方案详情

文

Introduction

Application Note

As semiconductor devices continue to decrease in size to improve performance and take advantage of

advances in fabrication techniques, there is a need to analyse both their structure and chemistry at ever

increasing resolution. Typically this requires the use of TEM for metrology and failure analysis. Using ultrahigh

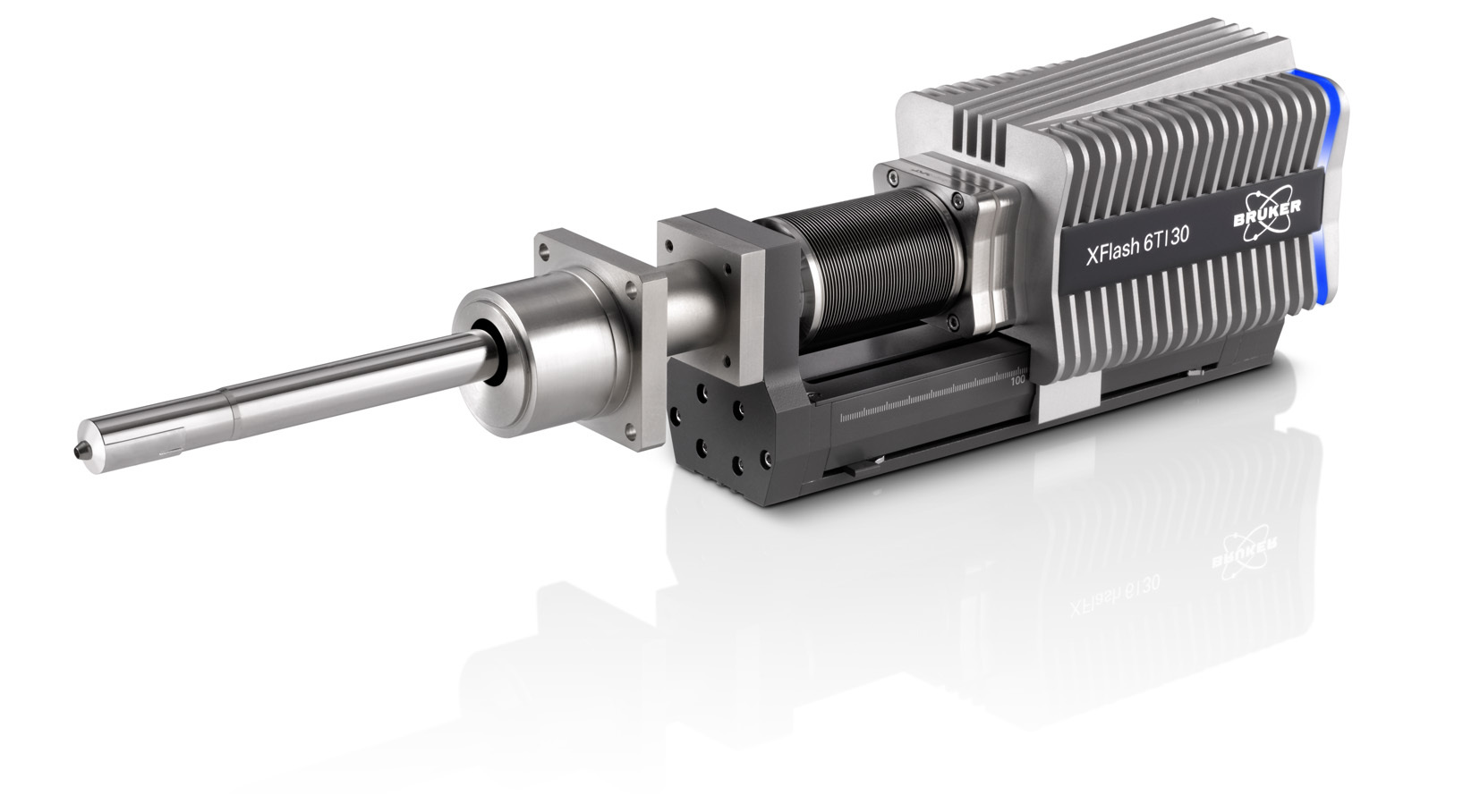

resolution FEG-SEM, low kV imaging and the new X-Max® Extreme EDS detector we demonstrate

the ability to retain some of this high resolution analysis in the SEM. This allows for better targeting of

resources and increased throughput of analysis.

方案详情

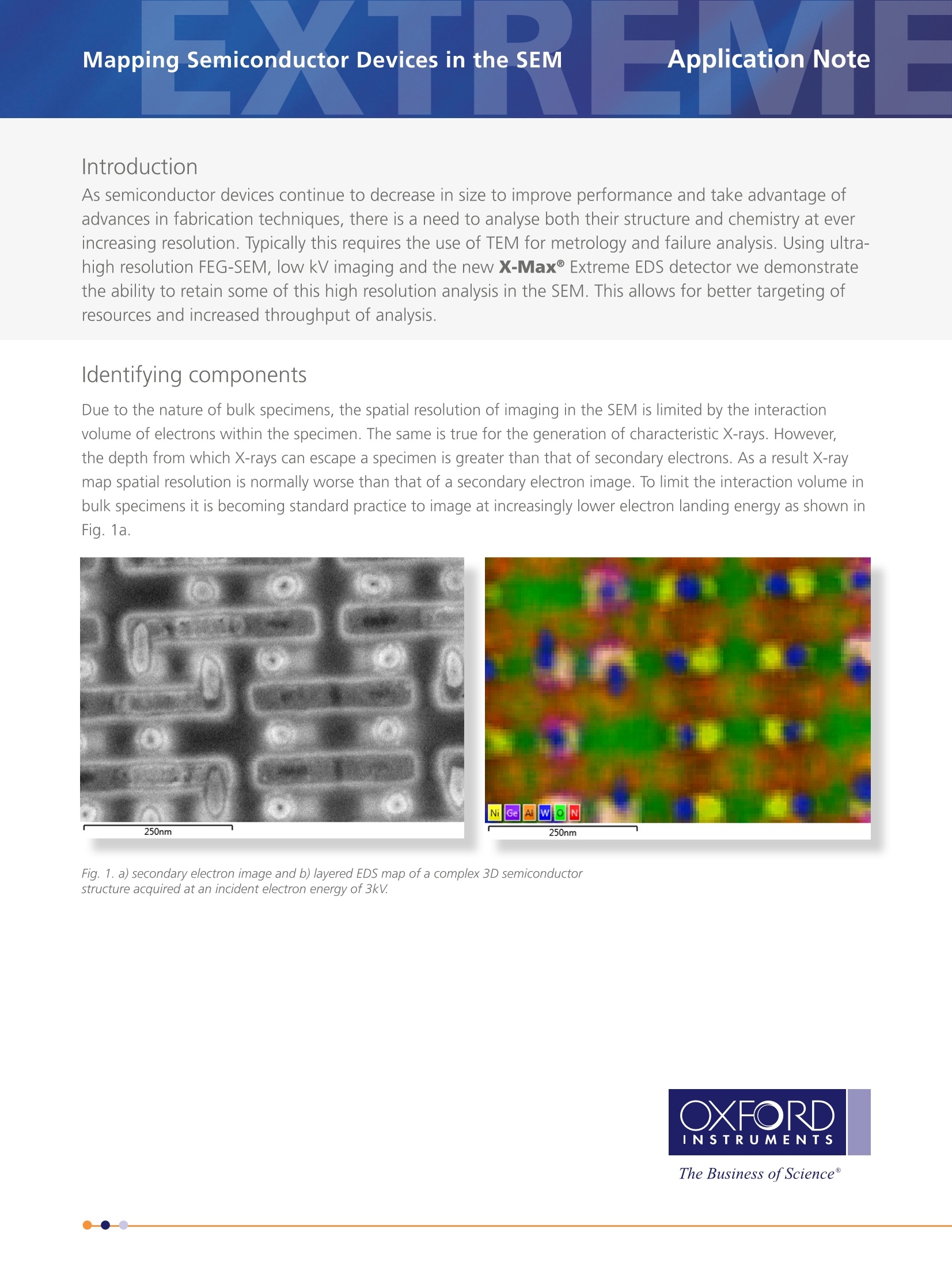

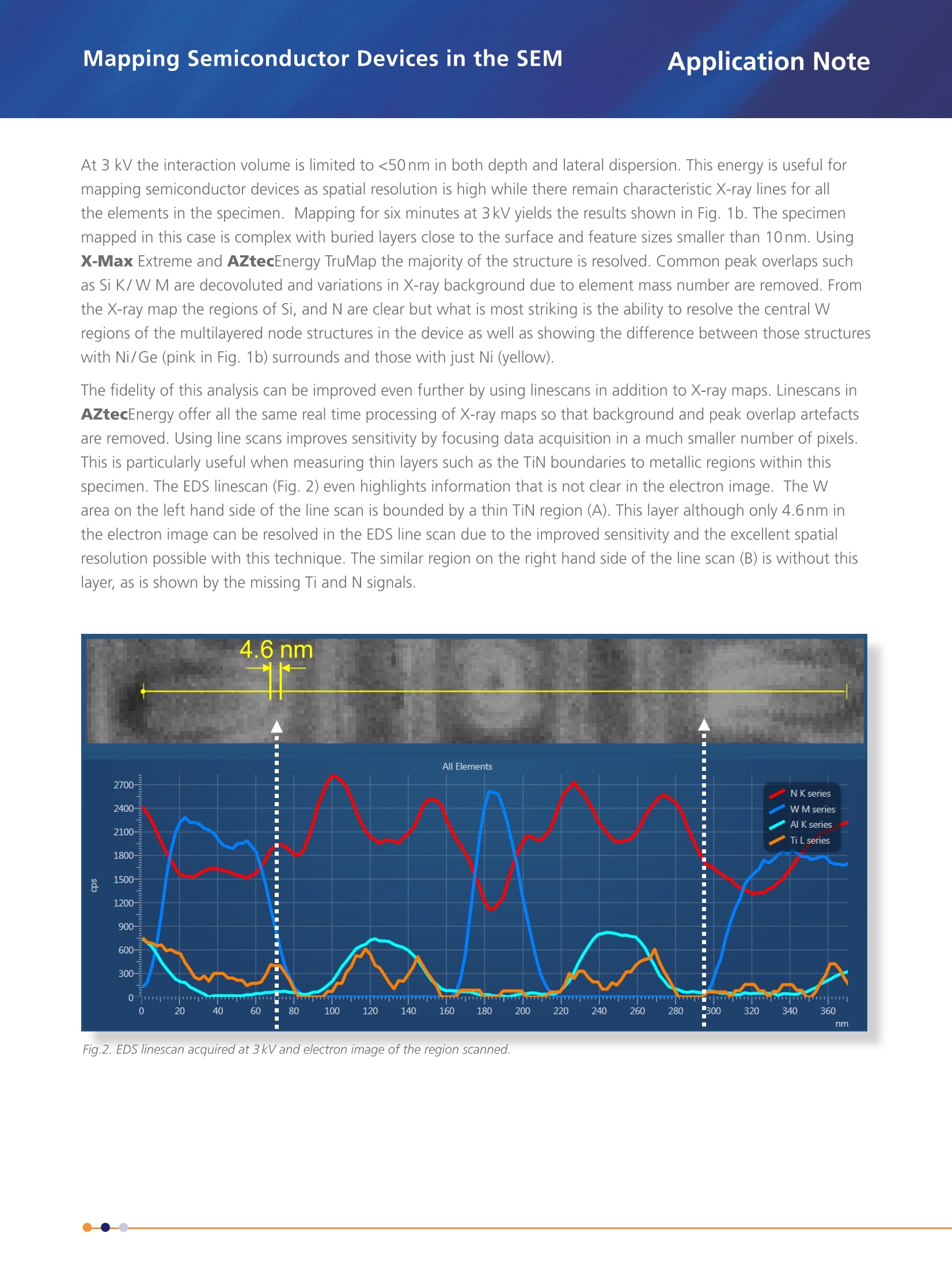

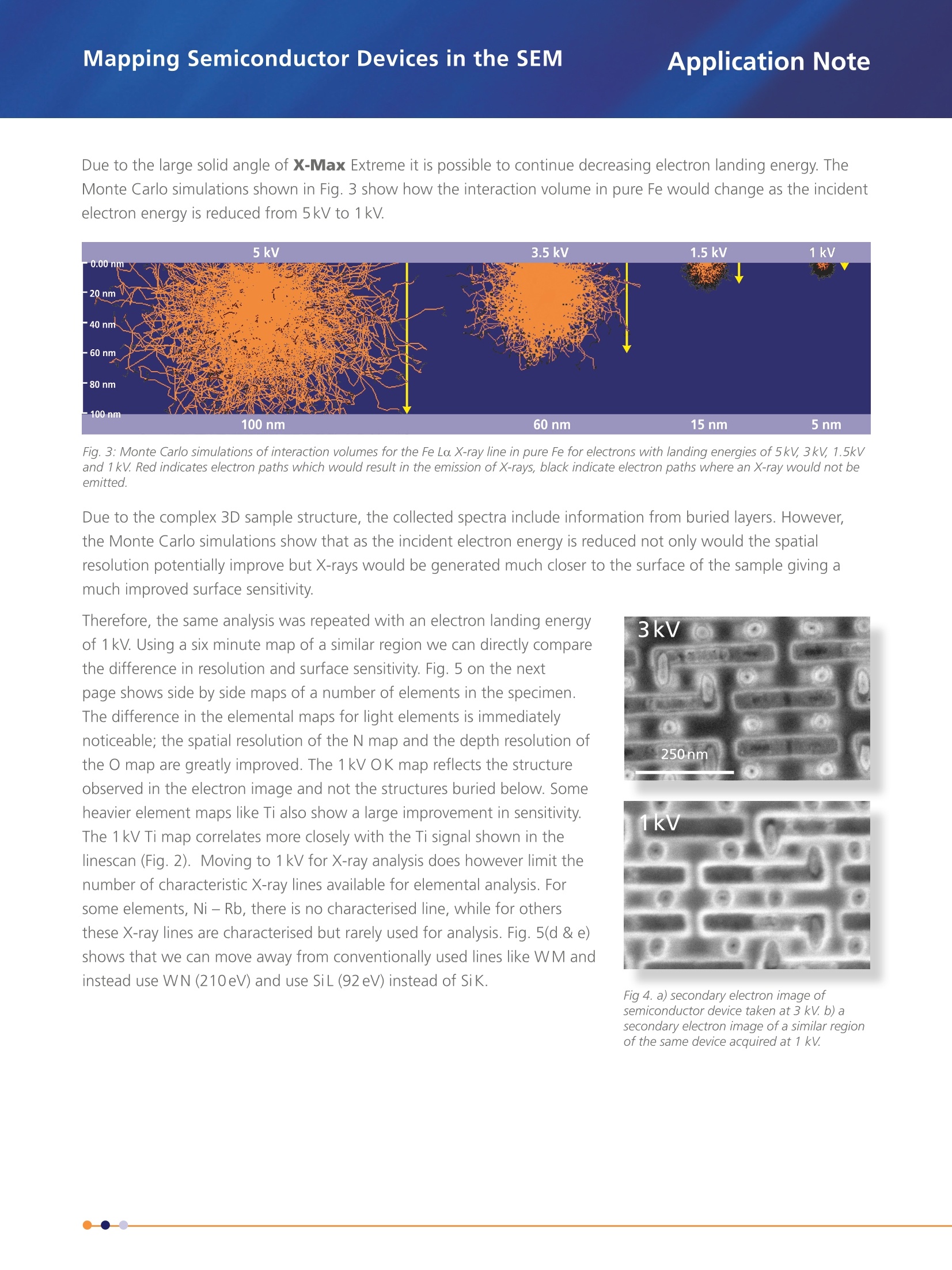

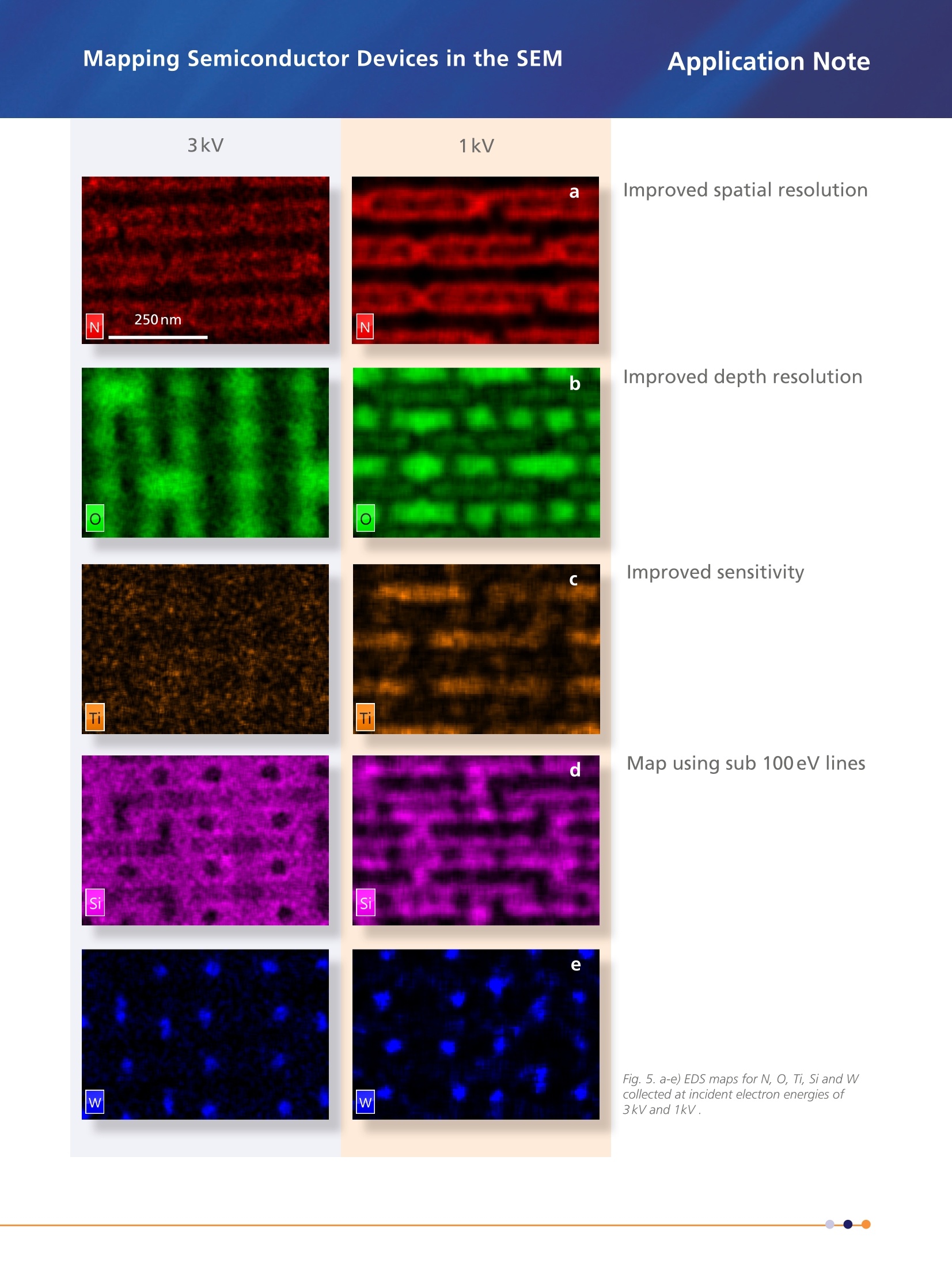

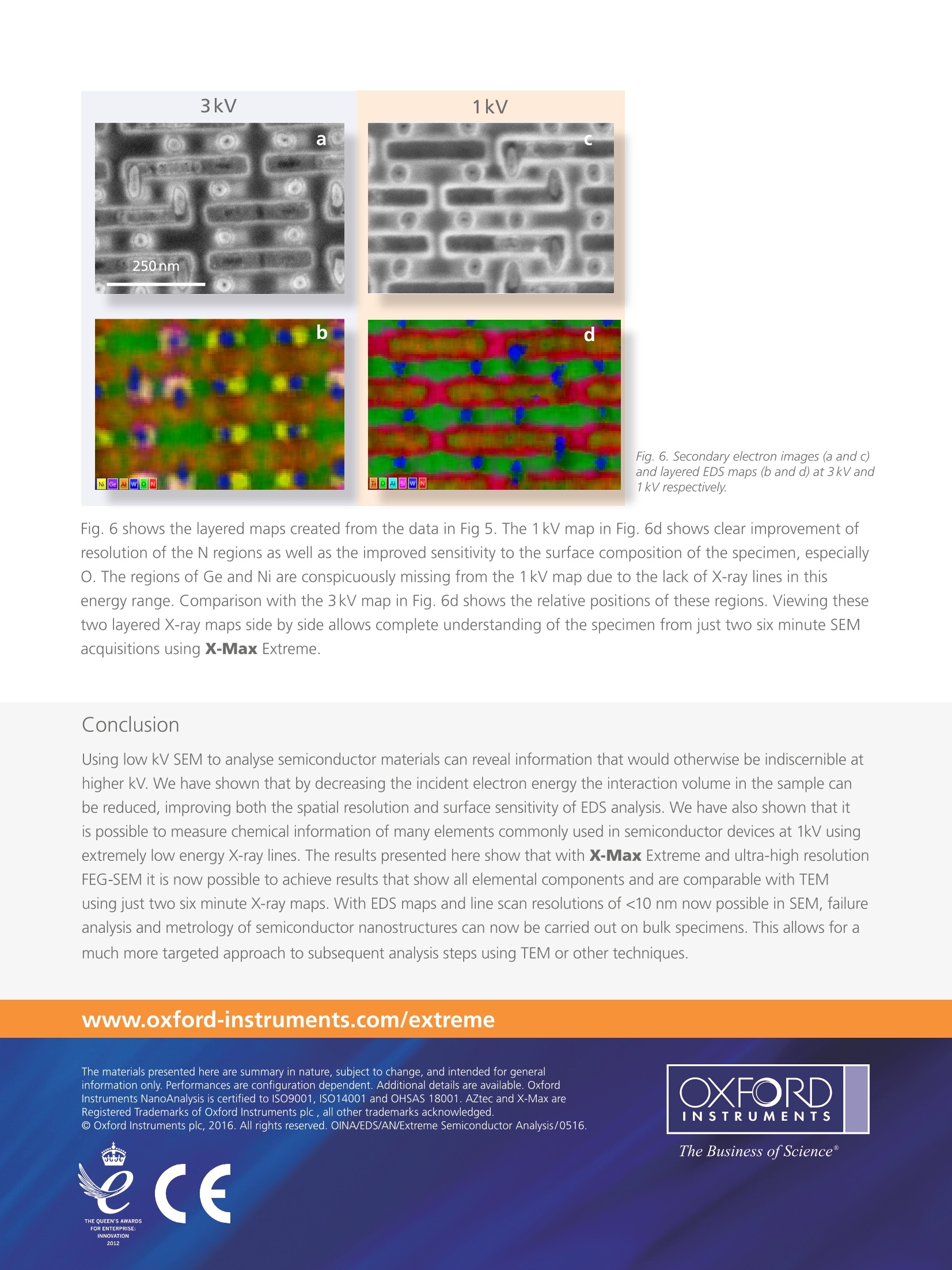

Application Note Mapping Semiconductor Devices in the SEM Mapping Semiconductor Devices in the SEM Introduction As semiconductor devices continue to decrease in size to improve performance and take advantage ofadvances in fabrication techniques, there is a need to analyse both their structure and chemistry at everincreasing resolution. Typically this requires the use of TEM for metrology and failure analysis. Using ultra-high resolution FEG-SEM, low kV imaging and the new X-Max@ Extreme EDS detector we demonstratethe ability to retain some of this high resolution analysis in the SEM. This allows for better targeting ofresources and increased throughput of analysis. Identifying components Due to the nature of bulk specimens, the spatial resolution of imaging in the SEM is limited by the interactionvolume of electrons within the specimen. The same is true for the generation of characteristic X-rays. However,the depth from which X-rays can escape a specimen is greater than that of secondary electrons. As a result X-raymap spatial resolution is normally worse than that of a secondary electron image. To limit the interaction volume inbulk specimens it is becoming standard practice to image at increasingly lower electron landing energy as shown inFig.1a. Fig. 1. a) secondary electron image and b) layered EDS map of a complex 3D semiconductorstructure acquired at an incident electron energy of 3kV. The Business of Science Application Note At 3 kV the interaction volume is limited to <50 nm in both depth and lateral dispersion. This energy is useful formapping semiconductor devices as spatial resolution is high while there remain characteristic X-ray lines for allthe elements in the specimen. Mapping for six minutes at 3 kV yields the results shown in Fig. 1b. The specimenmapped in this case is complex with buried layers close to the surface and feature sizes smaller than 10nm. UsingX-Max Extreme and AZtecEnergy TruMap the majority of the structure is resolved. Common peak overlaps suchas Si K/W M are decovoluted and variations in X-ray background due to element mass number are removed. Fromthe X-ray map the regions of Si, and N are clear but what is most striking is the ability to resolve the central Wregions of the multilayered node structures in the device as well as showing the difference between those structureswith Ni/Ge (pink in Fig. 1b) surrounds and those with just Ni (yellow). The fidelity of this analysis can be improved even further by using linescans in addition to X-ray maps. Linescans inAZtecEnergy offer all the same real time processing of X-ray maps so that background and peak overlap artefactsare removed. Using line scans improves sensitivity by focusing data acquisition in a much smaller number of pixels.This is particularly useful when measuring thin layers such as the TiN boundaries to metallic regions within thisspecimen. The EDS linescan (Fig. 2) even highlights information that is not clear in the electron image..1The Warea on the left hand side of the line scan is bounded by a thin TiN region (A). This layer although only 4.6 nm inthe electron image can be resolved in the EDS line scan due to the improved sensitivity and the excellent spatialresolution possible with this technique. The similar region on the right hand side of the line scan (B) is without thislayer, as is shown by the missing Ti and N signals. Fig.2. EDS linescan acquired at 3kV and electron image of the region scanned. Due to the large solid angle of X-Max Extreme it is possible to continue decreasing electron landing energy. TheMonte Carlo simulations shown in Fig. 3 show how the interaction volume in pure Fe would change as the incidentelectron energy is reduced from 5 kV to 1 kV. Fig. 3: Monte Carlo simulations of interaction volumes for the Fe Lo X-ray line in pure Fe for electrons with landing energies of 5kV, 3kV, 1.5kVand 1kV. Red indicates electron paths which would result in the emission of X-rays, black indicate electron paths where an X-ray would not beemitted. Due to the complex 3D sample structure, the collected spectra include information from buried layers. However,the Monte Carlo simulations show that as the incident electron energy is reduced not only would the spatialresolution potentially improve but X-rays would be generated much closer to the surface of the sample giving amuch improved surface sensitivity. Therefore, the same analysis was repeated with an electron landing energyof 1 kV. Using a six minute map of a similar region we can directly comparethe difference in resolution and surface sensitivity. Fig. 5 on the nextpage shows side by side maps of a number of elements in the specimen.The difference in the elemental maps for light elements is immediatelynoticeable; the spatial resolution of the N map and the depth resolution ofthe O map are greatly improved. The 1 kV OK map reflects the structureobserved in the electron image and not the structures buried below. Someheavier element maps like Ti also show a large improvement in sensitivity.The 1 kV Ti map correlates more closely with the Ti signal shown in thelinescan (Fig.2). Moving to 1 kV for X-ray analysis does however limit thenumber of characteristic X-ray lines available for elemental analysis.Forsome elements, Ni -Rb, there is no characterised line, while for othersthese X-ray lines are characterised but rarely used for analysis. Fig. 5(d & e)shows that we can move away from conventionally used lines like WM andinstead use WN(210eV) and use SiL(92 eV) instead of Si K. Fig 4. a) secondary electron image ofsemiconductor device taken at 3 kV. b) asecondary electron image of a similar regionof the same device acquired at 1kV. 3kV 1kV Improved spatial resolution Improved depth resolution Map using sub 100 eV lines Si Fig. 5. a-e) EDS maps for N, O, Ti, Si and Wcollected at incident electron energies of3kVand 1kV. Fig. 6. Secondary electron images (a and c)and layered EDS maps (b and d) at 3kV and1kV respectively. Fig. 6 shows the layered maps created from the data in Fig 5. The 1 kV map in Fig. 6d shows clear improvement ofresolution of the N regions as well as the improved sensitivity to the surface composition of the specimen, especiallyO. The regions of Ge and Ni are conspicuously missing from the 1 kV map due to the lack of X-ray lines in thisenergy range.Comparison with the 3kV map in Fig. 6d shows the relative positions of these regions. Viewing thesetwo layered X-ray maps side by side allows complete understanding of the specimen from just two six minute SEMacquisitions using X-Max Extreme. Conclusion Using low kV SEM to analyse semiconductor materials can reveal information that would otherwise be indiscernible athigher kV. We have shown that by decreasing the incident electron energy the interaction volume in the sample canbe reduced, improving both the spatial resolution and surface sensitivity of EDS analysis. We have also shown that itis possible to measure chemical information of many elements commonly used in semiconductor devices at 1kV usingextremely low energy X-ray lines. The results presented here show that with X-Max Extreme and ultra-high resolutionFEG-SEM it is now possible to achieve results that show all elemental components and are comparable with TEMusing just two six minute X-ray maps. With EDS maps and line scan resolutions of <10 nm now possible in SEM, failureanalysis and metrology of semiconductor nanostructures can now be carried out on bulk specimens. This allows for amuch more targeted approach to subsequent analysis steps using TEM or other techniques. www.oxford-instruments.com/extreme IntroductionApplication NoteAs semiconductor devices continue to decrease in size to improve performance and take advantage ofadvances in fabrication techniques, there is a need to analyse both their structure and chemistry at everincreasing resolution. Typically this requires the use of TEM for metrology and failure analysis. Using ultrahighresolution FEG-SEM, low kV imaging and the new X-Max® Extreme EDS detector we demonstratethe ability to retain some of this high resolution analysis in the SEM. This allows for better targeting ofresources and increased throughput of analysis.

确定

还剩3页未读,是否继续阅读?

牛津仪器科技(上海)有限公司为您提供《半导体器件中元素构成分析检测方案(X射线能谱仪)》,该方案主要用于其他中元素构成分析检测,参考标准--,《半导体器件中元素构成分析检测方案(X射线能谱仪)》用到的仪器有牛津仪器Ultim Extreme无窗超级能谱

推荐专场

相关方案

更多