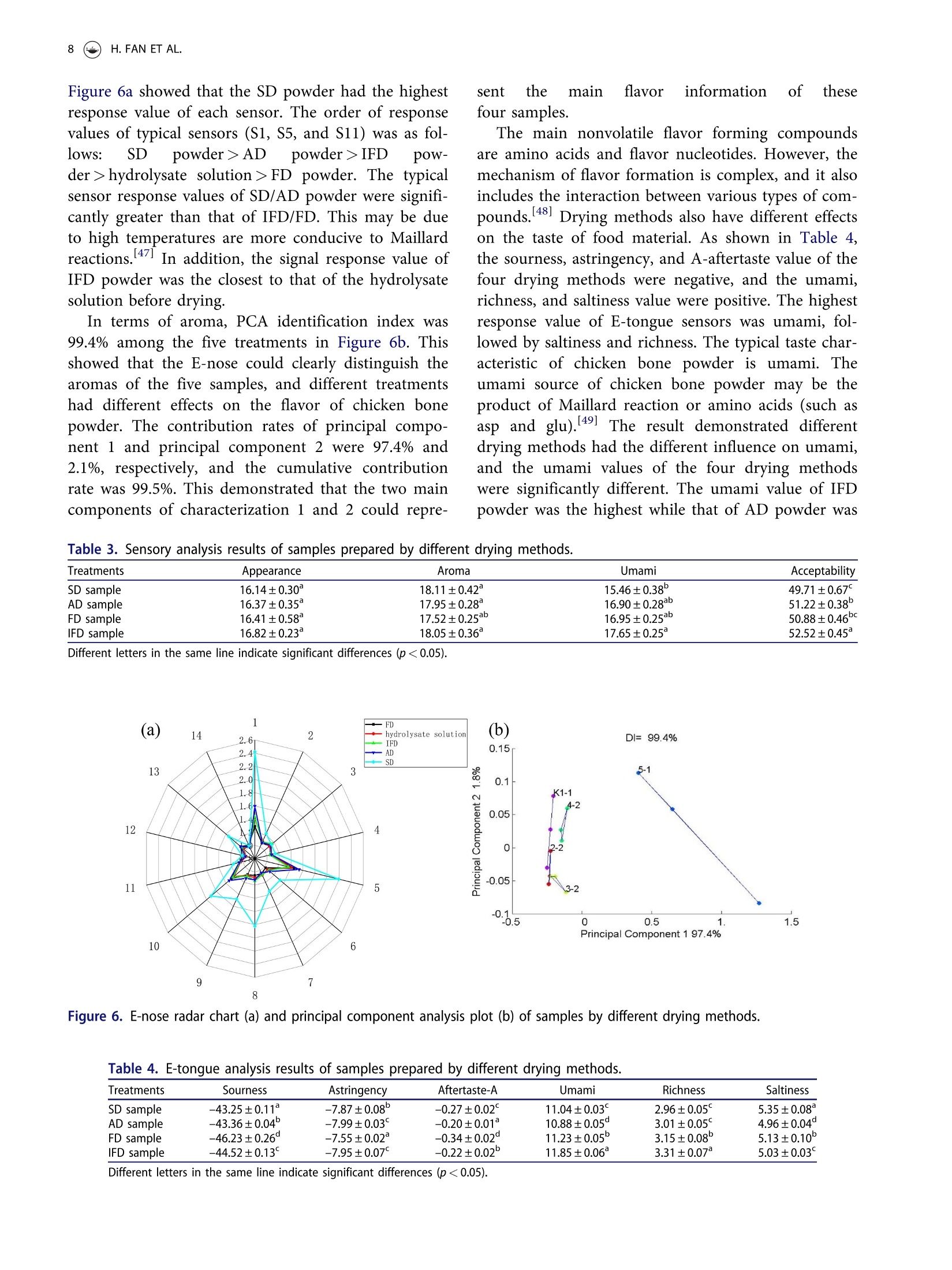

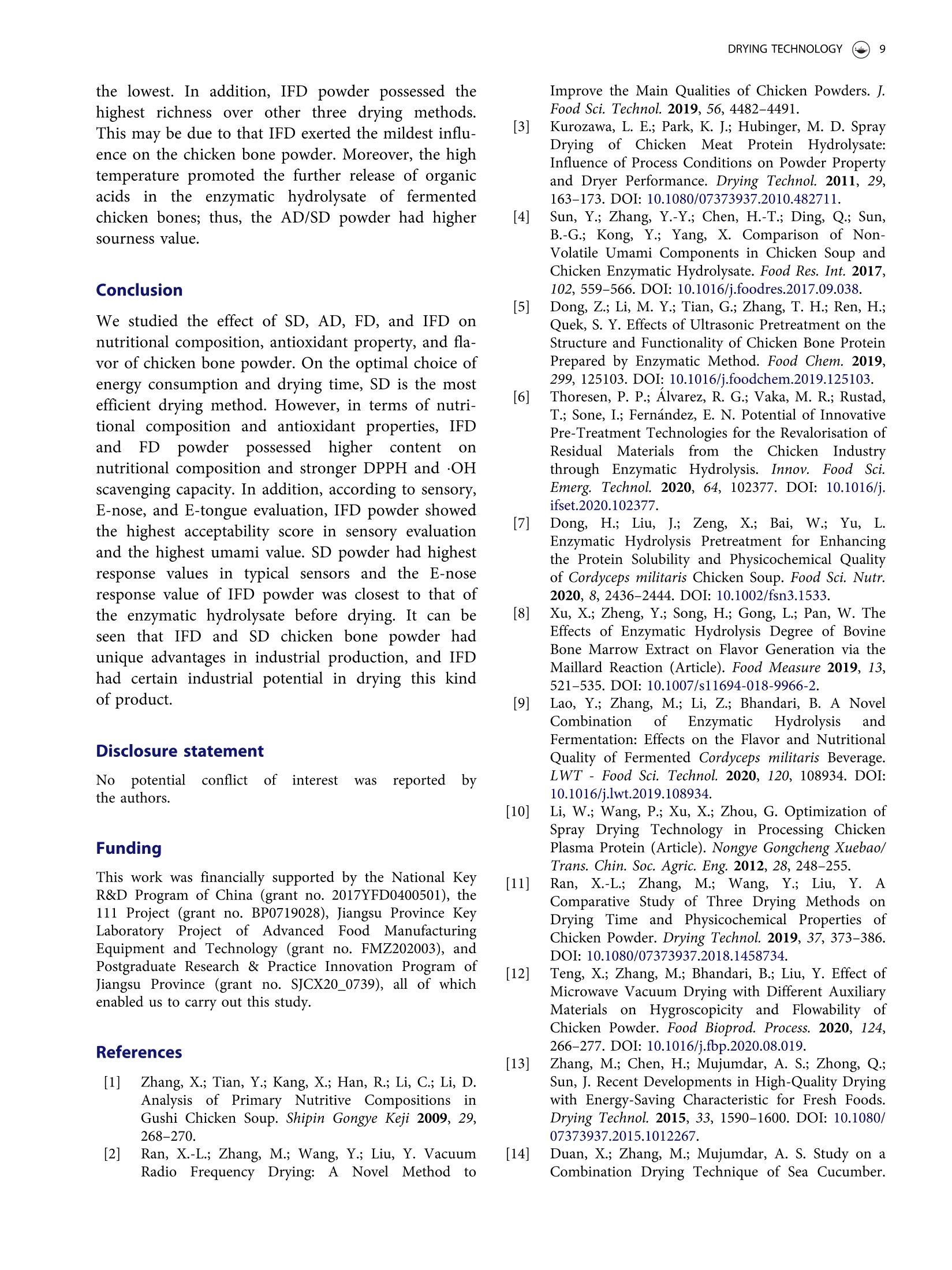

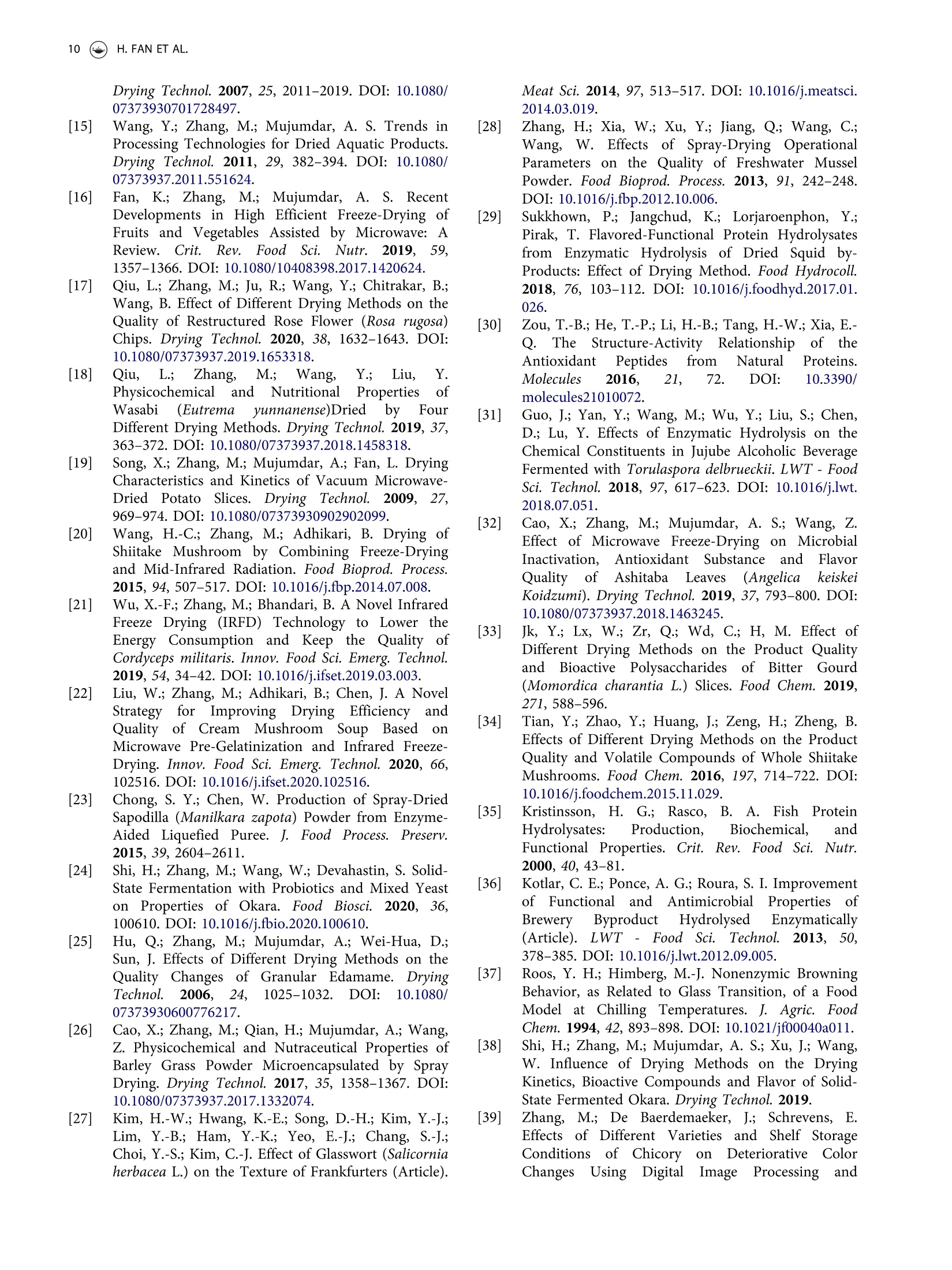

Taylor & FrancisTaylor & Francis GroupDrying TechnologyAn International journalISSN: (Print)(Online) journal homepage: https://www.tandfonline.com/loi/ldrt20 Taylor &FrancisTaylor & Francis GroupDRYING TECHNOLOGYhttps://doi.org/10.1080/07373937.2021.1894440 Effect of different drying methods combined withfermentation and enzymolysis on nutritionalcomposition and flavor of chicken bone powder Hanzhi Fan, Min Zhang, Arun S. Mujumdar & Yaping Liu To cite this article: Hanzhi Fan, Min Zhang, Arun S. Mujumdar & Yaping Liu (2021): Effect ofdifferent drying methods combined with fermentation and enzymolysis on nutritional compositionand flavor of chicken bone powder,Drying Technology, DOI: 10.1080/07373937.2021.1894440 To link to this article: https://doi.org/10.1080/07373937.2021.1894440 Submit your article to this journal C Article views: 36 View related articles C View Crossmark data C CrossMark https://www.tandfonline.com/action/journallnformation?journalCode=ldrt20 Effect of different drying methods combined with fermentationand enzymolysis on nutritional composition and flavor of chickenbone powder Hanzhi Fanab, Min Zhanga, Arun S. Mujumdar, and Yaping Liu° State Key Laboratory of Food Science and Technology, Jiangnan University, Wuxi, Jiangsu, China; PInternational Joint Laboratory onFood Safety, Jiangnan University, Wuxi, Jiangsu, China; Jiangsu Province Key Laboratory of Advanced Food Manufacturing Equipmentand Technology, Jiangnan University, Wuxi, Jiangsu, China; “Department of Bioresource Engineering, Macdonald Campus, McGillUniversity, Montreal, Quebec, Canada; Guangdong Galore Food Co., Ltd, Zhongshan, Guangdong, China ABSTRACT Chicken bone powder was dried by using spray drying (SD), hot air drying (AD), freeze dry-ing (FD), and infrared freeze drying (IFD) in this study. Nutritional composition, antioxidantproperty, physical property, energy consumption, and flavor were compared, respectively.The results demonstrated that IFD powder had the highest content of amino acid nitrogen(49 mg/100 g). And in terms of polypeptide content, IFD and FD powder showed no signifi-cant difference, were obviously higher than AD and SD powder. As for antioxidant property,IFD and FD powder had higher DPPH and ·OH scavenging capacity than AD and SD pow-der. In addition, IFD powder had the highest L* value (74.59) and SD powder had the low-est L* value (65.35), which was consistence with the result of appearance score. Concerningflavor and sensory evaluation, IFD powder showed the highest umami value (11.85) andacceptability score (52.52) among four drying methods. Besides, the typical E-nose sensorsresponse values of the IFD powder were closest to those of the enzymatic hydrolysatebefore drying and SD powder had the highest response value in all sensors. Finally on thebasis of energy consumption, SD showed the minimum drying timee and energyconsumption. Received 21 December 2020 Accepted 16 February 2021 KEYWORDS Chicken bone powder; hotair drying; freeze-drying;infrared freeze-drying; spray drying Introduction As meat production increases, the total amount ofanimal skeletons increases as well, ranging from 10%to 30%. Chicken is widely used as raw material inkitchen and food industry because of its nutritionalcompounds and delicious taste. However, the totalmass of chicken byproduct is 20% to 22% of thewhole chicken which needed to be utilized. In China,a development type of chicken skeleton is as the raw The key processing technology of chicken bonematerial of chicken powder seasoning, commonlypowder seasoning includes enzymatic hydrolysis andknown as chicken powder. This is essentially a com- drying.Enzymolysis of bone soup with enzymepound seasoning. Chicken powder seasoning refers to preparation can decompose large molecule proteinthe compound seasoning which is made of chicken/ into small molecule polymorphism or amino acid,chicken bone powder or its concentrated extract,[2] which not only enhances flavor 4and produces moreedible salt, monosodium glutamate (MSG), flavoring- abundant Maillard reaction precursor substances butnucleotide disodium, and other auxiliary materials as also reduces viscosity, which is beneficial to processingraw materials, with or without spices and/or food in all processes.[5]nThe soluble solids that could not bespices and other fragrant agents, and has the rich fla- extracted by high temperature cooking but could bevorand delicious taste of chicken. As families, further extracted by enzymolysis, so as to fully release restaurants and fast food manufacturing use such sea-soning products, chicken powder increasing in itsimportance and usage as a new seasoning after MSG;compound seasoning has huge advantage in condi-ment industryproduct development in China.Meanwhile, now fusion of western and Chinese sea-sonings is becoming popular. Chicken powder isbecoming more prevalent in global diet. ( C ON TACT Dr. Min Zhang i 区 m i n @ ji a ngna n .ed u .cn n e P rofessor o f School o f F o od Science and Technology, Jiangnan Univ e rsity, 214 1 22 Wuxi , P. R. China ) Figure 1. The flow chart of processing. nutrients and flavor substances, avoid the waste ofresources, improve the flavor of bone residue andreduce itstshardness,[6-8]Inn addition, fermentationcould further altered the taste of the food ingre-dients9]so tthat the combination of enzymatichydrolysis and fermentation may improve the flavorand taste of chicken bone powder. Spray drying (SD) is the most common technologyusing for chicken powder production because of fastdrying speed and high quality. 10 However, SD pow-der also showed dark color and high hygroscopicityrate.[11,12] TThus,wewanted to seek new dryingmethod for chicken bone powder production.Infraredfreeze drying (IFD) is a combination of traditionalfreeze drying (FD) and infrared drying technology. Atpresent, combined drying adapts to the trendofergy saavvinign gand high quality drying, 13-15forinstance IFD and microwave-assisted freeze-drying. 161Conventional FD is suitable for drying high-valuets171 becausengredientsbecause of its long drying timeand a lot of energy. [18.19]Nevertheless, The energy ofinfrared drying does not pass through the air, but isdirectly transmitted from the emission source andpenetrated into the target material, so it has advan-tages of short drying time and uniform heating asreported in the drying of Cordyceps militaris, mush-room and complex food system.[20-22] Thus, in thisstudy, chicken bone powder was prepared by f)urapproaches: SD, hot air drying(AD), FD, and IFDwhich using chicken bone fermentation combinedenzymatic hydrolysate as raw material. By evaluatingnutritional compositions, antioxidant properties, phys-ical properties, and flavor to compare the quality of the finished products of the four drying methods, tostudy whether IFD can be used as a potential dryingmethod in the production of chicken bone powder. Materials and methodsPreparation of chicken bone The fresh same batch of chicken skeleton was pur-chased from the supermarket in Wuxi China. It wassoaked in water for 3h to drain away the blood,removed all visible remaining skin, fat, and connectivetissue with a knife, and processed to obtain the rawmaterials for experiments. Enzymatic hydrolysis and fermentation The chicken bone was steamed at 121°℃ under highpressure for 35 min with high pressure steam boiler(DSX18L Shenant equipment Co., Ltd., Shanghai,China), and then, the cooked chicken bonewasminced. The process flow is shown in Figure 1. Enzymatic hydrolysis of chicken bone: The amountof enzymes needs to be kept to a minimum as it leadsto higher production costs and is not suitable forindustrial production. 23] The total enzyme content of1g/L was found to be sufficient after pretesting. Theratio of papain to flavouryme was 1:1. They were pur-chasedby WanBang Industrial Co., Ltd ((Henan,China). The activityy of thetwoenzymes was100,000 U/g and 50,000 U/g, respectively, and the ratioof material to water was1:3. The enzymolysis wasproceeded in a constant temperature water bath at60°C for 5h. When enzymatic hydrolysis is finished,the temperature was raised to 90°C for 30 min. Fermentation substrate preparation: 5 g/mL sodiumchloride: and 1g/mL glucosewere:2addedto thechicken bone enzymatic hydrolysate after cooling toroom temperature. Fermentation: 6% w/v composite probiotics (BisourBiotechnology Co. Hebei, China) and Saccharomycesrouxii (Angel Yeast Co. Yichang, Hubei, China) wereinoculated to the fermentation substrate. The compos-ite probiotics included four strains: Lactobacillus plan-tarum, Lactobacillus casei, Lactobacillus acidophilus,and Bifidobacierium lactis. The ratio of composite pro-biotics and S. rouxii was 1:1. The fermentation condi-tion: The composite probiotics was cultured at 37°Cfor 2 days. Then, S. rouxii was cultured at 28℃ for4 days. 24] The initial concentration of the compositeprobiotics and S. rouxii were 6×10 CFU/mL and5×10’ CFU/mL. After fermentation, the supernatant was collected after centrifuging at 7000 r/min, 4°Cfor 15 min. After the above treatment, the samples were con-centrated at 1300-11,300 Pa, 55°C, and 80 r/min withrotary evaporator (R-220PRO 9230 Flawil/Switzerland). The end point of the concentration wasthat the concentration volume was 1/10 of the originalvolume..Concentratedsamplewasthen ready tobe dried. Drying methods and conditions Hot air drying (AD) AD condition: The sample was homogenized by JHG-54-P100. homogenizer (Pulishengronghe equipmentCo., Ltd., Shanghai China) first. Then, the samplewas placed on a plate and dried in an oven (model101-1- BS, Shanghai Medical Devices Co., Shanghai,China) with 60°C. And the moisture content of thedrying end point was less than 5% (w.b.). Freeze drying (FD) FD condition: The sample was homogenized stthen the mold was frozen at -20°C for 24h, andfinally FD ((YT2S-01,,Nanjing MMicrowavePowerTechnology Research Institute, Nanjing, China) wasperformed. The drying conditions were as follows:cold trap temperature: -40°C; heating power: 2 W/g;vacuum degree: 80 Pa; the upper limit of tempera-ture: 50°C.25] Infrared freeze-drying IFD condition: The sample was homogenized first,then the mold was frozen at -20°C for 24h. This dry-ing equipment was remolded on the basis of FDequipment. The drying conditions were as follows:cold trap temperature: -40°C; heating power: 2W/g;vacuum degree: 80 Pa; the upper limit of tempera-ture: 50°C. Spray drying SD condition: The sample was homogenized first. Thedrying conditions were as follows (SD-05 Yibu DryingEquipment Co., Ltd., Jiangsu, China): air inlet tem-perature 180°C, air outlet temperature 60°C, feedflow rate 1.6-1.8 mL/min.[26] The end point of dryingwas water content of the product below 5%. Analytical methods Proximate compositions Ash protein, and fat contenitt were determined inaccordance withAOAC(2000)method.i.yYieldwasdetermined according to Kim’s study.27 It was calcu-lated as follows: Go: The weight of sample before drying; f: Themoisture content of the material used for drying; Gj:The weight of chicken bone powder collected; F: Themoistureecontent of theechicken bone pow-der collected. Amino acid nitrogen The sample of 3-4g was weighed, dissolved in water,and moved into a 100 mL capacity bottle. After mix-ing well, 10.00 mL sample was placed in 200 mL bea-ker, adding 60 mL water. Then, 10mL of methanalsolution was added and the magnetic force agitatorwas started. The milliliter of sodium hydroxide stand-ard solution was recorded when the pH changed from8.20 to 9.20, and the blank test was done at thesame time. Total sugar The determination of total sugar content of driedsample was based on the determination of total sugarcontent of meat products: GB/T 9695.31-2008 Polypeptides The content of polypeptides was measured by the for-lin-phenol colorimetric method. The sample of 2-3gwas weighed, dissolved in 15%6Trichloroacetic acidsolution, and the solution was diluted to 25 mL, mixedevenly and stood for 5 min. After filtration, 1 mL ofthe sample was aabbssoorrbbeedd,, and 5mL of Floriferolreagent Liquid A was added to mix evenly. The tem-perature was maintained at 30°C for 10 min. Afterthat, 0.5 mL of folinol test liquid B was added, whichwas shaken evenly immediately. The heat preservationwas confirmed at 30°C for 40 min. The light absorp-tion value was measured at 500 nm, and the polypep-tide content(g/100g)was calculated through thestandard curve. All chemical rreeaaggeennttss were boughifrom Sinopharm Chemical Reagent co.(Shanghai, China). Peptide solubility It was determined according to Zhang’s study.128 The1g chicken bone hydrolysate powder was put into the 50 mL beaker then 10 mL warm water (50±1°C) wasadded. Then, the sample was stirred for 60s to dis-solve. After that 1 mL of chicken powder solution wasimmediately absorbed and placed in a dry weighingbottle,and dried in an (105±1°C) oven for 4h. Thesolubility is calculated by the following formula: mj: The weight of sample before drying; m2: The con-stant weigh after drying. Color Chroma meter (Konica Minolta Japan) was selected todetermine chromatic value of sample before and aftertreatments. Measure aperture was 8mm, illuminantwas D65, and measuring time was 1s. Each experi-ment was repeated in triplicate. Antioxidant measurement According to Sukkhown’s research, 29] 1.5 mL chickenbone enzymatic ffermentation(1.5 mg/mL)samplecontaining 95% ethanolwas added to 1.5mL0.1 mmol/L DPPH containing 95% ethanol. The mix-ture was mixed well at room temperature and stoodfor 0.5 h. When DPPH encountered protic substancessuch as antioxidants, free radicals are scavenged andabsorbance decreased, indicating higher scavengingactivity of DPPH. Each experiment was repeated intriplicate. The clean up effect can be expressed as: A: The absorbance the control by replacing pureethanol solution; Ax: The absorbance of the resultingsolution at 517 nm. AccordingtoZou'sexperiment,30]antioxidantactivity was determined by scavenging hydroxyl rad-ical (OH). Sample solution of 4 mL, 9 mmol/L FeSO40.5 mL, 9mmol/L salicylic acid 0.5 mL, 8.8 mmol/LH202 0.5 mL were mixed well, heated for 30 min in37°C water bath. Each experiment was repeated intriplicate. The clean up effect can be expressed as: A: The light absorbance of the sample at 510 nm;A: The blank absorbance by replacing the samplewith 4mL of distilled water; A: The backgroundabsorbance of the sample by replacing 8.8 mmol/LH202 with 0.5 mL of distilled water. DPPH was bought from Sigma-Aldrich (Steinheim,Germany). Other chemical reagent were purchasedfrom Sinopharm Chemical Reagent Co.(Shanghai, China). Energy consumption The energy consumption of different methods; wasmeasured by the electricity meter (DTS634, CHNT,Leqing, Zhejiang, China). The energy consumption ofHAD and SD were measured directly by the electricitymeter. And the energy consumption of IFD and FDwere the sum of heating system, vacuum system, andcoldhydrazine system. All measurements wererepeated in triplicate. Flavor and taste Sensory analysis: Four treatments were evaluated by atrained panel of 8 members. Appearance, aroma, andumami were analyzed. The total score for each indica-tor was 20 points, and the higher the score, the betterthe sensory evaluation.31Acceptability representedthe total score of appearance, aroma, and umami. E-nose: Ann jE-nose (inose; Ruifen TradingCorporation, Shanghai, China) was selected to obtainthe flavor information of samples. It was regarded asan olfactory sensor to quantify the content of aromasubstances.The E-nose detection system was com-posed of three parts: 14 sensor arrays (S1-S14), signalprocessing system, and pattern recognition system.The application of these sensors are displayed inTable 1. The test conditions: gas flow rate was 1.0L/min; target measurement time, Vwaitingtime, andcleaning time were 100 s, 10 s, and 120 s, respectively.About 4g sample were put into each sample bottle.Before the test, the E-nose sensors were cleaned for50 min and all sensor signals needed to be calibrated.The sample was placed in 40°C oven for 30 min inorder to evaporate flavor substances. E-tongue: In this experiment, E-tongue (SA402BInsent Inc., Atsugi-shi, Japan) was used to detect dif-ferent taste substances. This equipment consisted ofeight kinds of taste sensors including sourness, astrin-gency, bitterness, aftertaste-B, aftertaste-A, richness,umami, and saltiness. Before sample measurement, thesensors needed a 50 min self-test to ensure that thesensors were working within the correct mV range..[32] One-way analysis of variance was performed on theexperimental data and reported in the form of mean-±standard deviation. IBM SPSS 22.0 (IBM Inc., USA)was usedto determinee thesignificancelevel of Table 1. The application of E-nose sensors. Sensor no. General description Reference Ammonia, used as sensor for aromatic compounds Benzene HS Reacts to sulfur compounds, HzS 1×10 g/L. Otherwise sensitive to many terpenes and sulfur organic Mainly hydrogen, selectively (breathing gas) Detects alcohol, partially aromatic compounds, broad range Organic acid esters and terpenes, aromatic compounds, less polar compounds Propane Sensitive to methane (environment) ca. 1×10’ g/L. Broad range Aromatic compounds, sulfur organic compounds 2s Highly sensitive, broad range sensitivity, reacts to nitrogen oxides NO, Aliphatic hydrocarbons, aromatic compounds Propane S10 Hydrocarbons CH4 S11 Aromatic compounds Toluene S12 Alcohol, organic solvents C2HsOH S13 Alkenes, aromatic compounds, less polar compounds Propane S14 React to high concentrations >0.1 g/L, sometimes highly selective (methane) CH4 difference bbetween themeans. Duncan'ss multiplerange tests and descriptive were used to compare themeans at the 5% significance level. Results and discussionNutritional composition The content of amino acid nitrogen, polypeptide, andtotal sugar could be seen from Figure 2. IFD and FDpowder exhibited higher amino acid nitrogen contentof 49 mg/100 g and 47 mg/100 g, respectively. SD pow-der showed the lowest amino acid nitrogen content,followed by AD powder. Amino acid nitrogen wasdegraded at high temperature, thus causing loss. Interms of polypeptide, FD and IFD powder had higherpolypeptide content of 562 mg/100 g and 560 mg/100gwith no significant difference (p>0.05). SD and ADpowder had relatively lower polypeptide content of510mg/100g and 540 mg/100 g. In terms of totalsugar, FD sample had the highest total sugar contentof 27.25 mg/100 g, followed by IFD sample, AD sam-ple and SD sample. This may be due to that SD andAD had great damage to the structure of enzymatichydrolysate.Besides,the dryingg ttiemperaturewashigher, the total sugar was easy to be degraded, andthe degree of local caramelization and Maillard reac-tionndeepenedr,esulting in the great loss oftotal sugar.33] Proximate compositions and color As can be seen from Table 2, the powder preparedfrom FD (66.35%)/IFD (66.27%) had higher proteincontent than that of SD (58.42%)/AD (61.57%) pow-der. And there was no significant difference betweenFD and IFD powder. The fat content in FD powder(17.85%) was highest, followed by IFD (17.55%), AD(17.58%), and SD powder (15.07%). The ash content in SD powder was obviously lower than that of others.This is because the high temperature affected thenutrients, color, and texture of the sample. 34Interms of yield, the yield of SD powder was the lowest,it may be due to that the loss of material was thegreatest in components of SD equipment. In terms ofpeptide solubility, the peptide solubility of four dryingmethods was greater than 95%. The results showedthat the hydrolyzed protein was consisted of shortchain peptides with hydrophilic amino acids.s. Theincreased solubility of the hydrolyzed products wasbecause of the smaller molecules in which they werecomposed, compared to the intact proteins.35] Theionizableamino)andcarboxyl ggrroouuppss of newlyexposed amino acids could improve the hydrophilicityof the hydrolyzed products. The peptide solubility ofAD (95.57%)/SD (95.65%)) powder was significantlystronger than FD (95.03%)/IFD (95.08%) powder. The color of dried samples is an important indexto determine the acceptability of samples. The chro-minance of chicken bone powder prepared by thefour drying methods was shown in Table 2, and theSD, AD, FD, IFD finished products were shown inFigure 3. The powder prepared by SD had the lowestL* (65.35) value and the highest a* (4.05) value, andhe difference was significant. Thiswas consistentwith the dull color of the SD sample in the picture.This may be due to the high inlet and outlet air tem-peratures during SD process, which promoted thebrowning of amino acids leading to the darkening ofolor.36,37] AD sample was followed by FD samplewith low L* value, because the set temperature in ADwas lower than that of in SD, which reduced thedegree of browning. Moreover, IFD sample had thehighest L* (74.59) and b* (17.00) value and the lowesta* (1.45) value. It demonstrated the brightest andyellowish in IFD sample. This result was similar toShi et al [38] This may be because the environment of a 50- b Figure 2. Effect of different drying methods on nutritionalcompositions. IFD was operated in high vacuum and the sampleswere dried by direct sublimation from the solid state,which made the samples less prone to thermal degrad-ation and browning.39 Antioxidant activity of the four samples was assessedby DPPH free radical scavenging capacity and ·OHfree radical scavenging capacity. IFD powder and FDpowder had significantly stronger DPPH free radicalscavenging capacity than AD (21.37%) powder andSD (17.38%)powder in Figure 4. And there was nosignificant difference between FD (25.64%)) powderand IFD (25.45%) powder. This result indicated thatantioxidant peptides were stable in FD/IFD and rela-tive unstable in SD/AD. High temperature environ-ment in SD/AD caused peptide degradation, resultingin the decline of antioxidant capacity of peptide. 40] Ingeneral, the samples which prepared by lower tem-perature drying methods could protect a wide varietyof antioxidant peptides. Besides, antioxidant activity ofthe four samples was also assessed by .OH free radicalscavenging capacity. The order ofOH radical scav-enging ability of the four samples: FD sample> IFDsample> AD sample>SD sample. This was generallyconsistent with the results of DPPH scavenging abilityand color. The results showed that different dryingmethods had different effect on the antioxidant cap-acity of protein (p<0.05) and FD could better protectthe structure and functional properties of peptides.This was also consistent with Liu’s findings. 41 Hightemperature in SD/AD caused the degradation of anti-oxidant peptides[.29] Energy consumption and drying time As shown in Figure 5, when drying until the moisturecontent dropped below 5%, IFD saved 19.18% of timeand 26.91% of energy compared with FD, which wassimilar to Lao’s results. 42] And SD saved 88.46% oftime and 17.70% of energy compared with AD. IFD/FD consumed1muchmore energyytthanAD/SDbecause the equipment also required a vacuum andcold trap system and they account for a large propor-tion of total energy consumption. 38.43] However, thequality of AD/SD dried powder was inferior to that ofIFD/FD powder, which was consistent with the previ-ous results of nutrient content and antioxidant prop-erties. Compared with FD, IFD decreased energyconsumption and shortened drying time. Flavor and taste evaluation For sensory evaluation, it can be seen from theTable 3 that the appearance evaluation result was con-sistent with the previous color analysis results, IFDhad the highest appearance score and SD had the Characteristic Type of dried hydrolysate SD sample AD sample FD sample IFD sample Proximate compositions Protein (g/100 g) 58.42±0.26 61.57°±0.22 66.35°±0.24 66.27°±0.23 Ash (g/100 g) 11.88°±0.23 12.47°±0.16 12.50±0.31 12.42°±0.28 Fat (g/100 g) 15.07±0.17 17.58°±0.16 17.85°±0.12 17.55±0.20 Physical properties L* 65.35°±0.18 68.47±0.13 73.15±0.11 74.59°±0.15 a* 4.05°±0.05 2.05±0.08 1.63±0.05 1.45±0.07 b* 16.37±0.11 16.55±0.04 16.81b±0.17 17.00°±0.15 Peptide solubility (%) 95.65°±0.12 95.57°±0.12 95.03°±0.15 95.08°±0.12 Yield (%) 10.85 13.57 13.52 13.85 Different letters in the same line indicate significant differences (p<0.05). SD Sample AD Sample FD Sample IFD Sample Figure 3. Picture of chicken bone powder with different drying methods. Figure 5. Energy consumption and drying time of differentdrying methods. Figure 4. Effect of different drying methods on antioxi-dant property. E-nose compared the flavor features of the samplestreated by four drying methods and hydrolysate solu-tion. It was found that aromatic compounds andfuran compounds were the main sources of volatileflavor substancesin boiled chicken [45] The mainsource of aroma is the Maillard reaction that occursduring the drying process which produces a series ofvolatile compounds. The E-nose sensor S1 representsaromatic compounds, S5 represents pyrazine com-pounds, and S11 represents volatile compounds suchas aldosterone and aromatic hydrocarbons.I46 Figure 6a showed that the SD powder had the highestresponse value of each sensor. The order of responsevalues of typical sensors (S1, S5, and S11) was as fol-lOWS: SD powder> AD powder> IFD pow-der>hydrolysate solution>FD powder. The typicalsensor response values of SD/AD powder were signifi-cantly greater than that of IFD/FD. This may be dueto high temperatures are more conducive to Maillardreactions.[47]In addition, the signal response value ofIFD powder was the closest to that of the hydrolysatesolution before drying. In terms of aroma, PCA identification index was99.4% among the five treatments in Figure 6b. Thisshowed that the E-nose could clearly distinguish thearomas of the five samples, and different treatmentshad different effects on the flavor of chicken bonepowder. The contribution rates of principal compo-nent 1 and principal component 2 were 97.4% and2.1%, respectively, and the cumulative contributionrate was 99.5%. This demonstrated that the two maincomponents of characterization 1 and 2 could repre- Sent the main flavor information of thesefour samples. The main nonvolatile flavor forming compoundsare amino acids and flavor nucleotides. However, themechanism of flavor formation is complex, and it alsoincludes the interaction between various types of com-pounds.148]Drying methods also have different effectson the taste of food material. As shown in Table 4,the sourness, astringency, and A-aftertaste value of thefour drying methods were negative, and the umami,richness, and saltiness value were positive. The highestresponse value of E-tongue sensors was umami, fol-lowed by saltiness and richness. The typical taste char-acteristic of chicken bone powder is umami. Theumami source of chicken bone powder may be theproduct of Maillard reaction or amino acids (such asasp and glu).49The result demonstrated differentdrying methods had the different influence on umami,and the umami values of the four drying methodswere significantly different. The umami value of IFDpowder was the highest while that of AD powder was Table 3. Sensory analysis results of samples prepared by different drying methods. Treatments Appearance Aroma Umami Acceptability SD sample 16.14±0.30° 18.11±0.42° 15.46±0.38° 49.71±0.67° AD sample 16.37±0.35° 17.95±0.28° 16.90±0.28 51.22±0.38” FD sample 16.41±0.58° 17.52±0.25 16.95±0.25ab 50.88±0.46 IFD sample 16.82±0.23° 18.05±0.36° 17.65±0.25° 52.52±0.45° Different letters in the same line indicate significant differences (p<0.05). 8 Figure 6. E-nose radar chart (a) and principal component analysis plot (b) of samples by different drying methods. Table 4. E-tongue analysis results of samples prepared by different drying methods. Treatments Sourness Astringency Aftertaste-A Umami Richness Saltiness SD sample -43.25±0.11° -7.87±0.08° -0.27±0.02 11.04±0.03 2.96±0.05 5.35±0.08° AD sample -43.36±0.04° -7.99±0.03 -0.20±0.01° 10.88±0.05° 3.01±0.05 4.96±0.04 FD sample -46.23±0.26° -7.55±0.02 -0.34±0.02° 11.23±0.05° 3.15±0.08° 5.13±0.10° IFD sample -44.52±0.13 -7.95±0.07 -0.22±0.02° 11.85±0.06° 3.31±0.07° 5.03±0.03 Different letters in the same line indicate significant differences (p<0.05). the lowest. In addition, IFD powder possessed thehighest richness over other three drying methods.This may be due to that IFD exerted the mildest influ-ence on the chicken bone powder.Moreover, the hightemperature promoted the further release of organicacidsinthe enzymatic hydrolysate of fermentedchicken bones; thus, the AD/SD powder had highersourness value. Conclusion We studied the effect of SD, AD, FD, and IFD onnutritional composition, antioxidant property, and fla-vor of chicken bone powder. On the optimal choice ofenergy consumption and drying time, SD is the mostefficient drying method. However, in terms of nutri-tional composition and antioxidant properties, IFDand FD powderr possessed higher content onnutritional composition and stronger DPPH and ·OHscavenging capacity. In addition, according to sensory,E-nose, and E-tongue evaluation, IFD powder showedthe highest acceptability score in sensory evaluationand the highest umami value. SD powder had highestresponse values in typical sensors and the E-noseresponse value of IFD powder was closest to that ofthe enzymatic hydrolysate before drying. It can beseen that IFD and SD chicken bone powder hadunique advantages in industrial production, and IFDhad certain industrial potential in drying this kindof product. Disclosure statement No potential conflictt of interest was reported bythe authors. Funding This work was financially supported by the National KeyR&D Program of China (grant no. 2017YFD0400501), the111 Project (grant no. BP0719028), Jiangsu Province KeyLaboratory Project of AdvancedFooddManufacturingEquipment and Technology (grant no. FMZ202003), andPostgraduate Research & Practice Innovation Program ofJiangsu Province (grant no. SJCX20_0739), all of whichenabled us to carry out this study. ( Reference s ) ( [1] Zhang, X.; Tian, Y.; K ang, X.; Han, R . ; Li, C .; Li, D. Analysis of P rimary N utritive Compositions in Gushi C hicken S o up. Shipin Gongye Ke j i 2009, 29 , 268-270. ) ( 2 Ran, X .-L.; Zhang, M.; Wang, Y.; L iu, Y. Vacuum Radio Frequency Drying: : A Novel Method to ) Improve the Main Qualities of Chicken Powders. J.Food Sci. Technol. 2019,56,4482-4491. [3] Kurozawa, L. E.; Park, K. J.; Hubinger, M. D. SprayDryingof Chicken MeatProtein Hydrolysate:Influence of Process Conditions on Powder Propertyand Dryer Performance. Drying Technol. 2011, 29,163-173. DOI: 10.1080/07373937.2010.482711. ( 4 Sun, Y .; Z hang, Y . -Y.; Chen, H . -T.; D i ng, Q.; Sun,B.-G. ; Kong, Y. ; Yang , X . Comparison of Non- Volatil e Umami Components i n Chicken Soup and Chicken Enzymatic Hydrolysate. F o od Res. I n t. 2 017,102, 559-566. DOI: 1 0. 101 6/ j. f o o d re s. 20 17 .0 9. 03 8. ) ( 5 Dong, Z . ; Li, M. Y . ; Tian, G . ; Z h ang, T. H.; Ren, H.;Quek, S. Y. E ffects of Ultrasonic Pretreatment o n theStructure and F unctionality of Chicken B o ne Pr o teinPrepared by Enzymatic Method. F ood C hem. 2019, 299,1 2 5103. D O I: 10 . 1016 / j.foodc h e m. 2019 . 1251 03 . ) ( 6 Thoresen, P. P.; A lvarez, R . G .; V aka, M. R.; R u stad,T.; Sone, I.; Fernandez, E. N. Potential of Innovative Pre-Treatment Technologies for the Revalorisation of Residual Materials from the Chicken Industry through E nzymatic H yd rolysis. I n nov. Food Sci.Emerg.Technol.2020,6 4 ,10 2 377. DOI: 10 . 10 1 6/j . i f set .2020 . 102377. ) ( [7] Dong , H .; Liu, J; Zeng, X.; B ai, , W.;.; Yu, L. E nzymatic H ydrolysis P retreatment for Enhancingthe P rotein S olubility and P hysicochemical Q u alityof Cordyceps m ilitaris Chicken Soup. F ood Sci. Nutr.2020,8,2436-2444. DOI: 1 0.1 00 2 /fs n 3.15 3 3. ) ( 8| Xu, X .; Zheng, Y .; Song, H.; Gong, L.; Pan, W. TheEffects of Enzymatic Hydrolysis Degree of B ovine Bone Marrow Extract on Fl a vor Generation vi a the Maillard R eaction ( Article). Food Measure 2019,13 , 521-535.DOI: 1 0 . 1 0 07/s1 1 69 4-0 1 8 - 9 96 6- 2. ) ( [9] Lao, Y .; Zhang, M .; L i , Z .; B handari, B . A Novel Combination off Enzymatic Hydrolysis and Fermentation: Effects o n the F l avor a n d Nutritional Quality of Fermented Co r dyceps militaris Beverage. LWT-F o od Sci. T e chnol.2020,1 2 0,1 0 8934. DOI: 1 0 .10 16 /j.lwt . 2 0 1 9 .1 0 8 9 3 4 . ) ( 10 L i, W.; Wang, P .; Xu, X.; Zhou, G. Optimization o fSpray Drying Technology i n P r o cessing ChickenPlasma Protein ( Article) . Nongye Gongcheng Xuebao/Trans. C hin. Soc. Agric. Eng. 2012, 28, 248-255. ) ( |111 Ran, X.-L.; Zhang, N M.: ; Wang, g , Y Y.; Liu , Y. A Comparative Study o f T hree D rying Methods on Drying ; 1 Time a nd P h ysicochemical P r operties o fChicken Powder.Dr y ing Technol. 20 1 9, 37, 37 3 -386. DOI: 1 0.1 08 0 / 0 7 373 937 . 201 8 .1 45 87 3 4. ) ( 12] T eng, X .; Z hang, M.; Bhandari, B . ; Liu, Y. Effect o fMicrowave Vacuum Dr y ing with Di f ferent A u xiliary Materials on Hygroscopicity and Flowability o f Chicken P owder. F ood B i oprod. P rocess. 2020, 124, 266-277.DOI: 10 .1 016/ j .fbp.2020.0 8. 019. ) ( 13] Zhang, M.; Chen, H . ; Mujumdar, A. S. ; Zhong, Q. ; Sun, J. Recent Developments in High-Quality Dryingwith E nergy-Saving C h aracteristic f o r F r esh F o ods.Drying T echnol. 2 015, 3 3, 1 590-1600. DOI: 1 0 . 10 80 / 07373937.2015.1 0 1226 7 . ) ( 14 D uan, X .; Zhang, M .; M ujumdar, A . S . S t udy o n a Combination Drying T echnique o f Sea Cucumber. ) ( Drying T echnol. 2007,25,2 0 11-2019. DOI: 10.10 8 0 / 0 7 3739307 0 1 7 28497. ) ( 15 Wang, Y.; Z hang, M.; Mujumdar, A. S. Trends inProcessing Technologies for Dried Aquatic Products.Drying T echnol. 2011, 29, 382-394. DOI: 1 0 .108 0/ 073 7 3 9 3 7 . 201 1 .55 162 4. ) ( 16 Fan, K. ; ; Zhang, M.; Mujumdar, A. S. Recent Developments in H igh Efficient Freeze-Drying ofFruits and V egetables A ssisted b y Microwave: :i A Review. Crit. R R ev. FoodSci. Nutr. 2 019, 591357-1366. DOI: 1 0 . 10 8 0 /104 0 8 3 98.2 0 1 7 .1420624. ) ( |171 Qiu, L .; Zhang, M.; J u , R.; W ang, Y.; Chitrakar, B.;Wang, B . E f fect o f Different Drying Methods on th e Quality of Restructured Rose Flower (Rosa rugosa)Chips. D rying T echnol. 2020, 38, 1 632-1643. DOI: 10 .108 0 /07373 9 37.2 0 1 9 . 1 653 3 1 8 . ) ( 1181 Qiu, , Zhang, N M.: Wang, Y.; Liu, Y Physicochemical and Nutritional l FProperties Wasabi (Eutrema yunnanense)Dried 1 by y Four Different Drying Methods. Drying Technol. 20 1 9, 37, 363-372. DOI: 1 0.1080 / 07373937.2 01 8 . 14 5 831 8 . ) ( 19 Song, X.; Zhang, M.; M ujumdar, A . ; Fan, L . Drying Characteristic s and Kinetic s of Vacuum Microwave- Dried P otato Slices . Drying Technol . 2009, 27、 969-974. D OI: 10.1 0 80/0737393090 2 9 0 209 9 . ) ( 201 Wang, H . -C.; Z hang, M.; A d hikari, B . D rying o f Shiitake Mushroom b y Combining Fr e eze-Dryingand M id-Infrared Radiation. F ood B i oprod. Process.2015,94,507-517.DOI: 10 . 1 016 / j. fbp. 2 0 14 . 07.0 08 . ) ( 1211 Wu, X.-F . ; Zhang, M . ; B h andari, B. A No v el Infrared Freeze Drying (IRFD) Technology to Lower the Energy Consumption n and K e ep the Quality ofCordyceps militaris. Innov. Food Sci. Emerg.Technol. 2019,54, 34-42. D O I: 10 . 1 0 1 6/ j .ifs et .2 0 1 9 .03.003. ) ( 22 Liu, W.; Zhang, M .; A dhikari, B.; Chen, J. A Novel Strategy y for mproving D rying 1 Efficienc y a and Quality of Crea m Mushroom S oupBased on Microwave Pre-Gelatinization a nd I n frared Freeze- Drying. Innov. Food S ci. Emerg. T echnol. 2020, 6 6, 102516.D O I:10. 1 016 / j. i f se t.2020 .10 2 5 16 . ) ( 23 Chong, S . Y .; Chen, W . P r oduction of Spray-Dried Sapodilla (Manilkara zapota) Powder f rom Enzyme-Aided Liquefied Pu ree. J . F o od P ro cess.. P reserv. 2015,39,2604-2611. ) ( 24 Shi, H.;Zhang, M .; W ang, W.; D e vahastin, S. S olid- State Fermentation with Probiotics and Mixed Yeast on Properties of Okara. Food Biosci . 2020, 36, 100610. D OI: 1 0 . 10 1 6 / j.fb i o .2 020 . 1006 1 0 . ) ( 25 Hu, Q .; Z hang, M .; M ujumdar, A . ; W e i-Hua, D. ; Sun, J . Effects o f Differen t Drying Methods on theQuality Changes o f ( Granular Edamame. Drying Technol. 2 2006, 24、 1025-1032.DOI: . 1 0 . 1080/ 0737393060077 6 217. ) ( |26 Cao, X.; Zhang, M.; Qian, H.; Mujumdar, A.; Wang,Z. P hysicochemical and Nutraceutical P r operties o f Barley Grass Powder M icroencapsulated by Spray Drying. Drying Technol. 2017, 3 5,1358-1367. DOI: 10 .108 0 / 0 7 3 7393 7 .2 0 17. 1 33207 4 . ) ( 271 Kim, H.-W.; H w ang, K. - E.; S o ng, D . -H.; K i m, Y.-J;Lim, Y.-B.; Ham, Y . -K.; Ye o, E.-J.; C hang, S.-J.;Choi, Y.-S.; K im, C . -J. Effect of Glasswort (S a licorniaherbacea L .) on t he T exture of Frankfurters (Article). ) ( Meat Sci. 2 014,97, 5 1 3-517. DO I : 10. 1 016 /j . meat sci. 20 1 4.03 . 019. ) ( [28 Zhang, H.; Xia, W .; X u , Y.; J i ang, Q . ; W a ng, C. ; Wang, vW.] E ffectst s o fS pray-Drying O perational Parameters on the Qualit y o f Freshwater Mussel Powder. F ood Bioprod. P rocess. 2013, 9 1, 2 42-248.DOI: 1 0 .10 16 /j.fbp.2 0 1 2 .10.0 0 6. ) ( 29 Sukkhown, P.; J a ngchud, K . ; Lo r jaroenphon, Y.; Pirak, T. Flavored-Functional Protein Hy drolysates from Enzymatic Hydrolysis o f Dried S quid b y -Products: Effect of Drying Method. F o od Hy d rocoll. 2018, 7 6,1 0 3-112. D O I: 10 . 1 0 16 / j.fo odhy d .201 7 . 0 1. 0 26. ) ( [30] Zou, T.-B.; He, T.-P.; L i , H . -B.; T a ng, H. - W.; Xia, E.-Q. The e Structure-Activity Relationship of f t he Antioxidant Peptides from Natural Proteins. Molecules 2016. 21、 72. DOI: 1 0 .3390 / m o l e cul es 2 1 010072. ) ( [31] Guo, J ; Y an, Y.; W ang, M.; Wu, Y.; Liu, S.; Chen, D.; Lu, Y. Effects of Enzymatic Hydrolysis o n t heChemical Constituents in Jujube A l coholic B e verage Fermented with T orulaspora d elbrueckii. LWT-Food Sci. Technol. 2018, 97,617-623. DOI: 1 0 .1 016 /j . l wt .20 1 8.0 7. 051. ) ( [32] Cao, X.; Zhang, M.; Mujumdar, A . S.; W ang, Z . Effect o f Microwave Freeze-Drying o n Microbial Inactivation, 1 Antioxidant i t s Substance and Flavor Qualit y of f Ashitaba a pLeaves (Angelica k eiskei Koidzumi). Drying Technol. 2019,37, 7 93-800.DOI: 1 0. 1 08 0/0 737393 7 . 2 0 18 . 14 632 4 5. ) ( 33| Jk, Y.; Lx, W.; Zr, Q.; Wd, C .; H, M . Effect of Different Drying Methods on t he Product Quality and B ioactiv e Polysaccharides of Bitter Gourd (Momordica charantia L.) S lices. Food Chem. 2 019, 271,588-596. ) ( 34] Tian, Y.; Zhao, Y.; Huang, J .; Zeng, H.; Zheng, B . Effects o f Different Dryin g Methods on the ProductQuality and Volatil e Compounds o f Whole Shiitake Mushrooms. Food Chem. 2016, 1 97, 7 14-722. DOI: 1 0 . 10 16/j .foo dc he m .2015.11 . 0 2 9. ) ( [35] lKristinsson, H. G.; Rasco, B. .1 AA. Fish h Protein Hydrolysates: Production, Biochemical, andFunctional P roperties. C rit. Rev. F Food Sci.Nutr. 2000,40,43-81. ) ( [36] Kotlar, C. E.; Ponce, A. G.; Roura, S . I . Improvement of Functional and A ntimicrobial P roperties of Brewery Byproduct Hydrolysed Enzymatically (Article). LWT-Food S c i. . Technol 2 2013, 50, 378-385. D OI: 1 0 .10 16 /j. l w t. 2 0 12 .09. 0 05 . ) ( [37 Roos, Y. H.; Himberg, M .-J. Nonenzymic B r owning Behavior, as Related to Glass Transition, of a Food Model at C h illing Temperatures. J. A g ric. F o odChem. 1 994, 42,893-898. DOI: 10.1 021/j f 0 004 0 a 0 11 . ) ( 38 Shi, H.; Zhang, M.; Mujumdar, A . S.; Xu, J.; Wang,W. I nfluence of Drying Methods on the Drying Kinetics, Bioactive Compounds a n d Flavor of Solid-State Fermented Okara. Drying Technol. 2019. ) ( [39 Zhang, M.; De B aerdemaeker, J .; ; S chrevens, E. Effects of D ifferent t Varieties and Shelf S torage Condition s of Chicory (on Deteriorativ e ( ColorChangesUsing Digital Image Processingand ) ( Analysis. Food Res. Int.2003, 36,669-676. D O I: 10 . 10 16/S0963- 9 9 6 9(03)0 0 015-2. ) 40| Orsini Delgado, M. C.; Nardo, A.; Pavlovic, M.;Rogniaux,H.;; Anon,1, M., C.;:Tironi.V. A.Identification and Characterization of AntioxidantPeptides Obtained by Gastrointestinal Digestion ofAmaranth Proteins. Food Chem.1.2016, 197,1160-1167. DOI: 10.1016/j.foodchem.2015.11.092. 1411 Liu, X.; Yan, X.; Bi, J; Wu, X.; Liu, J; Zhou, M.IdentificationOoff PhenolicCompounds andAntioxidantlActivity of GuavaaDehydratedbyDifferent Drying Methods. Drying Technol. 2020, 38,987-1000. DOI: 10.1080/07373937.2019.1607872. 421 Lao, Y.; Zhang, M.; Devahastin, S.; Ye, Y. Effect ofCombined Infrared Freeze Drying and MicrowaveVacuum Drying on Quality of Kale Yoghurt Melts.Drying Technol. 2020, 38,621-633. DOI: 10.1080/07373937.2019.1658600. 1431 Roknul, A. M.; Zhang, M.; Mujumdar, A.; Wang, Y.A Comparative Study of Four Drying Methods onDrying Time and Quality Characteristics of StemLettuce Slices (Lactuca sativa L.). Drying Technol.2014,32,657-666. IDOI:10.1080/07373937.2013.850435. ( 144| Huang, L.-L.; Zhang, M.; Yan, W.-Q.; M ujumdar,A. S.; Sun, D.-F. Effec t of Coatin g on Post-Drying of ) Freeze-Dried Strawberry Pieces(Article). J. FoodEng. 2009, 92,2、107-111. DO 10.1016/j.jfoodeng.2008.10.031. 45 Zhao, M.-M.; Cai, Y.; Cao, Y.; Feng, Y.-Z. Analysisof Volatile Flavor Compounds in Ten CommercialChicken Flavors (Article). Mod. Food Sci. Technol.2016,32,275-286,208. [46] Sun, Y.; Zhang, M.; Bhandari, B.; Yang, P. IntelligentDetection of Flavor Changes in Ginger duringMicrowave Vacuum IDrying Based on LF-NMR.Food Res. Int. 2019, 119,417-425. DOI: 10.1016/j.foodres.2019.02.019. 471 Teng, X.; Zhang, M.; Bhandari, B.; Xu, J.; Liu, Y. AComparative Study on Hygroscopic andPhysiochemicalPropertiesof Chickenn PowdersObtainieedd by Differentt DryingMe tMhods. DryingTechnol.2020,38, 1929-1942.DOI: 10.1080/07373937.2019.1679831. 481 Wang, W.; Zhou, X.; Liu Y. Characterization andEvaluation of Umami Taste: A Review. Trends Anal.Chem. 2020, 127,115876. ( 491 Sun, H .-M.; Zhang, C . -H.; L i , X.; L i, Y.; Dong, X.-B.;Wang, C.-Q.; Xie, X.L. Taste Compounds 1S in Maillard Reaction Products of Chicken Bone E xtract and I ts Enzymatic H ydrolysate ( Article). Mod. Food Sci. Technol. 2013, 29 , 1872-1877. ) Full Terms & Conditions of access and use can be found at O Taylor & Francis Group, LLC 摘要:采用喷雾干燥法(SD)、热风干燥法(AD)、冷冻干燥法(FD)和红外冷冻干燥法(IFD)对鸡骨粉进行干燥。营养成分、抗氧化分别对其性能、物理性能、能耗和风味进行了比较。结果表明,IFD粉中氨基酸氮含量最高在多肽含量方面,IFD和FD粉差异不显著,明显高于AD和SD粉。至于抗氧化性能,IFD和FD粉对DPPH和OH的清除能力高于AD和SD粉。另外,IFD粉的L值最高(74.59),SD粉的L值最低(65.35),与外观评分结果一致。有关风味和感官评价中,IFD粉的鲜味值最高(11.85)四种干燥方法的可接受度评分(52.52)。此外,典型的电子鼻传感器IFD粉的响应值与酶解物的响应值最接近干燥前和SD粉在所有传感器中响应值最高。关键词:鸡骨头粉;热风干燥;冷冻干燥;红外冷冻干燥;喷雾干燥

确定

还剩10页未读,是否继续阅读?

北京盈盛恒泰科技有限责任公司为您提供《鸡骨粉中营养成分和风味的影响检测方案(感官智能分析)》,该方案主要用于固态复合调味料中理化分析检测,参考标准--,《鸡骨粉中营养成分和风味的影响检测方案(感官智能分析)》用到的仪器有德国AIRSENSE品牌PEN3电子鼻

推荐专场

感官智能分析系统(电子鼻/电子舌)

相关方案

更多

该厂商其他方案

更多